_______________________________________________________________________________________________________________________________

EuropeanSafetySystemsLtd. Impress House, MansellRoad, Acton, London W37QHsales@e-2-s.com Tel: +44 (0)208 743 8880

www.e-2-s.com Fax: +44 (0)208 740 4200

DocumentNo. IS2462-PIssue E12-03-10 Sheet1of 3

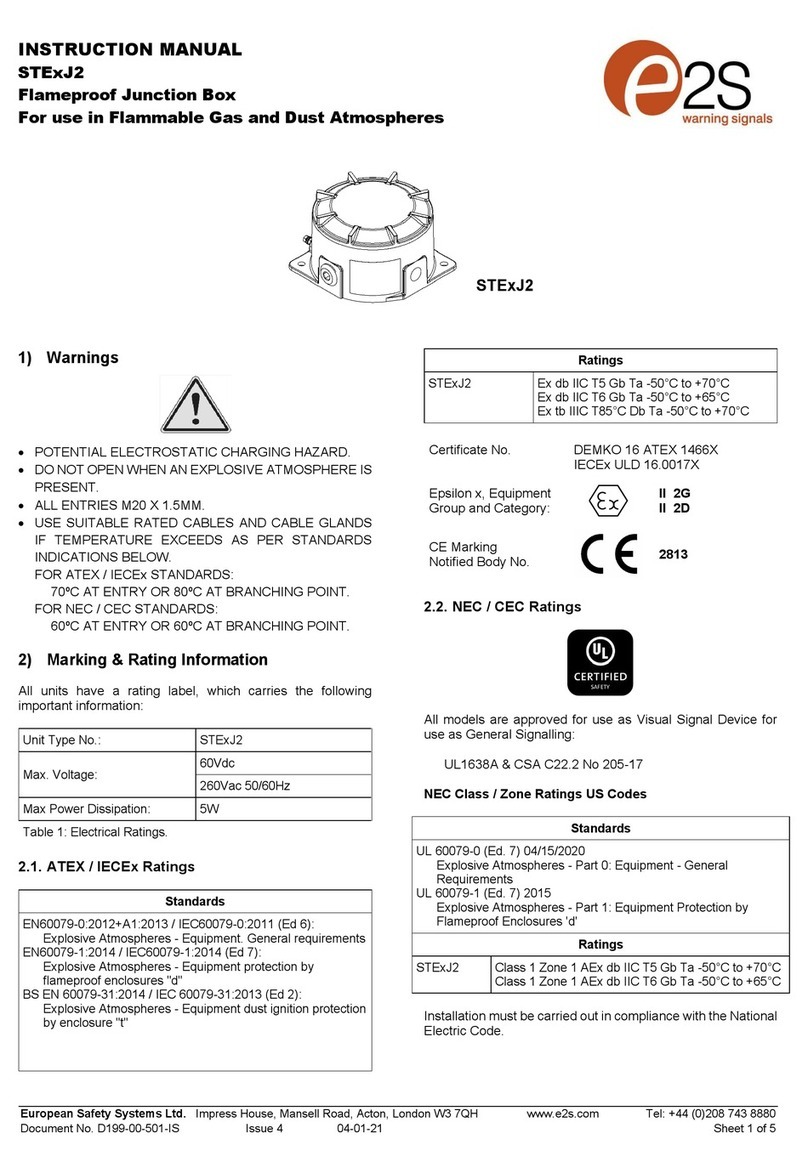

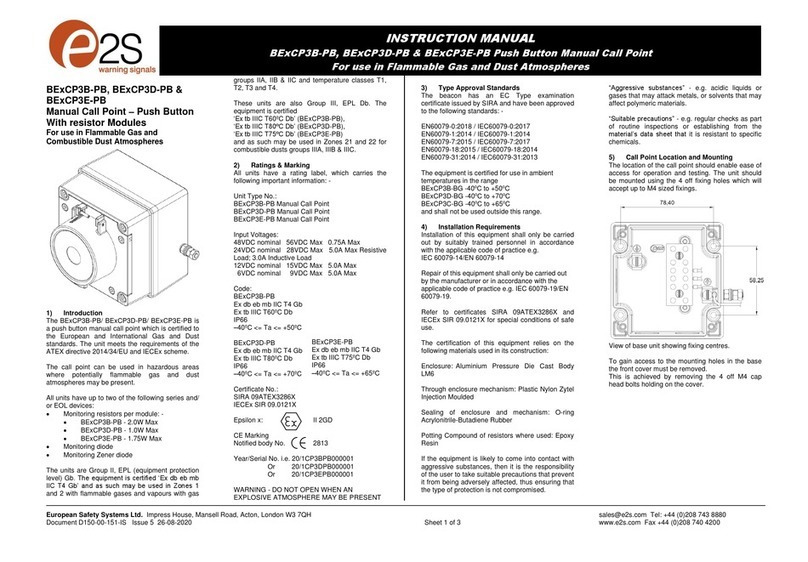

INSTRUCTIONMANUAL(ATEX/IECEx)

BExTBG05DFlameproofFlashtel

ForuseinFlammableGasand Dust

1)Introduction

TheBExTBG05DisaflameproofFlashtelwhichiscertifiedto

meettherequirementsoftheATEX directive94/9/ECand

IECExscheme.The Flashtelproducesavisualwarning

signalwhentriggeredbyatelephoneringingsignalandcan

be used inhazardousareaswherepotentiallyflammablegas

anddust atmospheresmaybe present. TheBExTBG05Dhas

aflashenergylevelof5joulesandcan beusedinZone 1

andZone2areaswithgasesingroupsIIA,IIBandIICand

TemperatureClassificationsofT1,T2,T3andT4.Theunit

can alsobe usedinatemperatureclassificationT5,ifthe

upperambienttemperatureisrestricted to+55ºCandT6if

theupperambienttemperatureisrestricted to+40ºC.The

unitcan be used inZone21 andZone22areasfor

combustibledustsandhasan IPratingofIP67andasurface

temperatureratingofT110ºCorT95ºCiftheupperambient

temperatureisrestricted to+55ºCandT85ºCiftheupper

ambient temperatureisrestrictedto+40ºC.

2)Marking

All unitshavearatinglabel,whichcarriesthefollowing

important information:-

UnitType No. BExTBG05D

Input Voltage: 230Vor115V

Codes: ExdIICT4forTa–50ºCto+70ºC

ExdIICT5forTa–50ºCto+55ºC

ExdIICT6forTa–50ºCto+40ºC

ExtDA21IP67T115ºCbased onmax. Taof+70ºC

CertificateNo’s KEMA00ATEX2006

IECExKEM10.0002

“Warnings” DONOTOPENWHENANEXPLOSIVE

GAS ORDUSTATMOSPHEREISPRESENT

COVERBOLTSCLASS A4-80

USE HEATRESISTINGCABLES ANDCABLEGLANDS

(Rated 110ºC)ATAMB. TEMPERATURES OVER40ºC

YearofConstruction/

SerialNo. i.e. 10 / 1DTB1300001

3) TypeApprovalStandards

TheFlashtelhasECTypeExaminationandIECEx

certificatesissued byKEMAandhasbeenapprovedtothe

followingstandards:-

EN60079-0:2006 IEC60079-0:2004(Ed4) General Requirements

EN60079-1:2007 IEC60079-1:2007 (Ed6) Flameproof Enclosure‘d’

EN61241-0:2006 IEC61241-0:2004(Ed1)DustGeneral

Requirements

EN61241-1:2004 IEC60079-1:2004(Ed1)DustEnclosurestD

4) Installation Requirements

TheFlashtelmustbeinstalledinaccordancewiththelatest

issuesof therelevantpartsof theEN60079 standardsorthe

equivalentIECstandards–Selection,Installationand

maintenanceofelectricalapparatusforuseinpotentially

explosiveatmospheres(otherthanminingapplicationsor

explosiveprocessingandmanufacture):-

EN60079-14:2008 ElectricalInstallationsinHazardous

IEC60079-14:2007 (Ed4) Areas(otherthan mines)

EN60079-10:2003 Classification of HazardousAreas

IEC60079-10:2008 (Ed1)

Theinstallationoftheunitsmustalsobeinaccordancewith

anylocalcodesthatmayapplyandshouldonlybe carried

outbyacompetentelectricalengineerwhohasthe

necessarytraining.

5) Zones,Gas Group, Category,IPRating and

TemperatureClassification

TheBExTBG05DbeaconshavebeencertifiedExdIICT4for

Ta–50ºCto+70ºC,ExdIICT5forTa–50ºCto+55ºCand

ExdIICT6forTa–50ºCto+40ºCforgasandIP67T115ºC

basedonmax.Taof+70ºCfordust. Thismeansthatthe

unitscanbe installed inlocationswiththefollowing

conditions:-

Area Classification Gas:

normaloperation.

Explosivegasairmixturenotlikelytooccur,

andifit does, it willonlyexist forashort time.

GasGroupings:

TemperatureClassification:

0518

II 2G/D

Equipment Groupand

Category:

Notified BodyNo.