4 © TrynEx International 2013 (REV A) F51067A

Safety

See additional Safety Information at the beginning of Operating Instructions and Maintenance Instructions

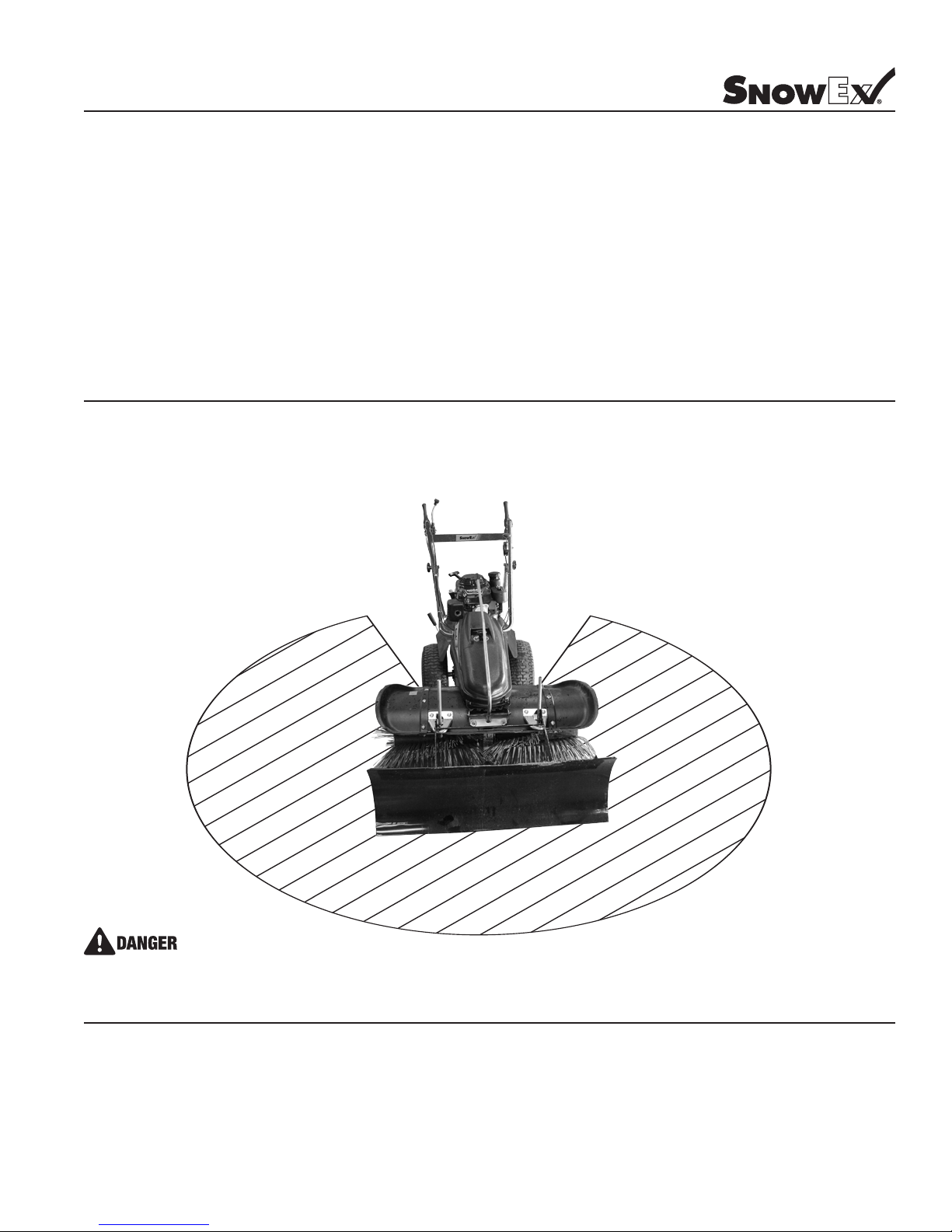

Your SS-4000 is manufactured to state-of-the-art technical regulations. Despite this, it is possible that

operation will result in danger to life and limb for the operator or third parties, impairments to the machine

and other physical assets.

The machine is intended exclusively for use for brushing operations in property maintenance and snow

clearance. Examples of intended use are: snow clearing; sidewalk, driveway & parking lot cleaning (with

multi-purposebrushes);springdebrisclean-up;dethatching;clearingdebrisfromarticialturf;andleaf

clean-up (with Multi-Purpose brushes). Any operation over and above these uses will be considered as a

non-intended use. SnowEx will not be held liable for any resulting damages. The operator alone is respon-

sible for any risk. Intended Use also includes observance of the Owner’s Manual and keeping to all service

and maintenance procedures.

Always keep the Owner’s Manual available at the machine’s place of work. In addition to this Owner’s

Manual, furnish all users with information regarding legal or other important regulations regarding accident

prevention. These duties can include handling hazardous materials; wearing personal safety equipment; and

trafcregulations.YoushouldsupplementthisOwner’sManualwithinstructionscoveringinformationrelated

touseofpoweredmachinery;andoperatingequipmentnearpeople,othermachinesandtrafc.

Donotsmokeorhaveanyopenamenearthemachine.Gasolinevaporscouldexplode.

Only use the machine in perfect condition and according to applicable regulations. Be aware of your sur-

roundings and alert to what you are doing to reduce hazards. You should always repair faults which could

inuencethesafetyofthemachine.

Personnel operating the machine must read the Owner’s Manual before using – especially all safety in-

formation. This includes people who occasionally work on or operate the machine such as for service and

transport. A clear understanding of how to operate the machine will reduce dangers involved with operating

powered equipment.

You must check that personnel operating the machine are paying attention to safety and hazards and under

observance of this Owner’s Manual. Operating personnel may not have long hair, or wear loose clothing or

jewelry, including rings – these items can catch and be pulled in by moving parts.

Keep all safety and hazard information for the machine complete and in readable condition. If the machine is

altered with regard to its safety or changes its operational behavior, stop operation immediately and report

the malfunction to the responsible department or person.

The SS-4000 may only be operated with brushes approved by SnowEx.

Donotcarryoutanyalteration,additionorrebuildingtothemachinewhichcouldinuenceitssafeopera-

tion. This especially applies to addition and alteration to safety devices and machine controls, and to welding

work on load-bearing components.

Personal protection equipment must be worn to prevent accidental injury. Observe all safety and hazard

information for the machine.

Rotatingbrushescauseyingdebris,wearsafetyglasseswithsideprotection.

Wear high-visibility clothing, especially when working around other machines, people and vehicles.

Be aware of and avoid pinch points when assembling and operating. Pinch points can exist around levers

and when putting two parts together (during assembly).

Usebarriersandtrafcconeswhenworkinginareasofpedestrianandvehicletrafctokeepeverythingata

safe distance.

UsegenuineSnowExpartsforreplacement.Thesemeetthespecictechnicalrequirements.Observeall

deadlines indicated in the Owner’s Manual for maintenance checks and service

Suitable and adequate mechanic’s equipment is required for performing maintenance and service proce-

dures.

TheSS-4000ispoweredbygasoline.Knowthelocationofreextinguishersandobserveresafetyproce-

dures.

This page contains safety information to highlight safety hazards and precautions involved with operating your SS-4000. This page must be

read and understood by all personnel who have any part with the assembly, use and care of this machine.