Lit. No. 30118, Rev. 00 June 15, 2020

TABLE OF CONTENTS

INTRODUCTION ..............................................................................................4

Recommended Tools...................................................................................4

Available Service Items ...............................................................................4

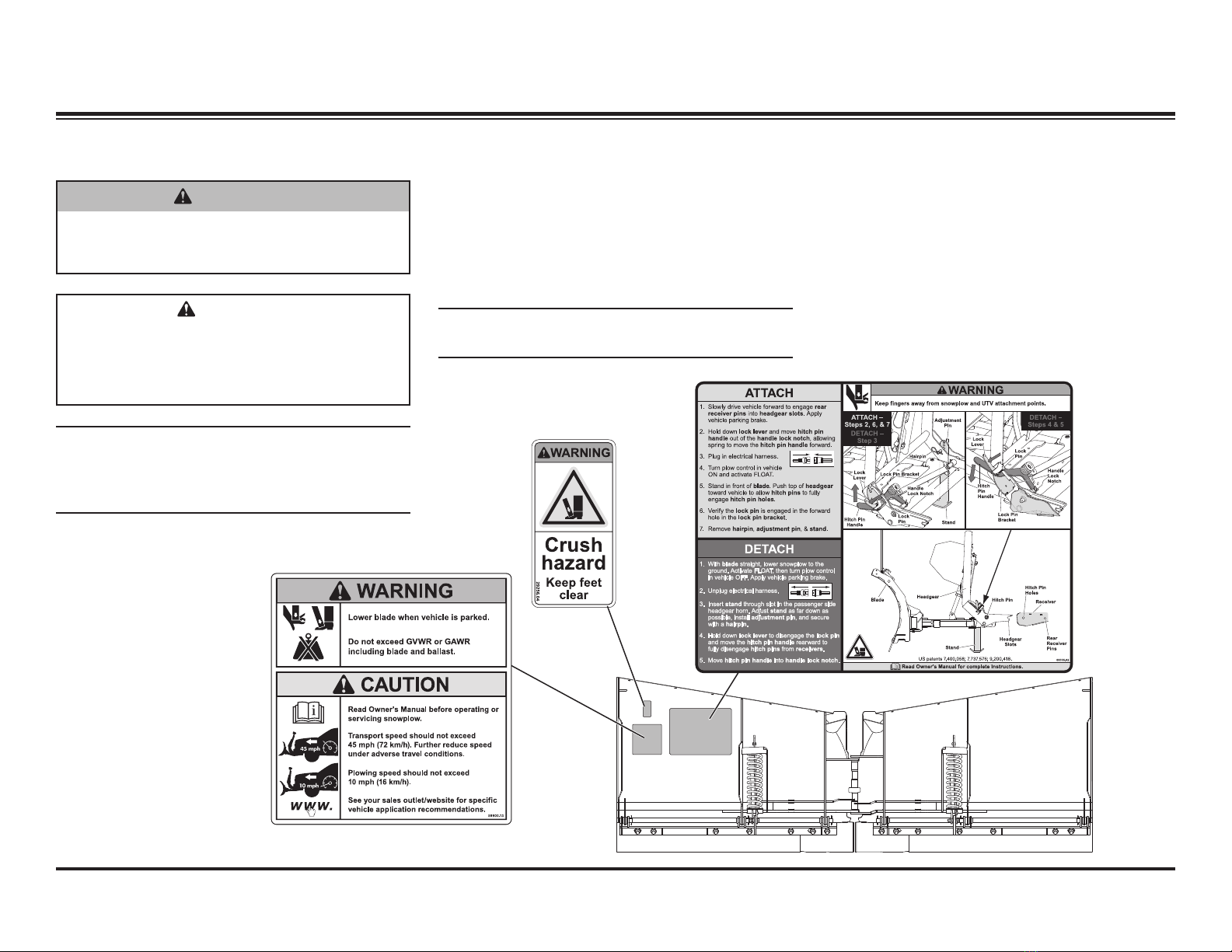

SAFETY ............................................................................................................5

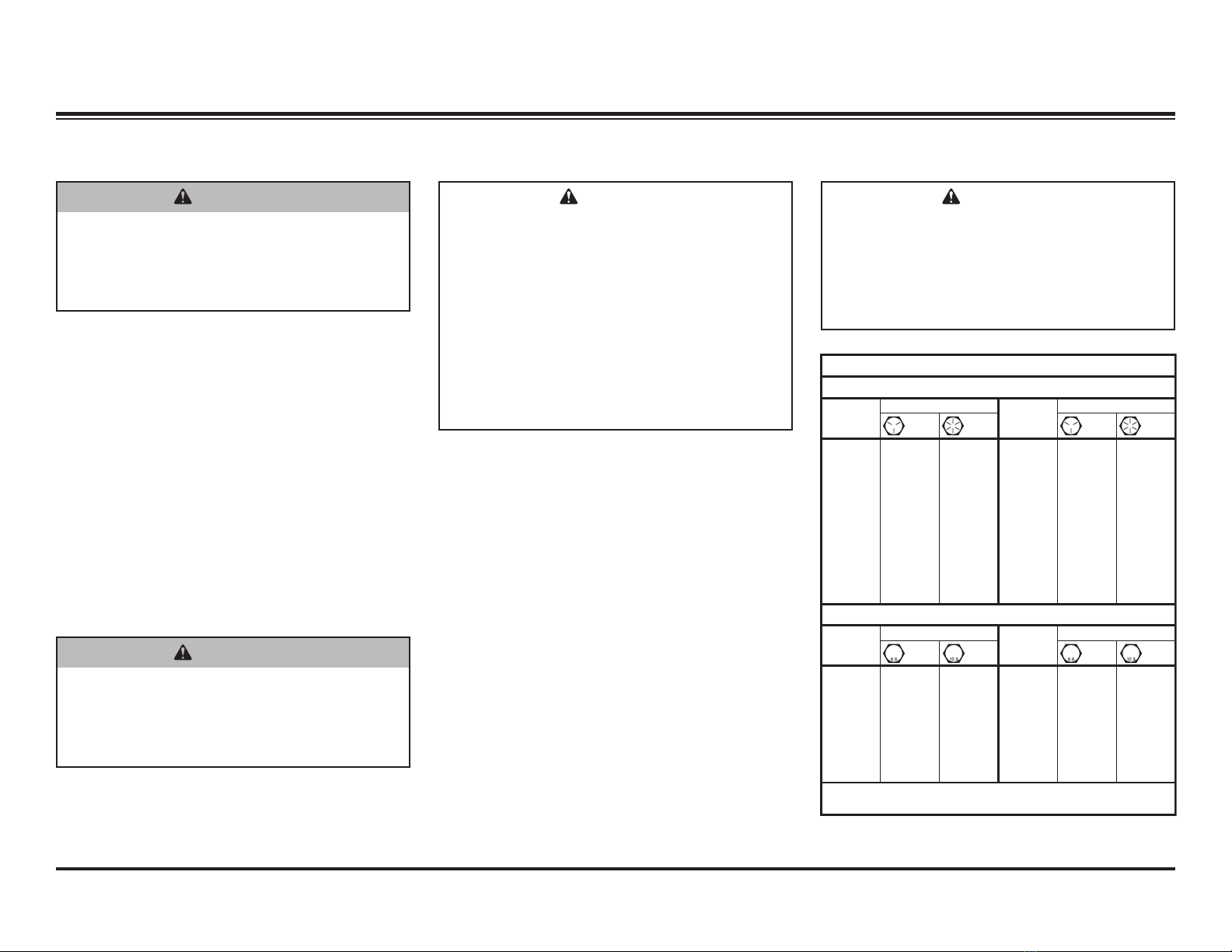

Torque Chart ................................................................................................7

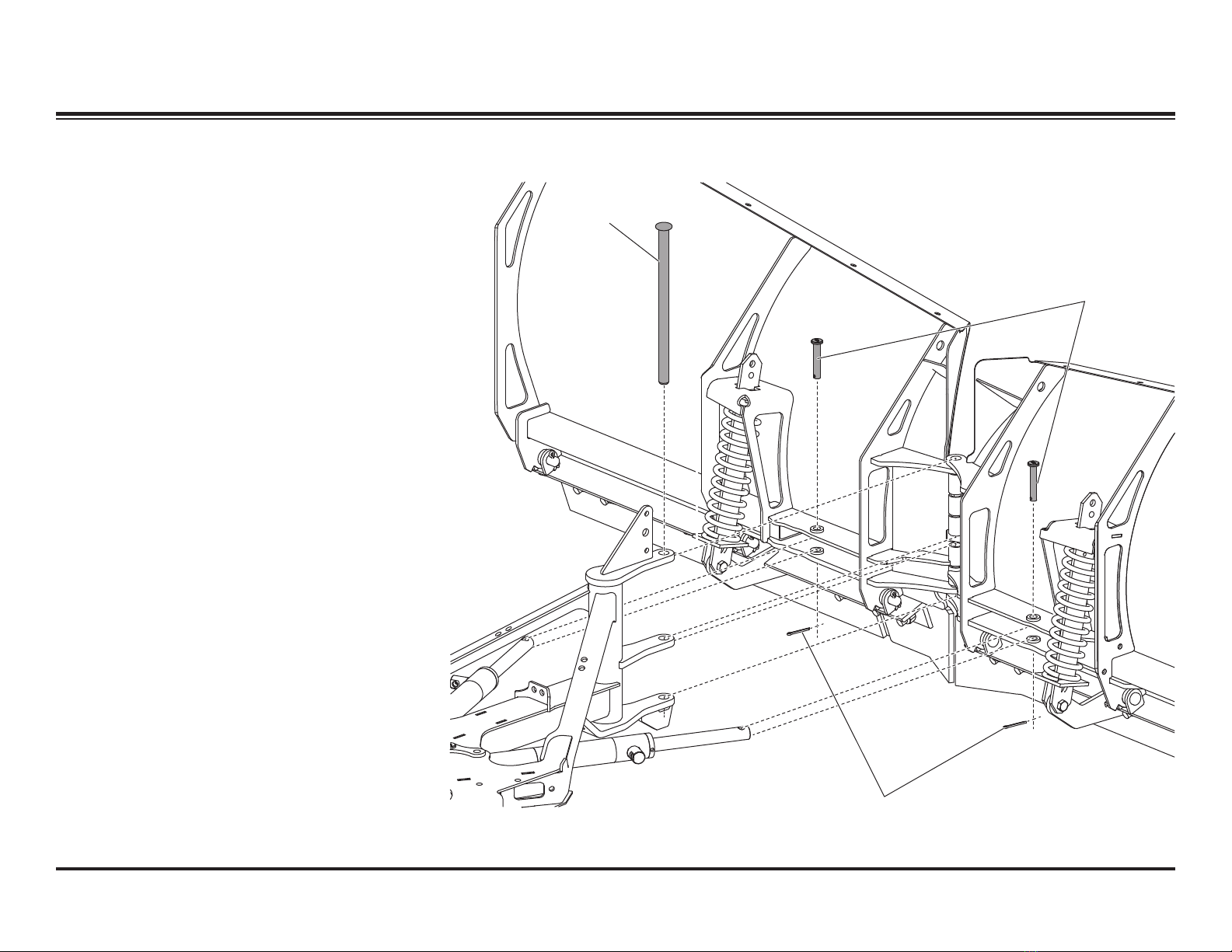

BLADE, T-FRAME & HEADGEAR.................................................................8

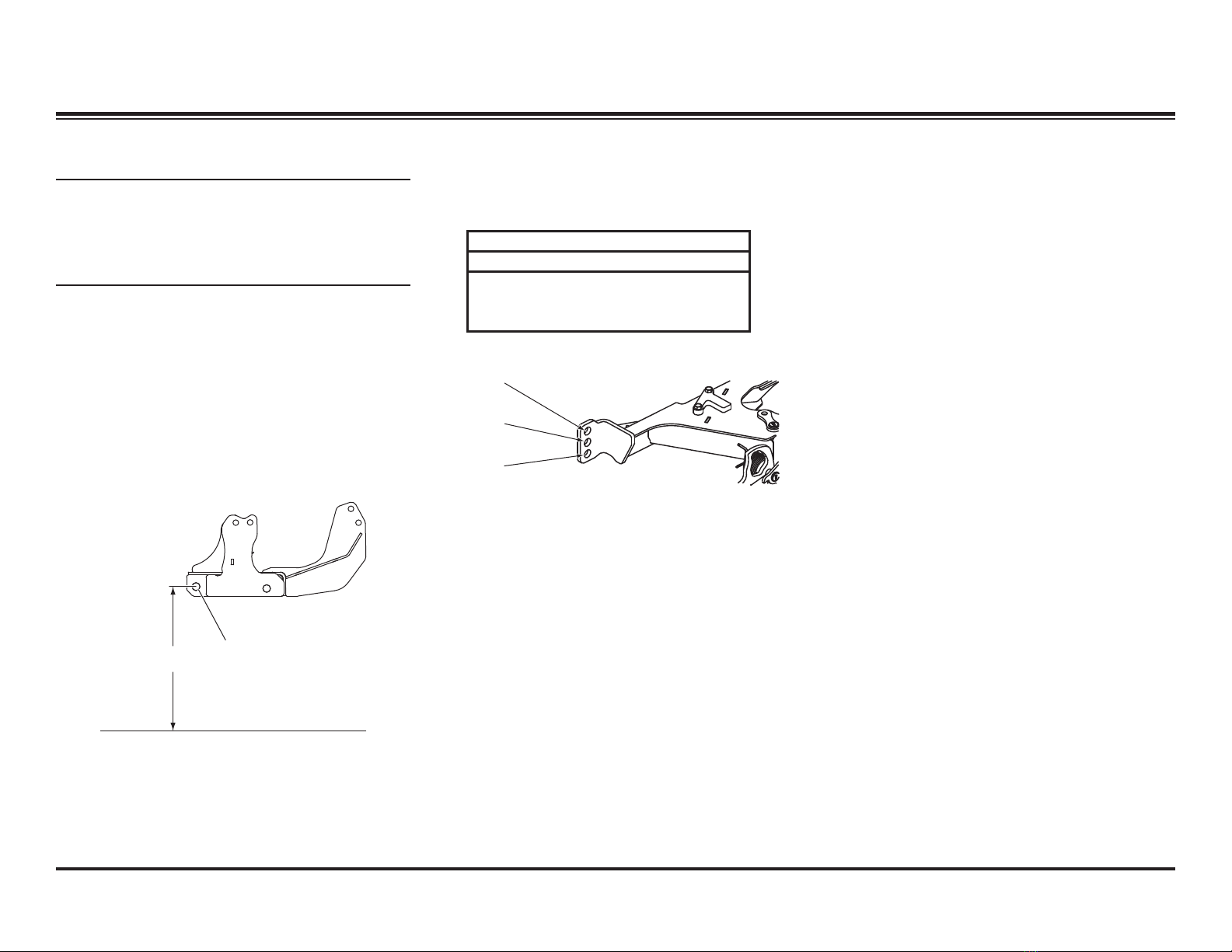

T-Frame Hole Position .................................................................................8

T-Frame to Blade Assembly ........................................................................9

Center Deflector, Blade Guides, and Angle Ram Adjustment ...................11

Using the Blade Spring Replacement Tool ................................................12

HYDRAULIC SYSTEM ..................................................................................13

Hydraulic System Specifications................................................................13

Hydraulic Unit Components .......................................................................14

Valve Location ...........................................................................................15

Cartridge Valves ........................................................................................16

Check Valves and Relief Valves ................................................................17

Hydraulic Fitting and Hose Installation ......................................................18

Ram Seal Installation.................................................................................19

Cartridge and Check Valve Removal........................................................ 20

Blade Drop Speed Adjustment ................................................................. 20

VEHICLE-SIDE ELECTRICAL COMPONENTS .........................................21

Harness Diagram.......................................................................................21

Harness Diagram – LED Headlamps........................................................ 22

CONTROLS – FLEET FLEX ELECTRICAL SYSTEM............................... 23

Overview................................................................................................... 23

Operating the POWER GRIP™ Hand-Held Control..................................24

Operating the Joystick Control.................................................................. 26

FLEET FLEX ELECTRICAL SYSTEM .........................................................28

Smooth Stop and One-Touch Float Features ............................................28

SECURITY GUARD™ Snowplow Anti-Theft System ............................... 29

ELECTRICAL & HYDRAULIC SCHEMATICS............................................32

Legend – Electrical & Hydraulic Symbols..................................................32

Electrical Schematic – RDV™ V-Plow...................................................... 33

Hydraulic Schematic – RDV V-Plow ......................................................... 34

Raise......................................................................................................... 35

Lower/Float ................................................................................................37

Angle Right .............................................................................................. 39

Angle Left ..................................................................................................41

BUCKET BLADE™ (Vee) ......................................................................... 43

Compact (Scoop) ...................................................................................... 45

Right (PS) Wing Extend .............................................................................47

Right (PS) Wing Retract............................................................................ 49

Left (DS) Wing Extend ...............................................................................51

Left (DS) Wing Retract.............................................................................. 53

Hold in Raise Position .............................................................................. 55

Striking an Object While Plowing Forward ............................................... 56

Striking an Object While Back Dragging....................................................57

Detach....................................................................................................... 58

Attach........................................................................................................ 59

Scrape Maxx™ Down Force Kit................................................................ 60

Headlamps.................................................................................................62

Electrical/Harnesses...............................................................................62

Electrical Schematics ............................................................................ 63

TROUBLESHOOTING.................................................................................. 69

How to Use the Troubleshooting Guide .....................................................70

Electrical Testing........................................................................................70

Fuse Replacement.....................................................................................70

Before You Begin .......................................................................................71

Solenoid Coil Activation Test (SCAT).........................................................72

Individual Solenoid Coil Test......................................................................75

Control/Cable/Plow Module Test ...............................................................76

Motor and Motor Relay Test...................................................................... 77

Pump Pressure Test ..................................................................................78

Relief Valve Inspection and Adjustment ....................................................79

Scrape Lock Adjustment........................................................................... 80

Replacing Damaged Bearing Sleeves .......................................................82