Sohal RX 400 User manual

MIG / MAG

MANUAL

RX 250 / RX 400

April, 2007

INDEX:

About Mig.

Advantages of Mig.

Brief description of all parts.

Setting welding current.

Problems and their solutions.

Cause of welding defects and

their solutions.

Technical information.

Circuit diagram of power source.

Circuit diagram o wire feeder.

Torch spare guidelines AK25-P

Torch spare guidelines 36KD-P

Installation guide.

3

3

4- 8

9

10

11

12

13

14

15

16

17

2

ABOUT MIG:

MIG (Metal Inert Gas) welding, also sometimes called GMAW (gas

metal arc welding), is a welding process that was originally developed

back in the 1940's. MIG welding is a semi automatic process in which a

relatively thin wire is feed through welding gun instead of using a flux

coated electrode. The wire fed continuously by a wire feeder from a coil

and a shielding gas is used as an alternate of flux, this mechanism gives

continuous non stop weld and many advantages comprising electrode

welding. Originally Argon was used for shielding the weld pool. This inert gas

acts as a shield, keeping air borne contaminants away from the weld zone.

Due to high cost of Argon, the weld process was modified by replacing

Argon with CO2, because this is active gas some amount of Mn and Si was

added to welding wire for cancelling the poor effect of CO2 on weld pool.

Today ‘s MIG wire is actually MAG(metal active gas ) wire. So, the name

MIG/MAG welding be famous.

The primar y advantage of MIG welding is that it allows metal to be

welded much quicker, slag free and continuous than traditional welding

"stick welding" techniques. Some major advantages of MIG are listed

below:

* It produces long continuous welds.

* Welds much faster, 3 to 5 times faster.

* No slag formed during welding.

* No need to chip or brush welding.

* Clean weld with very little spatter.

* Easy machinable softer welds.

* No burn out at bead corners.

* Great metal filling speed.

* Ideal for thin metal welding.

* Good finish.

ADVANTAGE OF MIG:

3

BRIEF DESCRIPTION OF ALL PARTS:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 16

17

18

19

20

FRONT

4

31

32

33

34

35

36

37

38 39

40

REAR

BRIEF DESCRIPTION OF ALL PARTS:

5

POWER INDICATOR: It is placed in front of wire feeder shows the power is

on from power source and control cord to wire feeder has been

connected.

GAS CHECK: Press Gas check push button to check the flow of shielding

gas on conical nozzle and scaling on flow meter.

WIRE CHECK: Press Wire check push button to check the motor rotation

and for feeding wire in torch when you change an empty wire roll with

new one.

WIRE SPEED: This is knob to set a wire feed speed according to welding

volts and for control of welding current, To run motor fast or want to

increase in welding current rotate it clock wise and vice-versa. The

rotating device below knob is called potentio meter.

GAS PLUG: Connect the torch gas pipe here. When gas check or torch

trigger is pressed the gas comes from this plug and passes to welding

end of torch.

TORCH PLUG: This is base plug for the plug that is attached with torch,

make the connections by connecting these plugs. When you press

torch trigger the trigger switch works through this plug if this plug is not

connected torch switching will not work.

Feeder Motor: This is variable speed motor attached with a feed roll and

gearbox. It feeds wire at a constant speed set from wire speed knob.

CENTRAL ADAPTOR PM-3b: It’s the connector to connect welding torch,

Mig wire and welding current runs through this connector.

VOLT METER: By pressing OCV CHECK switch in front of power source, It

shows the open circuit volts of power source and when you do the

welding it shows welding volts.

AMPERE METER: It shows welding current during welding.

OCV CHECK: Press this toggle to check the set value of OCV(open

circuit volts).

POWER ON: Power on toggle switch. It is used for switching power source

control circuit and wire feeder ON or OFF. By switch off machine from

this switch does not mean the power is removed from power source, it

only cuts power of control circuit.

1.

2.

3.

4.

5.

6.

7

8.

9.

10.

11.

12.

6

POWER LED: It shows power is connected to machine and POWER ON

toggle switch is set to on.

WELD LED: The weld led shows the status of welding volts, when OCV

CHECK toggle switch or torch trigger is pressed will glow.

COURSE CONTROL SWITCH: It is 3-POLE 4-WAY rotary switch, It’s one step

increment make increase in OCV about 5-Volts.

FINE CONTROL SWITCH: It’s function is same as course control switch, the

only difference is it’s step size, a step of it will only change in OCV about

2-Volts.

WIRE FEEDER TERMINAL: Terminal for connecting wire feeder welding

lead. It is positive terminal.

WORK TERMINAL: It is negative terminal and connected to workpiece or

work table through a work lead.

WIRE FEEDER CONTROL PLUG: Connect one side Plug of 3 Core

connection lead here and other plug on the back of wire feeder.

Through these connection power is provided to wire feeder and to

make control between wire feeder and power source.

AIR VENT: This is out-let for cooling air at bottom of machine, keep the

surface clean below it, to prevent air blockage

WIRE SPOOL PIN: This pin is for fixing wire spool. Note that it could not

rotate freely, a tensioning spring is placed inside it.

CONTROL PLUG: A already mentioned connect control lead plug here.

GAS IN-LET: Connection for shielding gas.

HOLDER CABLE IN-LET: A welding cable has gone inside from here to

give positive current for torch. It’s other end is connected to Wire feeder

terminal.

HEATER PLUG: Connection for CO2 heater plug.

FUSE FOR CONTROL TRANSFORMER: This is fuse holder and a fuse inside

in protects control transformer from faulty conditions.

FUSE FOR FAN: Fuse for cooling fan.

13.

14.

15.

16.

17.

18.

19.

20.

31.

32.

33.

34.

35.

36.

37.

7

FUSE FOR HEATER: To protect heater supply from short circuit, in caseif

heater cable or heater gets faulty.

COOLING FAN: Give forced air in machine to cool DIODES and MAIN

TRANSFORMER.

SUPPLY COVER: It protects surrounding from touch with terminal strip

behind it. After connecting power supply place the cover back in its

original position.

38.

39.

40.

8

ST EP N O.

COU RSE F INE

OCV

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

22.8

23.7

24.7

25.7

26.3

27.6

28.7

29.9

30.9

32.5

34.3

36.1

37.4

39.7

42.0

44.5

Setting welding current:

* The values shown in table are only for guidelines.

Actual value may differ from table.

18

18.3

18.5

18.9

19.3

19.5

19.8

20.6

21.5

22

22.5

23

23.5

24

25

26

60

65

70

75

85

95

105

115

130

145

160

175

190

210

230

250

WE LD I NG

VOLTS

WE LD I NG

CU RR E NT

MIG RX 250

MIG RX 400

ST EP N O.

COU RSE F INE

OCV

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

WE LD I NG

VOLTS

WE LD I NG

CU RR E NT

9

27.5

28.5

29.5

30.8

31.6

32.9

34.3

35.8

36.8

38.4

40.2

42.3

43.8

46.1

48.8

51.5

20.0

20.3

21.2

21.5

21.4

22.3

23.8

23.9

23.6

24.4

26

26.9

27.6

29.6

30.7

32.4

100

130

140

160

180

200

200

220

250

260

280

300

320

340

360

380

PROBLEMS & THEIR Solutions:

Problem Cause Solutions

Power indicator does not

glow.

Wire feeder’s power

indicator does not glow or

it is not functioning.

Torch switch does not

work, But wire & gas Push

buttons on wire feeder are

working.

By pressing torch switch

Gas does not come.

Wire dose not come.

Current does not come.

While setting voltage from

rotary switches, voltage

variation is not linear.

One phase or all three

phases of power are

missing.

Faulty PCB.

Dust in torch switch or

loose connection of torch

plug.

Gas cylinder empty or

Heater does not heat up or

Pressure regulator faulty or

gas pipe blocked or faulty

solenoid valve.

Wire coil jam or Pressure

lever loose or Motor not

running.

Breakage of control

cable.

Loose wire on switch.

Damaged contacts of

switch.

Three core control cable

damage.

Melted fuse of PCB.

Check power supply status

then check fuses then

check supply cable &

connection strip at back

of machine.

Replace control cable.

Replace Fuse.

Replace PCB.

Wash the torch switch with

a oil based cleaning

agent or replace switch.

Replace torch plug.

Check step by step all

causes and replace the

faulty component.

Grease wire spool or set

appropriate pressure on

wire by adjusting pressure

lever then check motor if

faulty replace it else

replace PCB.

Find breakage area and

repair it or replace it with

new cable.

Tighten the loose wire.

Replace rotary switch.

1.

2.

3.

4.

5.

6.

7.

10

*We provide this information to guide only a certified engineer, There is always risk of electric shock during

repair please don’t do it your self, always get services from a professional engineer or company.

Cause of Welding defects and their solution’s:

Welding defect Cause Solutions

Black burned welding

bead.

Proper color good welding

but some fine holes like

needle holes in welding.

Weld bead raise (hollow

from inside) in-between or

probably at the end of

welding.

Low penetration.

Thin sheet burns during

welding.

Improper shielding gas.

Wrong selection of

shielding gas.

High welding current.

Faulty shielding gas.

Poor quality welding wire.

Dust, oil or cutting oil on

job.

Wrong selection of

shielding gas.

Low welding current.

If gas heater does not

heat up replace it or

increase gas flow, shield

welding area from air flow.

Replace gas cylinder with

a cylinder from different

lot.

Replace wire with an old

lot of wire or change its

brand.

Clean the job.

If you are using argon

mixed gas, use Co2

shielding gas.

Increase welding current.

Use Argon mixed gas

instead of Co2.

Set the welding current to

a relative lower value, if it

is not possible increase

the welding speed.

1.

2.

3.

4.

5.

11

* NOTE : The information provided above may different from actual.

Rated input voltage

Supply voltage

Rated frequency

Phase

Rated power

Rated duty cycle

OCV

Output current

Type of transformer

Insulation class

400

+

_

415 10%

50

3

9.5/7.8

60

22~45

50~250

Double star

Class H

IT EM

400

+

_

415 10%

50

3

19.4/17.5

60

28~54

80~400

Double star

Class H

RX 250

RX 400

TECHNICAL INFORMATION:

MAIN TR ANSFORMER

Required MCB 16 Amp. 3P 25 Amp. 3P

Supply Cable 1.5 mm2 or 3/20 2.5 mm2 or 7/22

Cooling Fan

Heater

220V AC 150W

220V AC 80W

Feeder Motor 24V DC

Solenoid Valve

24V DC

24V DC 24V DC

Main Contactor

16 Amp. Coil24V AC 16 Amp. Coil24V AC

220V AC 150W

220V AC 80W

Diodes 150 N 40 150 N 40

OCV Selector Switches 3P 4W 16Amp. 3P 4W 25Amp.

Fuses Control Tr.

Fan

Heater

PCB 78C

2.5 Amp

1 Amp

1 Amp

5 Amp.

2.5 Amp

1 Amp

1 Amp

5 Amp.

Welding Lead 25 mm2 35 mm2

MODEL

12

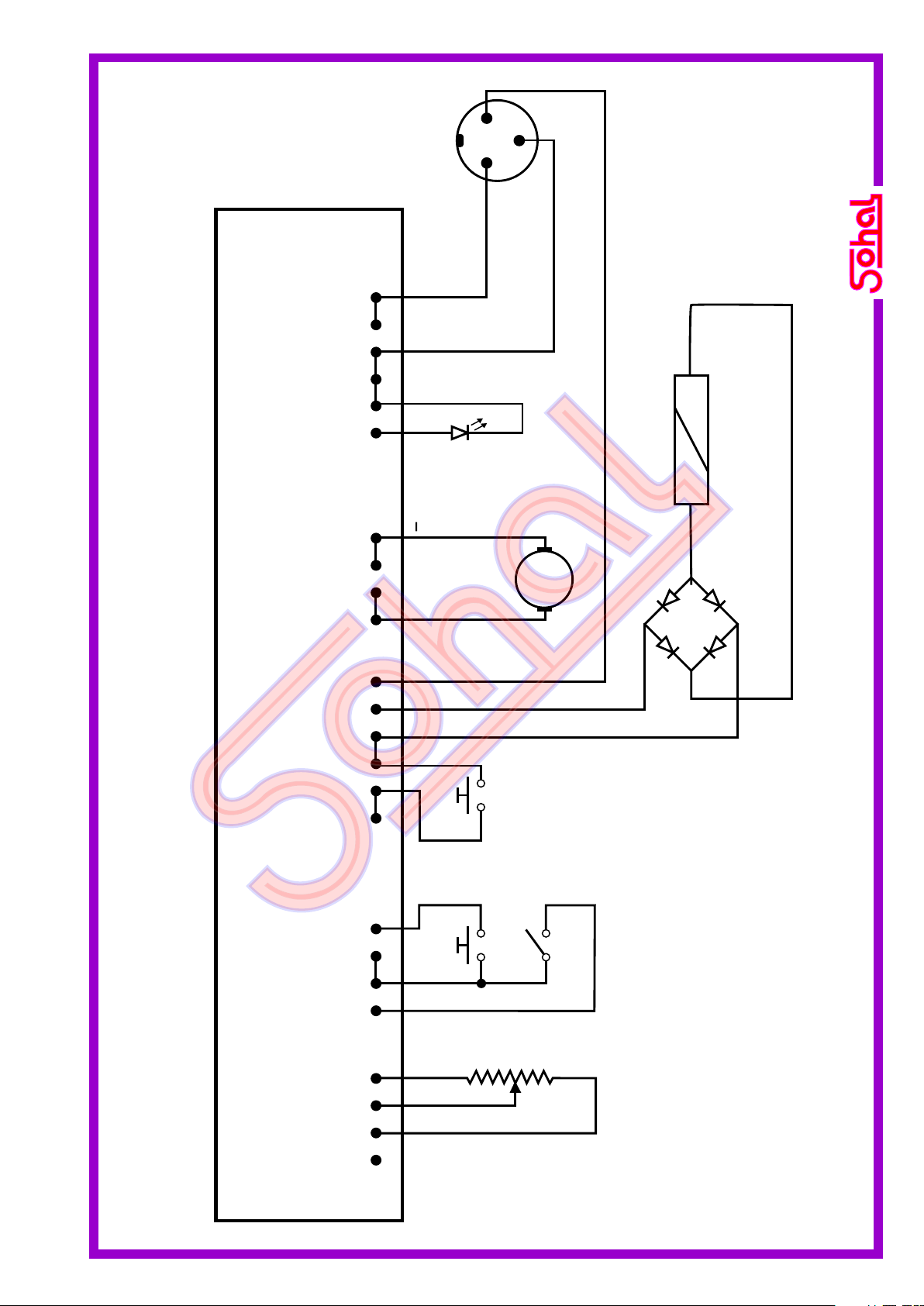

CIRCUIT DIAGRAM OF MIG RX 250 POWER SOURCE

L3

415-V

415-V

1

1

2

2

3

3

4

4

C

C

P

PP

P

P

P

1/3

1/3

2/3

2/3

3/3

3/3

B

L2

L1

M1

+

+

+

_

_

M2

Shunt (75m V/300 Amp. )

AUTO

Tr.2

Tr.1

Tr.3

2 x 2Amp.

220-V

26-V

FAN1

Q0

50-V

300-A

Q1

Y

L1

A1

Cont.1

F1

A2

Sw4

5Amp.

R

Sw3

F2

F3

3 PIN HCL PLUG (1)

(TO WIRE FEEDER)

HEATER PLUG

(2)

1

1

3

3

2

2

Sw1(

(

½

3

Sw2(

(

½

3

Sw2(

(

½

3

Sw2(

(

½

3

Sw1(

(

½

3

Sw1(

(

½

3

13

CIRCUIT DIAGRAM OF MIG RX 250 WIRE FEEDER.

Pot. 4K7 T. Sw.

P.B. (WIRE) P.B.

(GAS)

SOLENOID VALVE

COIL.

Arm.

+

1

2

3

3 PIN PLUG

(TO POWER SOURCE)

SOHAL 78 (PCB)

CN1CN2CN3CN4CN5

1 Amp.

14

Contact Tip

0.8 or 1.2mm

Contact Tip

Holder

Nozzle Spring

Swan Neck

Torch Body Plastic Ergo Handel with trigger

Trigger

Gas Nozzle

Liner Insulated

Power Cable 3m

Adaptor Nut Central

Adaptor

PM-3

Torch Plug

Gas Hose

28

8

90

M6

M6

M8

80

102

57

15

4

M8

1

M8

M 10x1

7

18

10

58

120

59

40

MIG TORCH SOHAL AK25-P

42

M 10x1

TORCH SPARE GUIDELINEs:

15

Contact Tip

0.8 or 1.2mm

Ergo Handel with trigger

Trigger

Gas Nozzle

Liner Insulated

Power Cable 3m

Adaptor Nut Central

Adaptor

PM-3

Gas Hose

Torch Plug

28

8

90

M6

M 10x1

18

10

58

120

59

40

MIG TORCH SOHAL 36KD-P

Contact Tip

Holder

Gas Diffuser

Swan Neck

80

16

M8

M6

28

70

32.5

M8

1

M 10x1

16

105

84

42

TORCH SPARE GUIDELINEs:

16

INSTALLATION GUIDE FOR MIG RX 250 / 400

17

Phone: +91-0161-2532255, Fax: +91-0161-2531116

SOHAL ELECTRIC WORKS

13243, Link Road, Chowk Dholewal, Ludhiana-141003 (PB.).

E-mail: mail@sohal.org

WWW.SOHAL.ORG

Other Sohal Welding System manuals

Popular Welding System manuals by other brands

ESAB

ESAB Precision Plasmarc EPP-600 manual

WIELANDER+SCHILL

WIELANDER+SCHILL WS 40 instruction manual

Miller

Miller Syncrowave 250 DX user manual

Thermal Dynamics

Thermal Dynamics cutmaster A60 operating manual

Kemppi

Kemppi MasterTig 535ACDC operating manual

Lincoln Electric

Lincoln Electric INVERTEC V160-S Service manual

Sonics

Sonics H520 T/E instruction manual

SIP

SIP P177 user manual

Rothenberger Industrial

Rothenberger Industrial ROXY KIT ECO manual

Timco Tools

Timco Tools iT500MIG Operation manual

Miller Electric

Miller Electric Big Blue 251D owner's manual

Lincoln Electric

Lincoln Electric POWER FEED 15M IM761 Operator's manual