SnowWolf AlphaBlower 24-84-H Manual

!

Operation & Maintenance Manual

REMEMBER: Register your product! No claims for warranty shall be considered unless your product

registration card is completed online within 30 days of purchase. Go to: snowwolfplows.com/registration.

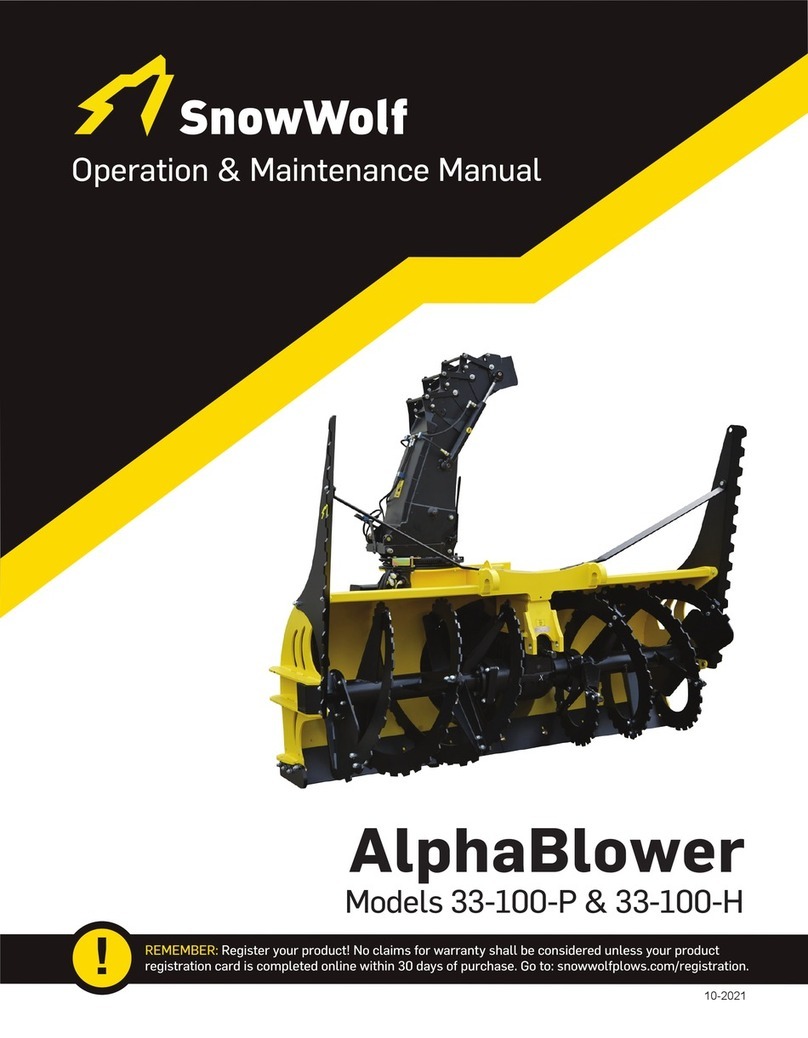

AlphaBlower

Model 24-84-H & 24-84-P

2023 Rev 1

MANUFACTURER'S WARRANTY

One-Year Limited Warranty

SNOWWOLF International, hereinafter referred to as SNOWWOLF, warrants new SNOWWOLF SNOW

BLOWERS at the time of delivery to the original purchaser, to be free from defects in material and

workmanship when properly set up and operated in accordance with the recommendations set forth by

SNOWWOLF.

SNOWWOLF'S liability for any defect with respect to accepted goods shall be limited to repairing the

goods at a SNOWWOLF designated location or at an authorized dealer location, or replacing them as

SNOWWOLF shall elect. The above shall be in accordance with SNOWWOLF warranty adjustment

policies. SNOWWOLF'S obligation shall terminate twelve (12) months after the delivery of the goods to

original purchaser including cutting edge breakage or wear. This warranty shall not apply to any machine

or attachment which shall have been repaired or altered outside the SNOWWOLF factory or authorized

SNOWWOLF dealership or in any way so as in SNOWWOLF'S judgment, to affect its stability or reliability,

nor which has been subject to misuse, negligence or accident beyond the Company recommended

machine rated capacity.

Warranty Claim

To submit a warranty claim, a return authorization from SNOWWOLF must be obtained. The failed part

may then be returned. Tampering with the failed part may void the warranty. This warranty does not

include freight or delivery charges incurred when returning machinery for servicing. Dealer mileage,

service calls, and pickup/delivery charges are the customers' responsibility.

Exclusions of Warranty

Except as otherwise expressly stated herein, SNOWWOLF makes no representation or warranty of any

kind, expressed or implied, AND MAKES NO WARRANTY OF MERCHANTABILITY IN RESPECT TO

ITS MACHINERY AND/OR ATTACHMENTS ARE FIT FOR ANY PARTICULAR PURPOSE. SNOWWOLF

shall not be liable for incidental or consequential damages for any breach of warranty, including but not

limited to inconvenience, rental of replacement equipment, loss of profits or other commercial loss. Upon

purchase, the buyer assumes all liability for all personal injury and property resulting from the handling,

possession, or use of the goods by the buyer.

No agent, employee, or representative of SNOWWOLF has any authority to bind SNOWWOLF to any

affirmation, representation or warranty concerning its machinery and/or attachments except as specifically

set forth herein.

This warranty policy supersedes any previous documents.

No claims for warranty shall be considered unless warranty registration is sent to SNOWWOLF

within 30 days of purchase!

Manufactured By:

15100 Business Parkway

Rosemount, MN 55068

www.snowwolfplows.com

1

AlphaBlower Operation and Maintenance Manual

CONTENTS

Introduction..........................................................................................................................................3

Owner Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

AlphaBlower Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety......................................................................................................................................................7

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safe Operation Needs A Qualified Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Importance of Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operation.............................................................................................................................................11

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Pre-Operation Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Snow Blower Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AlphaBlower Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Daily Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Monthly Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

PTO Revolutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Skid Steer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Entering and Exiting the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

AlphaBlower Installation Skid Steer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Connecting The Snow Blower To A Skid Steer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

AlphaBlower Adjustment Skid Steer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

AlphaBlower Installation To Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Connecting The Snow Blower To The Tractor’s Three-Point Hitch . . . . . . . . . . . . . . . . . .16

PTO Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

AlphaBlower Adjustment Tractor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Hydraulic Couplers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Checking AlphaBlower Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Operating The AlphaBlower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Clearing a Plugged AlphaBlower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

AlphaBlower Removal Skid Steer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

AlphaBlower Removal Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Maintenance.......................................................................................................................................29

Maintenance Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

AlphaBlower Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2AlphaBlower Operation and Maintenance Manual

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Oil Change on the Cut Out Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fan Shaft Splines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Auger Axle Couplings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Gearbox Adjusting Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cutting Edge Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

24-84-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

24-84-H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Storage And Return To Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Parts......................................................................................................................................................39

AlphaBlower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

AlphaBlower Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Deluxe Chute, 4-Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chute, Telescopic (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Blower Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Hydraulic Swivel Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Hydraulic Swivel Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chute, Hydraulic Tilt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chute, Swivel Stopper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Blower Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Gearbox Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Blower Housing / Wear Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Rubber Flap Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Auger Axle Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cutting Edge / Axle Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Fan Axle Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Wear Shoe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Blower Skidsteer Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Hydraulic Manifold, Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Decal Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Specifications....................................................................................................................................67

AlphaBlower Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3

AlphaBlower Operation and Maintenance Manual

Introduction

Owner Information

Thank you for your decision to purchase a

SnowWolf AlphaBlower. To ensure maximum

performance of your equipment, it is mandatory

that you thoroughly study the Operator’s Manual

and follow the recommendations. Proper

operation and maintenance are essential to

maximize equipment life and prevent personal

injury.

Operate and maintain this equipment in a safe

manner and in accordance with all applicable

local, state, and federal codes, regulations and /

or laws. Follow all on-product labeling and

instructions.

Make sure that all personnel have read this

Operator’s Manual and thoroughly understand

safe and correct operating, installation and

maintenance procedures.

SnowWolf is continually working to improve its

products. SnowWolf reserves the right to make

any improvements or changes as deemed

practical and possible without incurring any

responsibility or obligation to make any changes

or additions to equipment sold previously.

Although great care has been taken to ensure the

accuracy of this publication, SnowWolf makes no

warranty or guarantee of any kind, written or

expressed, implied or otherwise with regard to the

information contained within this manual.

SnowWolf assumes no responsibility for any

errors that may appear in this manual and shall

not be liable under any circumstances for

incidental, consequential or punitive damages in

connection with, or arising from the use of this

manual.

Keep this manual available for frequent reference.

All new operators or owners must review the

manual before using the equipment and annually

thereafter. Contact your SnowWolf Attachments

Dealer for assistance, information, or additional

copies of the manual. Contact

www.snowwolfplows.com or call 1-800-905-2265

for a complete list of dealers in your area.

Serial Number Location

Please record snow blower information in the

space provided for future reference.

Always use the serial number of the snow blower

when requesting service information or when

ordering parts. Early or later models (identification

made by serial number) may use different parts,

or may require a different procedure in doing a

specific service operation.

NOTE: This document and the information

provided are the property of SnowWolf

and may only be used as authorized

by SnowWolf.

The snow blower serial number plate is located on

the left side of the frame, below the discharge

chute.

Model Number:

Serial Number:

Dealer Name:

Dealer Number:

Date of Purchase:

This manual suits for next models

1

Table of contents

Other SnowWolf Snow Blower manuals