Contents

Notes on system installation -------5

Installation requirements -----------5

Second fix installation ------------5

Fixture and fittings --------------5

As fitted drawings --------------5

Cable type and routing ------------5

Fire sensor cover ---------------5

Earth continuity ---------------5

Power supply -----------------5

Mains supply -----------------5

Devices -------------------5

Local Manual Call Point -----------5

EN54 information ------------6

Optional functions with requirements of

this European standard ------------6

System wiring --------------6

Cable separation ---------------6

Lightning protection ··············· 6

Requirements of cables ------------7

Loop Cable usage ················ 7

Mains Supply cable --------------7

Repeat indicator to Control panel cable ----7

Loop cable ------------------7

Enhanced cables ················· 7

Standard cables ················· 7

Devices per Device loop -----------8

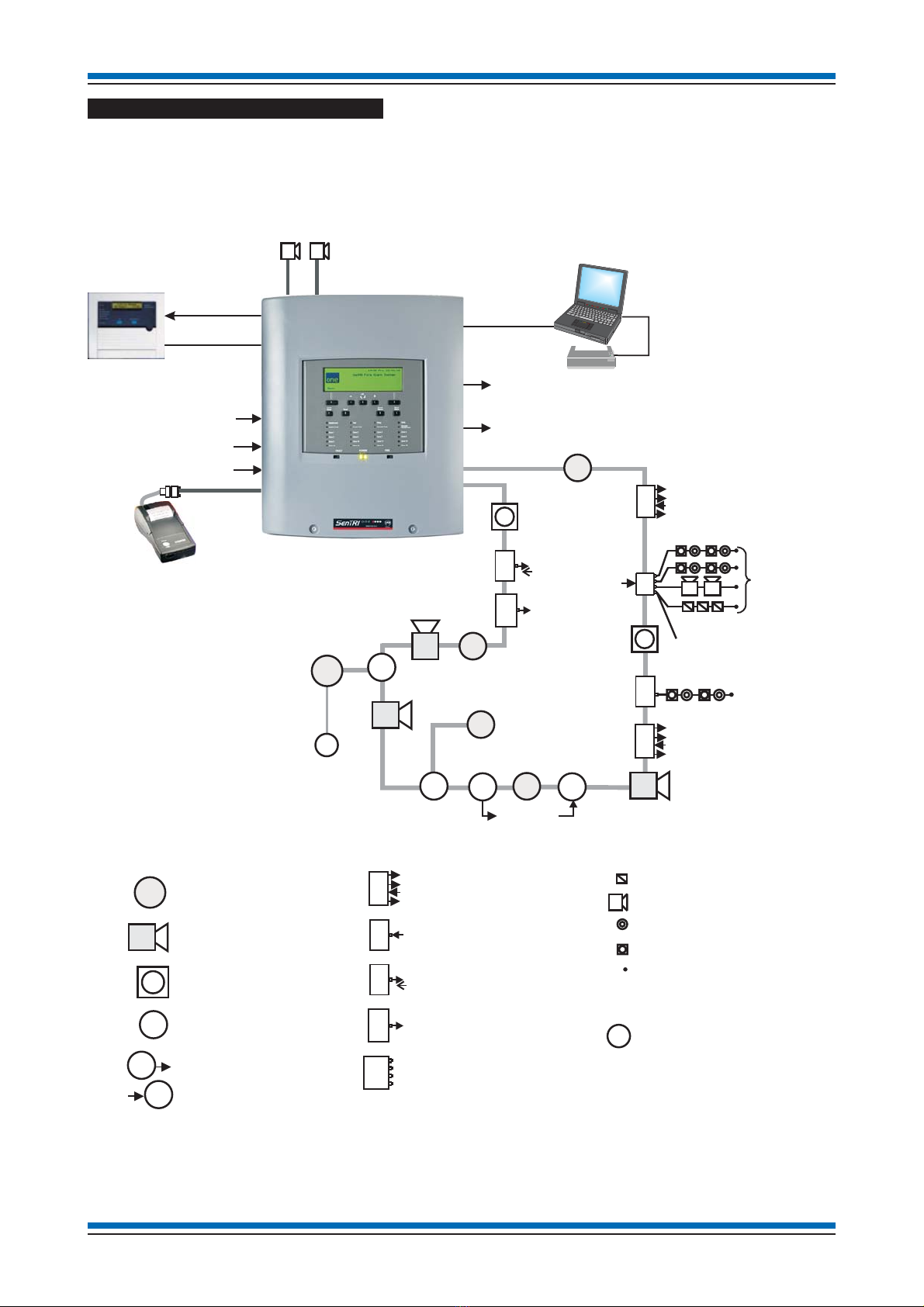

SenTRI ONE System Architecture -------10

SenTRI ONE panel -----------11

Features ····················· 11

Technical data ----------------12

Control panel ·················· 12

Power supply ·················· 13

Panel installation ------------14

How to disassemble the panel to gain

access to the Backbox-------------14

How to mount the backbox and

dedicated cable entry points ----------15

Flush Mounting the backbox ---------16

Refitting the electronics module --------16

Cable termination on enclosure --------17

Wiring test ···················· 17

Mains supply -----------------18

Mains and battery supply connections ······18

Removable terminal blocks ----------18

Terminals for external circuits on

Main Control Board -------------19

Device loop circuit --------------20

Master alarm circuits -------------21

Common Fault contacts ------------21

Fire Output contacts -------------22

Repeat indicator panel ------------22

External Evacuation input -----------23

Class Change input --------------23

RS232 Port------------------ 23

USB Port------------------- 23

Battery installation --------------24

On completion of panel installation ------25

Repeat Indicator panel ----------26

Technical data ----------------26

Installation ------------------26

S-Quad Sensors -------------27

General specification -------------27

Base ---------------------27

Base Gasket -----------------27

Base labels ------------------ 27

Indicators ------------------27

Dust Cover ------------------27

Do'sandDon't----------------27

Siting --------------------27

Metal back box ----------------28

In - Out wiring to SenTRI bases --------28

Programmable input/output ----------28

Tools for S-Quad ------------29

To remove a SenTRI device ----------29

To fit a SenTRI device ------------29

To fit a dust cover --------------29

To remove a dust cover ------------29

SenTRI device Semi-flush fixing kit

(SEN-FLUSH) -------------30

Technical data ----------------30

Beam sensor (Supported)---------31

Technical Data ----------------31

Installation ------------------32

Parallel bracket assembly ············ 32

SenTRI Speech, Sounder Strobe mark II - 33

Technical data ----------------33

Installation ------------------34

Retrofitting a System SenTRI device ······34

Manual Call Points -----------35

Glass or Resettable element options ·······35

Optional Back box ··············· 35

Technical data ----------------35

Installation ------------------35

Keyswitch Interface / MCP--------37

Keyswitch assembly -------------37

Back box ···················· 37

Technical data ----------------37

Installation ------------------38

Operation ------------------38

Label --------------------38

Features -------------------39

Cables --------------------39

Installation ------------------39

Interface Modules for SenTRI - Low voltage

(LV) Input/Output ------------39

Wiring diagrams ---------------40

Technical data ----------------41

Installation instructions

2