SMP TechSmart T55003 User manual

1

To ensure correct operation and service, read the following

instructions before operating the T55003 Tool.

T55003

TPMS Tool Manual

1. T55003 INTRODUCTION

The T55003 interacts with the tire pressure sensor through

wireless (radio frequency) communication to:

•Retrieve data from the tire pressure sensor

•Verify the identities of each tire

pressure sensor mounted on vehicle

•Assist a technician to reset TPMS

on the vehicle

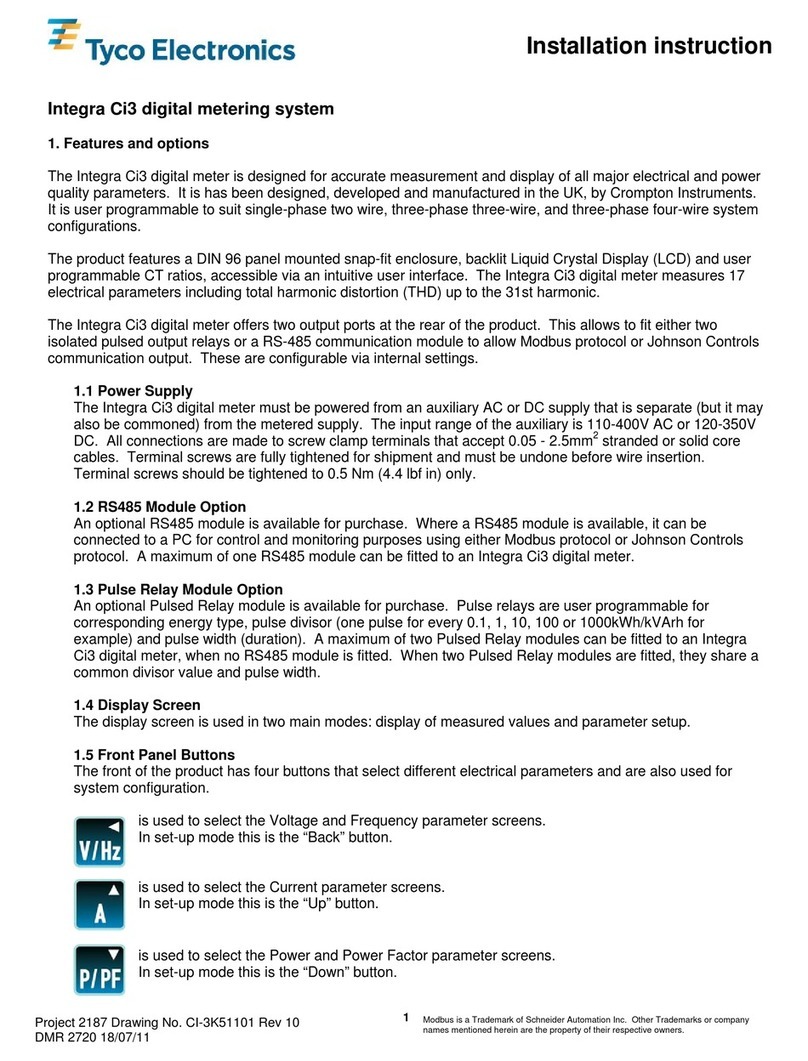

2. KEYPAD SUMMARY AND FUNCTIONS

9 volt battery Included,

rechargeable – install in

back of tool prior to operation

USB Connection – to connect

with computer to download

software updates

Cancel Key – press to return to the

previous menu without option validation

or press and hold to turn off tool

Arrow Keys – navigation through menu

and adjust options up and down

Keypad – key in sensor identication number

Selection Key – press to enter chosen

function or validate an option

Power Key – power on the tool;

check battery status Transmit Key – to start a test cycle

LCD

Display

Antenna

Transmit

Key

Power

Key

Arrow

Keys

Keypad

Cancel

key

Selection

Key

USB

Port

Cradle

2

Power Key

(A) Press the Power Key to power on the tool

(1) At power on, the tool displays the

TechSmart®logo.

(2) After pressing the Transmit Key, the message

“TRIGGER PROCESSING” is displayed.

(3) After a few seconds, the tool will vibrate, make

a noise and display the tire sensor data.

(2) Then it displays the software

version number.

TechSmart

Version 001-01

(3) Finally, the tool displays the vehicle

selection menu.

Scroll up/down or increase/decrease

numerical values

Arrow Keys

(A) Press the Cancel Key to return to previous

page without modifying an option

(B) Press and hold the Cancel Key for 3 seconds

to power off the tool

Cancel Key

Starts the acquisition cycle for a sensor

(1) After selecting a vehicle from the “VEHICLE

SELECTION” on the main menu, the screen will

indicate “(o) READ SENSOR”. Press the Transmit

Key to gather sensor information.

Transmit Key

Press the Selection Key to open a menu, enter an

option or conrm an option

Selection Key

Activate Sensor

(1) From the main menu, select the “VEHICLE

SELECTION” option with the Selection Key .

(2) Proceed to select the desired vehicle manufacturer

using the Arrow Keys , and enter using the

Selection Key .

3. QWIK-SENSOR™ACTIVATION

FOR OE SENSOR REPLACEMENT

(2) If the battery power is low, “LOW BATT” will

ash and the tool will turn off. Recharge

the 9V battery with the included charger to

restore power to the tool.

(B) Press and hold Power Key after powering on

to display battery status

(1) When the tool is powered on, press the

Power Key to display the battery level.

BATTERY LEVEL L OW B AT T

3

(3) Proceed to desired manufacturer model using the

Arrow Keys and enter with the Selection Key

. After choosing model, indicate production

year using the Selection Key .

(4) Select QWIK-SENSOR™. Correct sensor color will

be displayed based on inputted information.

(4) Select Clone-able sensor or QWIK-SENSOR™.

For QWIK-SENSOR™correct sensor color will be

displayed based on inputted information.

(6) Press the Transmit Key . The tool will begin

to locate and receive data from the selected

tire sensor, indicated by the message

“TRIGGER PROCESSING”.

(7) After a few seconds, the tool will vibrate,

make a noise and display the tire sensor

data. The QWIK-SENSOR™is now activated

and can be relearned to the vehicle following

OE relearn procedure.

(5) Using the Arrow Keys select “ACTIVATE

SENSOR” using the Selection Key . Place the

QWIK-SENSOR™in the cradle or if the sensor is

in the wheel, ensure the PSI is ‘0’.

Ensure the car being worked on is at least

10 feet from all cars and TPMS sensors

(OE, Clone-able, or QWIK-SENSOR™).

Scan OE Sensor ID Number

(1) From the main menu, select the “VEHICLE

SELECTION” option with the Selection Key .

(2) Proceed to select the desired vehicle manufacturer

using the Arrow Keys , and validate with the

Selection Key .

(3) Proceed to desired manufacturer model using the

Arrow Keys and enter with the Selection Key

. After choosing model, indicate production

year using the Selection Key .

4. OE SENSOR REPLACEMENT

USING TECHSMART®“COPY ID”

Before removing tires, complete all steps

through step (15). Use TPMS Application

and Cross Reference Guide to determine

appropriate OE-Matching Clone-able sensor or

QWIK-SENSOR

™

needed to replace OE sensors.

(6) Place tool by tire (start at left front). Position the

tool near the valve stem between the rim and

rubber, as shown.

Ensure the car being worked on is at least

10 feet from other vehicles and TPMS sensors

(OE, Clone-able, or QWIK-SENSOR™).

(5) Select “READ SENSOR”.

4

(7) Press the Transmit Key . The tool will begin

to locate and receive data from the selected

tire sensor, indicated by the message

“TRIGGER PROCESSING”.

(8) The screen will indicate that the OE sensor ID

number has been stored into the tool’s memory.

(9) Display will show sensor information. Log OE ID

number and tire location.

Write ID to Clone-able sensor or

QWIK-SENSOR™

Ensure the car being worked on is at least

10 feet from other vehicles and TPMS sensors

(OE, Clone-able, or QWIK-SENSOR™).

(10) Press the Cancel Key to display sensor menu.

(11) To write the OE sensor ID that was just detected

to a new Clone-able sensor or QWIK-SENSOR™,

use the Arrow Keys and select “COPY ID”

to display OE

sensor information. Place the

Clone-able sensor or

QWIK-SENSOR

™

in front

of

T55003 antenna or in the cradle, as shown.

(12) Press the Transmit Key to begin writing

the OE sensor ID number onto the Clone-able

sensor or QWIK-SENSOR™.

(13) The tool will display “COPY ID” and write the OE

sensor ID number onto the new

Clone-able sensor

or QWIK-SENSOR™

.

ID Verication

Ensure the car being worked on is at

least 10 feet from other vehicles and

TPMS sensors (OE, Clone-able, or

QWIK-SENSOR™).

(14) Press the Cancel Key to go back to the

“VEHICLE IN PROCESS” menu. Scroll to “SAME

VEHICLE” and press Selection Key . Hold the

programmed Clone-able sensor or QWIK-SENSOR

™

in front of the antenna or the cradle, as shown and

press Transmit Key .

Match this number with the number recorded in step

(9) to verify that the correct OE ID number has been

written onto the Clone-able sensor or QWIK-SENSOR

™

.

Installation

(15) Break down tire in accordance with vehicle

manufacturer’s specications, remove OE

sensor, install new

sensor on wheel, replace tire

on car and pressurize.

Ensure tire pressure is at

or above the minimum tire pressure listed on

the placard of the car.

5

Repeat for remaining tires. All OE sensors

should have UNIQUE ID NUMBER. All

Clone-able sensor or QWIK-SENSOR™

should be cloned to match the OE number for a

specic tire location exactly. Remove old sensors

from the area.

If you are experiencing difculties, please

see Troubleshooting Guide on page 7.

5. MANUAL ID WRITING

(1) To retrieve general OE sensor information, refer

to steps 1 – 9 of Scan OE Sensor ID Number

on pages 3 – 4.

(2) Press the key to return to the main menu.

From the main menu, select “VEHICLE

SELECTION” to enter sensor writing menu.

Choose make, model and year.

(3) Select Clone-able sensor or QWIK-SENSOR™.

For QWIK-SENSOR™correct sensor color will be

displayed based on inputted information.

(4) Press the Selection Key to choose

“WRITE ID”.

(5) Once in the sensor writing menu, press the

Selection Key to input sensor ID. Arrow will

move from left side to right side of screen. Clear

old numbers by pressing .

(6) Once the sensor ID has been entered, press

the Selection Key again to move arrow to

left side of screen. The “ENTER ID” message

will change to “PROG. SENSOR”

When entering ID, select (h) hexadecimal

with arrow keys . Then enter ID number.

(7)

Place the new Clone-able sensor or QWIK-SENSOR

™

or in the cradle, as shown and select again

to move arrow to left side of screen. The “ENTER

ID” message will change to “PROG. SENSOR”.

(8) To program the OE sensor ID onto the new

Clone-able sensor or QWIK-SENSOR™,

press the Transmit Key .

(9) The new Clone-able sensor or QWIK-SENSOR™is

now programmed with the OE sensor’s ID number.

ID Verication

(10) Press the Cancel Key to go back to the

“VEHICLE IN PROCESS” menu. Scroll to “SAME

VEHICLE” and press Select Key . Hold the

programmed Clone-able sensor or QWIK-SENSOR

™

in front of the antenna or the cradle, as shown

and press Transmit Key .

6

The sensor is ready to be installed on the vehicle.

Match this number with the number recorded in step

9 to verify that the correct OE ID number has been

written onto the Clone-able sensor or QWIK-SENSOR

™

.

After adjusting setting, use the key

to return to main menu.

(1) From the main menu, select “SETTINGS” with

the Selection Key .

(2) Use the up and down Arrow Keys and

select , the feature to be adjusted.

6. ADJUSTING T55003 SETTINGS

7. UPDATING T55003 SOFTWARE

To access the latest software version for your

TechSmart®T55003, please visit:

www.QWIKSENSOR.com

Units

Use the Selection Key to enter unit selection and

use the Arrow Keys to highlight desired units

(kPa/ °C or PSI/ °F) and select with .

Auto-Off

User can adjust how quickly the tool will turn off

after a period of non-use. This feature can also be

disabled. Press Select Key to move cursor to the

right of display and use the Arrow Keys to select

desired amount of auto-off time.

Zone

User can modify the zone between America, Europe,

Asia and other.

Format

Change the display format between decimal and

hexadecimal with . The preset setting is AUTO that

automatically changes format based on input.

Buzzer

User can select if the tool will vibrate after receiving

tire sensor information. Scroll to “BUZZER ON” on

settings screen, press Selection Key and use

Arrow Keys to toggle between “YES” or “NO”.

Backlight/Contrast

User can adjust the brightness and contrast of

display. Press Selection Key to move cursor to

right of display and use the Arrow Keys to

adjust ±1%.

Tip: A brighter display will consume battery

more quickly

7

(1) This device will not cause harmful interference

(2) This device must accept any interference

received, including interference that may cause

undesired operation.

NOTICE

This device complies with Part 15 of the FCC Rules

and with RSS-210 of Industry Canada. Operation is

subject to the following two conditions:

Any changes or modications in construction

of this device which are not expressly

approved by the party responsible for

compliance could void the user’s authority

to operate the equipment.

9. TECHNICAL SPECIFICATIONS

Dimensions: 152mm x 82mm x 33mm

Battery: 9V

Communication port: USB

Display: 4 line LCD, 65mm x 32mm

Weight: 220g

Temperatures: Operational: 5°C to 45°C /

41°F to 113°F

Storage: 0°C to 60°C /

32°F to 140°F

Relative humidity: 70% - 80%

8. TROUBLESHOOTING GUIDE

PROBLEM: TPMS light remains on after installation

of new sensors.

SOLUTION: May require over-inating tire and then

reducing PSI to proper level to activate sensor(s).

Spare tire may be equipped with TPMS. Check

vehicle owner’s manual to verify if TPMS monitors

spare tire. If so, ensure proper air pressure and

functioning sensor in spare tire.

PROBLEM: Newly written ID number on Clone-able

sensor or QWIK-SENSOR™does not match the OE ID

number after using “COPY ID”.

SOLUTION: Check your format in settings. Change

to appropriate format. Hexadecimal reads ID number

in alphanumeric format (numbers and letters) while

decimal format reads ID number in only numeric

format (numbers only). Try writing the sensor

manually or go through the auto relearn process.

PROBLEM: After scanning sensor, “NO SENSOR

DETECTED” appears on screen.

SOLUTION: Try re-positioning the T55003 tool.

Ensure correct sensor is being used via the “TPMS

Application & Cross Reference Guide” and matches

the OE part number of the sensor on the vehicle.

Ensure the vehicle being worked on is at least 10

feet from all other vehicles and TPMS sensors (OE,

Clone-able, or QWIK-SENSOR™). Position the tool

near the valve stem between the rim and rubber.

PROBLEM: TPMS lamp is illuminated in vehicle after

removing damaged OE sensors.

SOLUTION: Remove uninstalled OE sensors from the

area as damaged sensors will continue to transmit signal.

10. SAFETY TIPS

SWITCH ON SAFELY

Do not switch on the device when

wireless tool is prohibited or when it

may cause interference or danger.

SWITCH OFF WHEN REFUELING

Do not use the device when lling

vehicle with gasoline. Do not use near

fuel or chemicals.

SWITCH OFF NEAR BLASTING

Adhere to any restrictions. Do not use

the tool when blasting is in progress.

USE SENSIBLY

Use only in normal conditions as

indicated in product instructions. Do

not touch the antenna unnecessarily.

QUALIFIED SERVICE

Only qualied personnel may install or

repair this device.

ENHANCEMENTS AND BATTERIES

Use only approved enhancements and

batteries for the T55003 tool. Do not

connect incompatible products.

WATER RESISTANCE

The tool is not water resistant – keep

it dry.

CONNECTING TO OTHER DEVICES

When connecting to any other device,

read user guide for detailed safety

instructions. Do not connect

incompatible products.

THIS DEVICE IS A RADIO

TRANSMITTER AND RECEIVER.

11. CARE AND MAINTENANCE

The T55003 is a product of superior design and

craftsmanship and should be treated with care.

Follow the suggestions below to help maintain

warranty coverage:

8

•Keep the device dry. Precipitation, humidity and

all types of moisture may contain minerals that

will corrode electronic circuits. If device does get

wet, remove the battery and allow the device to

dry completely before replacing.

•Do not use or store the tool in dusty, or dirty areas.

Keep the electronic components clean.

•Do not store the device in hot areas. High

temperatures can shorten the life of electronic

devices, damage batteries and warp or melt

certain plastics.

•Do not attempt to open the device other than

instructed in this guide.

•Do not drop, knock or shake the device. Rough

handling can break internal circuit boards

and mechanics.

•Do not use harsh chemicals, cleaning solvent or

strong detergent to clean the device. Do not paint

the device. Paint can clog the moving parts and

prevent proper operation.

•Do not touch the main display with hard or angular

material. Objects like earrings or jewelry may

scratch the display.

•Use a soft, clean and dry cloth to clean the device.

•Use only the supplied antenna. Unauthorized

antennas, modications or attachments could

damage the device and may violate regulations

governing radio devices.

•The power connection cord is NOT COMPATIBLE

with a USB interface. Please do not use with other

USB devices.

All of the above suggestions apply equally to your

device, battery or any enhancements. If device is

not working properly, contact Standard Motor

Products, Inc.

12. RF CERTIFICATION

13. WARRANTY

14. QUESTIONS

This device meets guidelines for exposure to

radio waves.

This device is a radio transmitter and receiver. It is

designed not to exceed the limits for exposure to

radio waves recommended by international

guidelines developed by the independent scientic

organization ICNIRP and include safety margins

designed to assure the protection of all persons,

regardless of age and health.

For further information see ICNIRP “guidelines for

limiting exposure to time-varying electric, magnetic

and electromagnetic eld (up to 300GHz)” or contact

Standard Motor Products, Inc.

The SAR value for this device is less than 5W/kg.

This value is the reference level for general public

exposure to time varying electric and magnetic

elds (unperturbed rms values) for the 3-150 KHz

frequency range.

Standard Motor Products, Inc. products are guaranteed

from material defects for 365 days after the date

of purchase. If the product fails under normal

circumstances within the rst year, Standard Motor

Products, Inc. will repair or replace the product.

Product will not be replaced or repaired if damaged

from misuse or incorrect application. To obtain

repair or replacement of the product under warranty,

please contact Standard Motor Products, Inc. Proof

of purchase and date of purchase are required to

validate the warranty claim.

Standard Motor Products, Inc. is not liable for any

direct or consequential loss or property damage

arising from use of product.

Any questions pertaining to warranty information

or other questions not answered in the preceding

pages can be answered by the TechSmart®place

of purchase or by Standard Motor Products, Inc.’s

Customer Service.

1-888-621-8767 (USA)

1-877-666-5325 (Canada)

For additional information on TPMS and TechSmart®

products, visit

www.QWIKSENSOR.com

Thank you for your purchase

and enjoy your new

TechSmart®T55003

Clone-able Tool!

Warranty does not cover tire valves or

screws for tire valves. The tire valves

and screws need to be replaced when

rotating tires, changing tires or changing

the TPMS sensors. If installing/reinstalling

a TPMS sensor, new valves and screws

should be used.

We recommend that you only use

Standard Motor Products, Inc. replacement

parts. Other brands will not function

properly with this tool.

TS10885

Table of contents

Other SMP Measuring Instrument manuals