Snap-On Diagnostics DGA 1000 User manual

DGA 1000

Diagnostic Gas Analyzer

i

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Back Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Screen Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Action Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Function Selection Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Screen Navigation Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Standard Keyboard (not shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Optional Lightpen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Optional Oil Temperature Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Optional Remote Control Keypad Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

General Setup Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Standard Lead Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

To Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Connecting to a Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Connecting the Optional Temperature Probe to the Vehicle . . . . . . . . . . . . . . . . . . . . . . . .1-19

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

Analyzer Screen Display Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Measurement Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

CO Corrected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Lambda and AFR Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Lambda (l) and Catalytic Converter Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

O2 and NOx Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Air-Fuel Ratio and the Stoichiometric Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Vehicle Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Preliminary Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Testing Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Setting Up the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Two-Speed Idle (TSI) Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Catalytic Efficiency Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Optional Catalytic Converter Test Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Catalytic Converter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Pre-test Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Test Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Before Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Disabling the Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Disabling the Ignition System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Catalytic Converter Test Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

1– Leak Check Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

2–Leak Check Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

3–Gas Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table of Contents

ii

Table of Contents

4–O2/Check Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5–Gas Tag Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

6–Gas Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Test Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Front Panel and Exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Keyboard and Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

CRT Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Sample Probe and Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Control and Error Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Accessory Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Maintenance Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Fundamentals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Combustion and Air-Fuel Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Combustion Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Oxides of Nitrogen (NOX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Hydrocarbons (HC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Carbon Monoxide (CO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Carbon Dioxide (CO2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Oxygen (O2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Interpreting Air-Fuel Ratios and Emissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Stoichiometric Fuel Mixture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Catalytic Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Vehicle Testing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Testing Gasoline-Fueled Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Testing Propane-Fueled Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Data Collection Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Engine Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Tail Pipe Exhaust Gas Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Testing Under Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

On-Road and Dynamometer Testing Under Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Air Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Carburetor Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Vehicles Without Feedback Fuel Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Lean-Misfire Adjustment Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Lean-Drop Adjustment Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Accelerator Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Power Valve Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

High Fuel Level In Float Chamber Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Combustion Gases in the Cooling System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Fuel Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Exhaust Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Fumes In Passenger Compartment Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

No-Start Condition—Fuel Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Diagnostic Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Data Analysis Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Air-Fuel Ratio Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Five Gas Combination Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

iii

This manual contains instructions for setup and use of the

DGA 1000 Gas Analyzer

and dynamometers. A table of contents

and is provided to make this manual easy to use.

Some of the information shown in text or illustrations is obtained

using optional equipment. A

Snap-on

Sales Representative can

determine option availability.

For Service or Technical Support, call Emissions Technical

Support Group at 1-800-225-5768.

Conventions

This section contains a list of conventions used in text.

Check Note

A check note provides additional information about the subject in

the preceding paragraph.

Example:

✓Keep the probe tip openings clean and free of debris.

Testing Tips

Testing tips provide information that applies to a specific test. Each

testing tip is introduced by this icon for easy identification.

Example:

X

Check vehicle manufacturer specifications and procedures

before testing.

Chapter References

Additional information in text is referenced by chapter number and

section name.

Example:

For additional information refer to

Chapter 4–

Maintenance

.

Using this Manual

iv

Using This Manual

Equipment Damage

The possibility of damage to vehicle or equipment is introduced by

a signal word indicating this condition.

Example:

After extended testing, operate the engine at 1500 RPM

with no load for several minutes with the cooling fan in

place. This helps reduce test induced engine heat.

Safety Messages

Safety messages are provided to help prevent personal injury and

equipment damage. All safety messages are introduced by a

signal word indicating the hazard level. The types of safety

messages are:

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury to the

operator or to bystanders.

Indicates a potential hazard which, if not avoided,

could result in death or serious injury to the operator

or to bystanders.

Indicates a potential hazard which, if not avoided, may

result in minor or moderate injury to the operator or to

bystanders.

The three-part message panel, used with safety messages, uses

three different type styles to further define the potential hazard:

•

Normal type states the hazard,

•

Bold type states how to avoid the hazard, and

• Italic type

states the possible consequences of not avoiding

the hazard.

Some safety messages contain visual symbols with signal words.

Example:

Risk of burns.

Do not remove radiator cap unless engine is cold. Pressurized

engine coolant may be hot.

Hot engine coolant can cause serious burns.

Using This Manual

v

Abbreviations

The following abbreviations are used in this manual.

A current, amperage

AIR Air Injection Reaction

Ccarbon

CNG Compressed Natural Gas

CO carbon monoxide

CO2carbon dioxide

COMM communication

DTC Diagnostic Trouble Code

EGR exhaust gas recirculation

FID flame ionization detector

Hhydrogen

HC hydrocarbons

Hz hertz

km/h kilometers per hour

lb pound

LPG Liquefied Petroleum Gas (Propane)

mV millivolt

MIL malfunction indicator lamp

NDIR Non-Dispersive Infrared

NO nitric oxide

NO2nitrogen dioxide

NOx oxides of nitrogen

NRLHP normal road load horsepower

O2oxygen

OBD On-board Diagnostics

OIML International Organization of Legal Metrology

PC personal computer

PCV positive crankcase ventilation

ppm parts per million

RPM revolutions per minute

TPS throttle position sensor

vol volume

°C degrees Celsius

°F degrees Fahrenheit

vi

Using This Manual

Trademark Acknowledgements

Snap-on®

is a registered trademark of Snap-on Technologies, Inc.

EquiServ®,

a unit of Snap-on Tools, is a registered trademark of Snap-on Tools Company.

Copyright Information

DGA 1000 Gas Analyzer Operating Instructions

©2001, Snap-on Diagnostics

The information, specifications and illustrations in this manual are based on the latest

information available at the time of printing.

Snap-on

reserves the right to make changes

at any time without notice.

I

Safety Information

For your safety, read this manual thoroughly before operating

the Analyzer System.

The

DGA 1000 Gas Analyzer

is intended to be used by skilled,

professional, and properly trained automotive technicians. The

safety messages presented here and throughout this user’s

manual are reminders to the operator to exercise extreme care

when using this test instrument.

There are many variations in procedures, techniques, tools

and parts for servicing vehicles, as well as in the skill of the

individual doing the work. Because of the vast number of test

applications and variations in the products that can be tested

with this instrument, the manufacturer cannot possibly

anticipate or provide advice or safety messages to cover every

situation. It is the automotive technician's responsibility to be

knowledgeable of the system that is to be tested. It is essential

to use proper service methods and test procedures and to

perform tests in an appropriate and acceptable manner that

does not endanger your safety, the safety of others in the work

area or the equipment or vehicle being tested.

It is assumed that, before using this tool, the operator has a

thorough understanding of vehicle systems. understanding the

principles and operating theories of vehicle systems is

necessary for competent, safe and accurate use.

Before using the

DGA 1000 Gas Analyzer

, always refer to and

follow the safety messages, and applicable test procedures

provided by the manufacturer of the vehicle or equipment being

tested.

II

Safety Information

Read All Instructions

Read all instructions and safety messages in this manual. All

safety messages in this section contain a signal word, a three-

part message, and, in some instances, a symbol/pictorial.

The signal word indicates the level of hazard in a situation.

•

Danger indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury to the operator

or bystanders.

•

Warning indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury to the

operator or bystanders.

•

Caution indicates a potentially hazardous situation which, if not

avoided, may result in moderate or minor injury to the operator

or bystanders.

Safety messages in this section contain three different type

styles.

•

Normal type states the hazard.

•

Bold type states how to avoid the hazard.

• Italic

type states the possible consequences of not avoiding

the hazard.

An icon, when present, gives a graphical description of the

potential hazard.

IMPORTANT SAFETY INSTRUCTIONS

Vehicle exhaust gases contain carbon monoxide (CO),

which is a colorless and odorless lethal gas.

• Perform tests in a well-ventilated area and route

exhaust outside while testing with engine running.

• Only run engines in a well-ventilated area (4 turns of

air per hour) and avoid breathing exhaust gases.

Extended breathing of exhaust gases can cause injury.

Ignition coils, coil terminals and spark plugs emit high

voltages.

Do not touch ignition coils, coil terminals and spark

plugs while they are in operation.

These components may cause injury.

Engine systems can malfunction expelling fuel, oil

vapors, hot steam, hot toxic exhaust gases, and other

debris.

Wear safety goggles, user and bystander.

Engine systems that malfunction can cause injury.

Safety Information

III

Risk of fire.

• Wear safety goggles and protective clothing,

user and bystander.

• Do not position head directly over or in front of

the carburetor or throttle body. Do not pour

gasoline down the carburetor or throttle body

when cranking or running the engine, when

working with fuel delivery systems or any open

fuel line. Engine backfire can occur when the air

cleaner is out of normal position.

• Do not use carburetor sprays or fuel injector

cleaning solvents when performing diagnostic

testing.

• Keep a dry chemical (Class B) fire extinguisher

rated for gasoline, chemical and electrical fires

in the work area.

Fire can cause death or serious injury.

A test vehicle may move if not properly prepared.

• Block the drive wheels before performing a test with

the engine running. Unless instructed otherwise, set

the parking brake and put the gear selector in

neutral (standard transmission) or park (automatic

transmission). If the vehicle has an automatic

parking brake release, disconnect the release

mechanism for testing and reconnect when testing

is completed.

• Do not leave a running engine unattended.

A moving vehicle can cause injury.

Gases produced by batteries are highly explosive.

• Avoid sparks when connecting or disconnecting

power leads to battery.

• Always connect red positive (+) power lead to

positive (+) battery terminal and the black negative

(-) power lead to a good vehicle ground as far away

from the battery as possible.

• Avoid making accidental connection between

battery terminals through tools, jumper leads, etc.

• Keep lighted cigarettes, sparks, flames and other

ignition sources away from batteries.

• Always keep a dry chemical (Class B) fire

extinguisher near work area.

Battery explosion can cause injury.

IV

Safety Information

The engine compartment contains electrical connections,

and hot or moving parts.

• Do not place test equipment or tools on fenders or

other places in the engine compartment.

• Keep yourself, test leads, clothing, and other objects

clear of electrical connections and hot or moving

engine parts.

Contact with electrical connections and hot or moving

parts can cause injury.

Misdiagnosis may lead to incorrect or improper repair

and/or adjustment.

Do not rely on erratic, questionable, or obviously

erroneous test information or results. If test

information or results are erratic, questionable, or

obviously erroneous, make sure that all connections

and data entry information are correct, and that the

test procedure was performed correctly.

Improper repair and/or adjustment may cause vehicle or

equipment damage or unsafe operation.

SAVE THESE INSTRUCTIONS

1-1

Introduction

The

DGA 1000 Gas Analyzer

is a versatile test instrument for

analyzing exhaust gases of internal combustion engines. When

used with other tools and equipment, the analyzer can also detect

and locate ignition, fuel, exhaust, emission control, and engine

service problems.

It is generally assumed that the fuel, ignition, and emission control

systems are functioning properly when exhaust gas concentrations

are within limits specified by the vehicle manufacturer or the local,

state or federal government. If exhaust gas concentrations exceed

those specified limits, repairs or adjustments are probably needed.

For more information on emissions and exhaust gases, refer to

Chapter 5–Fundamentals

✓Always follow manufacturer specifications when working

on emission control devices to comply with anti-tampering

laws.

1

1-2

Introduction

Functional Description

Front Panel

The front of the analyzer includes controls for operating the unit,

the monitor screen for viewing tests and the printer, which provides

a written record of test results. Descriptions of the items labeled on

the analyzer front view follow

Figure 1-1

.

A—9" Video Display Screen

Displays all screen information and symbols available for use with

each screen.

B—Enter Key and Arrow Keys

Use the:

— Middle ENTER key to select a chosen item or symbol.

— Arrow keys () around the ENTER key to:

•

Select a menu item or a symbol,

•

Move up and down to change a selected value, or

•

Move forward and backward within screens.

C—Infrared Sensor

Receives the signals from the optional remote control.

Figure 1-1:

Analyzer—Front Panel View

Introduction

1-3

D—Vehicle Set-up Key

Use to set-up the vehicle information when in emissions

measurement display.

E—PRINT Key

Use to:

— Access message/customer input screen.

— Press TWICE to start printing.

F —Freeze/Store Key

Use to:

— Stop or freeze all test screen information necessary for

saving a screen to memory.

— Press TWICE to store information to memory.

G—On/Off Switch

Use to:

— Turn the electrical power on and off.

1-4

Introduction

Back Panel

Important features for analyzer operation and maintenance are

located on the back panel. Descriptions of the items labeled on the

analyzer back panel follows

Figure 1-2

.

A—Filter Sample, secondary in-line filter.

B—Printer 24 columns.

C—Filter In-line water drain filter.

D—O2and NO Sensor Cover

Remove this cover to replace O2or NO cells.

—O2sensor detects concentrations of oxygen in the exhaust

gas sample.

—NO sensor (optional) detects concentrations of nitrogen

oxides in the exhaust gas sample.

E—Primary Filter Bowl Assembly

Removes moisture and other exhaust contaminants that are

potentially harmful to the analyzer.

F —Main AC Power Source

Connection for the AC power cord.

Figure 1-2:

Analyzer—Back Panel View

Introduction

1-5

G—Voltage Switch

Use this switch to select either 230VAC or 115VAC power input.

H—Auxiliary Outlet

Use this outlet to connect optional equipment.

J —Filter Bowl Water Drain Input

Water from filter bowl inlet port.

K—Gas Sample Exhaust [1] Outlet

Vehicle gas sample exit port from NO cell.

L —Optional Oil Temperature Probe Port

Use this connection for the optional temperature probe, optional

part number 6004-0407-04.

M—RPM Pickup Port

Use this connection for the grey RPM pickup.

N—Sample Gas Port

Connect the exhaust sample hose/probe to this inlet.

O—Water Outlet

Sample filter bowl water drain.

P—Calibration Gas Inlet

Use this inlet to supply calibration gas to the analyzer.

Q—Optional Lightpen ENTER Button Port

Use this connection for the single wire on lightpen harness.

R—Optional Lightpen Port

Lightpen connector, part number 7009E9321-97.

S—Clean Air Inlet Port

Has a charcoal filter installed to filter the ambient air going into the

gas bench for calibration.

T —RS 232 Port

For communication to an external data logging PC.

✓Contact

Equiserv

for additional information.

U—Keyboard Port

Connection for the optional keyboard.

V—Service Key Port

Service connection is only used by a Service Representative.

1-6

Introduction

Screen Displays

The screen displays a number of universal symbols to allow easy

navigation around the various menu and screen displays using the

ENTER and ARROW key pad.

Additional details of these symbols follow

Figure 1-3

.

✓Use the arrow keys () followed by the ENTER key to

select items in Group 1 functions.

.

Figure 1-3

: Screen Displays

Introduction

1-7

Action Indicators

On the lower left side of the Measurement Screen, a status symbol

is displayed when a fault or error occurs.

Auto zero/Auto calibration

A pre-warning that indicates a Auto zero/Auto calibration is

required. Auto zero/Auto calibration is automatically performed by

the analyzer when measurements are stopped. Measurements can

be continued for a maximum of 30 minutes while the Auto zero/

Auto calibration symbol displays. After this time, the analyzer stops

measurements and performs an Auto zero.

Bench Exhaust Flow Problem

Indicates that the gas bench exhaust is blocked.

Low Flow

Indicates that the sample probe or hose is restricted.

Water

Indicates that there is too much water in the filter bowl assembly or

the water filter is clogged. Wait until the analyzer removes the

water from the bowl or empty the water from the bowl.

Warnings/Errors

Refer to

Chapter 4–Control and Error Status

for more

information and how to solve error codes.

1-8

Introduction

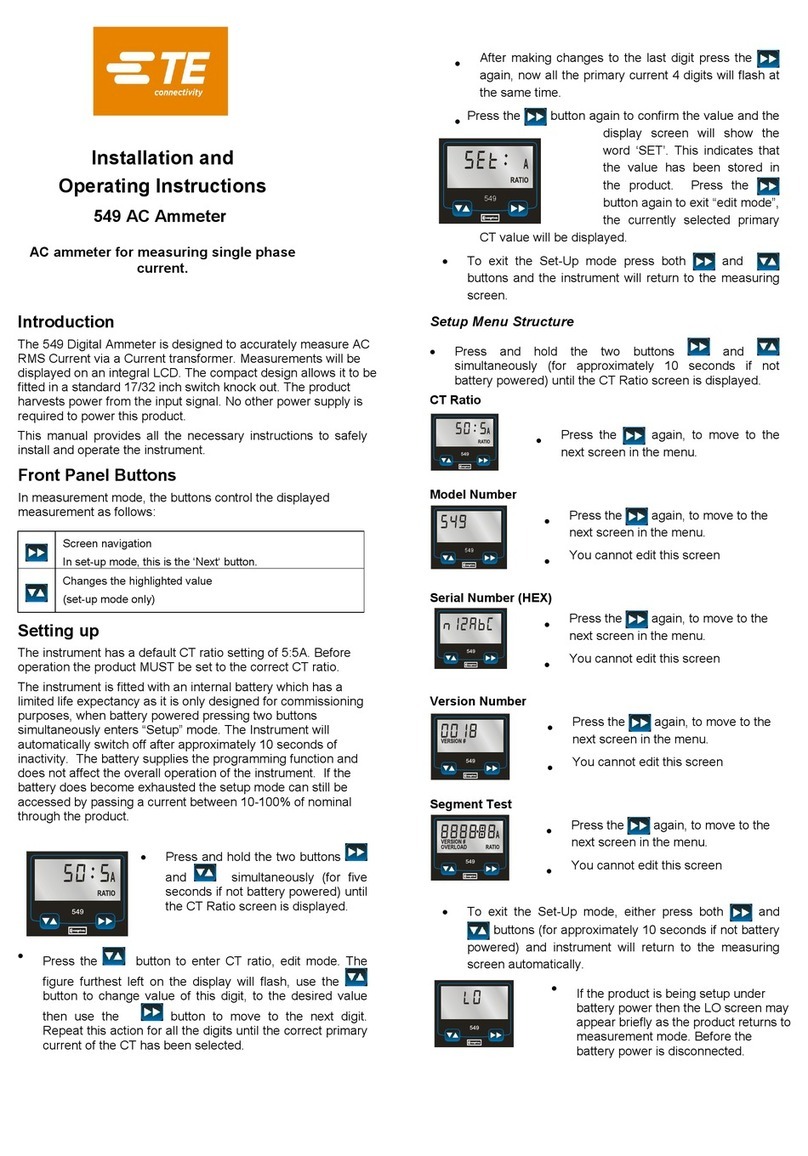

Function Selection Symbols

Selection symbols, shown in

Figure 1-4

, display on the lower right

of the screen.

Warnings/Errors

Select with arrow keys, and press ENTER to get information about

the warning symbols which can appear on the left side of the

screen.

✓Follow the instructions on the screen to solve the error.

Most of the errors can be solved easily. When there are

error codes mentioned, refer to

Chapter 4–Maintenance

for a list of error codes.

Standby

Select with arrow keys, and press ENTER to put the analyzer in

the STANDBY mode. The pump stops running. Press ENTER to

start the pump again. The analyzer does an Auto calibration and a

HC hang-up check. The unit returns to normal operation.

Auto zero

Select with arrow keys, and press ENTER to perform an Auto

calibration/Auto zero. The analyzer performs a forced Auto

calibration/Auto zero followed by a HC hang-up check.

✓If the action symbol appears on the left of the screen,

select Auto zero to correct the error.

Figure 1-4

: Selection Symbols on Measurement Screen

Table of contents

Popular Measuring Instrument manuals by other brands

Extech Instruments

Extech Instruments 250W Series user manual

Agilent Technologies

Agilent Technologies 81200 installation guide

ACIN

ACIN Betz 2500/250 manual

RADIOMETER

RADIOMETER ABL800 FLEX Operator's manual

TE Connectivity

TE Connectivity 549 Installation and operating instructions

Hioki

Hioki 3275 instruction manual