Sofraser 9601 User manual

V2.6.1

User Manual

Viscosity Processor

9601

Original version

Ref.: 237/5

User Manual 9601

Ref.: 237/5 1

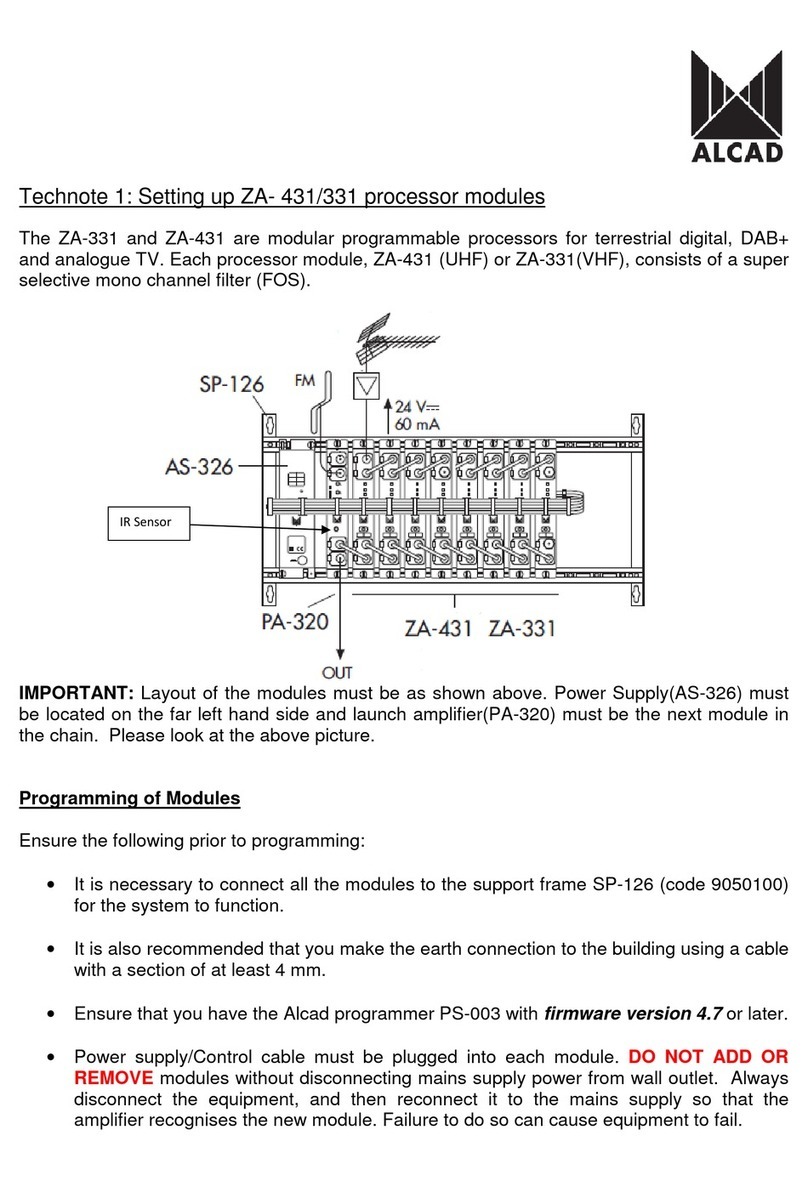

IMPORTANT

THE OFFSET ADJUSTMENT IN THE AIR

MUST BE THE FIRST TASK COMPLETED.

Offset adjustment procedure is detailed in § 5.1

1. CLEAN AND DRY THE SENSOR ROD.

2. BE SURE THE PROCESS IS EMPTY. THE ROD MUST BE VIBRATING IN THE AIR.

3. INSTALL THE SENSOR ON THE PROCESS AND FIX IT WITH ITS 4 SCREWS.

4. REACH THE OFFSET ADJUSTMENT FUNCTION BY ENTERING INTO THE MENU AND CHOOSING

THE FUNCTION NUMBER 1 (OFFSET). PRESS “OK”.

5. FOLLOW THE INSTRUCTIONS DISPLAYED ON THE ELECTRONICS SCREEN.

6. PRESS “OK” TO ADJUST THE OFFSET. IT MEANS THE RAW SIGNAL IS SHIFTED TO THE VOLTAGE

REFERENCE DEFINED IN THE FACTORY CALIBRATION STAGE.

A MESSAGE SAYING THE OPERATION WAS SUCCESSFUL APPEARS.

PRACTICAL ADVICES AND IMPORTANT WARNINGS ARE ALSO LISTED IN THE 9601 TECHNICAL MAN-

UAL IN §1.6 AND §3.12.

User Manual 9601

Ref.: 237/5 2

TABLE OF CONTENT

1GENERALITIES........................................................................................................................................................ 3

1.1 Navigation.....................................................................................................................................................................................................................3

1.2 Diagnosis......................................................................................................................................................................................................................3

1.3 Security codes..............................................................................................................................................................................................................3

2UTILISATION MODE ................................................................................................................................................ 4

2.1 “Bargraphs” view ..........................................................................................................................................................................................................4

2.2 “Compensated viscosity” view......................................................................................................................................................................................4

2.3 “Acquisition graph” view ...............................................................................................................................................................................................4

2.4 Information –version....................................................................................................................................................................................................5

2.5 Synoptic........................................................................................................................................................................................................................6

3ADAPTATION MODE ............................................................................................................................................... 7

4BLOCK “DISPLAYS” ............................................................................................................................................... 8

4.1 Menu of the block “Displays” ........................................................................................................................................................................................8

4.2 Choose the Viscosity Unit ............................................................................................................................................................................................8

4.3 Choose the Temperature Unit......................................................................................................................................................................................8

4.4 Activate viscosity correction .........................................................................................................................................................................................8

4.5 Status............................................................................................................................................................................................................................9

4.5.1 Current outputs status..........................................................................................................................................................................................10

4.5.2 Relays status........................................................................................................................................................................................................10

4.5.3 Raw data ..............................................................................................................................................................................................................10

4.6 Synoptic of Block “Display”.........................................................................................................................................................................................11

5BLOCK “SETTINGS” ............................................................................................................................................. 12

5.1 Set the offset...............................................................................................................................................................................................................12

5.2 Set the alarms.............................................................................................................................................................................................................12

5.3 Set and test the current outputs.................................................................................................................................................................................13

5.3.1 Set the current outputs.........................................................................................................................................................................................13

5.3.2 Test the current outputs .......................................................................................................................................................................................14

5.4 Choose the method of kinematic viscosity calculation...............................................................................................................................................15

5.5 Set the bargraphs.......................................................................................................................................................................................................15

5.6 Set the graph scales...................................................................................................................................................................................................15

5.7 Activate the Pt100 ......................................................................................................................................................................................................16

5.8 Define the filter............................................................................................................................................................................................................16

5.9 Synoptic of Block “Settings” .......................................................................................................................................................................................18

6BLOCK “PARAMETERS” ...................................................................................................................................... 19

6.1 Viscosity corrections...................................................................................................................................................................................................19

6.2 Compensation table....................................................................................................................................................................................................20

6.2.1 Reading of the compensation table .....................................................................................................................................................................20

6.2.2 Modification of the compensation table................................................................................................................................................................20

6.3 Define the density coefficient .....................................................................................................................................................................................20

6.4 Modify the security codes...........................................................................................................................................................................................21

6.5 Synoptic of Block “Parameters”..................................................................................................................................................................................22

7BLOCK “CONFIGURATION” ................................................................................................................................. 23

7.1 Define the thermal drift table and the calibration data ...............................................................................................................................................23

7.2 Define the filter inputs.................................................................................................................................................................................................23

7.3 Define the adjustment data ........................................................................................................................................................................................23

7.4 Synoptic of Block “Configuration” ...............................................................................................................................................................................24

User Manual 9601

Ref.: 237/5 3

1Generalities

Before any use, read carefully the technical manual in order to ensure the good installation of

the unit.

1.1 Navigation

: Press on this key enables to return to the previous level.

: Press on this key enables to return to the “Bargraphs” view (see § 2.1).

1.2 Diagnosis

When an anomaly is detected by the processor, the symbol appears on the main “Bar-

graphs” view.

Press F6 and the details about the anomaly appear.

Type of anomaly:

-Out of range: Viscosity.

We consider that the sensor is out of range when viscosity exceeds 110 % of full scale range.

-Out of range: Offset.

An offset setting is needed. It means that Vbrut needs to be shift to the reference 9000mV.

It is necessary to respect the method of Offset setting described on § 5.1 “Set the Offset”.

-Out of range: Compensation table.

The referenced temperature, that can be set on “Compensated viscosity” view (see § 2.2) or

the instantaneous temperature is out of the table.

-Alarms.

Message that appears at the reach of the low or high threshold for viscosity, temperature or

density.

-Rupture.

Message that appears when there is a rupture (viscosity, temperature or density) generally re-

lated to a connexion problem.

1.3 Security codes

4 security codes, CODE 0 to CODE 3, are defined.

Refer to:

-Technical manual : §7 –Specific notes and manufacturing parameters

-User manual : §6.4 –Modify security codes

User Manual 9601

Ref.: 237/5 4

2Utilisation Mode

The Utilisation mode enables to visualize viscosity, temperature and density values in various

forms.

Information related to the sensor identification is gathered in a view accessible since this mode.

The Utilisation mode enables the access to the Adaptation mode.

2.1 “Bargraphs” view

“Bargraphs” view is the principal view.

The following data are displayed:

Viscosity, temperature and density bargraphs.

Instantaneous viscosity, temperature according to the selected unit and density (coefficient or

densimeter).

2.2 “Compensated viscosity” view

The viscosity at referenced temperature calculation requires knowing the viscosity evolution in func-

tion of temperature.

All the reference curve points are saved in the compensation table of the “Parameters” block.

The reference temperature can be modified starting from this view as following:

Using the keyboard, enter the new value of the reference temperature.

Press OK: the modification is done and the viscosity is re-calculated according to this new val-

ue of reference temperature.

2.3 “Acquisition graph” view

Instantaneous measurements

Compensated viscosity calculated at

reference temperature

User Manual 9601

Ref.: 237/5 5

The acquisition graph represents viscosity and temperature.

One graph represents 120 values and the acquisition time can be set in the “Settings” block.

For example:

For an acquisition time setting at 30s, the graph will represent an acquisition of 1 hour.

A first pressing on F6 enables to display the viscosity graph, with the same time scale of the graph for

viscosity and temperature.

A second pressing enables to display the temperature graph.

2.4 Information –version

The information view is accessible starting from the main view by pressing on .

Electronic version

Program version

User Manual 9601

Ref.: 237/5 6

2.5 Synoptic

Navigation between the three views “Bargraphs”, “Compensated viscosity” and “Acquisition

graph” is possible by pressing on the key F4.

Starting from all these views, pressing on the key F1 enables to reach to the Adaptation mode

main menu.

F4

F4

F4 F4F4

F6 F6

User Manual 9601

Ref.: 237/5 7

3Adaptation Mode

The Adaptation mode enables to adapt parameters, settings and configuration of the processor

according to the using conditions.

The Menu is accessible, starting from all the Utilisation Mode views, by pressing on the F1 key.

The Menu enables to reach the various block of the Adaptation Mode.

To select the block you want to reach, use the arrows and press “OK”.

Displays: see § 4

Settings: see § 5

Parameters: see § 6

Configurations: see § 7

User Manual 9601

Ref.: 237/5 8

4Block “Displays”

4.1 Menu of the block “Displays”

Use the arrows to select the function you wish and press “OK”.

4.2 Choose the Viscosity Unit

The security code 3 is needed.

To choose the new viscosity unit, it is enough to select it with the arrows and to press “OK”.

The change is automatically done.

4.3 Choose the Temperature Unit

The security code 3 is needed.

To choose the new temperature unit, it is enough to select it with the arrows and to press “OK”.

The change is automatically done.

4.4 Activate viscosity correction

The security code 3 is needed.

User Manual 9601

Ref.: 237/5 9

Select the correction you want to apply using the arrows, for example table C1.

If it is indicated “OFF”: the correction is activated and if you press on F3, it will disable the cor-

rection.

If it is indicated “ON”: the correction is disabled and if you press on F3, it will activate the cor-

rection.

Only one correction can be enabled.

If you activate a new correction, it will automatically deactivate the previous one.

The correction, which is activated, is displayed on the “Bargraphs” view.

For example:

Correction C1 is activated.

4.5 Status

This function enables to reach:

Status of current outputs

Status of relays

Raw data

The data visualized starting from this block is not modifiable.

Select the function you want to reach by using the arrows.

User Manual 9601

Ref.: 237/5 10

4.5.1 Current outputs status

It makes it possible to visualize the instantaneous values of current outputs corresponding to

the viscosity, the compensated viscosity, the temperature and the density.

The setting of current outputs is made starting from the block “Settings”.

4.5.2 Relays status

It makes it possible to visualize the status of the relays allocated to viscosity, compensated vis-

cosity, temperature and density alarms.

Relays are NO type.

Under normal functioning, the coils of the relay are under tension and the contact is closed.

In anomaly, the coils are not under tension and the contact is opened: measurements out of set

point, processor power supply is turn off…

The setting of High and Low thresholds is made starting from the block “Settings”.

4.5.3 Raw data

This view is intended for SOFRASER after sales service.

In the case of a special calibration, this window can change and display more parameters (2 pages).

In this example:

Temperature and Density are under their Low thresholds.

This is an anomaly so contacts are opened.

User Manual 9601

Ref.: 237/5 11

4.6 Synoptic of Block “Display”

User Manual 9601

Ref.: 237/5 12

5Block “Settings”

5.1 Set the offset

Air is used as reference fluid in order to adjust the raw signals during the installation.

The offset adjustment must be done:

At each new installation of the sensor on the process

At each observation of the signal drift in the air (§ 4.5.3).

Each time the information is indicated on the “Diagnosis” view.

The stages to follow to proceed to the offset adjustment are describes below:

Step 1

Enter in the “Settings” block

Step 2

Enter the security CODE 2 and choose the function “Offset”.

Step 3

Clean the sensor rod and make sure that it is clean and dry.

Step 4

Make sure that the process is empty so that the sensor is vibrating in the air during the

adjustment, i.e. that the rod is not immersed.

Step 5

Install the sensor using the fastening screws.

Step 6

Adjust the assembly offset in the air to fix Vbrut to the reference of 9000 mV by pressing

on the F3 key “Shift”.

Step 7

Press on OK to take into account the offset adjustment.

Step 8

Confirmation of the adjustment validity :

The offset adjustment is successful :

Press on

The offset adjustment has failed :

Start again : press on OK

Ignore : press on ESC

Consequences of a failed offset adjustment:

Viscosity is calculated starting from the amplitude corrected with offset.

So, if the offset is not adjusted correctly, the viscosity value will be false.

5.2 Set the alarms

It makes it possible to set LOW and HIGH thresholds and hysteresis of viscosity, compensated

viscosity, temperature and density alarms.

Pressing OK does the navigation from one threshold to another.

The modification of a value is done using the keyboard. Pressing on OK will immediately take

the value modified into consideration and will make it possible to skip to the following threshold.

User Manual 9601

Ref.: 237/5 13

Low threshold of temperature alarm

Hysteresis of low threshold

Example:

Alarm 1 = alarm corresponding to the viscosity LOW threshold

Alarm 2 = alarm corresponding to the viscosity HIGH threshold

Viscosity unit = cP

LOW threshold = 15

Hysteresis = 5

Alarm 1 is activated when the viscosity reaches 10 cP. It stays active as

long as viscosity does not reach the set point 15 cP.

The relay associated is opened as long as Alarm 1 is activated.

HIGH threshold = 100

Hysteresis = 10

Alarm 2 is activated when the viscosity reaches 110 cP. It stays active as

long as viscosity does not reach the set point 100 cP.

The relay associated is opened as long as Alarm 2 is activated.

High threshold - Viscosity

0

1

Set Point

Hysteresis

Viscosity

Alarm 2

Low threshold - Viscosity

Set Point

Hysteresis

Viscosity

0

1

Alarm 1

Relay opened

closed Relay opened

closed

5.3 Set and test the current outputs

5.3.1 Set the current outputs

It makes it possible to set viscosity, compensated viscosity, temperature and density current

outputs.

User Manual 9601

Ref.: 237/5 14

Minimal physical viscosity value: 0.0 cP

Value of the current output for the minimal physical value: 4mA

Maximum physical viscosity value: 1000.0 cP

Value of the current output for the maximum physical value: 20mA

Burn: Value of the current output in the event of rupture of the measurement signal.

Pressing on OK does the navigation from one value to another.

The modification of a value is done using the keyboard. Pressing on OK key will immediately

take the value modified into consideration and will make it possible to skip to the following thresh-

old.

5.3.2 Test the current outputs

Code 1 is needed to access this testing function.

This function permits to SOFRASER after-sales service to test current outputs by generating a

current.

To test an output :

For the output you want to test, define a current on this view:

Measure the signal on the appropriate connector on the back module of the equipment. The

measured signal should be equal to the defined testing current.

You have to stay on the view “current generator” to proceed to the test.

COM + AOUT 0: viscosity current output

COM + AOUT 1: temperature current output

COM + AOUT 2: compensated viscosity current output

COM + AOUT 3: density current output

User Manual 9601

Ref.: 237/5 15

5.4 Choose the method of kinematic viscosity calculation

It is possible to calculate the kinematic viscosity in 2 ways:

Starting from the density measured by a densimeter (in option):

When the 9601 processor is delivered with a densimeter, the density input configu-

ration (4/20 mA) is the following one:

4 mA →0,4 g/cc

20 mA → 2 g/cc

By considering that the density is constant.

The choice of the calculation method is done by selecting it with the arrows.

Caution: if the user chooses to work with kinematic viscosity values, the viscosity unit (§ 4.2)

must be “ cSt “ in order to activate the conversion.

5.5 Set the bargraphs

Bargraphs are displayed on the main view, which is accessible by pressing on .

The bargraphs scales require to be modified during a change of viscosity or temperature unit in

order to remain in coherence with the range of the physical units.

Only high thresholds of bargraphs can be modified.

The modification of a value is done using the keyboard. Pressing on OK key will immediately

take the value modified into consideration and will make it possible to skip to the following thresh-

old.

5.6 Set the graph scales

It makes it possible, for the user, to set the working range to visualize on the acquisition graph:

minimum and maximum of the scales and acquisition frequency.

Scale minimum

Always equal to 0

Acquisition frequency

Minimum : 1s

Maximum : 120s

Number of points

120 points

By default:

Scale maximum: equal to the maximum of viscosity and temperature range.

Acquisition period: 30s.

The scales must be verified and adjusted following:

Modification of the viscosity unit (§ 4.1)

Modification of the temperature unit (§ 4.2)

User Manual 9601

Ref.: 237/5 16

Example:

Acquisition time:

A point will be recorded and traced every sec-

onds. The graph will represents 2 minutes of

acquisition.

5.7 Activate the Pt100

With Pt100: makes it possible to activate all displays and functions related to

the temperature.

Without Pt100: when the temperature measurement is not available or when

the user prefers to work without temperature indication.

It will cancel all displays (bargraphs, graphs, instantaneous measurements) and will block the

access to all the functions related to the temperature (temperature unit, temperature and viscosity

compensated alarms, temperature and viscosity compensated current outputs, compensation ta-

ble…)

5.8 Define the filter

This function permits to activate and define parameters of the viscosity filter.

Two parameters need to be defined by the user :

Samples number: number of values that are used to calculate the averaged viscosity.

Four possibilities are proposed (4, 8, 12 or 16 values) and the user can deactivate the

filter by choosing “no filter”.

Sampling period : this period corresponds to the new viscosity value acquisition period.

At each period, a new value enters in the table and the oldest is getting out. The filtered viscosi-

ty is updated.

Four periods are proposed (50, 100, 200, 400 ms) and the user can define an other period from

50 ms to 36000 ms.

User Manual 9601

Ref.: 237/5 17

The first filtered viscosity value is calculated (samples number * sampling period) after the

starting of the sensor.

For example:

Samples number = 12 –Sampling period = 100ms

Time

100ms

200ms

Start

500ms

1s

1 2 3 4 5 6 7 8 9 10 11 12

2 3 4 5 6 7 8 9 10 11 12 13

3 4 5 6 7 8 9 10 11 12 13 14

1st filtered value

Filtered value updated

Filtered value updated

User Manual 9601

Ref.: 237/5 18

5.9 Synoptic of Block “Settings”

If "Other" is selected

Other manuals for 9601

1

Table of contents