Smokemaster X-4OO Instruction Manual

@

NOWNER

AND

SERVICE

MANUAL

SMOKEMASTER'

MODEL

X-4OO

SELF-CONTAINED

ELECTRONIC

AIR

CLEANER

TABLE

OFCONTENTS

PAGE

OWNERSMANUAL

PART

I

INTRODUCTION

COMPONENTS.

PRINCIPLES

OFOPERATION

OPERATINGINSTRUCTIONS

MAINTENANCE

.

SERVICE

INSTALLATION

AND

SERVICE

PART

II

SPECIF|CATTONS ......5

GENERALINFORMATION.. 6

Application 6

Make-UpAir... 6

Sizing 6

INSTALLATION 7

GHECKOUT.... I

SERVICE 9

ELECTRICALTROUBLESHOOTING. .....10

DTAGNOSTTCCHECKS ......11

PARTSLIST. ....13

GUIDESPECIFICATIONS ....14

MADEWITHPRIDEINTHEU.S.A.

OWNER

MANUAL

SMOKEMASTER

PART

1

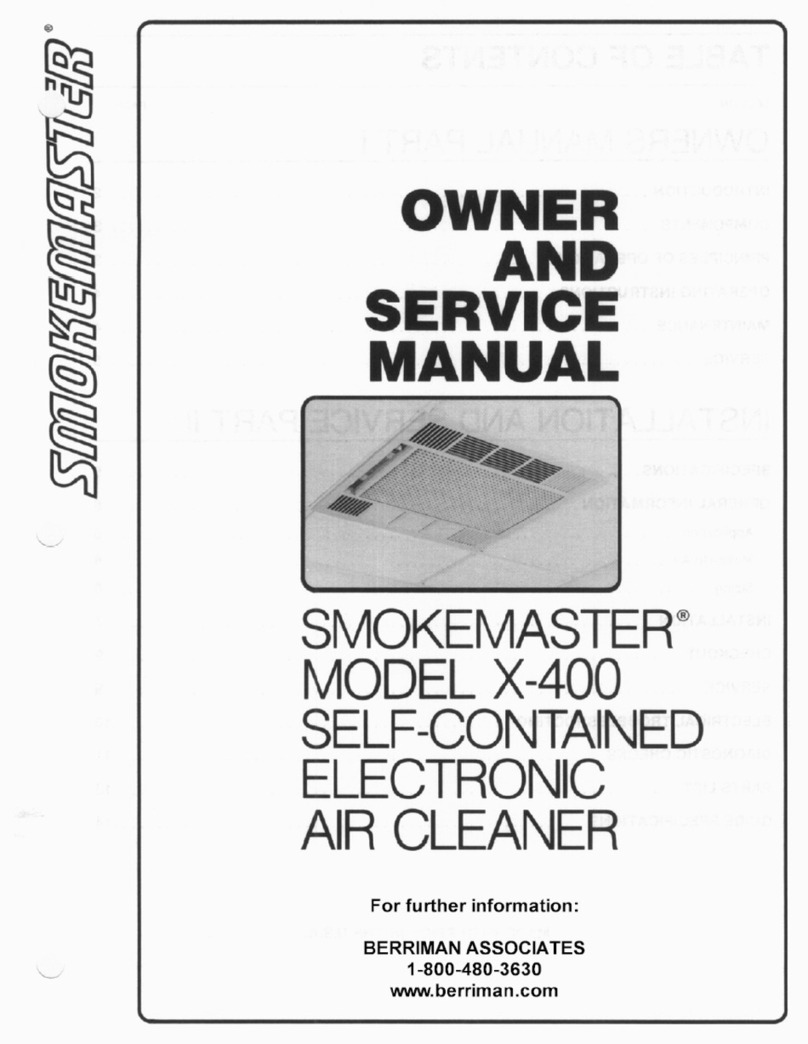

Your Smokemaster

X-400

is an advanced

self-contained

electronic

air cleaner.

ThemodelX-400

is an

efficient indoor pollution fighter while reducing costly energy consumption. It is designed to be

installed

in the space

of a 2 x 2 drop ceiling

panel.

CLEAN

AIR

A clean fresh atmosphere

is a plus to any business.

With your new Smokemaster

Electronic

Air

Cleaner,

your customers

and ernployees

cannow breathe

air that is relatively freeof smoke,

dust or

pollen.This is especially

important with regardto today'sconcern

with the effects

of smokersupon

non-smokers

and also

for a morecomfortable

environment

for allergy

sufferers.

LOWER

ENERGY

CONSUMPTION

A common

solutionto the problem

of dense

concentrations

of smokeis to exhaust.

Excessive

exhaust-

ing is wasteful and very expensive.

One is exhausting

expensively

heated

or cooled

air and needing

to heator coolthe outdoor air coming

in. A Smokemaster

X-400

drastically

reducesthe need

for out-

sideair. Thismeans

you can

saveas

muchas40percent

on heating

andcooling

bills.

REDECORATING

Smokeparticles also ha_ve

a tendency to settle out as a dulling film on mirrors, windows, trophies,

bottles

and glassware.

In fact, most of the particles

which prJiuct soiling and staining are lust too

smallto beremoved

by_average

dusting.Electronic

air cleaning

gets

rid of-theseparticles

before

they

have a chance

to start the soiling process.

Less

soiling meansioig"t periods betweenredecorating.If

the appearance

of your business

is important to you, electronic

air-cleaningis certainly a plus.

EXTRACOMFORT

AND SAVINGS

The

effective

air patternof the ModelX-400

creates

a morecomfortable

atmosphere

by constant

slight

air movement.

This slight movement

also

helpsto eliminate

existingdrafts. Another side benefiiof

the air recirculation

Pattern

is that it distributes

the heated

or cooled

air more evenly.

Thisevendis-

tribution helps

to reduce

the amountof heated

or cooled

air needed

for the samedegiee

of warmth or

cool.

LOWOPERATING

COST

In addition to reduced

heating/cooling

billsand redecorating

bills,the relativelylow cost

of maintain-

ing an X-400

electronic

air cleaner

is another

financialboostto your business,

this air cleaner

hasno

throwaway filter or other parts that must be periodically

replaced.

The durable electronic

cellsand

prefilter screens

are washedand used over and over again.No replacement

parts meansreduced

maintenance

cost.

2

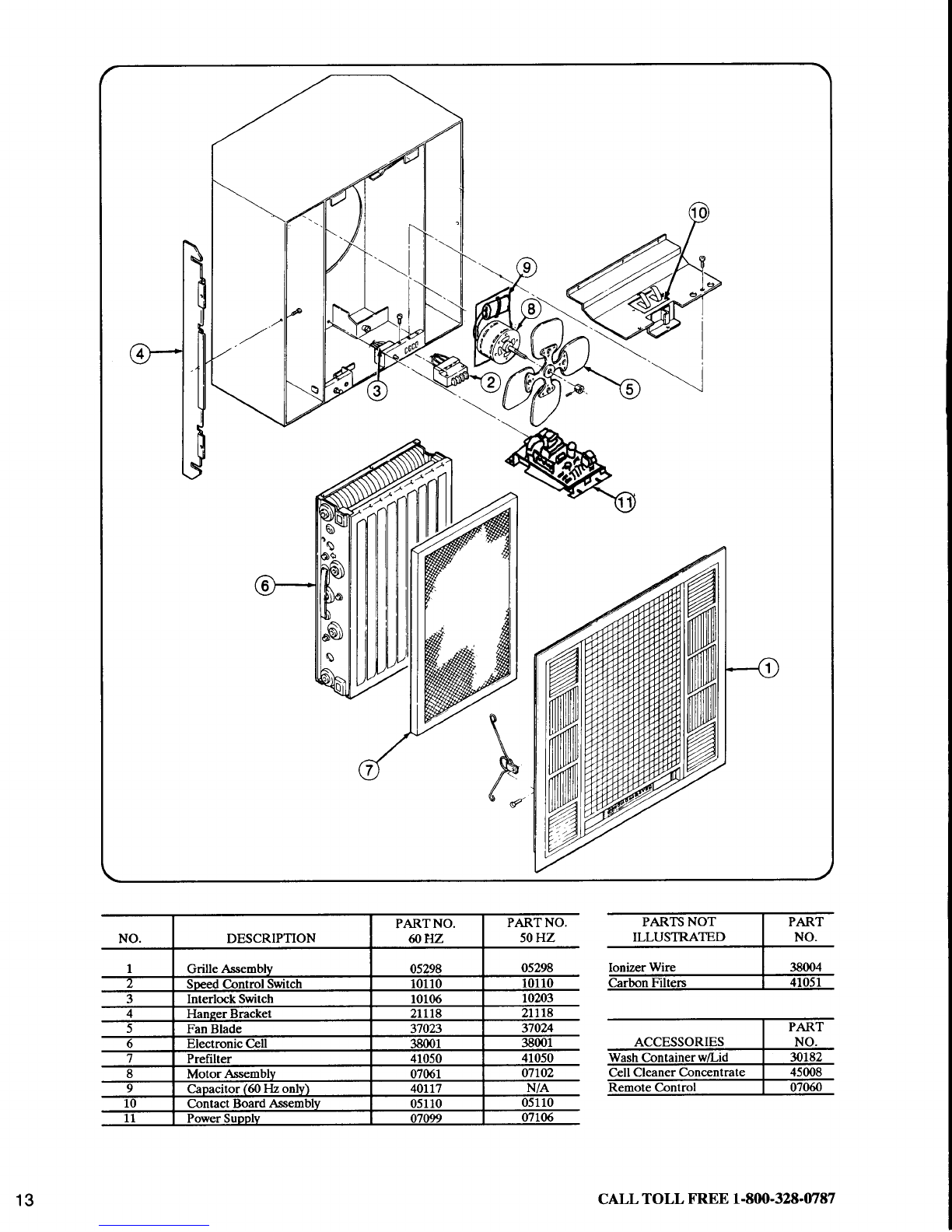

COMPONENTS

COMPONENTS

OF

THEX.4OO

ELECTRONIC

AIR CLEANER

Cabinet

The sturdy corrosion resistant steel cabinet

requires only 13-9116" spaceabove drop ceiling

for installation.

Mounting System

Speciallydesigned support bars simplify installa-

tion - makes mounting of air cleaner safe and

Becureevenduring installation.

Power

Supply

Solid state power supply assures trouble-free,

highly reliableservice.

Grille

Attractive one-piece grille conveniently drops

down. All serviceable components are accessible

through the grille opening.

ElectronicCelle

One electronic cell charges and collects airborne

particles. The compact design allows easyremoval

for cleaningand service.

FanMotor

Motor driven fan operates at 3 speedsproviding

the choiceof circulation level. Elastomeric

suspen-

sion systemeliminatesvibration noise.

Capacitor

PRINCIPLES

OFOPERATION

HOWYOURELECTRONIC

AIR CLEANERWORKS

,irbornc contaminants arc trappcd bv a process

callcd

ElcctrostaticPrccioitation." Thc fan-draivs particulatc

rden

airsucccssivcli

throughthcprcfilter,thccill ionizing

Airbornc contaminants arc trappcd bv a proccss

callcd

"Elccrostatic Prccipit-ation.:' Th" fa.n-

draivs p-articulatc

ladenair succcssivcli

throush thcprcfilter.thccill ionizins

section and ccll c6llcctor-scctioh. Thc ionizinc sectionrzlng seoron

section and ccll c<i

Collcain3

Sccrion

L---__1///

Ctcen

Air

Our

+

il]|q;i';;-"i;;i.i;ili;.s;-i;'ii,eildilfti'-J"piiiiii.irmDarts an clcctncal charlc to tnc lnclvldual par

which arc thcn drawn by cfcarostatic forccs to th.c <

sitcly charged .collcctor pl:

discharsedSackinto thcroom.

srtclY cna

discharged

.ncal chartc to tnc rnctvldual D

,rawn

bv cfcctrostaticforccs

to th,

collcao'r platcs. Clcaned air i

lc op.po-

rs thcn

Electronicccllsmust

bc washed

pcriodically

to maintain

cff

icicnt

pcrform

ancc.

3

Cherging

Scclion \_

r--!\:

------n4....

Dirty :. ... .

Air .---\.:..

In '--t4

','...

F--:-J\. .

L=.4

OPERATING

INSTRUCTIONS

SAFETY

INTERLOCKSYSTEM

In order for all air cleaner functions to receive

operating power the grille must besecurelyin posi-

tion. This actuatesthe safety inter-lock switch. Air

cleanerwill not function without grille in place.

FANSWITCH

Your electronic air cleanerhas an Off-Low-Med-Hi

switch. The electroniccollectionsystemand built-in

fan are designed to run simultaneously. Turn off

the air cleanerbeforedropping the grille to remove

the electronic

cellsfor cleaning.

SYSTEMLIGHT

Your electronic air cleaner is equipped to tell you

simply and quickly that it is working properly. The

amber system light tells you at a glancethe status

of the power supply. The systemlight should beon

when the unit is on.

TEST

BUTTON

Pushing the white button labeled "push to test"

generates

a snapping noise which indicates proper

function of collectorsystem.

MAINTENANCE

WASHING

THEELECTRONIC

CELL AND PREFILTER

To maintain peak efficiency, the electronic cells

and prefilter in your electronic air cleaner must

bewashed regularly. The washing is necessary

to

remove dirt particles collected from the air.

Check with your Air Quality Engineering

representativeto determine how often your cells

needto bewashedfor your particular application.

Grille may be removed from machine for periodic

washing. CAUTION

1. Beextremelycareful when working with X400

cell and filter. The edgesof the celle

and filter,

and the collection platee and ionizing wlreo of

the cell may be eharp.

2. When cleaningthe cellsand filtere, besureto

wear rppropriete protective geat, espectallygog-

gleeand glovee. Skin contactwith either alka-

line or acid detergent solution should be

avoided.

3. Usea etable

platform to etandon when work-

ing wlth the electronic air cleaner.

4. Electronic air cleaners and their components

aresuoceptibleto damage.Teke carewhen work-

ing wlth them to avoid equipment

damage.

1. Fill wash tub with cell cleaningdetergentand

hot water per detergent manufacturer's instruc-

tions.

2. Immerse cells in CLEANER and remove immedi-

ately.

3. Remove cells and set aside for five minutes to

allow CLEANERto penetrate.

4. Rinsecells well with hot water. Make certain no

residue remains on cells. Residue will adversely

affect cell performance by causing frequent arcing

and low efficiency.

.5. Inspect cells for broken wires or bent plates.

Repair or replaceas necessary.

(See

ServiceSection

for ionizer wire replacement

procedure.)

5. Removelint from prefilter with vacuum cleaner

or wash with mild detergent solution.

SERVICE

In the event of air cleaner malfunction there are

somesimple checks

you canperform to determine

if a serviceman

mugt becalled.

1. Checkcircuit fuse or breaker.Correct if fuse is

blown or breakeris tripped.

2. Be sure electronic cell is in place,intake grille

is closed

and unit is turned on.

If the problem persists, call serviceman.

The fol-

lowing information will beuseful to him.

1. Whether or not ambersystemlight is on.

2. If pushing white test button results in a snap-

ping sound.

ARCING

Frorr time to time you may hear a snapping noise

coming from the electronic air cleaner.This arcing

occurs when the air cleaner collects an unusually

large particle, when cell is wet, extraordinarily

dirty or damaged.

If an unusual amount of arcing persists,check

first

to determine if the electronic cell needs washing.

Look also for any sign of bent collector plates or

brokenionizer wires.

If arcing still occurs when cell is clean and dry,

consult your serviceman

or dealerfor repair.

INSTALLATION

ANDSERIIICE

SMOKEMASTER

PART

2

SPECIFICATIONS

Model X-400includes

oneelectronic

celland

a3-

speed

fan. Discharges

air in up to four directions

parallelto ceilinguponwhichit ismounted.

CAPACITY:

ELECTRICAL RATINGS:

Voltage

andFrequency

- l2OYac,6OHz;

220240Vac,50

Hz

CURRENT

AND POWBRCONSUMPTION:

EFFICIENCY: Up to 97percent

efficiency

is

delivered

asmeasured

according

to theNBSDust

Spot

Method

usingatmospheric

dust

as

outlined

in

theAmerican

Society

of Heating,

Refrigeration

and

Air Conditioning

Engineers

(ASHRAE) Srandard

52-76.

WEIGHT: 54lbs.(25

kg)shipping,44lbs.

(20

kg)

installed,

including

electronic

cells.Each

cellweighs

91,2tbs.(a3 kg).

AMBIENT TEMPERATURE

RATING:

Shipping

andStorage:

-40

to +150

degrees

F.

Operating:+40to *125 degrees

F.

UNDERWRITERS

I,ABORATORIES

INC.,

LISTED:

FileNo.855711,

Guide

No.AGGZ

(ffiHz models

only)

CANADIANSTANDARDS

LISTED:

FileNo.

LR89416-1

DIMENSIONS:24"

x24'x 13518"

GENERALINFORMATION

APPLICATION

TheX-400

ismounted

intheroom

orarea

where

theairistobecleaned.

Onevery

common

appli-

cationisthe

removal

oftobacco

smokefrom

the

air.Typicalinstallations

include

conference

rooms,

lounges,

offices,

lunchrooms,

etc.

Because

itprovides

itsown

circulation,

the

X-400

maybeused

inalmost

any

applicationrequiring

theremoval

ofairborne

particulate

contamination

from

anenclosed

space.

WARN

The

X-400Electronic

AirCleaner

isnot

explosion

proof.

ltmustnot

beinstalled

where

there

isdanger

of

vapo/,

qas,

ordust

MAKE.UP

AIR

Recommended

quantities

ofcleanoutdoor

ventlla-

tion

airfor

various

applications

are

described

in

Table2ofthe

ASHRAE

Standard

62-89

.Ventilation

forAcceptable

Indoor

Air

Quality.'ASHRAE

(American

Society

of

Heating,

Refrigerating,

and

Air

Gonditioning

Engineers,

Inc.,Phone

#404-636-

8400)notes

that

these

recommended

outdoor

air

quantities

maybereduced

bytheuse

ofclean,

recirculated

airifthe

IAQProcedure

6.2is

used.

Appendix

EofASHME62-89

includes

recom-

mendations

fortheuseofclean

recirculated

air.

However,

inmost

cases,

adequate

control

ofcar-

bondioxide

generally

requires

aminimum

clean

outdoor

air

quantity

ofno

lessthan

15cubic

feetof

air

per

minute

per

person.

Additional

ventilation

maybe

requiredfor

toxic

con-

taminants.

Inany

event,

theaircleaner

must

be

used

onlyin

areas

which

areventilated

for

human

occupancy

inorder

todisipate

anyincidental

gen-

eration

ofozone.

stzrNG

Electronic

aircleaners

are

generally

best

sized

according

tothe

use

ofthearea

andthe

volume

of

theroom

(Air

Changes

per

Hour

Method).

Secondary

factors

toconsider

inapplying

elec-

tronic

air

cleaners

include:

-type

ofcontamination

-number

ofoccupants

-orrtside

airquality

-anticipated

fansetting

-rate

ofcontaminate

generation

By

considering

these

factors,

thenumber

ofair

cleanersrequired

can

beadjustedupordown

to

account

forabnormalities

in

operatingconditions.

Follow

Steps1through

4below

todetermine

the

numberof

aircleaners

required:

Steo1

-Measurethelength,rividth,

andheight

oftheroomin

feet.

Step

2-Determine

theAirChanges

per

Hour

required.

See

ChartAbelow.

Step

3-Determine

theC.F.M.

(Cubic

Feet

per

Minute

ofAir).See

ChartBbelow.

Step

4-Plugthefigures

from

Steps1-3

intothe

sizingformula

below

andcalculate

thenumber

of

aircleaners

required.

SIZING

FORMULA

LxWx Hof Room

xAirChanges

/ Hr.

= # ofX400's

C.F.M.of

Air

(see

Chart

B)x60Min.

NOTE:

The

maintenance

interval

for

cellcleaning

canbe

lengthened

byincreasing

thenumber

of

aircleaners

beyond

therequired

number.

CHART

A. AIRCHANGES

PERHOUR

Load Descrlptlon

of

Appllcatlon AlrChanges

Per

Hour

Llght Generaloffices

&

computer

rooms 4-5

Average Conference

and

break

rooms 6

Heavy Designated

smoking

areas,

bingohalls,

bars,

&elilra

smoky

areas.

8-10

CHART

B. CUBIC

FEET

OFAIRPER

MINUTE

The

aircleaner

has

athree-speed

fan

motor.

Usethe

C.F.M.that

corresponds

tothespeed

that

theair

cleanerwill

operate

onnormally.

Low

speedwhere

noise

isaprime

concern

and

high

speed

wherenoise

isnot

afactor.

ModelX400 Low Medlum Hlgh

c.F.M. 175 275 400

Nolse

Level 45

dB(A) 50.5

dB(A) 56.5

dB(A)

INSTALLATION

IMPORTANTI Read theeeinstructions carefully.

A hazardous condltion or damage to product

could result lf lnstructions are not followed.

CAUTION

1. Do not connect power source until after the

electronic alr cleaner ia nounted. Electrical

ehockand equipment danage may result.

2. Be eure to turn air cleaneroff prior to service

or inetallatlon. Motor has automatic thermal

overloadeolt will stop when overheated.It will

automatically

start after a coollng

period.

3. Avold electrlcal ehock by being careful when

air cleaner le turned on for electrical check.

Aleo, be careful when working nearair cleaner's

moving parts.

4. Weargloves

when lnstalling air cleanerto pro-

tect handsfrom cuts.

EQUIPMENT

NEEDED

1. Phillips screwdriver

2. Wire cutters

3. Pliers

4. Knife

5.Hacksaw

5.Electric

drill (with 1/8" bit)

7. Wire Pliers

8. Four 1/4 inch turnbuckles from your local

hardware

store.

9. Twelve gaugegalvanized steelwire (enough to

hang four wires from true ceiling to T-bar level).

10. Enough twelve or fourteen gauge electrical

wire and conduit to reachnearestunswitched cir-

cuit (see

electricalinstallation instructions).

11.Junctionbox fittings asneeded.

ITEMSSUPPLIEDASLOOSEPARTS

1. Two support bars

2. Six #8 self-tapping sheetmetal screws

3. Two flat washers

4. Two wire connectors

UNPACKING

Note: It is easierto leave air cleanerin box until

Step

5.

1. Remove grille and unpack from protective

cardboard.

2. Takeout prefilter

3. Remove

electroniccell by turning the retaining

turnstile latch. Then raisecell off hooks.

4. Removemounting barsfrom inside of cabinet.

5. Lift air cleaner

out of box.

PREPARATION

The model X-400 air cleaner is designed to be

installed within a T-bar drop ceiling. Removetiles

from ceiling to open an area23 inches (one 2' x 2'

ceiling tile) to accommodateair cleaner.The area

between the drop ceiling and true ceiling must be

free of obstructionssuchaspipes,ducts, etc.There

must be at least 14 inches between the bottom of

the T-barand true ceiling.

Make sure air cleaner will be oriented and located

for good air circulation.

MOUNTING

WARNING

Air cleanercould fall from celling if improperly

mounted. Installation lnstructions must be fol-

lowedcatefully to avoid iniury to people

anddam-

ageto equipment.

1. Attach f.our72 gaugegalvanizedsteel suppoft

wires to true ceiling at location shown in Fig. 1.

Twist eachwire at least four times to provide safe

support for the air cleaner, The free end of each

wire should extend six inches or more below the

bottom of the T-bars.

tu

Turnbuckles

FIGURE1

2. At the end of each opening, set a support bar

acrossthe T-bars. The "1" shaped portion of the

support barsshould beoriented sothe hook sideof

the "1" is toward the opening (not toward the

adjacent

T-bars).SeeFig.1.

3. Using an electric drill with and 1/8" drill bit,

drill through the holes in the stepped portion of

the support bars and through the T-bars. Attach

the support bars to the T-barswith four #8 sheet

metal screws

provided.

4. Hook the turnbuckles to the support bars and

then securethe support wires to the eyesof the

turnbuckles (see Fig. 1). Twist the wire at least

four times.

5. Adjust the turnbuckles until the support bars

are securelysuspended

by the support wires. Do

not overtighten the turnbuckles to avoid lifting

or buckling the T-barframework.

6. Lill air cleanerbody into opening and let body

drop into Jshapedportion of support bars.

7. Fasten

air cleaner

body to support barsusing

two #8 self-tapping screws and flat washerg.

Screws

are installed through slotsin endsof air

cleaner

into support bars. Adjust location

of air

cleaner

relativeto support barsvia slotsprior to

tightening of screws.

ELECTRICALINSTALLATION

CAUTION

This ptocedure

should beattempted

only by per-

sons qualified to install electrical wiring. All

wiring must comply with applicablecodes

and

ordinances.

1. Locate an unswitched 120 volt AC, 60 }Jz.

power circuit with a junction box near the air

cleaner

location.

2. Check the circuit breaker or fuse for that cir-

cuit and determine

whetherit is rated15amperes

or 20 amperes(as marked on the device).

The

required copperwire sizewill be:

AWG #14 for 15ampere

circuits.

AWG #12 fot 20

amperecircuits.

3. CAUTION: Turn off the building circuit at the

fuse

or circuit breaker

before

proceeding.

4. Connect the black and white wires from the

pigtails in the air cleaner junction box to the

corresponding

colorsin the supply circuit (Fig.2).

Blackfrom

AirCleaner

5. If grounded conduit is used to route the power

wiring to the air cleaner, no further grounding is

neceseary.

[n the absence

of a grounded conduit

connection,the green wire in the field wiring com-

partment should be connectedto a grounded con-

ductor. DO NOT connect the grounding wire from

the air cleaner to the white wire or the building.

The air cleaner frame must be electrically con-

nectedto the frame of the building of the electrical

conduit system. Input electrical power should be

run through flexible conduit as recommended by

the National Electrical Code or your local author-

ity.

COMPLETING

THEASSEMBLY

1. Install electronic

cell.

2. Checkto makesure the electroniccell is oriented

for correct airflow. arrows on side of cell should

point up. The contact board needs to be properly

seated.

3. Install the prefilter.

4. Install the grille by squeezingtwo of the mount-

ing springs locatedalong one side of the grille and

inserting the "legs" of the springs into the slots in

the mounting bars.Besure the grille is oriented so

it will swing up and cover the air cleanercorrectly.

Swing the grille up and attach the remaining two

springs to the other mounting bar. At this point,

simply push the grille toward the air cleaner and

the springs will pull the grille up into its final posi-

tion.

5. Turn electricpower backon and pressHI, MED,

LO button.

6. Make sure fan runs on all three speedsettings.

7. Presstest button. An audible snap indicatescol-

lection sectionof cell is functioning.

8.Cleanup installation

area.

8

=N

FIGURE

2

CHECKOUT

Before leaving installation, be sure the X-400 is

properly installed and operates correctly. Check

the following:

MOUNTING

eThe X-400 is securely fastened to the true ceil-

ing.

ASSEMBLY

.Electronic cell is correctly oriented-airflow

arrowspointing toward blower.

oPrefilterscreenproperlyinstalled.

OPERATION

.Fan runs correctly on all speedsettings.

oSystemlight turns on when fan is running.

.Snapping noise is heard when test button is

pushed.

.Opening intake grille stops fan and turns out sys-

temlight.

NOTE: If the X-400 does not appear to work right,

refer to ELECTRICAL

TROUBLESHOOTING.

CLEANUP

.Clean the surfaces

of the air cleaner.

.Clean up the installation

area.

SERVICE

WARNINGI

The following instructionsarelntended for qual-

ified service

personnel

only. Dangerous

line vol-

tage circuits are exposed

during this procedure.

Dieconnect

powerat fuee

before

servicingunit.

MOTOR

REPLACEMENT

PROCEDURE

1..Disconnect

powerat fuse

or circuitbreaker.

2. Open grille. Remove prefilter and cell to pro-

videaccess

to motor.

3.Remove

fan blade

from motor.

4. Disconnect

fan motor leadsat plug disconnect

near

electrical

compartment.

5. Remove 5 screws holding motor to unit to

remove

motor.

5. Install new motor, connect

electrical

lines and

replace

fan, cell, prefilter and grille.

7. Connectpower and check

new motor operation.

PO\ilER SUPPLY REPLACEMENT

PROCEDURE

1.Disconnect

powerat fuse

or circuit breaker.

2. Open service grille and remove prefilter and

cell.

3. Remove six Phillips head screws holding the

electrical cover in place.Disconnect the two high

voltage wires from the back of the cell contact

boardassembly

and lay the electrical

coveraside.

4.Disconnect:

1. White wire from power supply.

2. BlackWire from power supply.

3. Charcoaland pink high voltagewires (one

each)

at power supply.

5. Cut wire ties holding the above wires to the air

cleaner.

5. Remove4 screwsholding power supply in place

and removepower supply.

7. Mount new power supply in placereconnect

wir-

ing.

8.Use

wire tiesand re-tiewiresin place.

9. Reconnect

the high voltage wires and reinstall

the electricalcover.

10.Replace

the electronic

celland prefilter.

11.

Closeservicegrille.

12. Reconnect

power and test power supply with

test button to besure unit is operating properly.

IONIZINGWIRE REPLACEMENT

The fine tungsten ionizing wires in the charging

sectionof th; electroniccell may break or hcome

damaeed.

Inspect

the cellfrom ihe upstream

side

after "washini to make sure that irone of the

wires arebroFenor out of position. During oPera-

tion, a broken or deformed wir-e

generally causes

a short to qround, possibly with visible arcing or

sparkins. This conilition,-or any other short in

tfre ionlzins section of the celf, will cause the

indicator lig"ht

to to out.

Broken wires must be replaced for air cleanerto

function effectivelv withbut arcing. Remove all

parts of the broktin wire. If nece-ssary,

the cell

inav be temporarily used with one wire missing.

See'PARTS

LIST trir part number of replacement

wire. Wires come cdt to length with -eyelets

at

each end for easy installatioir in the electronic

cell.

1. Use care to avoid damage to the spring conn-ec-

tor or other parts of the cell during the instaua-

tion.

2. Hook one end of the ionizing wite over the

spring connector

at oneend of the cell.

3. Hold the opposite eyelet with a needlenose

pii"ti ""a stret'chthe wiie the length of the cell'

b;t;"s, the opposite spring conneltor and hook

the eyeletover it.

MOTORMAINTENANCE PROCEDURE

The rnanufactuter of the motor used in the X-400

recommends oiling of the motor at least once a

year. The followinlg procedurecanbefollowed:

*De-energize

the unit.

*Remove

the prefilter and cellsfrom the cabinet'

rRemove

the fan bladefrom the motor shaft.

*tlnscrew the four nuts holding the motor and

Io-wer ihe motor. THE WIRINd NEED NOT BE

DISCONNECTED.

*Therearetwo oil holeson the motor:

1.Nearthe motor shaft.

2. On the end opposite

the motor shaft near

the bearingPlate.

Fivedropsof SAE

20weight non-detergent

oil

or electric

motor oil in each

holeis adequate'

Wipe of excess

oil which misses

or runs out of

the oil holds.

Replace

motor, fan blade,

cell and prefilter in

thti unit.

Re-energizeand check out to ensure ProPer

operation.

ELECTRICALTROUBLESHOOTING

WARNING

The following instructions areintended for qual-

ified service

-personnel

gtlly.-

Den-g-erous

line vol-

iage circuits ire expoeed

ddring th-ls

procedure'

TROUBLESHOOTING

PROCEDURE

The following troubleshootingprocedure has

GL" aitiet ifr to speed

the slrviceman's

work

andinsure"that

anyinalfunction

in theelectronic

air cleaner is quickly detected and properly

repaired.

Most of the troubleshooting steps can be pe-r-

formed by observing the inditator-light. This light

is ON whenever the high voltage transformer is

working properly.

This procedureis outlined in the flow chart below'

A coirplete description is provided on the follow-

ing pages.

10

The trouble shooting procedure description is

divided into two sections:

1. DIAGNOSTIC CHECKS - Follow the

sequenceof checks

in the troubleshooting flow

chart to locatethe causeof a failure within the

air cleaner.

2. COMPONENT CHECKS - Explains how to

locate a faulty component within an assembly,

or how to prove a componentgood or bad.

TOOLSAND EQUIPMENT

Troubleshooting

the X-400canbeaccomplished

with only a few tools.

rScrewdrivers - long shank, plastic or rubber

handles;2 requiredfor some

arcchecks.

oNeedlenosepliers - for stringing ionizing

wires.

.Test Meter - Honevwell W859 ElectronicAir

Cleaner

Test Meter,'or Simpson260with 25k

Vdc probe.

rSolderingiron for replacingcomponents.

.Neon testlampfor line voltage.

DIAGNOSTICCHECKS

1.ENERGIZE

ETECTRONIC

AIR CTEANER

a. Besure that the electroniccells

and prefilter

screens

are clean,dry and properly installed in

the air cleaner.

b. Energizethe air cleanerand checkfor opera-

tion in all fan speeds.

In each casethe fan

should run and the SYSTEM

light should turn

on.

-If the fan doesnot run, check

the fan motor,

powersource,

and interlocksafety

switch.

-If the SYSTEMlight does not come on, go to

step3.

-If the fan runs and the SYSTEM

light comes

on, goto step

2.

2.CHECKCOTLECTOR

OUTPUT

a. With air cleanerturned on, push TEST

BUT-

TON to momentarily short out the collector

sectionof the electroniccell.

b. Arcing indicates that the electronic air

cleaneris working properly.

c. If no arcing noise is heard, check for a

failure in the electronic cell or cell contact

board.

3.REMOVE

CELLS

a.Turn off the air cleaner.

b. Open the service grille. Remove the elec-

tronic cells. Close

the grille.

c. Turn the air cleanerON. -If the light comes

on now, check the electronic cells for a short

circuit.'If the light remainsoff, go to step

4.

4. CHECK POWER SUPPLY AND INDICATOR

LAMP

a.Remove

electrical

cover.

b. Use a neon test light or a voltmeter to check

line voltageon the power supply.

-If the correct line voltage is present, continue

the checkout.

-If the correct line voltage is not measured on

the power supply, check backwards through the

switih and wiring to the Power sourceuntil the

problemcanbelocatedand corrected.

c.Checkthe voltageindicator light.

-If the voltage is correct (about 120Vac)and if

the light is out, replace

the assembly.

-If there is no voltage,rePlace

the power supply.

USEAN OHMMETER

TO CHECK

THE ELECTRONIC

CELLS

FORSHORT

CIRCUITS

COMPONENT

CHECKS

CHECK FAN MOTOR AND POWERSOURCE

-If the fan does not run when the switch is in

HIGH, MEDIUM and LOW positions, check vol-

tagesupplied to the motor.

1. If the motor does not turn with the correct

voltage applied, check to see that the shaft is

free to turn. Replace

the motor if necessary.

2. If the correct line voltage is not measured

check back through the wiring to the Power

source,

including interlock safety switch.

CHECK ELECTRONICCELLS

VISUAL INSPECTION

Carefully examine the electronic cell. Carefully

look for--

-Bentcollectorplates

-Brokenionizing wires.

-Dirt accumulationon insulators.

-Contact

tabs

-Ionizer and collectordamage

CHECK FOR SHORT CIRCUITS

Use an ohmmeter to check resistancebetween the

outside frame of the cell and both the ionizer and

collector contacts. In each case, the resistance

should beinfinite (open circuit).

11

X.4OO

SCHEMATIC

P, Ps

Hl VOLTAGE

p

I l--------r

l''

q -

|

l"'"c

! |

l,"c:l

ll*ol

!o"

t_J

ERLOCK

120

VAC

60HZ

SAFETY

SWITCH

120

VAC,

60HZ

A rnroroc* rAFETy

swtrcH

6 rrnurnel rrocr coNNEcrroNs

m-z$ VAC,

s0

Hz

Tffi

ACCESSORIES I NO.

Wash

ContainerVlid | 30182

CellCleaner

Conc€ntrate | 45008

13 CALLTOLL FRBE1.800.328.0787

GUIDESPECIFICATIONS

MODELX.4OO

Scope:

The following describes a self-contained electronic air cleaning device to be installed in a 2 x 2

foot ceiling tile opening.

Description:

1. Unit shall operate from two wire 120 volt, 60 }Iz. power eource,drawing no more than 0.8

amPereg.

2. Provision for ground wire connection

in field wiring compartment shall bemade.

3. Fanmotor shall beof PSC

designand capable

of running at three distinct speeds:hi, med and

lo.

4. Air discharge

from grille shall bein four different directions.

5. The unit shall not protrude below T-barceiling system.

6. Atmoepheric duet spot efficiency shall be 88%minimum when tested according to ASHRAE

Standard 52-76,and up 1s97o/o

efficient on lo speed.

7. Unit shall incorporate bell-mouthed fan orifice and rubber hubbed fan blade for purposesof

quieter operation.

8. Built in interlock switch system shall disconnectpower from all functions when servicegrille

is opened.

9. Airflow on Hi fan speedshall bea minimum of 400cfm.

10.

Unit shallinclude

1" metalmeshprefilter.

11.Fanmotor to bemounted on four elastomeric

vibration isolators.

12.Unit shall havea flanged grille lapping over T-bars

to correctT-barmisalignment.

13. Unit shall have a test button and system light to indicate proper operation of high voltage

power gystem.

14. Unit shall provide over 8,000volts to ionizer sectionand over 4,000volts to collectorsection

of cell.

15.Unit shall havehanger bar systemto provide safeand eecureinstallation of air cleaner.

15. Design of air cleanershall limit production of noxiougozoneto within OSHA approved lev-

els.

17. High voltage power supply design shall limit short circuited output current to less than 5

mA.

18.Unit shall havea total electronic

cell plate area

of at least52.9squarefeet.

19.Unit shall belisted by Underwriters Laboratories

for useasan electrostaticair cleaner.

AilR @UALilTV 4!!ll

quALlTl ENGINEERING,

lNc. TELEpHoNE:

[61a)s4444a6

3340 WINPARK

DRIVE

emcilm@eRllnG gg!!ry&.j'MTNNES.TA

MANUFACTURER

& WORLDWIDE DISTRIBUTOR

OFAIH CLEANING

SYSTEMS

TELEX:

291O13 OFFICENTR

SLPK

14

CERTIFICATE

OF

WARRANTY

LIMITEDONE

YEARSMOKEMASTER

WARRANTY

Air Quolity Engineering,

Inc.

wqrronts theSmokemqster

Electronic

Air Cleoners

tobe lreelrom delects

inworkmqnship or moteriqls.under normql useond service,

lor o period ofone(I

)yeor lrom thedqte

of purchose by the consumer,Il,ot ony time during the wqrronty period, the product isdefective or

mqlfunctions.

Air Quolity Engineering.Inc.shqllrepoir or reploce it (otAir Quolity Engineering's

op-

tion) within q reqsonqble period of time,

I1

the product isdelective,

(i)returntheunit or delective component with o bill ol soleor otherdoted proof ol purchose,tothere-

toiler trom which you purchosed it, or

(ii) pockoge the unit or component, qlong with prool ol purchose (including dote purchosed) ond o

shortdescription ol the mqllunction, qnd mail or ship. postqge or lreight prepoid. to the lollowing

qddress:

AIROUALITY

ENGINEERING,

lNC.CustomerService,

3340

WinparkDr.,

Minneapolis,

MN55427

Therepoired orreplqced pqrt orunitwill be shipped by Air Quolity Engineering,

Inc.lothepurchoser,

lreight collect,with the purchoser to be responsiblelor cll lreight chorges, Theworrqnty on qny re-

poired or replocement port shollbe toro durqtion ol time nolonger thon theremoinlng orunexpired

termoltheoriginol worronty, Thisworronty doesnotcover ony lqbor orother

service

chqrgesincurred

by the purchoser.

This

wqrrqnty shollnot cpply il it isshown by Air Quolity Engineering thot the delect or mqllunction

wqs cqused by domoge which occurred while the product wqs in the possession

ol q consumer,

Air Quolity Engineering'ssole

responsibiltyshqllbe to repoir or reploce lhe producl within the terms

stqtedqbove.

AIROUALITYENGINEERINGSHALLNOTBELIABLEFORANYCONSEOUENTIALDAMAGES

RESULTING

FROMANYBREACH

OFWARRANTY,

EXPRESS

ORIMPLIED,

APPLICABLE

TO

THISPRODUCT.

Some

stqtesdo notqilow the exclusionor limitqtion ol consequenticl domoges, so

thislimitotion moy

not opply to you.

THISWARRANry IS

INLIEUOF

ALLOTHER

WARRANTIES,

EXPRESS

ORIMPLIED,

ANDTHEWARRANTIES

OF

MERCHANTIBILITY

ANDFITNESS

FORA PARTICULAR

PURPOSEARE

HEREBYEXCLUDED

BEYONDTHE

ONEYEARDURATION

OFTHiSWARRANTY.

Somestqtesdo

not

qllowlimitotionsonhowlongonimplied

worronty losts,sothe qbove Iimitotion moy not opply to you.

Thiswqrronty givesyou speciliclegcl rights,

cnd you moy qlso

hqve other

rights

which vory lrom slqte

to stqte.

AilR EIUALil]rT

@mGilmeeRilnc AIROUALITYENGINEERING.INC.

3340 WINPARK DRIVE

MINNEAPOLIS,MINNESOTA

55427-2043

TELEPHONE:

[612)544-4426

TELEX:291O13OFFICENTBSLPK

MANUFACTUFEB

& WORLDWIDEDISTRIBUTOROF

AIR

CLEANINGSYSTEMS

51412 Rev.A Printedin the U.S.A.

This manual suits for next models

1

Table of contents

Other Smokemaster Air Cleaner manuals