SNDWAY SW-6510S User manual

ULTRASONIC THICKNESS GAUGE

SW-6510S

mm

4.27

Scan

Mat:

5920Steel

mmMax

mmMin

mmAvg

ULTRASONIC

THICKNESS GAUGE

User Instruction

Please read this instruction intently before your

first utilization.

1. The instrument is not allowed to disassemble or repair in any

ways.It is forbidden to do any illegal modification or perfor-

mance change for laser emitter. Please keep it out of reach of

children and avoid being used by any irrelevant personnel.

2. Due to electromagnetic radiation interference to other equip-

ment and devices, please don`t use the device in the plane or

around medical equipment and don`t use it in an inflammable,

explosive environment.

3. Discarded batteries or devices shall not be processed just like

household garbage, please handle them in line with related

laws and regulations.

4. If the company's products beyond the warranty period are

faulty, they can be handed over to the company to repair the

product, and the maintenance fee will be charged according

to the company's regulations.

5. The company cannot provide warranty for any damage to the

product caused by the user's own disassembly and assembly

of the company's products, improper transportation, storage,

or failure to operate according to the product manual, as well

as unauthorized alteration of the warranty card without proof

of purchase.

6. If there is any quality problem with the instrument, or if you

have any questions about the use of the instrument, please

contact the local distributor or manufacturer in time, and we

will solve it for you as soon as possible.

- 01 -

2 Overview

1 Packing List

This instrument is an intelligent ultrasonic thickness gauge. It

adopts the latest high-performance, low-power microprocessor

technology. Based on the principle of ultrasonic measurement,

it can measure the thickness of metals and other materials, and

can measure the sound speed of materials. It can monitor

various pipes and pressure vessels in production equipment,

monitor their thinning degree after being corroded during use,

and can also accurately measure various plates and various

processed parts. This instrument can be widely used in

petroleum, chemical industry, metallurgy, shipbuilding, aviation,

aerospace and other fields.

No. Names Quantity Remark

1 User Manual 1PC

1PC

1PC

1PC

1PC

1PC

2

3Standard Probe(5mhz Ф10)

4 Coupling Agent

5 Portable Package

6 USB Cable

The Meter

Standard Configuration

- 02 -

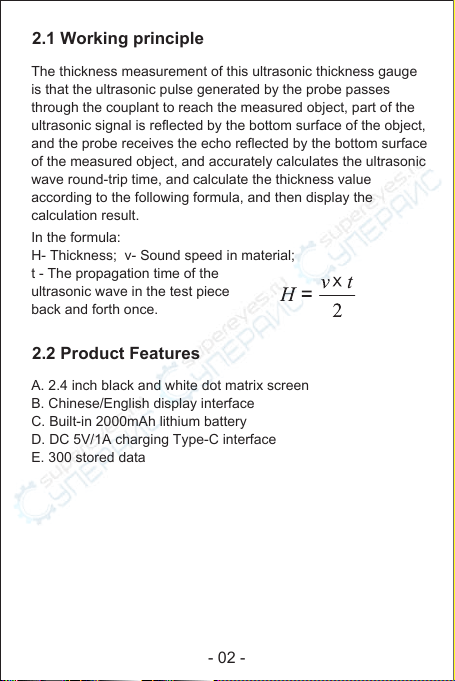

2.2 Product Features

A. 2.4 inch black and white dot matrix screen

B. Chinese/English display interface

C. Built-in 2000mAh lithium battery

D. DC 5V/1A charging Type-C interface

E. 300 stored data

2.1 Working principle

The thickness measurement of this ultrasonic thickness gauge

is that the ultrasonic pulse generated by the probe passes

through the couplant to reach the measured object, part of the

ultrasonic signal is reflected by the bottom surface of the object,

and the probe receives the echo reflected by the bottom surface

of the measured object, and accurately calculates the ultrasonic

wave round-trip time, and calculate the thickness value

according to the following formula, and then display the

calculation result.

In the formula:

H- Thickness; v- Sound speed in material;

t - The propagation time of the

ultrasonic wave in the test piece

back and forth once.

- 03 -

2.3 Technical Parameter

Note: 1) The standard probe of the instrument cannot use oily

couplant, otherwise the probe will be damaged! After using

the probe, wipe off any residual couplant on the probe to

prolong the life of the probe.

2) Please try to avoid using it in an oily environment. If it is

unavoidable, try to reduce the contact time with oily substances

as much as possible, and after use, dry the probe surface with

oil-absorbing paper.

300 sets, each set including current material,

Velocity of Sound, Unit, Measuring Value, the

MAX value, the MIN value and Average Value

Display 2.4 inch black and white dot matrix screen

Sound Velocity (1000~9999) m/s

Lower limit of pipe

measurement Ф20*3mm(steel)

Battery Built-in 3.7V 2000mAh Li-ion battery

Battery life

(fully charged) About 16 hours

Charging

specification DC5V 1A Type-C interface

Working Temperature

& Humidity 0°C~40°C, 10%RH~80%RH

Storage Temperature

& Humidity -10°C~+50°C, 10%RH~70%RH

Dimension 140x66x28.5mm

Unit 0.1mm / 0.01mm / 0.01in

Language Chinese / English

Measuring Range 1.00~300.00mm(the steel)

Main Functions

Single Measurement, Continuous

Measurement, Alarm Measurement,

Sound Velocity Measurement, Calibration

Accuracy H<10mm, ±0.1mm; H≥10mm, ±(1%H+0.1)mm

H is the thickness of the object

Storage capacity

ITEMS SW-6510S

- 04 -

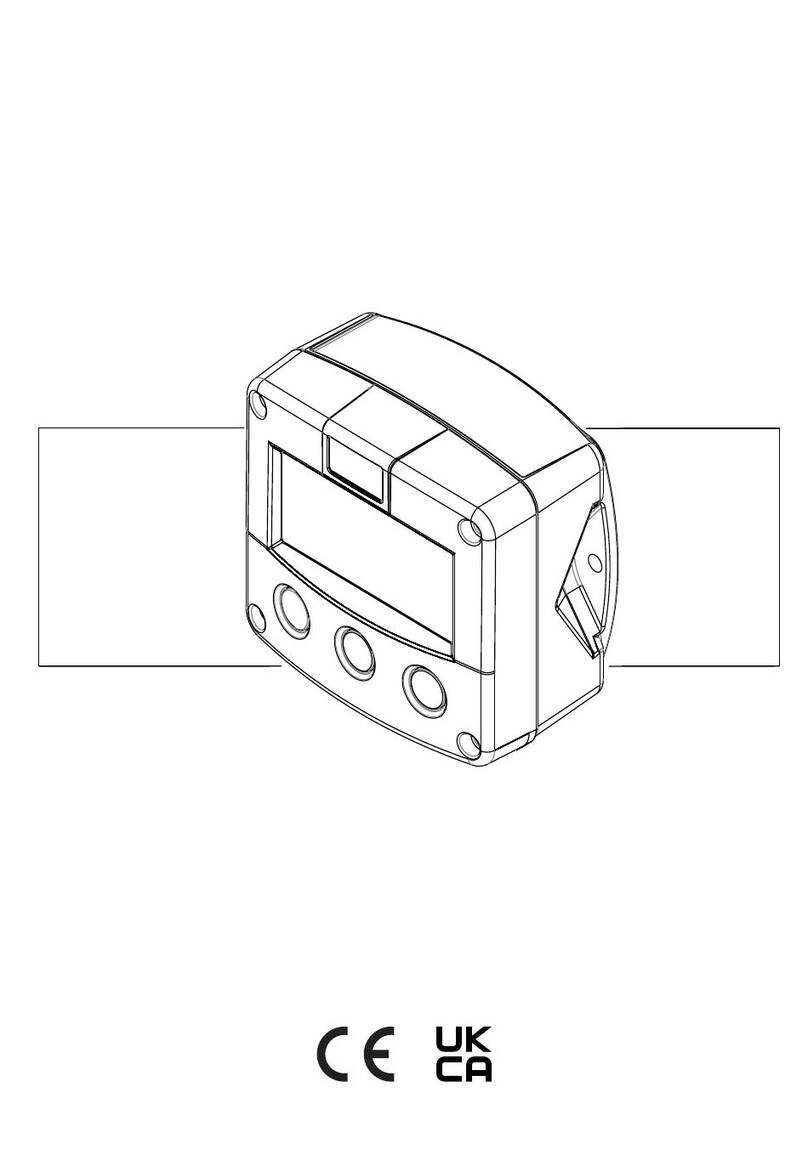

3 Structure and appearance

1. Housing 2. Buttons 3. Display

4. Transmitter socket 5. Receiver socket

6. Thickness calibration block 7. Nameplate

8. Ultrasonic thickness probe (probe for short)

7

mm

20.00

Scan

Mat:

5920Steel

mmMax

mmMin

mmAvg

3

2

1

8

45

6

- 05 -

4 Charging and maintenance of lithium battery

3.1 Main Display Interface

After the instrument is turned on, it will automatically enter the

main display interface, as shown in the following figure:

1) Coupling state: the coupling state between the probe and

the workpiece to be measured

2) Measurement mode: display the current measurement mode

3) Unit system: mm (in metric system), or in (in imperial system)

4) Battery power: Display of remaining battery power

5) Sound indication: alarm sound switch display

6) Information display: display thickness measurement value,

measurement material, sound speed, maximum, minimum,

average;

The product is powered by a built-in 3.7V 2000mAh lithium

battery, which is not removable. When the product cannot be

turned on or the battery is empty after turning on, please

charge it in time. Please use a DC5V, more than 1A charging

adapter to charge the product, and the charging port is Type-C.

While charging, the battery symbol scrolls to display.

When fully charged, the battery symbol becomes full.

mm4.42

Scan

Mat:

5920Custom 1

4.50mmMax

4.42mmMin

4.43mmAvg

1

5

4

3

6

2

- 06 -

A. Prepare the tested workpiece, refer to "6.1 Surface

Treatment of Measured Workpiece".

B. Insert the probe into the instrument and turn it on.

C. Instrument calibration. Refer to "7.5 Instrument Calibration".

D. Inversely measure the speed of sound. The sound speed of

the workpiece is uncertain, and the sound speed must be

measured back to obtain the correct sound speed of the

workpiece. Refer to "7.6 Reverse Measurement of Sound

Velocity".

E. Measure the thickness. Use the inversely measured sound

velocity value to measure the thickness of the workpiece of

the same material.

Note: When not in use for a long time, fully charge the product

first, and recharge it every six months to avoid battery damage.

6 Preparation before measurement

5 The general measurement process of the

instrument

6.1 Surface treatment of the workpiece to

be tested

If the surface of the object to be measured is rough or severely

corroded, please use the following methods:

● Use couplant on the surface of the measured object;

● Use rust remover, wire brush or sandpaper to treat the

surface of the measured object

● Multiple measurements around the same point

- 07 -

7 Instrument use

7.1 Turning the instrument on and off

Power on: Insert the probe into the instrument, short press the

key to power on.

Power off: long press the key to power off.

Automatic shutdown: the instrument will automatically shut

down if there is no operation, and the default time is 5 minutes.

Users can change the automatic shutdown time, refer to

"7.18 Shutdown Settings".

Forced shutdown: long press the power button for more than

10 seconds to force shutdown.

Apply the couplant evenly to the tested area, tightly couple the

probe to the surface of the tested material, and the screen will

display the thickness of the tested area. When the probe and

the material to be tested are well coupled, the screen will display

the coupling mark . If the coupling mark flashes or there is no

coupling mark, it means that the coupling is not good and needs

to be added with couplant. When the probe is removed, the

coupling symbol disappears and the thickness value remains.

7.2 single measurement

Figure 1. Add couplant.

- 08 -

Figure 2. Smear the couplant evenly, and tightly couple the

probe to the surface of the material to be tested.

Apply the couplant evenly to the measured area, then couple

the probe to the workpiece and move it along the surface of the

workpiece. The instrument will display the current value,

maximum value, minimum value and average value of the

measurement in real time.

7.3 Continuous measurement

7.4 Alarm measurement

The user can monitor the material with poor quality through the

alarm function. Press and hold to turn the alarm on or off.

The displayed on the screen means to open the alarm

measurement, and the displayed on the screen means to

close the alarm measurement.

For example:

Alarm setting: Standard value: 4.00mm

Tolerance limit: ±0.1mm (Refer to "7.19 Alarm Setting" for alarm

setting) When the measured thickness is less than 3.90mm or

greater than 4.10mm, the instrument will continuously issue a

- 09 -

7.5 Instrument calibration

Note: Probe calibration should be performed every time the

probe is replaced, the ambient temperature changes greatly, or

the measurement deviates.

When the instrument is used for the first time or has not been

used for a long time, please calibrate it first. Calibration must

use the calibration thickness block provided by the manufacturer.

After calibration, the material automatically becomes steel, and

the speed of sound becomes 5920m/s (0.233in/us).

"Beep beep beep" alarm sound, at this time, the thickness of

the object is detected to be unqualified. After the alarm, the user

can press any key to exit the alarm, or continue to measure.

1) Press and hold to enter the calibration mode, and the

screen displays "Please measure the calibration thickness

block" .

2) Referring to Figure 1 and Figure 2 in "7.2 Single

Measurement", apply the couplant evenly to the surface of

the standard thickness block on the case, and press the

probe on the couplant to make it in close and uniform contact

with the surface of the thickness block ; (Note: Do not apply

the couplant too thick, otherwise the instrument will record

the thickness of the couplant, resulting in a calibration error).

3) After the measured value is stable, press again to save

the calibration data. (Note: Before pressing , the displayed

value may not be 4mm. Please press again when the

value is stable. After calibration, the displayed value should

be within the range of 4±0.04mm, otherwise re-calibrate).

The calibration operation is as follows:

- 10 -

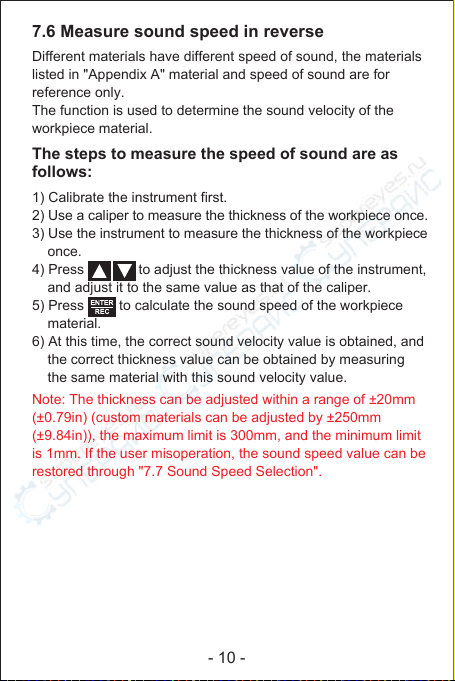

Different materials have different speed of sound, the materials

listed in "Appendix A" material and speed of sound are for

reference only.

The function is used to determine the sound velocity of the

workpiece material.

The steps to measure the speed of sound are as

follows:

1) Calibrate the instrument first.

2) Use a caliper to measure the thickness of the workpiece once.

3) Use the instrument to measure the thickness of the workpiece

once.

4) Press to adjust the thickness value of the instrument,

and adjust it to the same value as that of the caliper.

5) Press to calculate the sound speed of the workpiece

material.

6) At this time, the correct sound velocity value is obtained, and

the correct thickness value can be obtained by measuring

the same material with this sound velocity value.

Note: The thickness can be adjusted within a range of ±20mm

(±0.79in) (custom materials can be adjusted by ±250mm

(±9.84in)), the maximum limit is 300mm, and the minimum limit

is 1mm. If the user misoperation, the sound speed value can be

restored through "7.7 Sound Speed Selection".

7.6 Measure sound speed in reverse

- 11 -

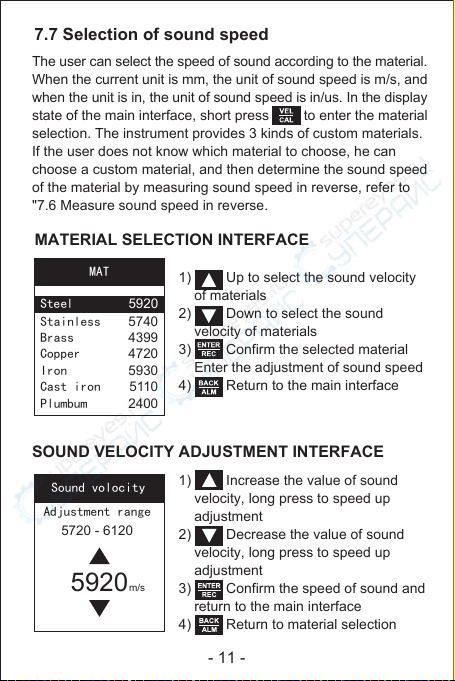

1) Up to select the sound velocity

of materials

2) Down to select the sound

velocity of materials

3) Confirm the selected material

Enter the adjustment of sound speed

4) Return to the main interface

Sound volocity

5920m/s

5720 - 6120

Adjustment range

1) Increase the value of sound

velocity, long press to speed up

adjustment

2) Decrease the value of sound

velocity, long press to speed up

adjustment

3) Confirm the speed of sound and

return to the main interface

4) Return to material selection

The user can select the speed of sound according to the material.

When the current unit is mm, the unit of sound speed is m/s, and

when the unit is in, the unit of sound speed is in/us. In the display

state of the main interface, short press to enter the material

selection. The instrument provides 3 kinds of custom materials.

If the user does not know which material to choose, he can

choose a custom material, and then determine the sound speed

of the material by measuring sound speed in reverse, refer to

"7.6 Measure sound speed in reverse.

7.7 Selection of sound speed

MATERIAL SELECTION INTERFACE

SOUND VELOCITY ADJUSTMENT INTERFACE

MAT

Stainless

Brass

Copper

Iron

Cast iron

Plumbum

5740

4399

4720

5930

5110

2400

Steel 5920

- 12 -

In single measurement and continuous measurement, long

press to save records, each record includes current

measurement value, maximum value, minimum value, average

value, and material sound velocity. The instrument can store up

to 300 sets of records. For viewing and deleting records, please

refer to "7.14 Recording Operation". Results of continuous

measurement cannot be saved until the probe is removed.

During measurement, measurement results cannot be saved to

prevent unstable data from being stored.

In single measurement and continuous measurement, short

press to clear the current measurement result (including

maximum value, minimum value and average value).

Continuous measurements do not clear the measurement until

the probe is removed.

7.8 CLEAR MEASUREMENT RESULT

7.9 Storage function

- 13 -

7.11 MATERIAL SELECTION

1) Select the previous option

2) Select the next option

3) Enter the selected option

4) Exit the menu and return to the

main interface

7.10 MENU

The menu includes: material selection, sound speed adjustment,

unit, recording operation, system setting, about, and factory

reset. Long press to enter the menu, the operation is as

follows:

Select from the menu.

1) Up to select material

2) Down to select material

3) Confirm the selected material

and return to the menu

4) Return to menu

Menu

Speed

Unit

Records

Setting

About

Reset

Material

Mat

Custom 1 5920

Custom 2

Custom 3

Aluminum

Steel

Stainless

Brass

5920

5900

6370

5920

5740

4399

Material

- 14-

Unit

0.1mm

0.01mm

0.01in

Select in the menu to adjust the range of sound speed

settings: The default value is ±200m/s (0.008in/us), and the

adjustable range of custom materials is: 1000m/s to 9999m/s

(0.039in/us to 0.394in/us).

1) Increase the value of sound

velocity, long press to speed up

adjustment

2) Decrease the value of sound

velocity,long press to speed up

adjustment

3) Save and return to menu

4) Return to menu

7.13 UNIT SETTINGS

7.12 THE ADJUSTMENT OF SOUND VELOCITY

Select in the menu.

Unit

1) Up to select units

2) Down to select units

3) Save and return to menu

4) Return to menu

Spd

5920m/s

Speed

- 15 -

DATA

002 4.44mm

003 4.42mm

001 4.50mm

Select the "Browse from the first page" function in the record

operation interface, the instrument will display the record list

from the first page of records, and display the record number

and current value of each record.

1) Page up

2) Page down

3) Enter the selected page

4) Return to the record interface

1) Up to choose functions

2) Down to choose functions

3) Enter the selected functions

4) Return to the menu

Select in the menu. When the instrument has no

record, it will prompt "no stored value" and cannot enter the

record operation.

7.14 RECORD

7.14.1 Browse from the first page

Records

first page

last page

selected item

Delete the item

Delete all

Records

- 16 -

In the record operation interface, select the "Browse from

selected group" function, the user selects the record to be

browsed, the instrument displays the record list from the page

where the record is located, and displays the record number

and current value of each record.

In the record list and record details functions, the user can long

press to delete the currently browsed record. Short press

to view the previous or next record details.

View record details: Enter the selected page, press

to select the record number, and press to view the details

(details include record number, current value, maximum value,

minimum value, and current value). After viewing details, short

press to return to the record list.

Select the "Browse from the last page" function in the record

operation interface, the instrument will display the record list

from the last page of records, and display the record number

and current value of each record. Please refer to 7.14.1. for

the operation.

7.14.2 Browse from the last page

7.14.3 Browse from selected groups

Data

001

4.50mm

Mat:

Custom 1 5920

Max: 4.50mm

Min: 4.50mm

Avg: 4.50mm

- 17 -

Select group

Select group

From 001 to 009

001

Del Group

group range

(001--009)

From to 001

001

1) Adjust the record number

2) Confirm the number of digits

currently modified (hundreds/tens/

units of record number), When the

units digit is confirmed, enter the

selected record number

3) Return to the record operation

interface

7.14.4 Deleted selected groups

In the record operation interface, select the "Delete Selected

Group" function, and the user can select the record to be deleted.

Deletion prompt: In this interface, the user can confirm whether

to delete. Use to select "Yes/No", select Yes, press

to delete; select No, press to return to the interface to

delete the selected group. Press to directly return to the

delete selected group interface.

It will take a while to delete the record,

and the instrument will prompt that it is

being deleted.

1) Adjust the record number

2) Confirm the number of digits

currently modified (Hundreds digit of

start record/end record/tens/units),

when the unit of the record is

terminated, enter the deletion prompt

3) Return to the record operation

interface

Deletion

Yes No

Delete

001-001

- 18-

Setting

Back light

Power off

Alarm

Language

Sound

Del

Do you confirm

to Delete all

saved data?

Yes No

7.15 system settings

Select in the menu.

Setting

1) Up to select functions

2) Down to select the function

3) Enter the selected function

4) Return to menu

Select the "Delete All" function in the record operation interface,

the user can choose to delete all records. Use to select

"Yes/No", select Yes, press to delete all records; select No,

press to return to the record operation interface. Press

to directly return to the record operation interface.

7.14.5 Delete all records

Table of contents