SMW Autoblok GFT-X User manual

Type GFT-X

GRIPPING FORCE TESTER

DEUTSCH

INSTRUCTION MANUAL

Date:

Version:

Language:

COPY OF THE

ORIGINAL

2018-10

8

English

SMW-AUTOBLOK 3

5

6

7

8

11

12

13

15

16

17

20

21

22

25

Übersicht

INSTRUCTION MANUAL

Gripping Force Tester

Type GFT-X

Content

Overview

General safety instructions

Description of function

Technical data

Operation

Measuring

Settings

Measuring head

Measuring procedere

Maintenance/ Service

Display software

Accessories / spare parts list

Trouble shooting

Change the power plug

Confirmation of receipt of the manual

Thank you for purchasing an Original-SMW-AUTOBLOK

Gripping Force Tester type GFT-X

.

This instruction manual contains the installation, the use and the

maintenance instructions of the gripping force tester „

GFT-X

“.

SMW-AUTOBLOK reserves the right to make changes without

notice.

This instruction manual is a part of the GFT-X and must be

passed to the new owner in case of sale.

This instruction manual may not be -in whole or in part- copied

without our written agreement.

&Please read the instruction manual carefully

before installation and use and always follow the

regulations.

Please note especially the sections which are

marked with the following signs:

•Danger of injury or danger to life if instructions

are not followed.

•Danger of damage to the gripping force tester.

Einbauerklärung

SMW-AUTOBLOK 5

Allgemeine Sicherheitshinweise

!

Englisch

1. Correct use

The Gripping Force Tester GFT-X is constructed according to DIN EN 61010-1; VDE 0411-1:2009-06. At the upper

front face the Handheld Unit contains an USB slave connector for data communication with a Windows based

computer and for power supply / recharging.

The Power Supply Plug operates in the range of 100V~- 240V~ alternating current and complies with EN60950-1

and UL60950-1.

General safety instructions

3. Safety requirements

In order to protect the unit against fi re, electric shock or potential destruction of the electronic components, it

must never be exposed to rain or extreme humidity.

Direct sun or heat are to be avoided as well.

4. Opening parts

Please do not try to open the handheld unit or the measuring device. There are no parts inside which you could

maintain.

5. Maintenance

Keep your Gripping Force Tester GFT-X in the transport case where it has optimum protection.

When the device is dispatched for maintenance or repair, it must also be sent in the transport case so that the

sensitive parts are protected in an optimum way during transportation.

Insufficient or improper maintenance makes any warranty from SMW-AUTOBLOK void.

In case of problems or questions please contact SMW-AUTOBLOK directly or one of our authorized offices.

2. Visual inspection

Please check the product for visible damage prior to use!

Danger!

Danger to the environment!

General precept sign!

Follow the instructions! Warning of risk of crushing!

Warning of hand injuries!General warning sign!

Warning of suspended load!

6 SMW-AUTOBLOK

9

6

5

4

3

2

1

Description of function

The Gripping Force Tester GFT-X allows the measurement of

tension when the chuck or collet is in either static or dynamic

mode. Using a complex array of strain gauges in the measuring

head, the mechanical forces are converted into an electrical signal

and amplified by the integrated electronics. The amplified signals

are transmitted from the measuring head with an integrated

UHF transmitter (433MHz) to the handheld unit to be displayed/

controlled.

Here the current clamping force and, in dynamic mode, the

accompanying number of revolutions of the chuck are displayed.

The handheld unit is equipped with a high resolution TFT display

which shows all important menu items as icons. These icons, which

are self-evidend, and a transparent command structure allows easy

operation also for occasional users.

All items are designated for use in severe workshop, the Handheld

Unit is in addition equipped with a silicon protector and offers

therefore utmost protection against shocks and drop down.

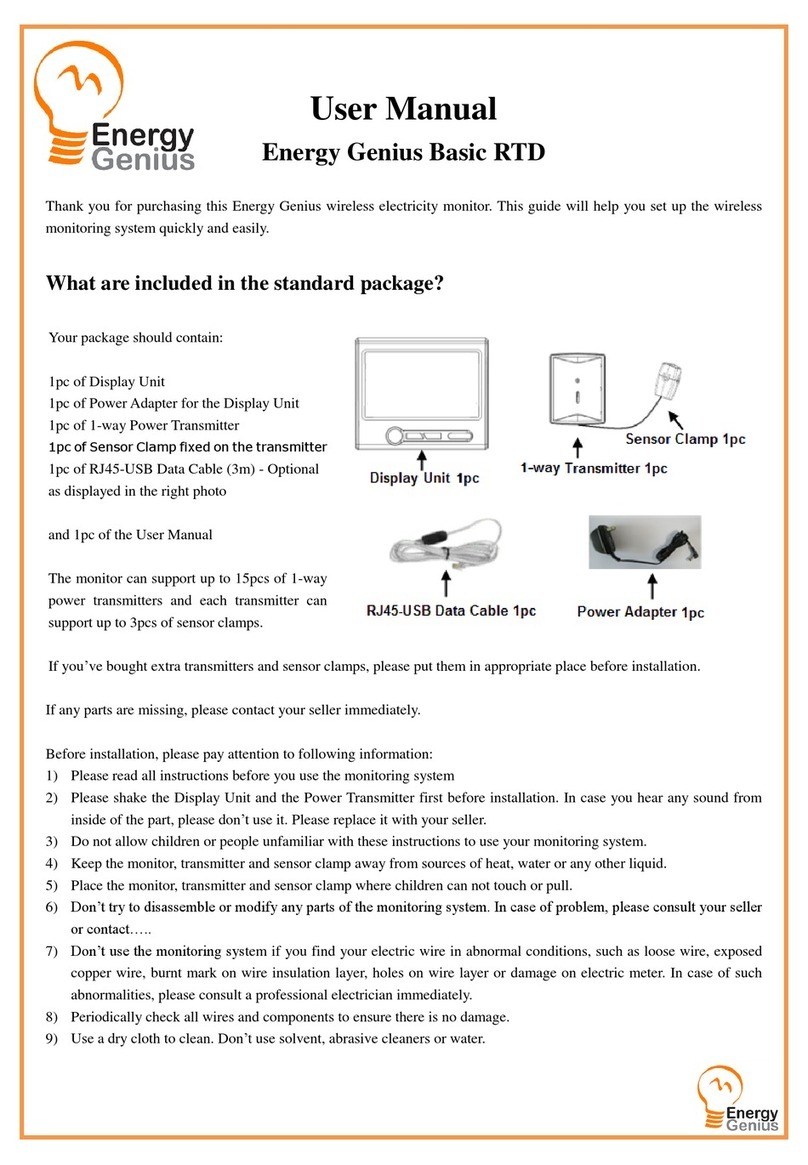

Pack list

1Handheld unit GFT-X with protector

2Power supply plug with USB master connector

3Adapter for North Amerika, United Kingdom, Australia and Europe

4GFT-X ChuckExplorer for Windows XP/7(CD contains display software and operating instructions)

5USB-connecting cable from handheld unit to PC / Laptop, approximately 1m length

6Measuring head M3 for jaw chucks with rotating electronics and 3 each of extension cylinder for jaw diameter ≥Ø 88 and

≥Ø 120 mm

7Torx-key T15 inclusive spare screws

8Stand with magnetic mounting for rpm measurement

9Loading bracket for measuring head

10 Installation help for measuring head

Power supply plug

100V - 240 V~

Charging cable

Measuring

Head M1

Measuring Head

M3 / M4

Measuring

Head M2

PC / Laptop

or

CD with Chuck-Explorer

USB interface power plug

Handheld unit

(Number 7, 8 und 10 not figured)

SMW-AUTOBLOK 7

Technical data

Technical data handheld unit GFT-X

Handheld unit GFT-X

Power supply via USB; 5 V DC

Measurement range/ gripping force F Indication in kN or lbf (selective by user)

Graphical bargraph in percent [%]:

0 - 80 % = green

80 - 95 % = yellow

95 - 100 % = red

Measurement range/ speed (rpm) Indication in 1/min (can be switched of)

Dimensions 220x100x50 mm

Weight 460 g

Operating temperature 0 - 40° C

Protection class IP54

Interface PC/ Laptop USB 2.0

Data cable/ charging cable approx. 1.5 m lenght

Charging cable for measuring heads approx. 1 m length incl. mating connector

Receiving frequency 433,92 MHz

Measuring head M1 Measuring head M2 Measuring head M3 Measuring head M4

(for collets) (for chucks)

Power supply Internal energy storage

Energy storage capacity approx. 1.5h on 50 % d.c.

Measurement range/ gripping

force F 0 - 75 kN 0 - 120 kN

0 - 180 kN (2-jaws)

0 - 270 kN (3-jaws)

0 - 540 kN (6-jaws)

0 - 30 kN (2-jaws)

0 - 45 kN (3-jaws)

0 - 90 kN (6-jaws)

Measurement range/ speed of

rotation (rpm)

>ca. 2001)

-

<10.000 rpm

>ca. 2001)

-

<8.000 rpm

>ca. 2001)

-

<6.000 rpm

Accuracy (F/ rpm) <5 %/ <1 % fsr <3 %/ <1 % fsr <1,5 %/ <1 % fsr

Clamping diameter 18 mm 42 mm 72 - 108 mm

Number of jaws 3 3

2 or 3; configurable via software

6 jaws mechanical only

(software of 3 jaws is recommended)

Dimensions Ø 18/ 57x56 mm Ø 42/ 57x63 mm Ø 68/ 57x63 mm

Weight 400 g 700 g 700 g 700 g

Operating temperature 0 - 40° C

Protection class IP65

Transmitting frequency 433,92 MHz

Charging time <3 minutes

Distance Handheld Unit/

Measuring Head >1m and <4m straight line (value may vary depending on the ambient conditions)

Technical data measuring heads

The GFT-X handheld unit is supplied by 5VDC (500mA) via a power supply plug with an input voltage range from 100VAC to 240VAC.

Different interchangeable blade assemblies for North America, United Kingdom, Australia and Europe are included. Please see page 22

for a guidance to exchange the interchangeable blade assemblies.

Furthermore GFT-X is equipped with a powerful battery (Li-Ion). A one time charge allows an operation up to 5 hours. During this time

frame, a measuring head can be loaded up to 4 times out of the handheld unit battery.

To guarantee uniterruptible measuring process, it is recommended charging the handheld unit fi rst. Charging condition of the battery is

indicated on battery symbol in status line, left side (see page 8).

Mains / Battery operation

* Measurement possible only from min. 60 rpm on, if the distance between the magnet and the measuring head is reduced from 3 mm to 2 mm.

** Theoretical value 540 kN at 6 jaw chucks, the real maximum mechanical permitted load is 270 kN for measuring head M3.

*** Theoretical value of 90 kN at 6 jaw chucks, the real maximum mechanical permitted load is 45 kN for measuring head M4.

8 SMW-AUTOBLOK

>80% >50% >10% <10%

Operation

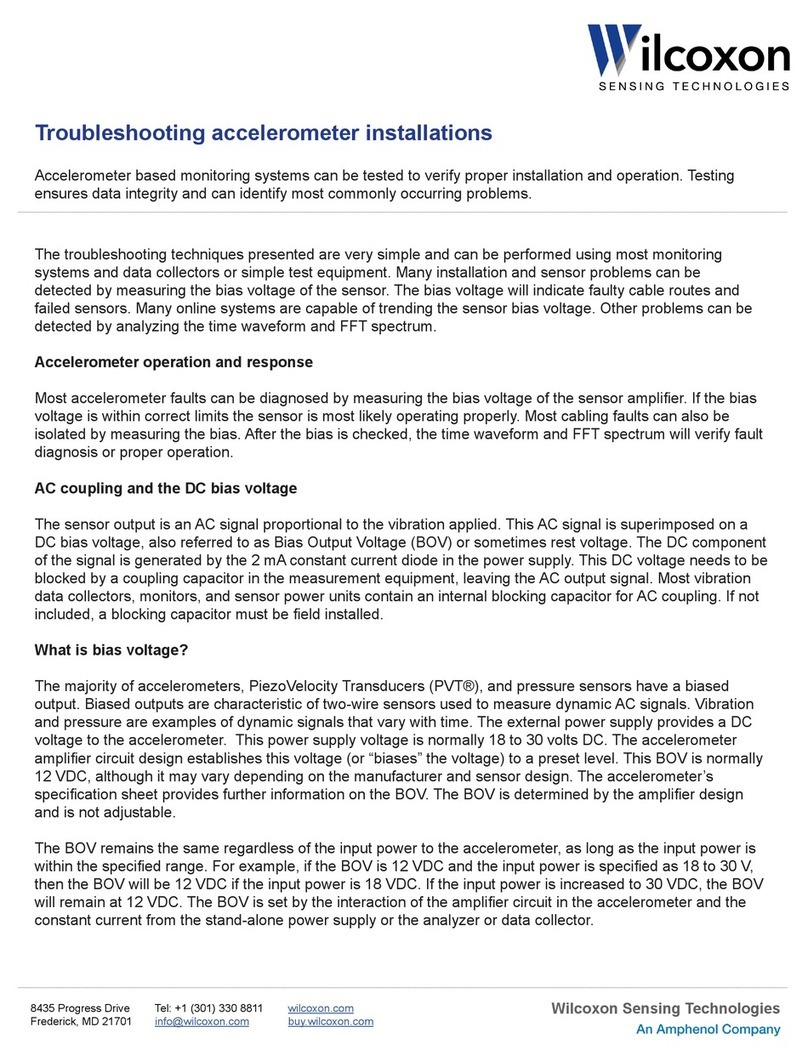

Handheld GFT-X

Powerswitch

Key pad

Speed buttons

Display Line for speed buttons

Command line

Set menu

Status line

USB interface/ power plugMeasuring head

power jack

Overview Keyboard GFT-X handheld unit

To switch on and off the handheld unit press “ON/OFF“ for about 2

seconds. First it appears the welcome logo, at the same tome blue

LED twinkles. The set menu appears after 2 seconds automatically.

Speed button – With this button

the above indicated menu item will

be chosen. These buttons are freely

configurable

Moves icon or line above

Moves icon or line down

Moves icon or character/number to the right

Moves icon or character/number to the left

Delete deletes last input

(character/number)

Menu Back to main menu

ESC Back one level above

OK Confirm selection

Status line

Indicates the current charging condition of the integrated Lithium-

Ion battery. At a remaining operating time of less than 10 minutes

a popup window appears and remembers you to connect the

handheld unit to a power supply or a PC.

If the charging symbol turns red it is not possible charging the

measuring head or the charging process stops.

(% = charging condition; min = remaining time)

If an unloaded measuring head shows >0kN (offset), tare is possible

by pressing „button right“ in the menu measurement.

Deviations >3% of measurement range couldn´t be compensated.

The measuring head should be returned for service.

Meaning of symbols color:

Green symbol: measuring head works fine, no tare applied

Yellow symbol: measuring head still working fine, however tare

has been applied

Red symbol: measuring head for service, offset to large

Green symbol if PC or power supply is attached and connection is

fine. Red symbol means no USB connection.

Green symbol indicates proper radio communication to measuring

head. Red symbol indicates disturbed radio communication or no

measuring head available/in range.

<10min

SMW-AUTOBLOK 9

Operation

Handheld GFT-X

The lowermost line of the display is

reserved for softkeys which can be

programmed by the user.

The left three icon are free to be

programmed, wheras the icon on the

right side is predetermind to load the

measuring head.

Setting/programming Speed Buttons:

• chose the relevant function

• activate the Icon (triangle on the left and a hightlighted frame)

• press desired speed button for about 2 seconds

• the Icon appears in the display

As soon as desired symbol appears in the Speed Button Bar, the

programming is finished sucessfully.

The softkeys could be programmed as often as desired.

Already programmed keys couldn´t be deleted. Only

overwriting is possible.

Indicates chosen measuring head M1 or M2. At M3 and M4 the

number of jaws is also indicated.

Charging condition of measuring head, quantitative indication only.

The charging condition detection of handheld unit is selflearning.

It takes several charging cycles till the charge status is detected

properly. First charge is already made at factory.

LED indicator

Left and right below the speed buttons two LED are located with

following meaning:

• While pressing ON twinkles some

times prior to Welcome Logo pears.

• Twinkles as soon display turns into

Power Save Mode (display almost

dark).

Charge indicator: LED is illuminated

during charging is in progress.

Speed buttons

Tara function always to refers to the dedicated handheld

unit. If measuring head is tared with different handheld units

the measuring head could be damaged.

Menu GFT-X handheld - outline

Use the arrow keys for easy navigation on Set menu. By pressing

OK you will end up directly to the important sub menu.

The chosen or activated Icon will be discovered by a triangle on the

left side and a hightlighted frame. A clear explanation is also shown

in the command line.

Measurement

Define new data collection

Settings

Menu measuring head

Menu collet chuck

Select language

10 SMW-AUTOBLOK

Operation

Handheld GFT-X

Menu overview

SMW-AUTOBLOK 11

Measuring

Individual measurement for an experimental setup

could easily be performed and displayed with this

function. The measuring head to be chosen should

be desired and activated under icon menu measuring

head.

If a pop up windows appears with „No Measuring Head connected!“

make shure that measuring head is switched on (white LED on

measuring heads front face is twinkling).

Radio communication should also be checked.

Measuring

If the measuring head is connected to

GFT-X handheld unit, following message

will be shown:

Serial Number: x x x x – x

Calibration expires: When using a new

measuring head it will give an advice

(see date code) to a label sticked on

the measuring head. The sticker shows

the date when factory calibration date

expires. Measuring head recalibration

After the first factory recalibration the expire date will be shown in

a format MM_YYYY like shown in the sample left.

Recalibration should be performed at least every 12 months

to garantee correct function of measurement head.

Version: y.y , Software-Version ..

To be confirmed by pressing OK.

Measuring head recalibration

The handheld unit now shows the

current measurement values. If no load

is applied to the measurement head and

the indication shows a value >0kN, tare

function can be applied by pressing.

Depending on individual Setting the

force only will be indicated or both

force and speed. The unit for force can

be adjusted to kN or lbf (1kN = 0,2248

1000lbf).

For 6 jaws measuring there is no specific

display soft ware. The operator needs to multiply the displayed

value for 3 jaws by 2. This is the correct value for a 6 jaw chuck.

The example shows 160.8 kN.

If needed the measuring head can be recharged directly form this

menu by using the relevant speed button. If no measuring head is

chosen the message „No Measuring Head connected!“ appears.

This window must be confirmed by pressing OK. Managing all

measurement heads must be performed under menu measuring

head.

Recharge measuring head

This Icon is available independent where you currently

are. It allows easy and fast loading of a linked

measurement head at any time. Just link the handheld

unit to the measurement head with the connecting

cable and press the relevant speed button.

The message “Measuring head battery charging…” appears.

Is the loading process finished after a few minutes the message

“Battery is fully charged” appears. Both popup windows should be

confirmed by OK.

Define new data collection

This function allows the aquisition of up to 20

measurement values and store them under a user

defined name. This data can be processed afterwards

by the ChuckExplorer.

This tool allows easy transferring the data to a PC, showing it on xy

diagram and archive it. The number of stored data to be transferred

to a PC is not limeted.

First put in your individual entry.

Navigate by using arrow keys, confirm

by corrections to be made by or back.

iD: up to 10 characters/numbers

Date: use format DayDay_Month-

Month_YearYear

(just use 2 last digits for year, e.g. 10

for 2010

Number: maximum 3 digits, numbers only, range from 1 to

254

Activate save or press the speed button floppy disk

to memorize your entries. Now you jump directly to

measurement mode. Besides the measurement values

the number of stored measurements is indicated.

Pressing disc symbol in the speed button all entries are

stored and a jump to measurement mode follows. If

windows keep staying the same the cursor shows you

an invalid or not complete entry. Please check this line

and try again.

12 SMW-AUTOBLOK

Settings

Handheld overview

Settings

Following functions are available in this menu:

Speed buttons layout for further

actions:

Accept / overtake measured

value

Finish series of

measurements and exit to

set menu

Delete measured value

Charge measuring head

Handheld unit always stores the last measurement head in use. If

you switch on the handheld unit after a while you dont have to

activate the measuring head again. The serial number will be stored

inside the device till a new entry follows.

Allows quantitative changing of brightness by pressing

arrow keys left or right, conformation by OK.

Indication of measurement values:

force and number of revolutions or force

only

Force unit to be changed from kN to lbf and

v.v.

Screen saver to be activated after x minutes when

no entries happens. Time to be set from 1 bis 43

minutes, acceptance of indicated value by pressing OK.

Reduces brightness to a minimum and helps to increase

operating time. When in Save mode the first entry leads

to normal indication again.

Contrast

Screen saver

Display

Units

Mene measuring head

The Gripping Force Tester GFT-X can operate with

different measuring heads. Available are measuring

heads for jaw chucks and collets. Furthermore, there is

a choice of different clamping forces, dimensions and

number of jaws available.

Activates the relevant measuring head with the triangle

from the index.

A sub menu will open and requires the entry of a new

mesauring head serial number.

Deletes the measuring head marked.

See „Recharge measuring head“ on page 11.

Add a (new) measuring head

Delete measuring head

Recharge measuring head

Choose measuring head

Basically only one measuring head can

communicate with handheld unit at the

same time. However this menu allows

administration of up to 10 measuring

heads. The activated measuring head is

marked with a triangle on the left side

of label. The image on the left shows a

measuring head with serial no 0001-1

which is active.

To navigate use the arrow keys, confirm

with OK.

Measuring heads for 6 jaw chucks have the same serial number

index as the 3 jaw measuring heads. Measuring heads of series M3

have serial numbers ending with xxxx-3, the M4 series xxxx-4.

SMW-AUTOBLOK 13

Measuring head

This menu refers to chuck jaw measuring head only,

which serial numbers ends with xxxx-3 or xxxx-4.

The measurement head M3 and M4 offers the choice

of 2 or 3 jaws.

Menu chuck

The selection of the number of jaws is

made with arrow keys of the keypad.

The active choice is indicated with a

white arrow.

For confirmation press OK.

Mesuring heads for 6 jaw chucks can

be used in 2 and 3 jaw chucks as well.

When using these measuring heads in a

6 jaw chuck, the soft ware of the 3 jaw

chuck is used, and the measured result is multiplied by 2.

The GFT-X handheld unit is prepared for several

languages:

There are four different measuring head available for the GFT-X.

Two for collets (M1 and M2) and two for chucks (M3 and M4).

The measuring head works according to the following principle:

Via a dedicated arrangement of strain gauges inside the measuring

head, the mechanical forces are converted into an electrical signal

which is amplified by the integrated electronics, transformed into a

digital radio signal via a micro-controller and sent to the handheld

unit. There the data signal is encoded and displayed.

Factory provided the measuring heads are calibrated.

After respectively 12 months a check-up and a recalibration

should take place by the manufacturer.

The date for the next calibration is shown under menu measurement

or marked on the measuring head.

Select language

German

English

Italian

Spanish

Russian

Chinese

Japanese

The selection is made with the arrow keys and confirmed by

OK.

Measuring head M1 and M2 for collets

Via the 3 contact surfaces (support) on the measuring head the

force is transmitted to the measuring elements inside the housing.

It is recommended to use special collets with smooth finish in order

to avoid damage to these contact surfaces. Furthermore, care must

be taken to insert the measuring head in such a way that it does

not get tilted.

The „jaw centre“ inscription must correspond to the centre of

one of the three collet jaws. Please note, that compliance with the

above instructions will be decisive for the quality of the measuring

values.

The maximum load is mentioned on each measuring

head. Please make sure that this value will not exceed,

because this can lead to non valid measurements or

even to the destruction of the measuring head.

Measuring Head

Please be assured, that prior to measuring procedure

the measuring head is tight and plane-parallel clamped

to the rotational axis.

14 SMW-AUTOBLOK

Measuring head

By operating M3 or M4 following hints have to be considerd:

Fig.: Measuring head M1 (max. 75 kN)

support

Fig.: Measuring head M2 (max. 120 kN)

The measuring head M3 and M4 are provided for the measurement

of tension or force in jaw chucks. The measuring head M3 is designed

for forces up to 90kN per jaw / 45kN with 6-jaw-chuck, the measuring

head M4 offers higher resolution up to a maximum clamping force of

15kN per jaw / 7.5kN with 6-jaw-chuck).

Different extension cylinders making the measurement head M3 and

M4 applicable for nearly all kinds of jaws. Extension cylinders for

minimum jaw diameter of 72, 88 and 108 mm are available by default.

Measuring head M3 and M4 for jaw chuck

Fig.: Measuring head M3 (maximum load 90 kN per jaw /

45kN with 6-jaw-chuck

)

Fig.: Measuring head M4 (maximum load 15 kN per jaw

/ 7.5kN with 6-jaw-chuck

)

Operation with 3-jaw chuck:

If operated with 15 or 25mm extension, the 8mm extension

must always be mounted to the unused jaws (180°).

Always fit the extension symmetrically (0°, 120° and 180°).

Always mount the extension cylinder firmly (screw the Torx

screw down tightly).

Only with original accessories correct measured values

are ensured.

The measuring head extension cylinder transmits the tension forces

to a load cell located inside the measuring head. For different chuck

diameters Extension Cylinders are supplied which can be easily

exchanged to suit. A T15 Torx key is included for loosening and

tightening the screws.

The extension cylinders are to be used as follows:

Measuring head extension cylinder for M3 and M4

Jaw chuck [dia. mm] 72 mm 86 mm 106 mm

Extention [mm] 8 mm 15 mm 25 mm

Assembly instructions see page 15.

Extention 25 mm

Extention 15 mm

Extention 8 mm

(0°)

F

2, 3 and 6 jaws

(0°)

F

2, 3 and 6 jaws

Extention 25 mm

Extention 15 mm

Extention 8 mm

F

2/6 jaws

(180°)

F

3/6 jaws

(240°)

F

3/6 jaws

(120°)

F

2/6 jaws

(180°)

F

3/6 jaws

(240°)

F

3/6 jaws

(120°)

Operation with 2-jaw chuck:

If operated with 15 or 25mm extension, the 8mm extension

must always be mounted to the unused jaws (at 120° and

240°).

Always fit the extension symmetrically (0° and 180°).

Always mount the extension cylinder firmly (screw the Torx

screw down tightly).

support

F

6 jaws

(60°)

F

6 jaws

(270°)

F

6 jaws

(60°)

F

6 jaws

(270°)

SMW-AUTOBLOK 15

Measuring procedere

Measuring procedere

Starting with the first measurement make shure that the measuring

head is fully charged. For this purpose the measuring head power

jack is to be linked to the charge receptacle of the measuring head.

From the safety point of view and to prevent

any injury, the loading bracket must be used

to put the measuring head M3 or M4 into the

chuck.

Mounting M3 und M4 measuring head

Take the loading bracket like shown in the picture and put the

measuring head M3 or M4 into it. After this, the measuring head

can be insert into the chuck until the loading bracket fit tighly in the

chuck. Now the chuck must be tensioned.

Because of that it is guaranteed, that the measuring head is not tilt

and it is in the optimum measuring position.

Put the measuring head like shown into the chuck.

Is the chuck tensioned, the loading bracket have to be removed.

Please be assured, that prior to measuring procedure

the measuring head is tight and plane-parallel clamped

to the rotational axis.

Powerswitch Power-LED, twinkles

when the measuring

head is active

Charge receptacle

Static Measuring

For static measuring the measuring head is clamped and switched

on. After the handheld unit has been switched on, the immediate

tension is recorded and shown on the display.

The unit will start operation by pressing the ON/OFF key for about

2 seconds If the LED is blinking, the measuring head is switched on.

Dynamic Measuring

Make sure that the measuring head is clamped exactly parallel to

the rotaion axis. (See page 13-15).

Stand Magnetic base

Magnetic for rpm measuring

Measuring head M1...M4

16 SMW-AUTOBLOK

Maintenance/ Service

After the measuring head has been clamped in a parallel plane

the stand with the magnetic base must be fastened to the support

of the processing machine and positioned in such a way that the

lateral distance between the flattened end of the stand and the

measuring head is approximately 3 mm. The distance between the

top of the cover and the edge of the flattened part of the stand

should be 1-2 mm approximately. The stand should end with the

yellow cover of the measuring head before the steel part begins.

If no data are displayed although the handheld unit is switched on

and the measurement menu is activated, proceed according page

20 Trouble shooting.

The GFT-X is supplemented by the powerfull software module

ChuckExplorer. This program permits transfer of the data displayed

and stored on the Handheld Unit to a PC / laptop. A USB connecting

cable is included in the delivery package.

The gripping force and the corresponding number of revolutions

can be graphically represented, printed and stored on the PC.

It is also possible to convert the measuring data into an Excel

spreadsheet and to store the graphical representation as bitmap.

These data can then be used for further processing in any program.

This module represents an invaluable tool for documentation, in

particular with regard to a consistent quality management.

Measured data display/Storage on PC

When the handheld unit is switched on and rmp measuring is

activated, the current gripping force is determined and shown

on the display. When the chuck is rotating at the same time, the

display shows besides the gripping force the corresponding actual

number of revolutions.

Calibration, Recalibration

The GFT-X is carefully tested and calibrated on a test bench at

the factory. A calibration certifi cate is enclosed. This calibration

certificate documents the traceability to national standards, which

realize the units of measurement according to the International

System of Units (SI).

The zero point of the measuring head could change due to stress

(material fatigue) and due to temperature variation.

In a narrow range the measured value can be tared (set to zero)

refering page 8.

The GFT-X is a calibrated measuring equipment, a recalibration

should be performed by the manufacturer after 12 months

of operation. For calibration purpose we will ask you to send the

complete GFT-X unit back to your supplier.

Maintenance, Service

The GFT-X is a measuring device and should therefore be

treated very carefully.

Special care must be taken with respect to the measuring head

extension with its crowned surface. Due to the gripping forces, this

surface might be subject to wear and tear in the course of time. A

replacement is advisable at the latest when a ridge becomes visible

on the disk (spare part numbers see page 20.

If problems occur which cannot be solved as described on

page 21, the complete GFT-X must be returned to the supplier.

A detailed description of the problem will shorten the time

to repair and save costs.

To operate the ChuckExplorer there is no need of detailed computer

knowledge. The program could be installed and runs under

standard hardware.

The function implementet are tested under Windows XP and

Windows 7.

To install the software please follow the instruction below:

Switch on the computer and start Windows

Insert Chuck Explorer disk in the CD-ROM drive

Installing ChuckExplorer

The setup program starts automatically. If it doesn‘t you can also

start the setup manually:

Open the file manager/explorer

Start the „AutoRun.exe „ program on the ChuckExplorer

CDROM

First install USB-driver, then ChuckExplorer.

ChuckExplorer is no ready to be installed, the installation path can

be freely chosen. At the end of this process, a message confirms the

successful installation and the program can be started immediately.

SMW-AUTOBLOK 17

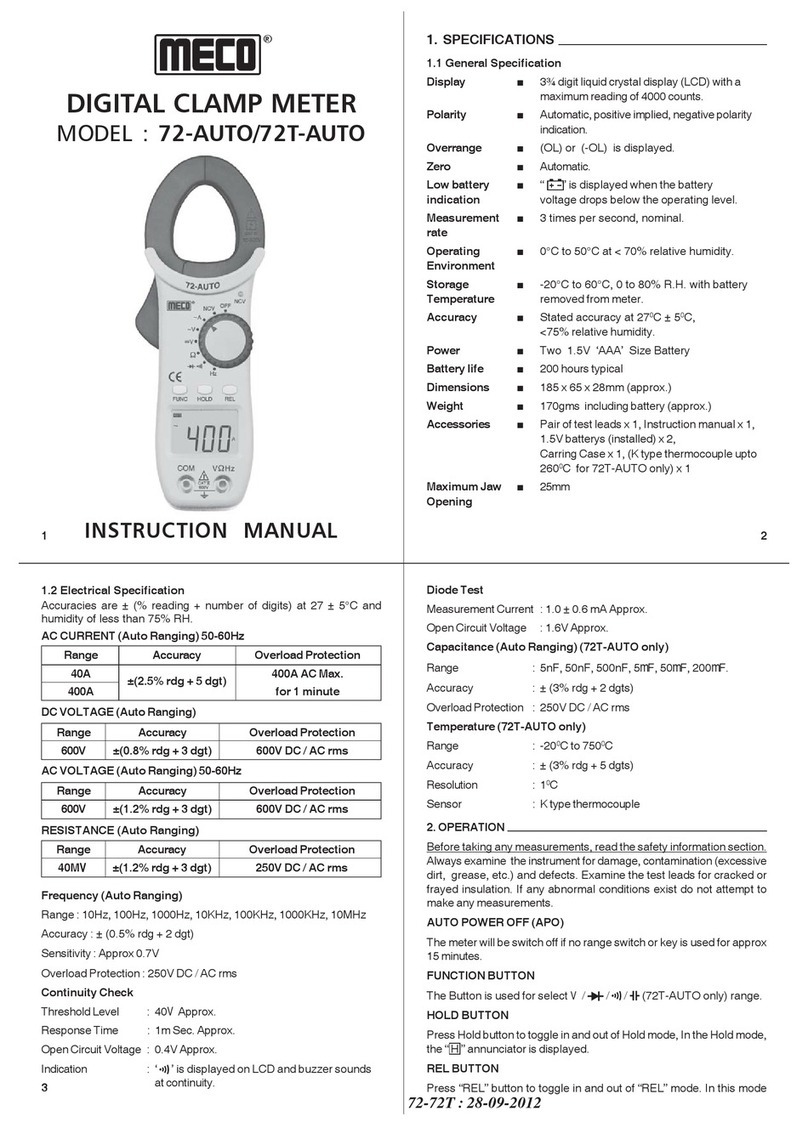

Display software

Screenshot ChuckExplorer

The window can be changed in its size, by clicking on the handle

with the mouse cursor.

The desired language can also be selected by Command File

Language. Actually, German and English version are available.

Handle for

window size

Spreadsheet Diagram Display

Button barCommand line

Using the software

Start ChuckExplorer by double click . With the command line all

individual settings can be perfomend.

Equally under File Interface the USB port to communicate with

GFT-X handheld unit could choosen.

Just activate the button Auto Scan. As soon the handheld unit is

found, the active port appears followed by the message „GFT on

COMx found!“at the lower part of the window.

Edit Copy chart: To copy the table into the clipboard. The

spreadsheet can be dropped easily in Excel or a Word processing

program for further processing.

Edit Copy chart: To copy the displayed diagram into clipboard

and could imported or paste in Bitmap-Format into other programs.

GFT-X Download: Data to be downloaded from a series of

Handheld Unit measures into ChuckExplorer.

GFT-X Delete memory Allows remote deleting of Handheld

Unit memory, it is recommended to do so after every download

to assure having sufficient memory space for next measurement

available.

Under Setup following parameters can be adjusted:

Graphic: By pressing „...“ key a color bulletin appears.

Choose the color you want for the diagram and its background.

Automatic measurement (Automatic mode):

The criteria to take over a measure automatically is the revolving

speed.

The speed should be within less than +/-5% of the maximal speed

and should be there for at least 3 seconds.

Automatic measurement settings:

Tolerance ± 1-10%,

Hold time 1-5sec (0,5sec steps)

Under Help, you will find information about the current software

version as well as comprehensive explanations concerning the

individual software functions and the terms used.

The menu bar is self-explanatory, i.e. a small info window will open

when the mouse pointer is positioned on the individual button.

Description of the individual push buttons:

Open file

Save the current measurement

Save all opened measurements

Print the current document

Connect the GFT-X handheld unit to the computer, read the memory

Delete internal memory of GFT-X handheld unit

(all measurement data will be discarded)

Show the previous measurement

Show the next measurement

Settings

Exit ChuckExplorer

18 SMW-AUTOBLOK

Display software

For starting the measurement, the measurement tab must be active

and the Start button must be pressed. The button start changes to

Stop, number of revolutions and gripping force will be indicated.

Manual measuringMeasurement

There is a general distinction between two different methods for

storing the measured values with the GFT-X handheld unit and

directly with the ChuckExplorer.

Ifthemeasured value recordingis made directlybytheChuckExplorer,

then there is the possibility of a manual and automatic measured

value recording.

In case of manual storing of the measured values, the user can

decide by himself at what rpm value or at what force he wants

to store a value. When automatic storing is activated, two new

input lines are provided. Here the maximum number of revolutions

and the number of steps are defined, the program divides the

maximum number of revolutions by the number of the measured

values to be stored and logs them as soon as the relevant numbers

of revolutions are reached.

After clicking on the Information tab, you can enter further

parameters (jaw type, hydraulic pressure, etc.) in the righthand part

of the display window.

These parameters are recorded together with the measurement.

Measurement preparations

Relevant data and parameters can be entered into the program and

included into the measurement log so that a measurement can be

documented.

Machine or chuck ID and the name of the tester are entered on

the left side in the upper part of the program window. Up to 10

names are stored by the program and are available for future

measurements. They can be displayed and selected by clicking on

the button beside the text field.

The Date field is feeded directly from the system, however it can

be changed in the same way. This is necessary e.g. if measuring

sequences stored on the handheld unit are read out only after

several days.

By each click on the Store button, a measured value is stored and

displayed in the table on the left and in the diagram. The scale of

the chart is switched to the optimum range in order to get a better

optical presentation.

If a measuring sequence is complete, it can be stored on hard

disk Stop, File, Datei Save. The ChuckExplorer suggest

automatically a filename, which consist of the collet-check box and

the date (e.g. Traub_07_09_10), however this line can be edited

individually. A printout on the printer is started via File Print.

Dependent on the printer and printer driver the diagram can vary.

Standby/On-line

(Communikation with

GFT-X handheld unit)

Measured gripping

force and rotational

speed

Gripping force in

percent from reference

value (measure no. 0)

Automatic measuring

If check box Automatic is activated , two new input fields are

displayed. Here you can enter the maximum number of revolutions

and the number of measurement steps. The software will then

determine automatically the equidistant numbers of revolutions

(rpm) for which the measured value is to be stored. The rpm

tolerance and the minimum time during which the rpm value must

be constant within the tolerance range can be set in menu item

Setup.

SMW-AUTOBLOK 19

Display software

The measurement is started by the Start button. If the maximum

number of revolutions is reached, the program will automatically

terminate the measurement and display the corresponding table of

values and the graphical evaluation.

Download data from GFT-X handheld unit

Measurements recorded by a series of measurements and saved in

the internal memory of the GFT-X handheld unit, can be downloaded

directly from the handheld unit with GFT-X Download and

afterwards indicated. If several IDs and/or series of measurements

transferred so it is possible to switch forwards and backwards .

A backup of data of the indicated series of measurements is

necessary before. Chose therefore File Save... or Save all.

After download and the backup of data on the PC, data memory

of GFT-X handheld unit can be deleted completely with GFT-X

Delete memory.

Loading and saving files

Choose File Save to save your recorded data. The directory

is user-defined, files end with *.gft. Will be several series of

measurements (Files) downloaded from GFT-X handheld unit, they

can be saved all at once with File Save.

Choose File Open to open an existing data file. The filename

appears in the Button bar.

Software update

The software of the GFT-X handheld unit is improved constantly and

is subject to certain changes. The actual software version will be

displayed in the welcome logo. An update is usually accomplished

at the manufacturer.

20 SMW-AUTOBLOK

Accessories / spare parts list

Pos. Id. No. Description

201542 GFT-X complete incl. case, Measuring Head M3 and Handheld Unit

201659 GFT-X case including Handheld Unit

1 201824 GFT-X case (case only)

2 201762 GFT-X Handheld Unit

3 196193 GFT / GFT-X Measuring Head M1 (optional)

4 196194 GFT / GFT-X Measuring Head M2 (optional)

5 196195 GFT / GFT-X Measuring Head M3 (standard)

201825 GFT-X Measuring Head M4 (optional)

201763 CD with ChuckExplorer and operating instructions

6 201764 Power Supply Plug USB incl. interchangeable blade assemblies

7 196839 Loading Bracket for GFT or GFT-X

8 198161 Recharging cable for GFT or GFT-X, 1m, Push-Pull

9 201765 USB-cable for GFT-X, 1.5m

10 036201 Extension Cylinders 8mm for GFT or GFT-X

11 036203 Extension Cylinders 15mm for GFT or GFT-X

12 036205 Extension Cylinders 25mm for GFT or GFT-X

13 201766 Stand with magnetic mounting for GFT or GFT-X

085961 Torx-key for GFT or GFT-X M3 and M4

033010 Spare screws

201922 Protector for GFT-X Handheld Unit

201923 Spare battery for GFT-X Handheld Unit

Table of contents