TAKEDO ENERGY USER MANUAL Release 3.1 dated 05-11-15

7

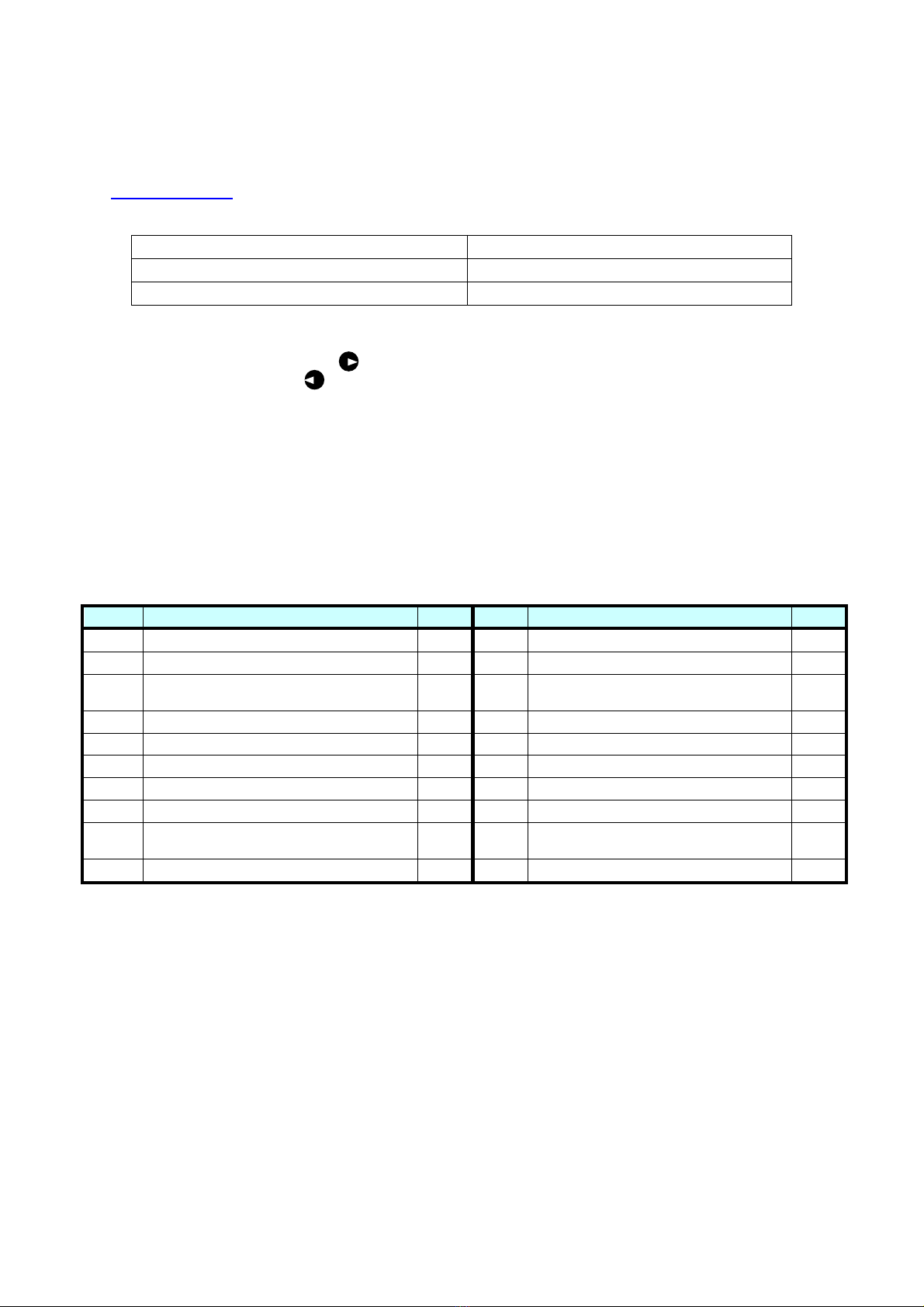

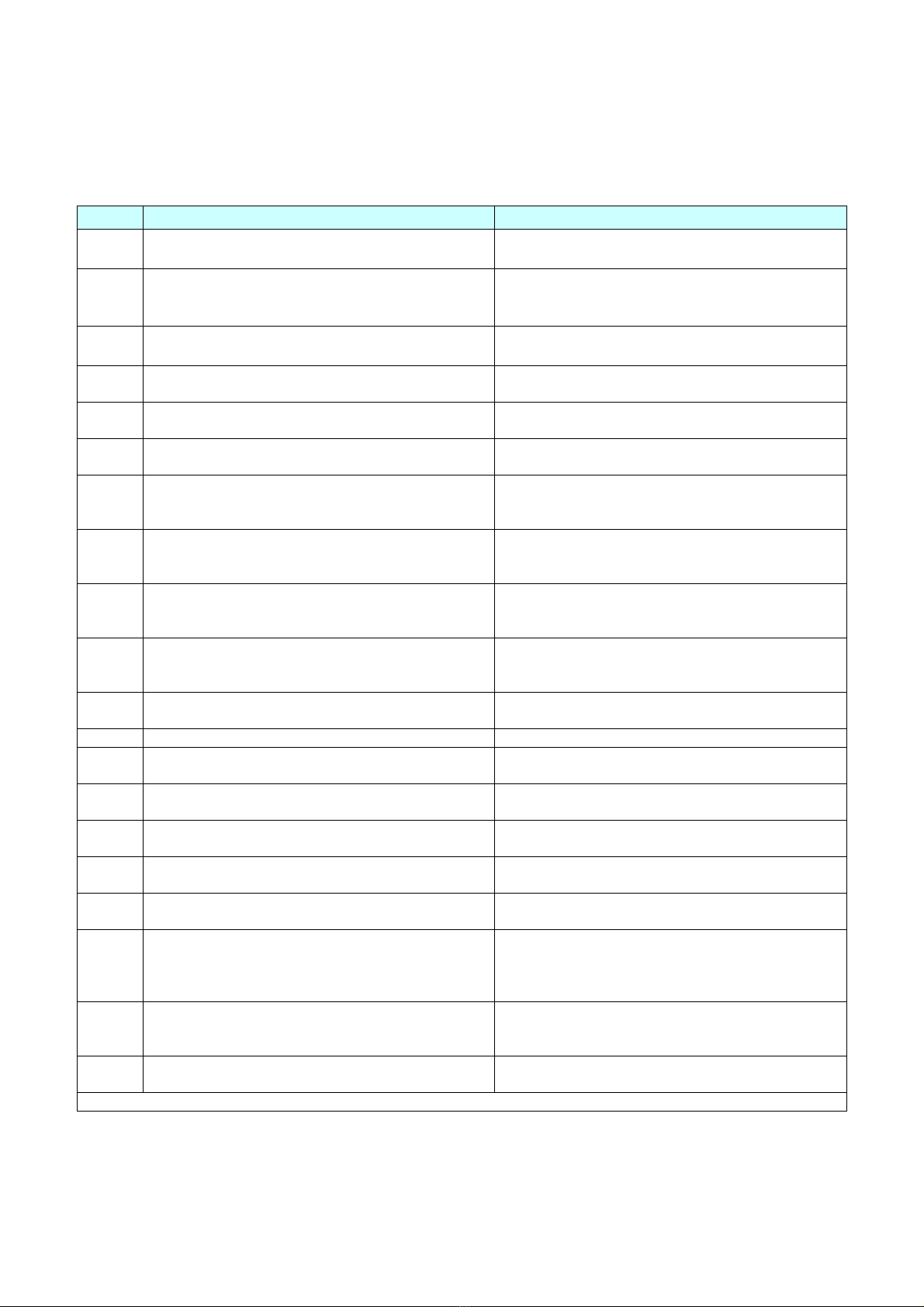

7.4 M4 = ACTIVE FAULTS AND WARNINGS

Listed below are the most common fault messages. Be careful not to reset the alarm or fault without first

having investigated the problems that caused the protection mechanism to cut in.

Always deselect the run command before resetting any fault.

Code Description Remedies / Indications

1

Overcurrent: current 4 times the nominal value

detected at the inverter output.

Check the condition of cables connected to

L1,L2,L3. Check insulation of LCL filter.

2

Overvoltage: bus voltage is too high.

Check that during the main inverter braking

phase, the voltage between B + and B-do not

exceed 800Vdc.

5 Charge switch: The charge switch is open when

the drive is in running.

Reset the fault and restart . If the fault happens

again, contact SMS.

7

several potential causes,

including a faulty component.

Cannot be reset from the keypad. Switch off

power and don’t reconnect it. Contact SMS.

8

-Component damaged

-Malfunction.

Reset the fault and restart . If the fault happens

again, contact SMS.

9

Undervoltage: BUS voltage is too low. Check that the voltage input to the inverter is

correct and steady.

10

11

Detection of fault in power connections (input or

output phase missing, earth fault, etc.).

Check the power cables on the input/output sides

and/or the insulation of LCL filter.

14

16

Temperature inverter undertemperature (-10°C)

inverter overtemperature (+90°C)

motor overtemperature.

Make certain the air flow around the drive is

sufficient to cool the heat sink and/or check for

possible motor overload.

22

23

- Parameter recovery failed

- Damaged or malfunctioning component

Reset the fault and restart .

If the fault happens again, contact SMS.

25

- operational fault

- component failure

Reset the fault and restart.

If the fault happens again, contact SMS.

26

Start-up of the inverter has been impeded. Cancel prevention of inverter start-up.

Contact SMS.

36

The control unit can’t control the

power unit and vice versa. Replace the control unit.

37

Optional board or control unit

changed. Reset

38

An optional board or power unit

with different nominal rating has been added. Reset

39

An optional board or power unit

has been removed. Reset

40

Unknown optional board or drive. Reset

41

IGBT temperature: IGBT Inverter Bridge

overtemperature protection has detected a short

term too high overload current.

Check device sizing.

Reduce the current limit of the device (requires

the keypad). Check the correct operation of the

cooling fan.

52

Keypad communication error:

The connection

between the control keypad and the frequency

converter is broken.

Check keypad connection and possible keypad

cable.

54

Optional board or connection slot

faulty.

Check board and slot

Contact SMS. .

If other types of fault should occur, please contact SMS.