Smokemaster F72 Series User manual

SMOKEMASTER®

MODELS F72A & F72B

INDUSTRIAL ELECTRONIC AIR CLEANER

THE F72 INDUSTRIAL ELECTRONIC AIR CLEANERS INCLUDE COMPONENTS REQUIRED

TO REMOVE AIRBORNE PARTICLES SUCH AS COOLANT MIST, DUST, SOOT, POLLEN,

BACTERIA, TOBACCO AND COOKING SMOKE FROM THE CIRCULATING AIR IN LARGE

RESIDENTIAL, COMMERICAL AND INDUSTRIAL MANUFACTURING FACILITIES. THE AIR

CLEANER IS MOUNTED IN THE RETURN AIR DUCT OF A FORCED AIR SYSTEM WHERE

AMBIENT TEMPERATURE DOES NOT EXCEED 125°F (52°C). ONE OR TWO ELECTRONIC

CELLS, OPERATED BY HIGH VOLTAGE POWER SUPPLIES, REMOVE AIRBORNE

CONTAMINANTS AT EFFICIENCIES AS HIGH AS 99 PERCENT. PERFORMANCE IS

MONITORED BY A STATUS LIGHT ON THE POWER SUPPLY.

xCleans the air at a rate of 1,000 to 12,000 cfm

(1,699 to 20,390 m³/hr.) in forced air systems.

xRated 80 to 99 percent efficient according to

the National Bureau of Standards Dust Spot

Method using atmospheric dust.

xSame high capacity, industrial electronic cell

used in all models.

xReversible electronic cell allows system

airflow to enter cabinet from either side.

xHigh voltage, solid state power supply retains

peak efficiency over a wide range of cell dirt

loading conditions.

xHigh voltage power supply uses voltage

doubler to provide increased ionization

voltage.

xF72 models are available in all single phase

voltages: 100-120 volt, 200-240 volt, 50 or

60 Hz.

xPerformance indicator light and test button

provides operational status.

xStrong, galvanized steel cabinet can be

installed vertically or horizontally.

xHinged power door allows easy access to cells

and filters.

2

TABLE OF CONTENTS

PAGE

SPECIFICATIONS 3

PLANNING THE INSTALLATION 5

Sizing 5

Location 5

INSTALLATION 7

Wiring 8

SERVICE 11

TROUBLESHOOTING 15

PARTS LIST 17

WARRANTY 20

3

SPECIFICATIONS

- IMPORTANT -

THE SPECIFICATIONS GIVEN IN THIS PUBLICATION DO NOT INCLUDE NORMAL MANUFACTURING TOLERANCES.

THEREFORE, THIS UNIT MAY NOT MATCH THE LISTED SPECIFICATIONS EXACTLY. ALSO, THIS PRODUCT IS TESTED

AND CALIBRATED UNDER CLOSELY CONTROLLED CONDITIONS AND SOME MINOR DIFFERENCES IN PERFORMANCE

CAN BE EXPECTED IF THOSE CONDITIONS ARE CHANGED.

MODEL

F72A-1003

F72A-1011

F72B-1003

F72B-1011

NO. OF CELLS

1

1

2

2

RATED VOLTAGE

100-120 Vac

200-240 Vac

100-120 Vac

200-240 Vac

FREQUENCY

50-60 Hz

50-60 Hz

50-60 Hz

50-60 Hz

POWER, NOMINAL

40 Watts

40 Watts

50 Watts

50 Watts

POWER, MAXIMUM

90 Watts

90 Watts

100 Watts

100 Watts

WEIGHT, SHIPPING

200 Lb.

200 Lbs.

300 Lbs.

300 Lbs.

WEIGHT, INSTALLATION

150 Lbs.

150 Lbs.

250 Lbs.

250 Lbs.

AMBIENT TEMPERATURE RATING: Air flow through cells -- 125°F maximum, 40°F minimum

Electronic cells -- 250°F maximum during washing or drying

CABINET: 16 gauge galvanized steel, hinged filter access door

POWER SUPPLY: Solid state, dual voltage power supply provides 9400 Vdc to the ionizer wires and

4700 Vdc to the collector positive plates. The solid state power supply is self-regulating so the output

voltage remains constant over a wide range of cell dirt loading conditions.

ELECTRONIC CELL SPECIFICATIONS, PN 38010:

Dimensions: 24.25” x 24.125” x 10.75” deep

Cell Weight: 60 Lbs.

Collection Area: 240 sq. ft.

Voltage Gradient: 20,000 volts per inch

Ionizer Wires: 11 wires per cell, .010” diameter, tungsten

MOUNTING: a) Vertical, standing or hanging cabinet with horizontal air flow

b) Horizontal mounting with vertical air flow

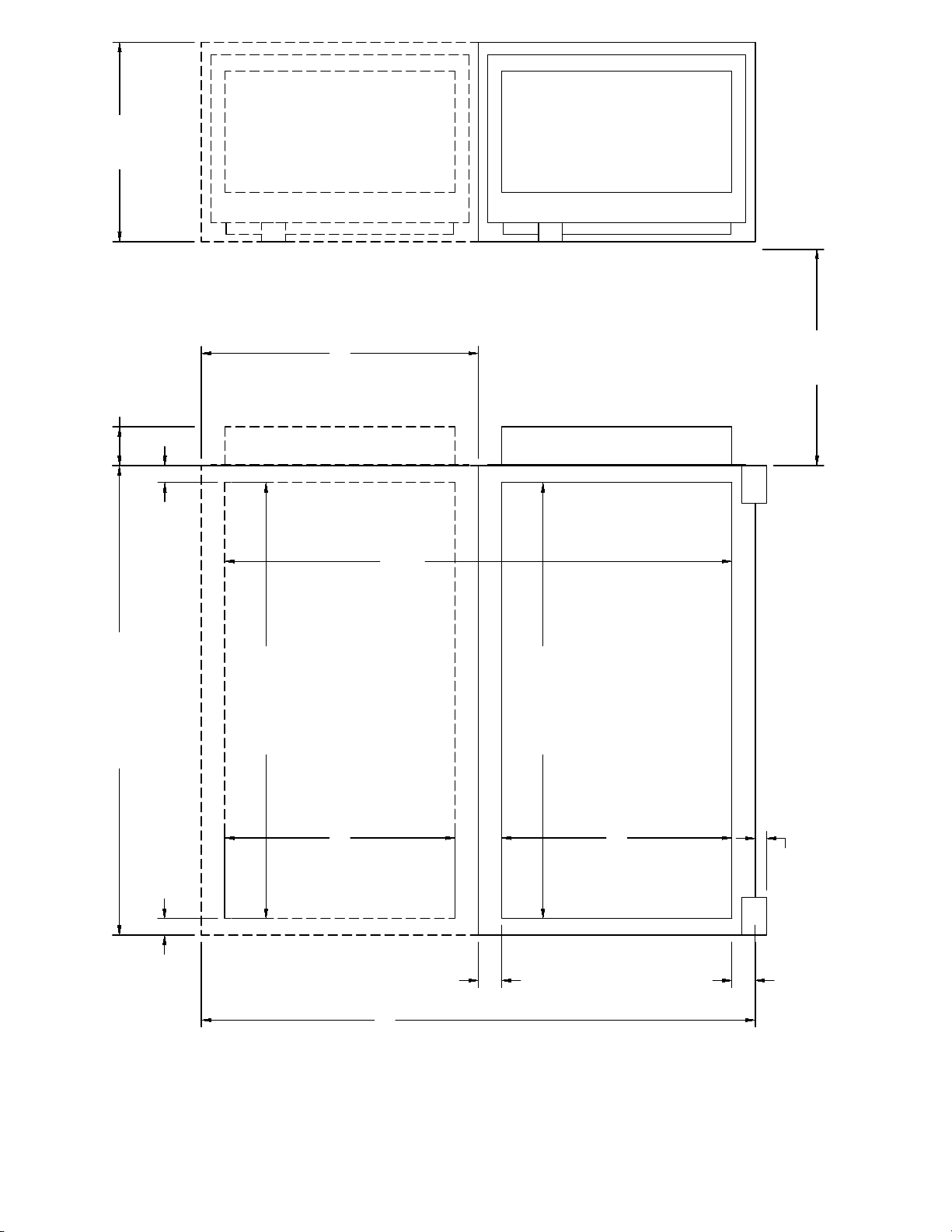

DIMENSIONS: See Fig. 1, Pg. 4

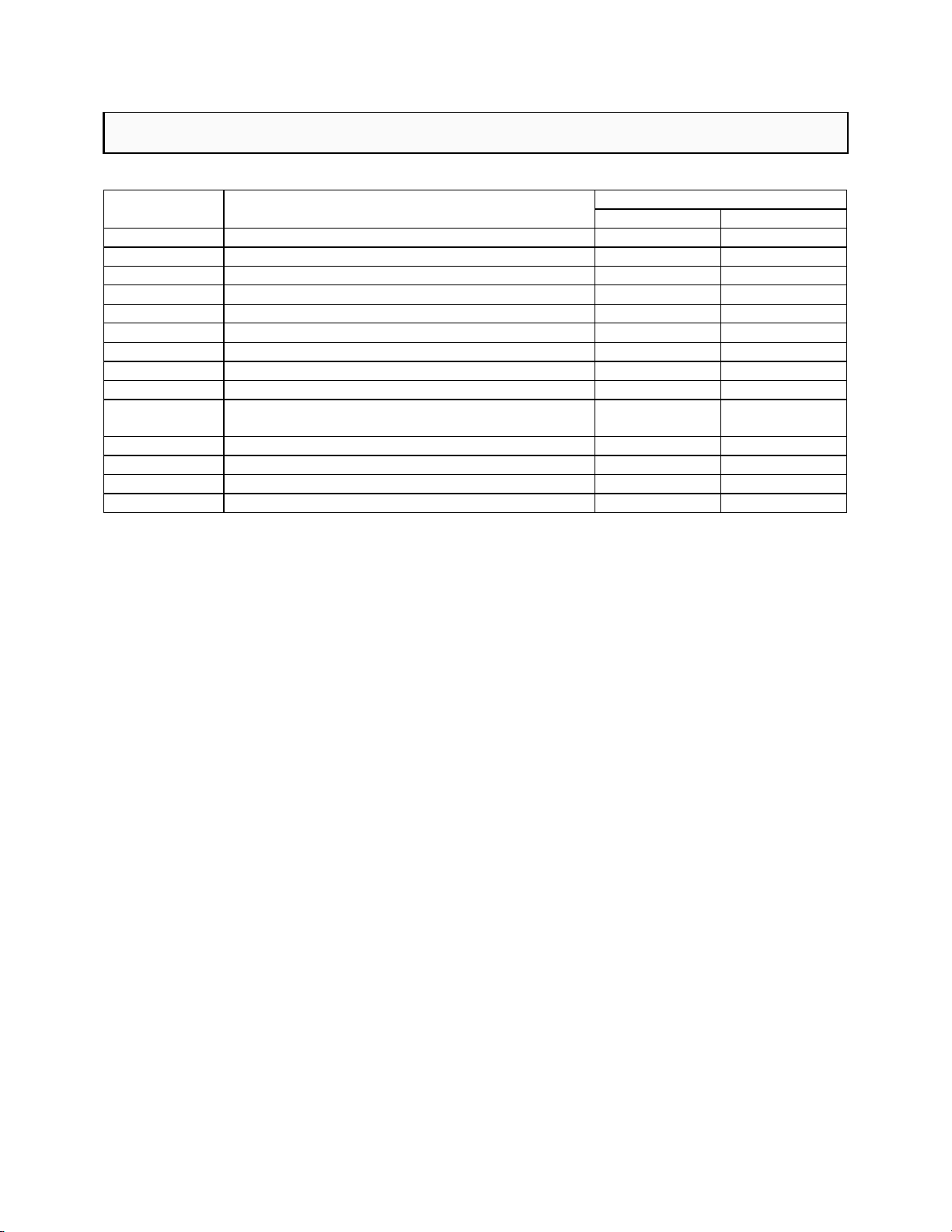

RECOMMENDED AIR FLOW (CFM) WITH CORRESPONDING PRESSURE DROP AND EFFICIENCY RATING

TABLE 1

F72A

F72B

F72B

2 UNITS STACKED

EFFICIENCYa

(PERCENT)

WATER

PRESSURE DROP

cfm

m³/hr.

cfm

m³/hr.

cfm

m³/hr.

in.

kPa

1,000

1,500

2,000

2,500

3,000

1,699

2,548

3,398

4,248

5,096

2,000

3,000

4,000

5,000

6,000

3,398

5,097

6,796

8,495

10,194

4,000

6,000

8,000

10,000

12,000

6,796

10,194

13,592

16,990

20,388

99

99

95

90

80

0.06

0.12

0.22

0.33

0.49

.015

.030

.055

.083

.122

*Efficiency ratings based on National Bureau of Standards Dust Spot Method and American Society of Heating, Refrigerating and

Air Conditioning Engineers Standard 52-76 using atmospheric dust.

4

49.50 F72B

25.50 F72A

29.20

45.38 F72B

21.38 F72A

24.31 DUCT

OPENING

DUCT

OPENING

2.06 2.06

21.00

STACKED

53.50

2.44

58.40

1.19 28.00

MINIMUM

CLEARANCE

FOR CELL

REMOVAL

AND SERVICE

45.38 F72B

21.38 F72A

24.31

2.44

4.10

Figure 1 – F72 INSTALLATION DIMENSIONS

5

PLANNING THE INSTALLATION

- WARNING -

The F72 Industrial Electronic Air Cleaner is not

explosion-proof. It must not be installed where

there is danger of vapor, gas or dust explosion.

INTRODUCTION

Clean air is the subject of numerous laws and

regulations. Typical requirements in the United

States are those put out by the Occupational

Safety and Health Administration (OSHA). Private

groups, such as the American Society of Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE) have also published numerous

recommendations.

Normally, clean air is defined in regulations and

recommendations as air having a limited amount

of contaminant in it, commonly expressed as parts

per million, or milligrams per cubic meter.

Approved counteractions are intended to lower or

eliminate the amount of contaminants in the air.

One of the more common methods of achieving

this goal is through the use of electronic air

cleaners.

At no time should an electronic air cleaner be

placed where there is a potential for explosion due

to the presence of explosive dusts, gases or

vapors. Contact the nearest Air Quality

Engineering, Inc., representative for assistance in

determining the correct application of an electronic

air cleaner.

AIR CLEANER SIZING

The F72 Induct Air Cleaner is usually sized

according to the capacity of the air handling

system and desired efficiency. See Fig. 4.

LOCATION AND POSITION

Because air-handling systems vary greatly in

arrangement and style, factors such as location,

air distribution, transitions, etc., require careful

consideration.

The F72 can be mounted in a vertical or horizontal

duct. If the air cleaner is to be mounted in a

vertical duct, position the F72 so that the hinged

access door opens down.

TRANSITIONS

When adapting the duct to fit the air cleaner, use

gradual transitions in duct size to prevent

turbulence and to increase efficiency.

Duct transitions should not exceed 20 degrees

(about 4 inches per lineal foot [101.6 mm per lineal

304.8 m]) on each side of a fitting.

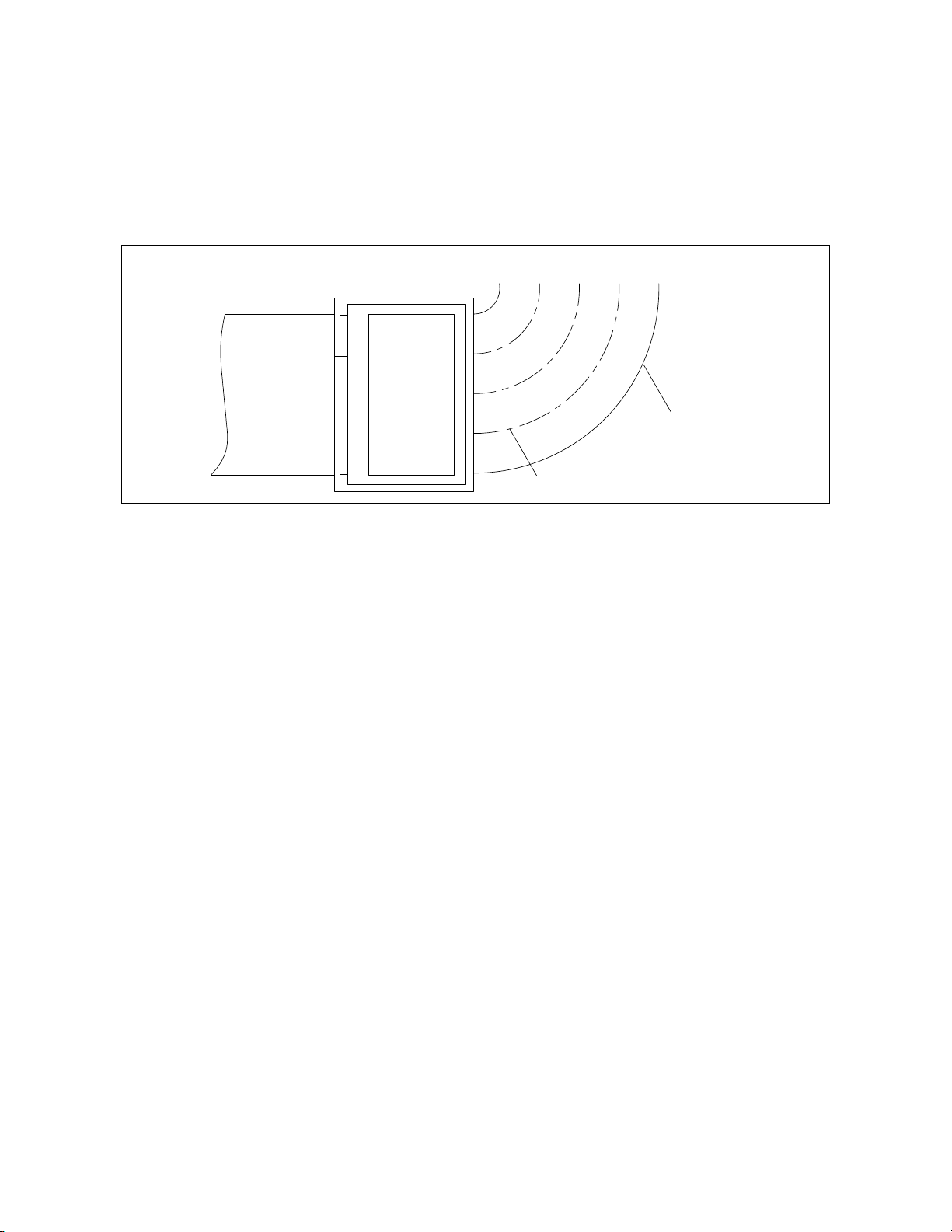

FIGURE 2 –TYPICAL INSTALLATION

OUTDOOR AIR

When outdoor air is added to the return air duct,

sufficient heat must be added to maintain a

uniform air temperature between 50°F and 125°F

[10°C and 52°C]. Two methods are

recommended:

1. Baffles. Mixing baffles should be used to mix

the outdoor air and the return air before it

enters the air cleaner.

2. Preheat Coil. If a large amount of outdoor air

is used, it must be heated. An appropriate

control system should be used to control the

heating element (electric strip heater, steam

coil, etc.)

Outdoor air intakes should be protected to prevent

the introduction of unnecessary contaminants.

Depending on the installation, it may be necessary

F72 ELECTRONIC

AIR CLEANERS

STACKED

AIR

DUCT

AIR

DUCT

6

to incorporate some or all of the precautions

mentioned below.

1. Air intakes should be hooded or louvered to

provide adequate protection from rain and

snow. The type of hood used will depend

upon the installation and expected weather.

2. Air intakes should always be equipped with a

“bird screen.”

At times, it may be desirable to install a prefilter

ahead of the electronic air cleaner. This is done to

remove contaminants that could be harmful to the

air cleaner or might cause excessively fast dirt

buildup or arcing in the electronic cell.

FIGURE 3 –TYPICAL INSTALLATION WITH TURNING VANES IN THE AIR DUCT.

COMMERCIAL APPLICATIONS

When deciding on the number of air cleaners

required for applications such as a restaurant,

bowling alley, store, bar or lounge, several

conditions must be considered. They are:

1. Air to be cleaned of dust, tobacco smoke,

greases, etc. These conditions may require a

higher efficiency in the electronic air cleaner

installation.

2. Capacity (cfm or m³/hr.) of equipment and

system.

3. Method of circulation must be forced air

distributed evenly to all parts of the controlled

area with the required air changes per hour.

4. Maximum number and average number of

people that will occupy controlled area.

5. The percent operating efficiency required of

the electronic air cleaner. The F72 efficiency

should be from 85 to 95 percent depending on

the application and purpose (see Efficiency

Chart, Fig. 4).

INDUSTRIAL APPLICATIONS

Sizing is determining how many air cleaning units

are required to maintain a desired level of air

quality. The process of sizing an industrial

application involves roughly figuring the number of

air cleaners needed and then modifying the figures

according to the specific characteristics of each

application.

For ambient air cleaning, the estimated number of

electronic air cleaners may be determined by the

relationship of air volume to the needed air

changes per hour.

An alternative method for calculating the estimated

number of electronic air cleaners can be used if it

is possible to measure the generation rate of the

contaminants and the allowable level of

contamination. To use either method of

calculation, consult your local sales

representative.

Regardless of the method used to calculate the

number of units needed to produce clean air, the

physical conditions of the space to be cleaned

may either limit this number or demand that more

units be installed. For ambient air cleaning, it is

important to establish a uniform airflow pattern

throughout the entire space. Limitations to the

calculated sizing may be a lack of space for

mounting areas or the number of units may

interrupt normal building operation; that is, a unit

cannot be mounted where an overhead crane will

F72 ELECTRONIC

AIR CLEANER

AIR

DUCT

TURNING VANES

RETURN

AIR DROP

DUCT

7

smash into it or where stand mountings seriously

interrupt building traffic patterns. The number of

units required by air volume and air changes per

hour might need to be increased when the shape

of a structure is such that effective capturing and

air distribution is not possible according to the

sizing calculations.

FIGURE 4 –F72 ELECTRONIC AIR CLEANER CAPACITY AND EFFICIENCY.

AIR CONDITIONING

Make certain the cooling coil is installed

downstream from the air cleaner cabinet to

prevent condensation and chilled air (cooler than

50°F [10°C]) from entering the cell.

HUMIDIFIERS

Location of the system humidifier is important to

the operation of the air cleaner. An evaporative-

type humidifier may be installed between the

furnace warm air duct and the return air duct

without affecting the electronic air cleaner. An

atomizing-type humidifier should be installed

downstream from the air cleaner. If the atomizing-

type humidifier is installed upstream, mist, salts

and minerals may decrease the efficiency of the

electronic cell and create a need for equipment

service.

When the atomizing-type unit must be used

upstream from the F72, the following precautions

should be taken:

1. It must be installed as far from the air cleaner

as possible.

2. A standard, disposable-type furnace filter

should be installed between the humidifier and

the air cleaner to trap water droplets and

mineral salts.

3. The electronic cell must be washed frequently

to prevent a mineral deposit buildup.

INSTALLATION

WHEN INSTALLING THIS PRODUCT

1. Read these instructions carefully. Failure to

follow them could damage the product or

cause a hazardous condition.

2. Check the ratings given in the instructions and

on the product to make sure the product is

suitable for your application.

3. Installer must be a trained, experienced

service technician.

4. After installation is complete, check out

product operation as provided in these

instructions.

- CAUTION -

Disconnect the power supply before installation to

prevent electrical shock and equipment damage.

8

- IMPORTANT -

This section includes information for the sheet metal and electrical installation. Make certain each person

involved with the installation is aware of the appropriate subsections in the manual.

INSTALLATION CHECKLIST

xTransitions

xComponents Assembled

- electronic cells

- power door

xTurning Vanes

xCheck Packing Materials Before Discarding

xWiring

SHEETMETAL INSTALLATION

Air Distribution and Duct Work

The F72 operates most efficiently when all of the

system air is delivered across the electronic cell at

a uniform velocity. Turning vanes should be

added to any return airdrop upstream from the air

cleaner (Fig. 3).

Gradual transitions to the F72 cabinet are

recommended in all duct work larger or smaller

than the cabinet opening. If transitions are used,

they should not exceed 20 degrees (4 in. rise per

linear ft. [101.6 mm rise per linear 304.8 m]).

INSTALL AIR CLEANER

Mount the F72 air cleaner as follows:

1. Fabricate and install the necessary vanes and

transitions.

2. Set the cabinet in position. If hanging

brackets are used, make certain the brackets

are strong enough to hold the cabinet and the

cabinet is attached firmly to the brackets.

NOTE: Place a spirit level on top of the cabinet

to make sure it is level.

3. a. Drill holes for sheet metal screws into the

cabinet face and also the duct.

b. Fasten the duct to the inside of the cabinet

flange opening with sheet metal screws.

c. Seal all joints in the return air system to

prevent dust from entering the clean air

stream.

Install the F72 components as follows:

FIGURE 5 –CORRECT CELL POSITION IN

THE F72

1. Slide the prefilter(s) and post filter(s) into

place.

2. Insert the electronic cell(s) into the cabinet

with the cell handle facing the door opening.

Make certain the arrow stamped on the cell(s)

points downstream (Fig. 5).

WIRING

- CAUTION -

Disconnect the power supply before installation to

prevent electrical shock and equipment damage.

9

4700 VDC COLLECTOR

POWER SUPPLY

HIGH VOLTAGE

OUTPUT: 9400 VDC IONIZER

100 Watts Max

INPUT: 120 VAC 50-60 Hz or

240 VAC 50-60 Hz

Units are not dual voltage

The line voltage supplied to the F72 air cleaner

must match the voltage rating stamped on the

front of the air cleaner.

- CAUTION -

Only persons qualified to install electrical wiring

should attempt this procedure. All wiring must

comply with applicable codes and ordinances.

A complete internal schematic diagram of the F72

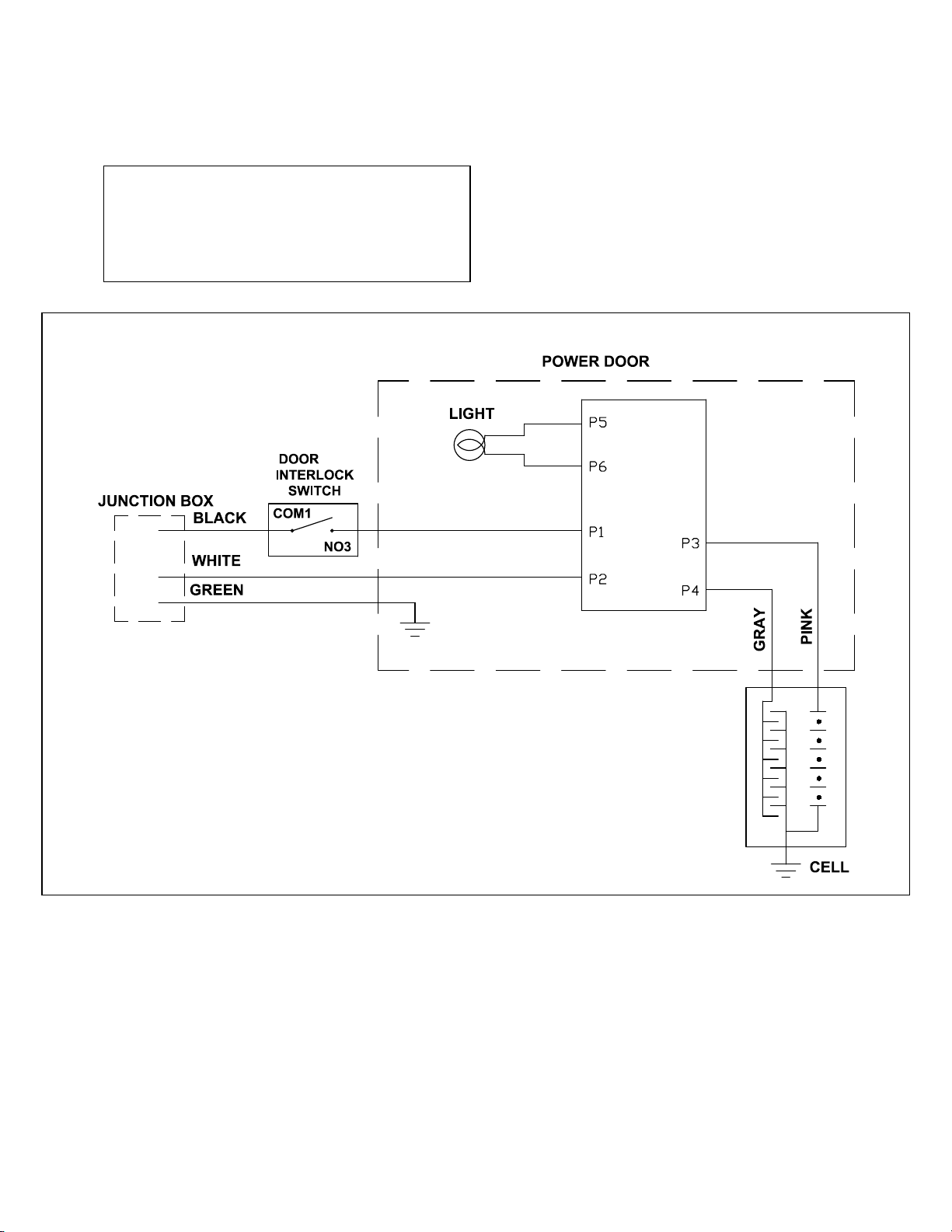

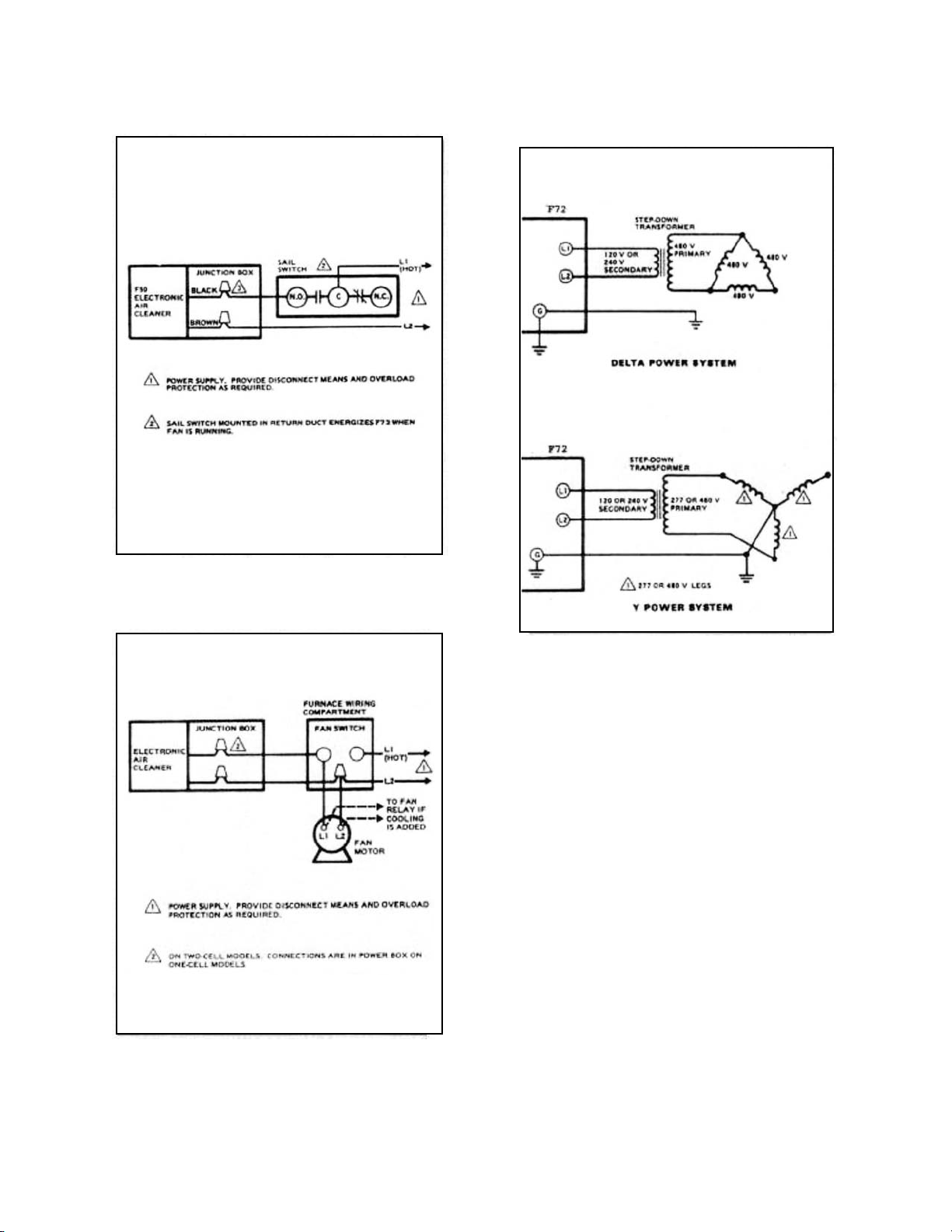

is shown in Figs. 6 and 7. Figs. 8 and 9 show

typical hookups. Fig. 10 shows typical hookups to

three phase voltage sources.

Figures 6 & 7 – F72 SCHEMATIC

10

FIGURE 8 –MULTI-SPEED OR MODULATING

BLOWER MOTOR. (Air cleaner is controlled by

a sail switch.)

FIGURE 9 –SINGLE SPEED BLOWER MOTOR.

(Air cleaner is controlled by the fan switch

and/or the fan relay.)

FIGURE 10 –F72 AIR CLEANER HOOKUP TO

THREE PHASE, HIGH VOLTAGE POWER

SUPPLIES.

11

SERVICE

CLEANING THE ELECTRONIC AIR CLEANER

The F72 is used to remove a variety of

contaminants from the air. In the process of

cleaning the air, however, parts of the air cleaner

will become dirty and the cleaning efficiency will

be lowered.

In order to maintain a high standard of reliability

and efficiency, it is necessary for the F72 to

receive periodic maintenance. Periodic

maintenance means cleaning the collector cells

and inspecting the electronic air cleaner both

visibly and with instruments. Service will be

required if the air cleaner seems damaged or

appears to be performing at substandard

efficiency.

Air Quality Engineering, Inc., recommends regular

cleaning and the use of an alkaline detergent

solution. The exact scheduling is a matter of

experience since each air cleaning situation

varies. Actual experience may dictate a greater or

lesser period between cleanings.

If, because of excessive buildup of captured

contaminants, the alkaline detergent solution

proves inadequate, the use of physical force (such

as high-pressure air, water or steam) or an acid

detergent solution may be required.

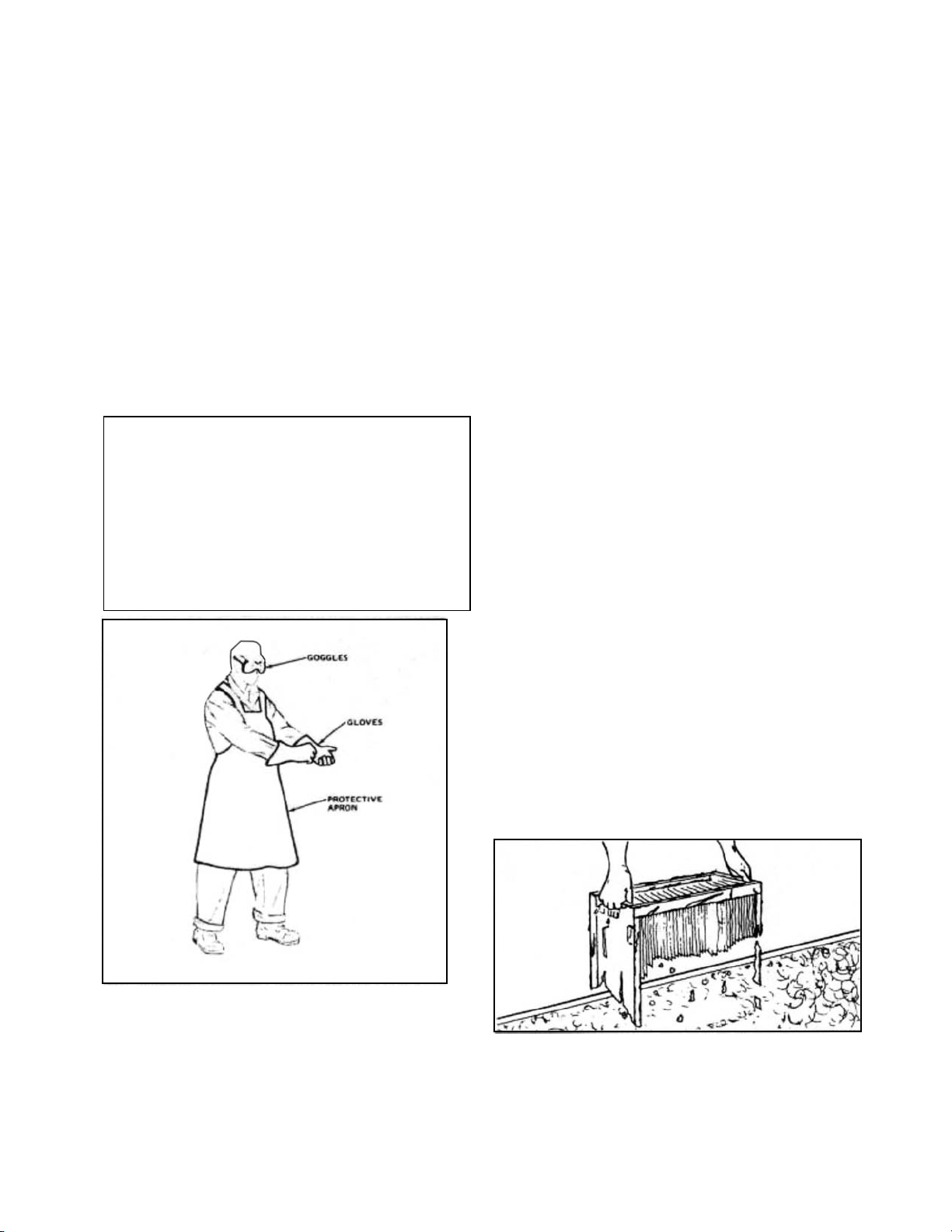

- CAUTION -

1. Be extremely careful when working with the

F72 cells and filters. The edges of the cells,

the filters, the collection plates and the ionizing

wires of the cells may be sharp.

2. When cleaning the cells and filters, be sure to

wear appropriate protective gear, especially

goggles and gloves. Skin contact with either

alkaline or acid detergent solution should be

avoided.

REMOVING THE ELECTRONIC CELLS AND

PREFILTERS

Before the electronic cells and prefilters can be

cleaned, they must be removed from the F72. Be

careful NOT to place a ladder or other heavy item

against the F72 unit, cells or prefilters. Electronic

air cleaners and their components are susceptible

to damage.

CLEANING THE PREFILTERS

The prefilters on an F72 do require cleaning. The

procedure is simple. Remove the prefilter and

shake the accumulated contaminants from it. If

this does not seem adequate, a vacuum can be

used; or the prefilter can be soaked in the alkaline

detergent solution. Do NOT soak the prefilter in

an acid detergent solution. Physical force

methods could also harm the prefilters.

THE ALKALINE DETERGENT SOLUTION

CLEANING METHOD

1. Provide a container large enough to hold the

electronic cells and prefilters to be cleaned.

2. Fill the container with detergent and hot water

sufficient to cover the electronic cell.

NOTE: Be careful to avoid prolonged skin

contact with the solution. Do NOT splash

solution in your eyes.

3. Soak the cells and prefilters in the solution for

about 15 minutes. The solution should be

agitated in some way, such as sloshing the

cells or prefilters or stirring the solution.

FIGURE 11 –WHEN SOAKING THE CELL,

AGITATE THE WATER.

4. Remove the cells and prefilters from the

alkaline cleaning solution and place them in

another container of hot water (150°F to 170°F

[66°C to 77°C] for rinsing. The cells and

prefilters should be rinsed for 5 to 10 minutes.

12

5. Remove the cells and prefilters from the rinse

water. Allow the cells and prefilters to drain

and dry before energizing them.

The collection plates of the electronic cells MUST

be checked for any detergent residue. If there is

any residue remaining, rinse if off since it may

affect the efficiency of the electronic air cleaner.

THE ACID DETERGENT METHOD

Air Quality Engineering, Inc., does sell an acid

detergent. However, acid cleaners should be

used only after alkaline detergents have proven to

be corrosive. They will decrease the life of cells.

If an acid detergent solution is used, be sure to

use a weak mixture. Do NOT place prefilters in an

acid detergent solution.

- IMPORTANT –

Acid cleaners must be properly handled. Refer to

the label on the acid detergent used. This means

wearing protective clothing, rubber gloves and

goggles, and reading all precautions on the label

of the detergent used. If contact is made in the

eyes, flush with a large amount of water and

consult a physician.

FIGURE 12 –BE SURE TO WEAR THE

PROPER EQUIPMENT FOR WORKING WITH

DETERGENT SOLUTIONS

NOTE: Be sure to provide adequate ventilation

when using acid detergents.

After the cleaning process is completed, the soak

water must be neutralized according to the U. S.

Environmental Protection Agency and state and

local pollution control guidelines and requirements.

Soda ash is one neutralizer.

1. Use a polyethylene or Type 316 stainless steel

container large enough to hold the electronic

cell. Other types of containers should be

avoided since the acid detergent may react

with the container material.

2. Following the instructions for temperature of

the water and amount of acid detergent used,

prepare the cleaning solution. The amount of

detergent and the soaking time will be

determined by the amount of contaminants

captured by the cells and the difficulty

encountered in removing the buildup. The

usual mix for acid solution is 2 oz. of acid

detergent to 1 gal. of water (59.2 ML to 3.8 L).

NOTE: It is recommended that acid cleaning of

any electronic air cleaner cells containing

metal oxide contaminants be performed with

room temperature or cold water. NEVER add

acid detergent to hot water.

3. Be sure to observe the cleaning operation

when the cells are placed in the acid detergent

solution. The amount of acid detergent should

be reduced if less than 30 seconds pass

before large amounts of bubbles are released.

The cells should NOT remain in the acid

detergent solution more than 30 seconds after

a vigorous reaction begins. It is a good idea to

remove the cells and inspect the cleaning

action of the acid detergent solution. If

contaminant deposits remain, the cells can be

returned to the solution.

FIGURE 13 –TOO MUCH TIME IN THE ACID

SOLUTION MAY HARM THE ELECTRONIC

CELL.

13

- IMPORTANT –

After the contaminants are removed by the acid

detergent solution, any further time the cells

remain in the solution serves only to decrease

their life.

4. After removing the cells from the acid

detergent solution, rinse them thoroughly for at

least five minutes.

5. Allow the cells to drain and dry before

energizing them.

STAINING

Occasionally after the soaking process, the cells

or prefilter may seem stained. If the stain is black

or very dark, it is probably detergent residue and

should be rinsed off at once. Detergent residue

may affect the electronic air cleaner’s efficiency.

If yellowing appears, it is probably staining. The

acid detergent solution will remove the yellowing.

However, it should be noted that the yellowing

does not affect air cleaner efficiency.

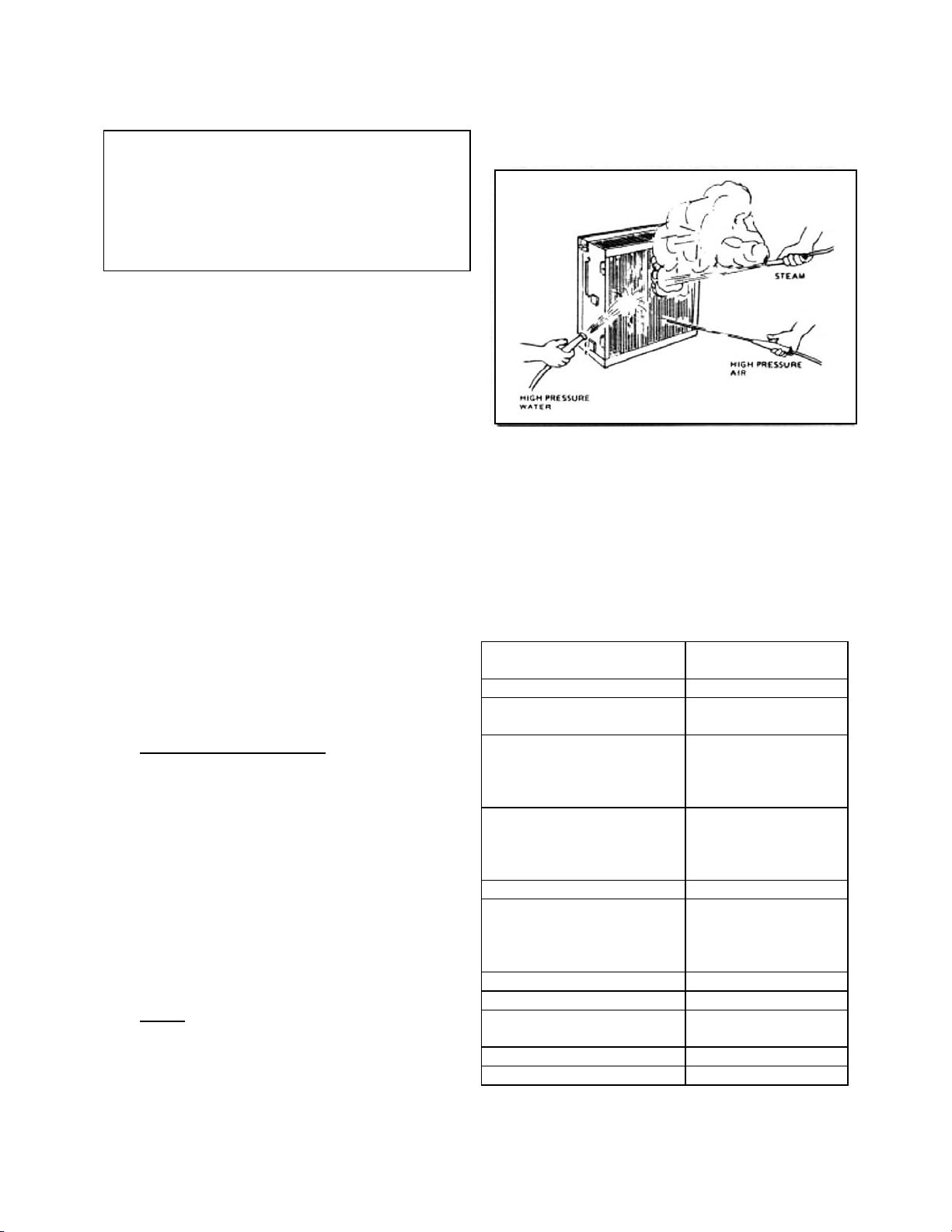

PHYSICAL FORCE METHODS

The following physical force methods may be

needed to clean some contaminants from the F72

cells. DO NOT use physical force methods on the

filter screens.

1. High Pressure Air or Water

Either of these methods should prove to be

adequate. However, care should be taken to

avoid damage to the electronic cells.

NOTE: Using any caustic detergent with high

pressure is dangerous.

If a detergent is required with the high-pressure

water, an alkaline detergent should be used if

allowed by the high-pressure equipment

manufacturer. DO NOT use an acid detergent

except when allowed by the equipment

manufacturer.

2. Steam

Extreme care must be exercised when steam

cleaning to avoid warping or bending the collector

plates of the electronic cells or any other damage

to the cells. Remember that the cells will be hot

after steam cleaning and that care must be taken

to avoid burns.

FIGURE 14 –IT MAY BE NECESSARY TO USE

PHYSICAL FORCE METHODS TO REMOVE

COLLECTED CONTAMINATION.

CONTAMINANTS AND CLEANING

PROCEDURES

The following is a selective listing of contaminants

captured by electronic air cleaners. This listing

gives the appropriate cleaning procedure for

various types of contaminants found on electronic

air cleaner collector plates and prefilters.

CONTAMINANT

CLEANING

PROCEDUREª

Animal Hair

Alkaline Solution

Cabosil

Alkaline Solution

High Pressure Air

Carbon –

(carbon black, soot, lamp

black, graphite, charcoal,

dust,etc.)

Alkaline Solution

High Pressure Air

High Pressure Water

Cooking Oils –

Veg. (soybean, peanut,

etc.)

Animal (lard, butter, etc.)

Alkaline Solution

Steam

Cotton Fibers

Alkaline Solution

Dust –

(silicon dioxide, calcium

carbonate and mineral

type compounds)

Alkaline Solution

Flour Dust

Alkaline Solution

Linseed Oil

Alkaline Solution

Lubricants

Alkaline Solution

High Pressure Water

Metal Oxides

Acid Solution

Metals

Acid Solution

14

CONTAMINANT

CLEANING

PROCEDUREª

Mineral Oil –

(petroleum base, diesters

and silicone)

Alkaline Solution

High Pressure Water

Paper Products

Alkaline Solution

Paint –

Oil Base, Water Base

Alkaline Solution

Pine Tar Resins

Alkaline Solution

Steam

Polyethylene

Alkaline Solution

Polyphenyleneoxide

Alkaline Solution

Polypropylene

Alkaline Solution

Rubber Molding

Accelerators

Alkaline Solution

Soaps

Alkaline Solution

Sodium Chloride

Alkaline Solution

Sugar –

(includes molasses)

Alkaline Solution

Steam

Talc

High Pressure Air

Alkaline Solution

Tobacco Tars and Smoke

Alkaline Solution

Varnishes

Alkaline Solution

Waxes –

(all types)

Alkaline Solution

Steam

Welding Fumes

Acid Solution

Wood Products

Alkaline Solution

ªCleaning procedures are listed in order of preference.

REPLACING THE CELLS

Before replacing the electronic cells, be sure to

visually check the electronic cells for bent or

damaged collector plates or broken ionizing wires.

Bent or warped collector plates may be bent back

into shape.

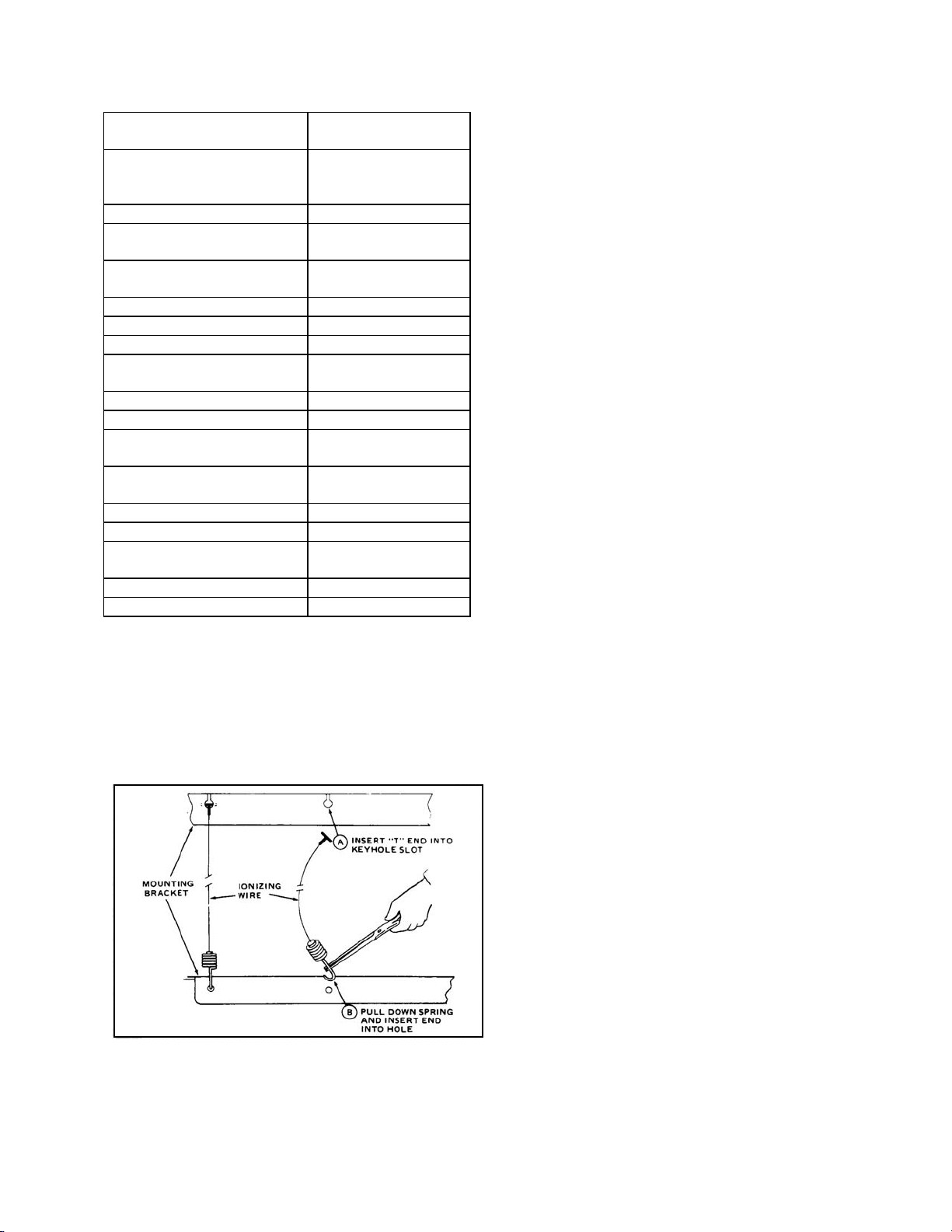

FIGURE 15 –REPLACING IONIZING WIRES

Broken or damaged ionizing wires must be

replaced for top efficiency. Remove all parts of

the broken or damaged wire. Replacement wires

come cut to length and ready for installation.

Remember that wires come cut to length and

ready for installation. Remember when replacing

the ionizing wires to:

1. Use care to avoid damage to the spring

connector or other parts of the cell during

installation.

2. Hook “T” end of the ionizing wire in the

keyhole slot at one end of the cell.

3. Pull down the spring with a needle-nose pliers

and insert hook into the hole.

Before replacing the cell, it might be a good idea

to check it for a short circuit. This is done by using

an ohmmeter to check the resistance between the

frame of the cell and both the ionizer and collector

contacts. In each case, the resistance should be

infinite.

15

TROUBLESHOOTING

- CAUTION -

1. During troubleshooting, dangerous line voltage

circuits are exposed. Use extreme care to

avoid electrical shock or equipment damage.

2. Although not normally lethal, the high voltage

output of the electronic air cleaner power

supply can produce a painful shock. Use

caution.

TROUBLESHOOTING PROCEDURE

The following procedure has been designed to

speed troubleshooting and to insure the quick

detection and proper repair of any malfunction in

the electronic air cleaner.

Most of the troubleshooting steps can be

performed by observing the performance indicator

light and by pushing the test button.

Troubleshooting can be done with only a few tools:

xTest Meter –Simpson 248 Hi Voltage meter or

equivalent.

xNeon test lamp for line voltage.

xScrewdrivers –long shank with plastic or

rubber handles.

xNeedle nose or long nose pliers –for replacing

ionizing wires.

FIGURE 16 –F72 TROUBLESHOOTING FLOW CHART

16

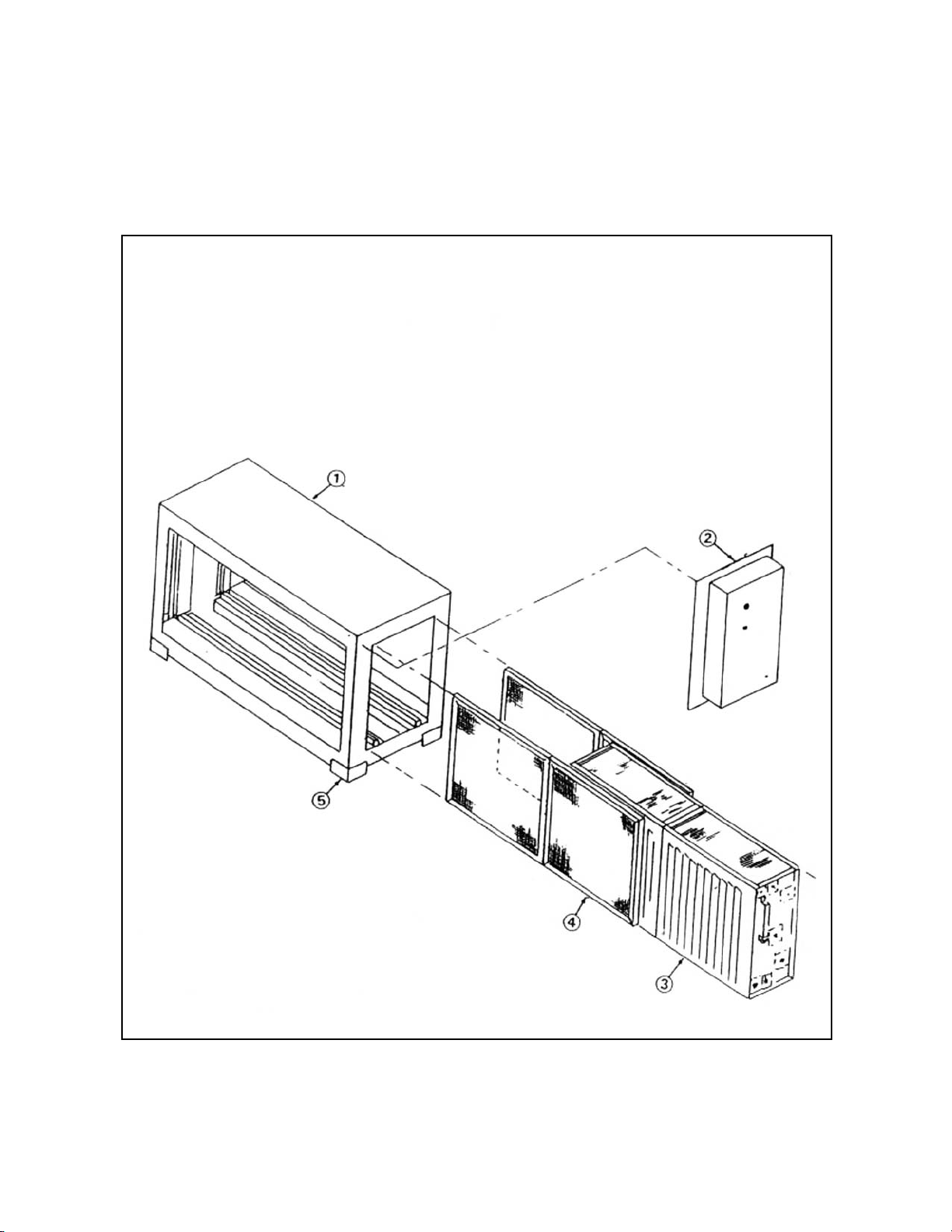

FIGURE 17 –EXPLODED VIEW OF THE F72 ELECTRONIC AIR CLEANER.

17

PARTS LIST

NO.

DESCRIPTION

PART NO.

F72A

F72B

1

Cabinet Assembly

05413

05416

2

Door, 120V

05414

05414

3

Door, 240V

05415

05415

4

Electronic Cell(s)-F72A (1), F72B (2)

38010

38010

5

Pre/Post Filters-F72A (2), F72B (4)

41113

41113

6

Cabinet Foot

21411

21411

7

Ionizer Wires

38005

38005

8

Indicator Light

10097

10097

9

High Voltage Power Supply Replacement Kit, 120V

07081

07081

10

High Voltage Power Supply Replacement Kit,

208-240V

07083

07083

11

Male Connector

46199

46199

12

Female Connector

46198

46198

13

Media Prefilter Frame

41111

41111

14

Media Prefilter Pad

41112

41112

18

NOTES:

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

19

NOTES:

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

20

CERTIFICATE OF WARRANTY

ONE-YEAR LIMITED WARRANTY

Air Quality Engineering, Inc. (AQE), warrants the Smokemaster® Electronic Air Cleaner to be free from

defects in workmanship or materials, under normal use and service, for a period of one (1) year from the

date of purchase by the consumer. If at any time during the warranty period the product is defective or

malfunctions, AQE shall repair or replace it (at AQE’s option) within a reasonable period of time.

If the product is defective:

(i) obtain a Return Goods Authorization (RGA) Number from your AQE representative,

(ii) return the unit or defective component with a bill of sale or other dated proof of purchase to the

retailer from which you purchased it, or

(iii) package the unit or component along with proof of purchase (including date purchased) and a

short description of the malfunction, and mail or ship postage or freight prepaid to the following

address:

AIR QUALITY ENGINEERING, INC.

Warranty/Return Goods Department

7140 Northland Drive North

Minneapolis, Minnesota 55428-1520

The repaired or replaced part or unit will be shipped freight collect by AQE to the purchaser with the

purchaser to be responsible for all freight charges. The warranty on any repaired or replacement part

shall be for a duration of time no longer than the remaining or unexpired term of the original warranty.

This warranty does not cover any labor or other service charges incurred by the purchaser.

This warranty shall not apply if it is shown by AQE that the defect or malfunction was caused by damage

that occurred while the product was in the possession of the consumer.

AQE’s sole responsibility shall be to repair or replace the product within the terms stated above. AQE

SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL DAMAGES RESULTING FROM ANY BREACH

OF WARRANTY, EXPRESS OR IMPLIED, APPLICABLE TO THIS PRODUCT. Some states do not

allow the exclusion or limitation of consequential damages so this limitation may not apply to you.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, AND THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY

EXCLUDED BEYOND THE ONE-YEAR DURATION OF THIS WARRANTY. Some states do not allow

limitations on how long an implied warranty lasts so the above limitation may not apply to you.

This warranty gives you specific legal rights and you may also have other rights that vary from state to

state.

AIR QUALITY ENGINEERING, INC. TOLL FREE: 1-800-328-0787

7140 NORTHLAND DRIVE NORTH TELEPHONE: (763) 531-9823

MINNEAPOLIS, MINNESOTA 55428-1520 FAX: (763) 531-9900

MANUFACTURER & WORLDWIDE DISTRIBUTOR OF SMOKEMASTER® AIR CLEANING SYSTEMS

PN 51587 Printed in the USA

This manual suits for next models

4

Table of contents

Other Smokemaster Air Cleaner manuals