6 (30)

2. Designed purpose of use

The AVANT Zoom snow plow is an attachment that is suitable for use with AVANT compact loaders that are

shown in Table 1. The Zoom snow plow (also called Extendable snow plow) is a versatile, articulated snow

plow with adjustable width. It is intended for clearing and pushing snow on street areas. This type of snow

plow is especially suitable for removing snow from e.g. pathways, from near doors or walls, and areas where

there are both narrow places and large areas. The side plates can be left down for collecting operating mode.

When one or both side plates are lifted, the plow will push snow to either side.

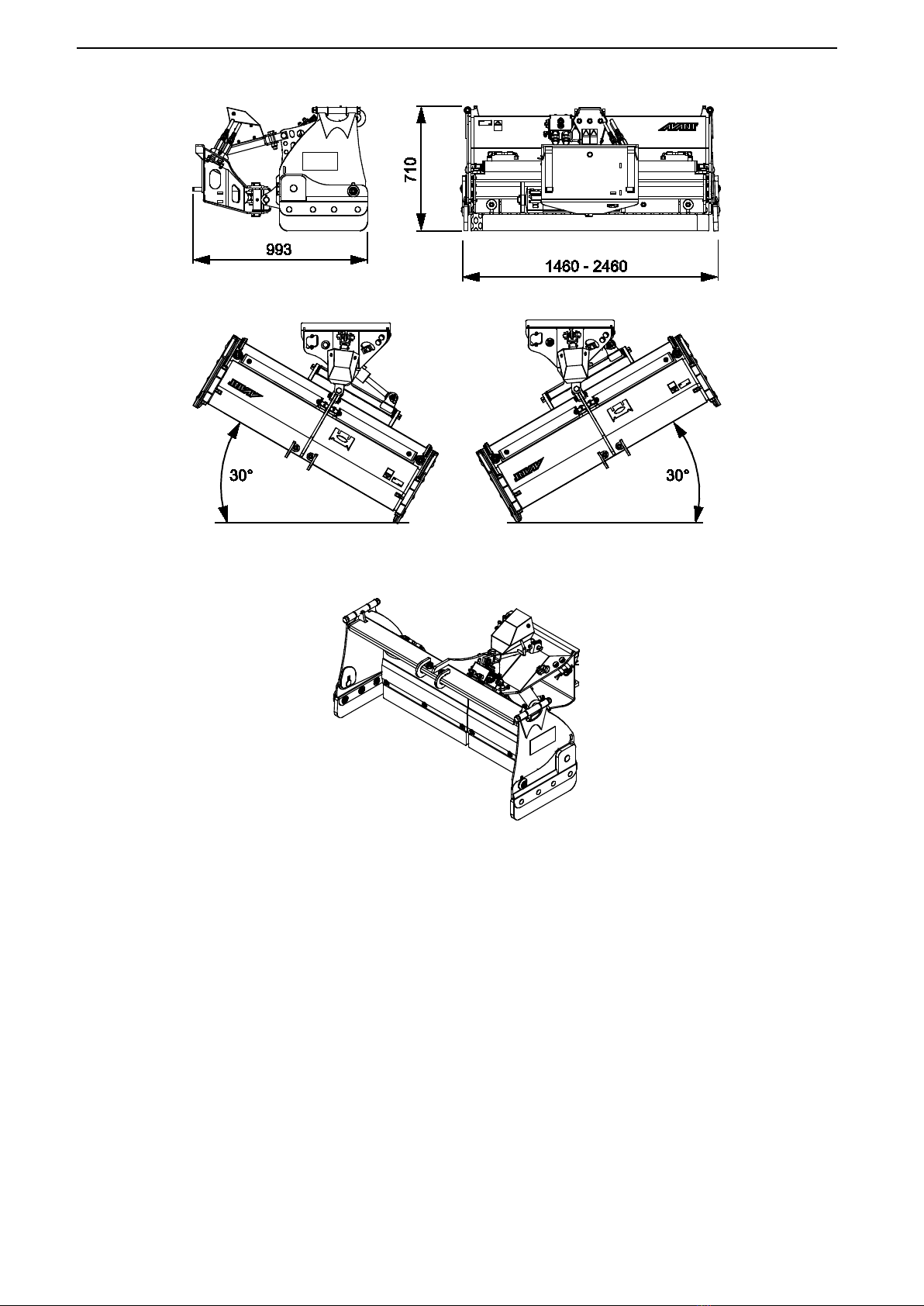

There are two hydraulic cylinders for stepless extending and retracting the straight blade sections of the plow.

This enables several different working widths and makes the snow plow very versatile at different work tasks

and areas. The plow is also equipped with hydraulic slewing, which makes it possible to tilt the plow towards

either side without interrupting work. An electro-hydraulic control valve on the snow plow makes it possible to

control the blade directly from the driver's seat. To operate all of these functions, the loader must be equipped

with Opticontrol®attachment control system.

The short overall design of the plow minimizes the torque force caused by the blade during use. The blade

edge is made of premium quality, wear resistant steel, and can be replaced if needed. A floating mounting

bracket allows vertical movement of the snow plow, as well as limited horizontal tilting for the best possible

ground surface following. To reduce the risk of a sudden stop if the blade hits an obstacle, there is a safety

bolt that will shear and allows the blade to tilt forward. Regardless of the shear bolt, the plow must be used

carefully and hitting obstacles at high speed must be avoided.

The Zoom snow plow is not designed for any other use than what is specified in this manual and it must not

be used for any other purposes than what it is intended for.

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. All repair work can’t be performed by the operator, and demanding repair and

maintenance operations are to be left for professional technicians. All maintenance work must be done using

proper safety equipment. Spare parts must be identical with original specifications, which can be ensured by

using only original spare parts. A separate spare parts catalogue may be available, consult your Avant dealer.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT dealer if you have additional questions about the operation or maintenance of the equipment, or if you

require spare parts or maintenance services.

Table 1 - Zoom snow plow - Compatibility with Avant loaders

Model

220

225

225LPG

313S

320S

420

423

520

R20

523

525LPG

R28

528

530

630

R35

635

640

735

745

750

755i

760i

850

860i

e5

e6

A425180 - - - - ••••(•)

It is recommended to use the attachment only with loaders marked with •in Table 1. When using with models

marked with (•), full performance may not be achieved. Additional counterweights may also be required. For

compatibility with a model not shown in table, contact your Avant dealer.