SnowWolf UltraPusher TE Manual

!

Operation & Maintenance Manual

REMEMBER: Register your product! No claims for warranty shall be considered unless your product

registration card is completed online within 30 days of purchase. Go to: snowwolfplows.com/registration.

HD Models 10,000 - 15,000 lb.

UltraPusher

2023 Rev 3

Models TE & TE/XT

MANUFACTURER'S WARRANTY

Two-Year Limited Warranty

SNOWWOLF International, hereinafter referred to as SNOWWOLF, warrants new SNOWWOLF SNOW

PLOWS at the time of delivery to the original purchaser, to be free from defects in material and

workmanship when properly set up and operated in accordance with the recommendations set forth by

SNOWWOLF.

SNOWWOLF'S liability for any defect with respect to accepted goods shall be limited to repairing the

goods at a SNOWWOLF designated location or at an authorized dealer location, or replacing them as

SNOWWOLF shall elect. The above shall be in accordance with SNOWWOLF warranty adjustment

policies. SNOWWOLF'S obligation shall terminate twenty-four (24) months after the delivery of the goods

to original purchaser including cutting edge breakage or wear. This warranty shall not apply to any

machine or attachment which shall have been repaired or altered outside the SNOWWOLF factory or

authorized SNOWWOLF dealership or in any way so as in SNOWWOLF'S judgment, to affect its stability

or reliability, nor which has been subject to misuse, negligence or accident beyond the Company

recommended machine rated capacity.

Warranty Claim

To submit a warranty claim, a return authorization from SNOWWOLF must be obtained. The failed part

may then be returned. Tampering with the failed part may void the warranty. This warranty does not

include freight or delivery charges incurred when returning machinery for servicing. Dealer mileage,

service calls, and pickup/delivery charges are the customers' responsibility.

Exclusions of Warranty

Except as otherwise expressly stated herein, SNOWWOLF makes no representation or warranty of any

kind, expressed or implied, AND MAKES NO WARRANTY OF MERCHANTABILITY IN RESPECT TO

ITS MACHINERY AND/OR ATTACHMENTS ARE FIT FOR ANY PARTICULAR PURPOSE. SNOWWOLF

shall not be liable for incidental or consequential damages for any breach of warranty, including but not

limited to inconvenience, rental of replacement equipment, loss of profits or other commercial loss. Upon

purchase, the buyer assumes all liability for all personal injury and property resulting from the handling,

possession, or use of the goods by the buyer.

No agent, employee, or representative of SNOWWOLF has any authority to bind SNOWWOLF to any

affirmation, representation or warranty concerning its machinery and/or attachments except as specifically

set forth herein.

This warranty policy supersedes any previous documents.

No claims for warranty shall be considered unless warranty registration is sent to SNOWWOLF

within 30 days of purchase!

Manufactured By:

15100 Business Parkway

Rosemount, MN 55068

www.snowwolfplows.com

1

UltraPusher Operation and Maintenance Manual

Introduction..........................................................................................................................................3

Owner Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Attachment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Safety......................................................................................................................................................7

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Safe Operation Needs A Qualified Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Importance of Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operation.............................................................................................................................................13

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Pre-Operation Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Attachment Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Daily Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Monthly Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Attachment Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Entering The Operator’s Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Leaving The Operator’s Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Connecting Attachment To The Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Operating The Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Attachment Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Maintenance.......................................................................................................................................21

Maintenance Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

UltraPusher Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Cutting Edge Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Cutting Edge Trip Spring Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Side Plate Wear Shoe Adjustment (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Side Plate Wear Shoe Replacement (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Storage And Return To Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Parts......................................................................................................................................................31

Models UPTE 84, UPTE 96, UPTE 108, UPTE 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Models UPTE/XT108, UPTE/XT120, UPTE/XT132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

2UltraPusher Operation and Maintenance Manual

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Trip Edge Generations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ActivEdge, AR400, 18” Sectional Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ActivEdge, AR400, 24” Sectional Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ActivEdge, Carbide, 18” Sectional Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ActivEdge, Carbide, 24” Sectional Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Spill Guard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Specifications....................................................................................................................................49

Specifications UPTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Specifications UPTE/XT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3

UltraPusher Operation and Maintenance Manual

Introduction

Owner Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Attachment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4UltraPusher Operation and Maintenance Manual

5

UltraPusher Operation and Maintenance Manual

Introduction

Owner Information

Thank you for your decision to purchase a

SnowWolf UltraPusher. To ensure maximum

performance of your equipment, it is mandatory

that you thoroughly study the Operator’s Manual

and follow the recommendations. Proper

operation and maintenance are essential to

maximize equipment life and prevent personal

injury.

Operate and maintain this equipment in a safe

manner and in accordance with all applicable

local, state, and federal codes, regulations and /

or laws. Follow all on-product labeling and

instructions.

Make sure that all personnel have read this

Operator’s Manual and thoroughly understand

safe and correct operating, installation and

maintenance procedures.

SnowWolf is continually working to improve its

products. SnowWolf reserves the right to make

any improvements or changes as deemed

practical and possible without incurring any

responsibility or obligation to make any changes

or additions to equipment sold previously.

Although great care has been taken to ensure the

accuracy of this publication, SnowWolf makes no

warranty or guarantee of any kind, written or

expressed, implied or otherwise with regard to the

information contained within this manual.

SnowWolf assumes no responsibility for any

errors that may appear in this manual and shall

not be liable under any circumstances for

incidental, consequential or punitive damages in

connection with, or arising from the use of this

manual.

Keep this manual available for frequent reference.

All new operators or owners must review the

manual before using the equipment and annually

thereafter. Contact your SnowWolf Attachments

Dealer for assistance, information, or additional

copies of the manual. Contact

www.snowwolfplows.com or call 1-800-905-2265

for a complete list of dealers in your area.

Serial Number Location

Please record attachment information in the space

provided for future reference.

Always use the serial number of the UltraPusher

when requesting service information or when

ordering parts. Early or later models (identification

made by serial number) may use different parts,

or may require a different procedure in doing a

specific service operation.

NOTE: This document and the information

provided are the property of SnowWolf

and may only be used as authorized

by SnowWolf.

The serial number plate is located on the rear of

the UltraPusher moldboard.

Model Number:

Serial Number:

Dealer Name:

Dealer Number:

Date of Purchase:

6UltraPusher Operation and Maintenance Manual

Introduction

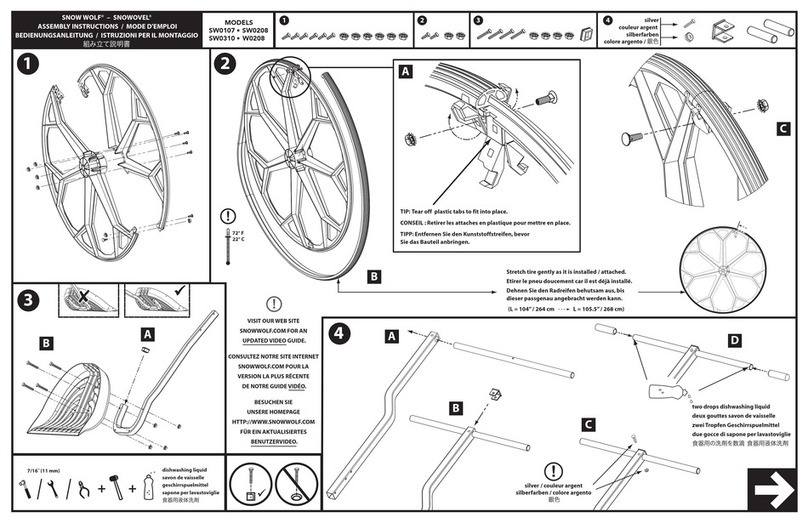

Attachment Identification

MOUNTING FRAME

BLADE

CUTTING EDGE

BLADE

MARKER

GUIDE

WEAR SHOE

TRIP

SPRINGS

WEAR SHOE

SIDE PLATE

CUTTING EDGE

BLADE

MARKER

GUIDE

7

UltraPusher Operation and Maintenance Manual

Safety

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Safe Operation Needs A Qualified Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Importance of Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

8UltraPusher Operation and Maintenance Manual

9

UltraPusher Operation and Maintenance Manual

Safety

Safety Information

Safety Alert Symbol

This SAFETY ALERT SYMBOL identifies

important safety messages on the

equipment and in the owner’s manual. When

you see this symbol, be alert to the

possibility of personal injury and carefully

read the message that follows.

The signal word DANGER on the machine

and in the manuals indicates a hazardous

situation which, if not avoided, will result in

death or serious injury.

The signal word WARNING on the machine

and in the manuals indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

The signal word CAUTION on the machine

and in the manuals indicates a potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury. It

may also be used to alert against unsafe

practices.

The signal word IMPORTANT identifies

procedures which must be followed to avoid

damage to the machine.

Safe Operation Needs A Qualified

Operator

AVOID SERIOUS INJURY OR DEATH

Operators must receive instructions before

operating the machine. Untrained operators

can cause serious injury or death.

For an operator to be qualified, he or she

must not use drugs or alcoholic drinks

which impair alertness or coordination while

working. An operator who is taking

prescription drugs must get medical advice

to determine if he or she can safely operate

a machine and the equipment.

Owner’s Responsibility

Operate and maintain this machine in a safe

manner and in accordance with all applicable

local, state, and federal codes, regulations and/or

laws; and in compliance with on-product labeling

and this owner’s manual instructions.

Make sure that all personnel have read this

owner’s manual, and thoroughly understand safe

and correct installation, operation and

maintenance procedures

Give operating instructions to the operators before

allowing them to operate the machine, and at

least annually there after.

10 UltraPusher Operation and Maintenance Manual

Safety

Importance of Safety

Operating Safety

• Read and follow instructions in this manual and

the machine’s Operators Manual before

operating.

• The UltraPusher attachment is intended for

use in snow removal. Use of this equipment in

any other manner is considered to be contrary

to the intended use of the attachment.

• Under no circumstances should young children

be allowed to work with this equipment.

• This equipment is dangerous to persons

unfamiliar with its operation.

• Check for overhead and / or underground lines

before operating equipment (if applicable).

• In addition to the design and configuration of

equipment, hazard control and accident

prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

• Check that the attachment is securely fastened

to the machine.

• Make sure all the machine controls are in

NEUTRAL before starting the machine.

• Operate the equipment only from the

operator’s position.

• Operate the equipment according to the

Operator’s Manual.

• When learning to operate the equipment, do it

at a slow rate in an area clear of bystanders.

• DO NOT permit personnel to be in the work

area when operating the equipment.

• The equipment must be used ONLY on

approved machines.

• DO NOT modify the equipment in any way.

Unauthorized modification may impair the

function and / or safety and could affect the life

of the equipment.

• DO NOT make any adjustments or repairs on

the equipment while the machine is running.

• Keep shields and guards in place. Replace if

damaged.

• DO NOT operate equipment in poor visibility

conditions such as fog, darkness, or any

conditions that limit clear visibility less than 300

feet (100 m) in front of and to the sides of the

equipment.

• DO NOT operate in a work area that has not

been inspected for foreign debris and

obstacles.

• Remove any foreign objects and clearly mark

any objects that cannot be removed.

• Wear safety glasses, gloves, hard hat, hearing

protection and other protective clothing when

operating or maintaining this equipment.

11

UltraPusher Operation and Maintenance Manual

Safety

Importance of Safety (Cont’d)

Fire Prevention Safety

• Flammable debris (leaves, grass, etc.) must be

removed regularly. If flammable debris is

allowed to accumulate, it can cause a fire

hazard. Clean often to avoid this accumulation.

• The equipment’s hydraulic motor compartment

must be inspected every day and cleaned if

necessary to prevent fire hazards and

overheating.

• All fuels, most lubricants and some coolant

mixtures are flammable. Flammable fluids that

are leaking or spilled onto hot surfaces or onto

electrical components can cause a fire.

Transporting Safety

• Comply with state and local laws governing

highway safety and movement of machinery

on public roads.

• Check local laws for all highway lighting and

marking requirements.

• Always yield to oncoming traffic and move to

the side of the road so any following traffic may

pass.

• Never allow riders on either machine or

equipment.

• If transporting the attachment on a truck or

trailer, make sure it is properly secured to the

transport vehicle.

Hydraulic Safety

• Always clean fluid spills. Do not use gasoline or

diesel fuel for cleaning parts. Use commercial

nonflammable solvents.

12 UltraPusher Operation and Maintenance Manual

13

UltraPusher Operation and Maintenance Manual

Operation

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Pre-Operation Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Attachment Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Daily Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Monthly Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Attachment Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Entering The Operator’s Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Leaving The Operator’s Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Connecting Attachment To The Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Operating The Attachment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Attachment Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

14 UltraPusher Operation and Maintenance Manual

15

UltraPusher Operation and Maintenance Manual

Operation

General Information

Pre-Operation Inspection

Before operating the UltraPusher for the first time

and each time thereafter, use the following list as

a guideline during equipment inspection.

1. Use only a machine of adequate power and

weight to operate the UltraPusher.

2. Check the UltraPusher and machine’s quick

tach mounts for damaged, loose or missing

parts. Repair as needed before operation.

3. Check that the UltraPusher blade is properly

attached to the machine. Be sure retainers are

used on the mounting pins.

4. Check that wear shoes (if equipped) are set at

the same working depth.

5. Make sure that all guards and shields are in

place, secured and functioning as designed.

6. Check cutting blade for wear or damage.

16 UltraPusher Operation and Maintenance Manual

Operation

Attachment Inspection

Daily Inspection

NOTE: Inspect the attachment by performing a

walk around daily before and after use.

Use the following inspection checklist

as a guideline.

Check the following items every 10 hours of

operation:

• Verify that the UltraPusher is properly

connected to the machine.

• Check that all shields and guards are in place.

• Check moldboard cutting edge for wear or

damage. Replace if necessary.

• Check Side Plates cutting edge’s for wear or

damage. Replace if necessary.

• Check that all cotter pins that retain pivot/

anchor pins are in place and not damaged or

missing.

• Check the UltraPusher to ensure that all

components are secure and that all bolts and

nuts are thoroughly tightened.

• Check the UltraPusher mounting hardware for

wear or damage. Inspect the pins and mount

(on the attachment) for wear or damage.

Repair or replace damaged parts if necessary.

Monthly Inspection

• Inspect the UltraPusher for cracks, bends, or

excessive wear.

• Check wear plates (if equipped) for wear.

• Check that all bolts are tight.

• Check blade and mounting plate for cracks or

damage. Replace if necessary.

• Check Side Plates cutting edge’s for cracks or

damage. Replace if necessary.

• Check for damaged or missing decals.

Replace if necessary.

• Lubricate as required.

AVOID SERIOUS INJURY OR DEATH

Before servicing the attachment:

• Always park on a flat level surface.

• Lower lift arms and place attachment flat

on the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Wait for all moving parts to stop.

• Stop the engine and remove the key.

SEE MACHINE’S OPERATOR’S MANUAL

FOR ADDITIONAL INFORMATION.

17

UltraPusher Operation and Maintenance Manual

Operation

Attachment Installation

See the machine’s Operator’s Manual for

detailed information on operating the loader.

Entering The Operator’s Position

Use the attachment safety treads, handles and

steps (on the machine) to enter the operator’s

position.

When in the operator’s position, lower safety seat

bar, start the engine and release the parking

brake.

Leaving The Operator’s Position

AVOID SERIOUS INJURY OR DEATH

Before leaving the operator’s position:

• Always park on a flat level surface.

• Lower lift arms and place attachment flat

on the ground.

• Place all controls in NEUTRAL.

• Engage the park brake.

• Stop the engine and remove the key.

• Wait for all moving parts to stop.

SEE MACHINE’S OPERATOR’S MANUAL

FOR ADDITIONAL INFORMATION.

Park the machine / attachment on a flat level

surface.

Place all controls in neutral, engage the park

brake, stop the engine and wait for all moving

parts to stop. Leave the operator’s position.

Connecting Attachment To The

Machine

CRUSH HAZARD

• Before moving the machine, look in all

directions and make sure no bystanders,

especially small children are in the work

area. Do not allow anyone between the

machine and attachment when

approaching the attachment for

connecting.

• Keep fingers and hands out of pinch

points when connecting and

disconnecting attachment.

Before connecting to the attachment, inspect the

machine’s mounting plate. (See the machine's

Operator’s Manual for inspecting the mounting

frame).

Enter the operator’s position. See “Entering The

Operator’s Position” on page 17.

Lower the machine’s lift arm and tilt the machine’s

mounting plate forward.

Drive the machine slowly forward until the top

edge of the machine’s mounting frame is

completely under the mounting flange of the

UltraPusher mounting frame.

Slowly raise and tilt the machine’s mounting plate

back until the UltraPusher is slightly off the ground

and attachment mounting frame fully contacts the

front of the machine’s mounting plate.

18 UltraPusher Operation and Maintenance Manual

Operation

Connecting Attachment To The

Machine (Cont’d)

Engage machine’s locking levers / wedges to

securely fasten the UltraPusher to the machine’s

mounting frame. (See the machine’s Operation

Manual for the correct procedure.)

Visually inspect that the wedge pins are securely

fastened into the UltraPusher mounting frame.

AVOID SERIOUS INJURY OR DEATH

The locking pins / wedges must extend

through the holes in the attachment

mounting frame. Failure to secure locking

pins / wedges can allow attachment to come

off.

SEE MACHINE’S OPERATOR’S MANUAL

FOR ADDITIONAL INFORMATION.

Engage machine’s locking levers / wedges (See

the machine's Operator’s Manual for detailed

information).

This manual suits for next models

1

Table of contents

Other SnowWolf Snow Blower manuals