3

SCarefullyplanyoursawingoperationinad-

vance. Donotstartcuttinguntilyouhavea

clearworkarea,securefooting,and,ifyou

are felling trees, a planned retreat path.

OPERATE YOUR SAW SAFELY

SDonotoperateachainsawwithonehand.

Serious injury to theoperator, helpers, by-

standers or any combination of these per-

sons may result from one-handed opera-

tion. A chain saw is intended for

two-handed use.

SOperatethe chainsaw only in awell-venti-

lated outdoor area.

SDo not operate saw from a ladder or in a

tree.

SMake sure thechain will notmakecontact

with any object while starting the engine.

Never try to start the saw when the guide

bar is in a cut.

SDo not put pressure onthe saw at theend

of the cut. Applying pressure can cause

you to lose control when the cut is com-

pleted.

SStop the engine before setting the saw

down.

SDo not operate a chain saw that is dam-

aged, improperly adjusted, or not com-

pletely and securely assembled. Always

replace bar, chain, hand guard, or chain

brakeimmediately ifit becomesdamaged,

broken or is otherwise removed.

SWith the engine stopped, hand carry the

chain saw with the muffler away from your

body, and the guide bar and chain to the

rear, preferably covered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKINGORDER

SHaveall chainsawserviceperformedbya

qualifiedservice dealerwith the exception

of theitems listed in the maintenance sec-

tionofthis manual. Forexample,ifimprop-

er tools are used toremove or hold the fly-

wheelwhenservicingtheclutch,structural

damage to the flywheel can occur and

cause the flywheel to burst.

SMake certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to CARBURETOR AD-

JUSTMENTS.

SNever modify your saw in any way.

SKeepthe handlesdry, clean, andfreeof oil

or fuel mixture.

SKeep fuel and oil caps, screws, and fas-

teners securely tightened.

SUse only Snappert/Poulan!accessories

and replacement parts as recommended.

HANDLE FUEL WITH CAUTION

SDo not smoke while handling fuel or while

operating the saw.

SEliminate all sources of sparks or flame in

the areas where fuel is mixed or poured.

Thereshouldbenosmoking,openflames,

orworkthatcouldcausesparks. Allowen-

gine to cool before refueling.

SMix and pour fuel in an outdoor area on

bare ground; store fuel in a cool, dry, well

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuel spills before starting saw.

SMove at least 10 feet (3 meters) from fuel-

ing site before starting engine.

STurn the engine off and let saw cool in a

non-combustible area, not on dry leaves,

straw, paper, etc. Slowly remove fuel cap

and refuel unit.

SStoretheunitandfuelinanareawherefuel

vapors cannot reach sparks or open

flames from waterheaters,electric motors

or switches, furnaces, etc.

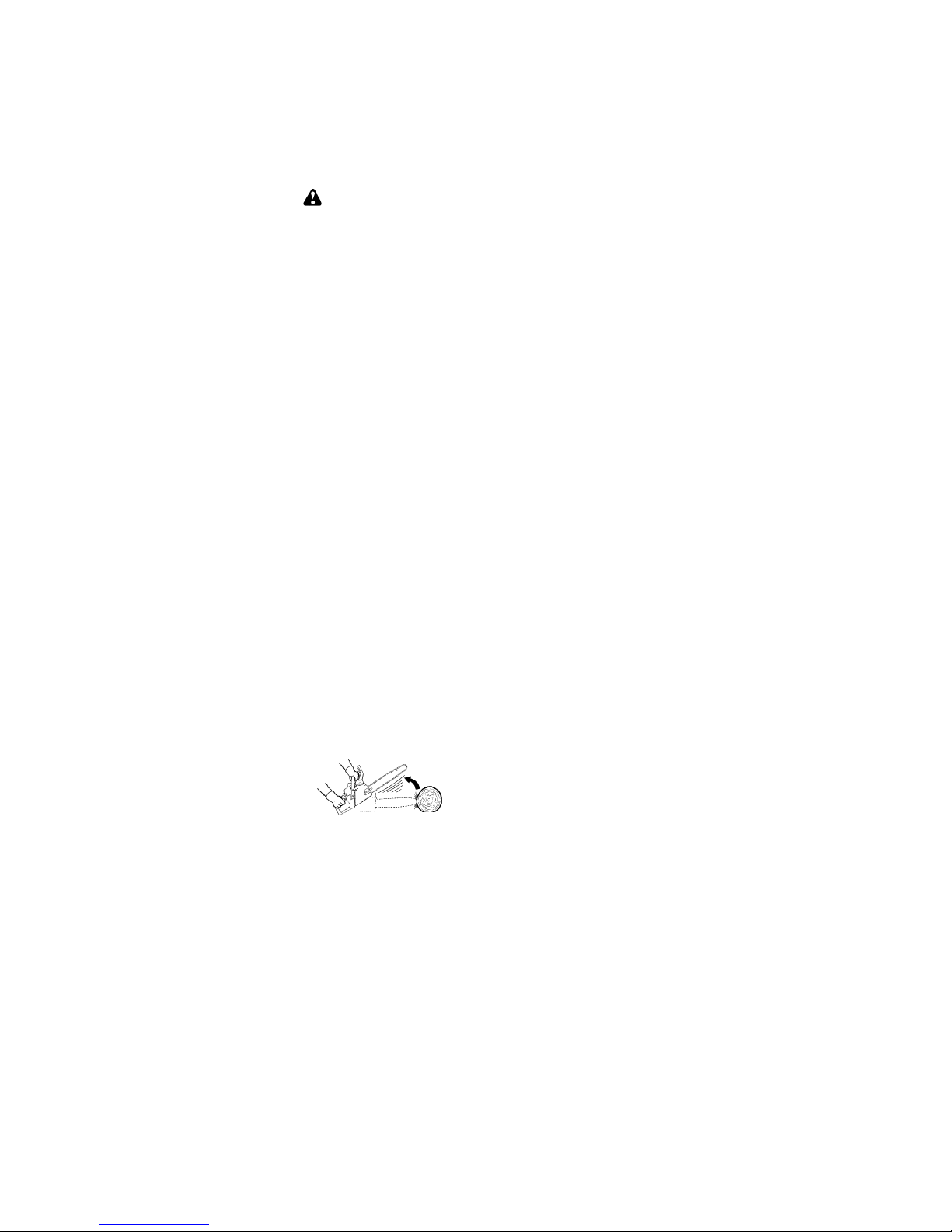

KICKBACK

WARNING: Avoid kickback which

can result in serious injury. Kickbackis the

backward,upwardorsuddenforwardmotion

of the guide bar occurring when the saw

chainneartheuppertip oftheguidebarcon-

tacts any object such as a log or branch, or

when the wood closes in and pinches the

sawchaininthecut.Contactingaforeignob-

ject in the wood can also result in loss of

chain saw control.

SRotationalKickbackcan occur whenthe

moving chain contacts an object at theup-

per tip of the guide bar. This contact can

cause the chain to dig into the object,

which stops the chain for an instant. The

result is a lightning fast, reverse reaction

which kicks the guide bar up and back to-

ward the operator.

SPinch-Kickbackcan occur when the the

wood closes in and pinches the moving

saw chain in the cut along the top of the

guide bar and the saw chain is suddenly

stopped. This sudden stopping of the

chain results in a reversal of the chain

force used to cut wood and causes the

sawtomoveintheoppositedirectionofthe

chain rotation. The saw is driven straight

back toward the operator.

SPull-In can occur when the moving chain

contacts a foreign object in the wood in the

cut along the bottom of the guide bar and the

saw chainis suddenly stopped. This sudden

stopping pulls the saw forward and away

from the operatorand could easily cause the

operator to lose control of the saw.

Avoid Pinch--Kickback:

SBe extremely aware of situations or ob-

structions thatcan causematerial to pinch

the top of or otherwise stop the chain.

SDo not cut more than one log at a time.

SDo not twist the saw as the bar is with-

drawn from an undercut when bucking.

Avoid Pull--In:

SAlways begincutting with theengineatfull

speedandthesawhousingagainst wood.

SUse wedges made of plastic or wood.

Never use metal to hold the cut open.

Kickback Path