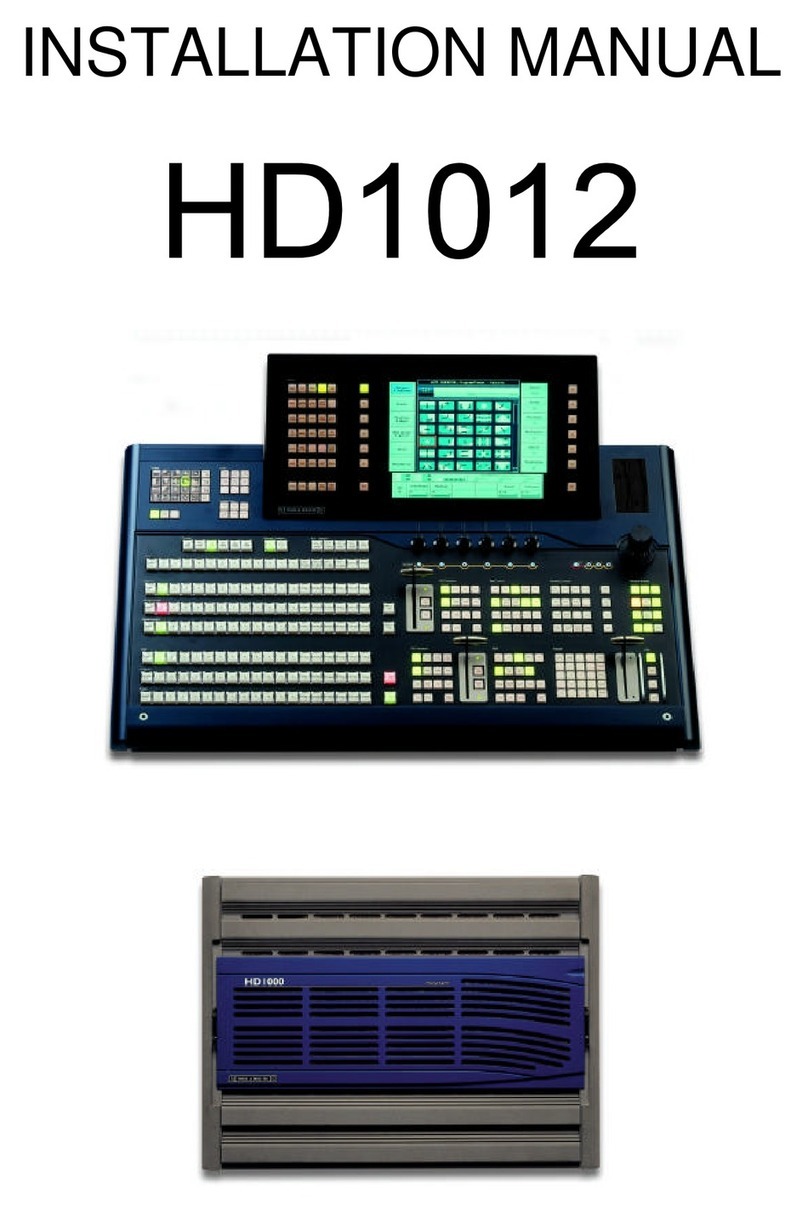

S&W Production & Post Production SD1012 Installation Manual - Issue 6, Rev 1 Page vii

CONTENTS

SECTION A - INSTALLATION............................................................................................. 1

ELECTRICAL SUPPLY CONNECTION ....................................................................................... 2

ON DELIVERY OF THE SYSTEM ............................................................................................... 3

LOCATION AND ENVIRONMENT ............................................................................................... 4

Environmental Considerations ........................................................................................... 4

Location ............................................................................................................................. 4

Control Panel Installation ................................................................................................... 4

Power Supplies .................................................................................................................. 5

Fusing ................................................................................................................................ 5

SYSTEM INTERCONNECTION ................................................................................................. 6

Introduction ........................................................................................................................ 6

Control Panel ..................................................................................................................... 6

Power ................................................................................................................................. 6

Inputs ................................................................................................................................. 9

Connecting to an Alternate Mainframe .............................................................................. 9

Referencing ........................................................................................................................ 9

Referencing - Input Timing ................................................................................................. 9

Referencing - System Delays ............................................................................................ 10

Outputs .............................................................................................................................. 10

Timings for VTR Pre-Read ................................................................................................. 12

CONTROL PORTS AND PROTOCOLS ...................................................................................... 14

Ports .................................................................................................................................. 14

FTP - Connecting to a PC .................................................................................................. 14

GVG 100 ............................................................................................................................ 14

GVG 4000 .......................................................................................................................... 15

Sony DVS .......................................................................................................................... 16

Using a Sony BVE-9100 Editor .......................................................................................... 18

VTR ................................................................................................................................... 20

Follow Real VTR ................................................................................................................ 20

S & W Tally ........................................................................................................................ 21

S & W Router ..................................................................................................................... 21

Aux ..................................................................................................................................... 21

Probel TX320 & DVE ......................................................................................................... 21

BBC Camera ..................................................................................................................... 21

Button Bus ......................................................................................................................... 21

P-Bus ................................................................................................................................. 21

General Purpose Inputs & Outputs ................................................................................... 22

The Inputs ................................................................................................................ 22

The Outputs ............................................................................................................ 23

Programming the Inputs ........................................................................................ 24

Programming the Outputs ........................................................................................ 25

Multiple Conditions .................................................................................................. 26

List of GPO Occurences .......................................................................................... 27

OTHER INSTALLATION PROCEDURES .................................................................................... 28

Setting the Real-Time Clock .............................................................................................. 28

System Reboot .................................................................................................................. 28

System Settings ................................................................................................................ 28

Remote Allocation of Aux Sources .................................................................................... 29

CONNECTOR PINOUTS ............................................................................................................. 32

Mainframe RS-422 & RS-232 ............................................................................................ 32

Tally & GPI ......................................................................................................................... 33

Control Panel to LCD......................................................................................................... 34

SECTION B - SPECIFICATIONS ........................................................................................ 37