Cloos qineo PULSE MASTER-Plus User manual

Brief

instructions

and

Operating

instructions

MASTER-Plus

Operating Panel

ii MA_QN_MP

Carl Cloos Schweisstechnik GmbH

Industriestrasse 34 · D-35708 Haiger

Tel. +49 (0) 2773 85 - 0, Fax +49 (0) 2773 85 - 275

E-Mail: [email protected]

Internet: http://www.cloos.de

These instructions are only valid in combination with the

operating instructions for the welding machine.

Release date: 24.04.15

Keep for future use

Brief instruction

- MASTER Plus -

• Schematic design

• Basic settings for commissioning

Brief instructions Schematic design

Procedure for commissioning

1. Select current contact tube, drive rollers and core or liner

according to the filler metal.

2. Check current contact tube and welding torch connection

for solid fit.

3. Check wire drive rollers for cleanliness and correct fit.

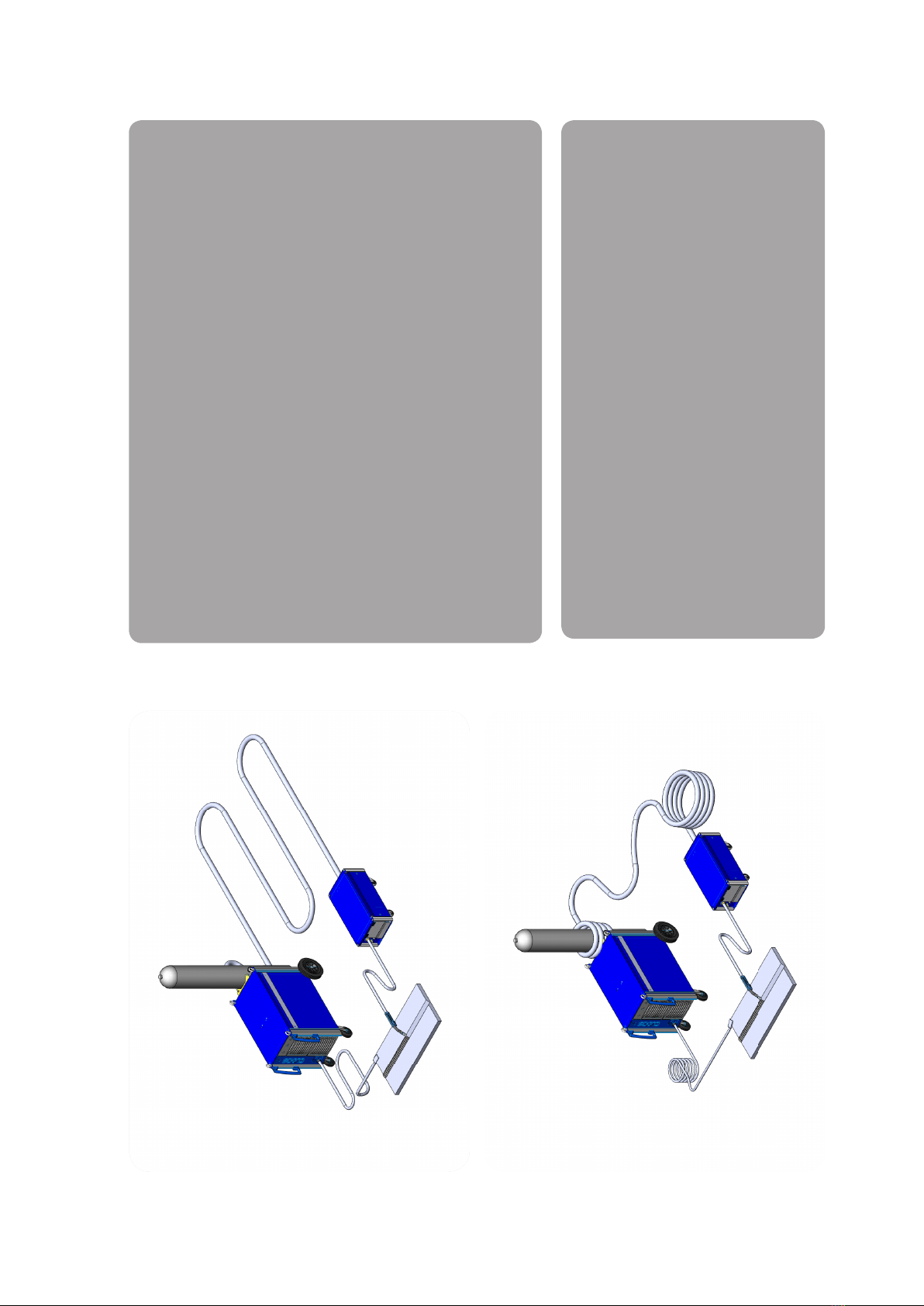

4. Lay connection cable assembly as shown at the top left.

5. Lay the earth cable as shown at the top left.

6. Check the earth cable on the welding machine and on the

workpiece / welding table for solid fit.

7. Adjust the correct gas flow rate.

8. Preselect the characteristic curve (see back).

Notice

Inductance effect

• The laying of the connection cable assembly and the

earth cable has a considerable effect on the welding char-

acteristics.

• Make sure that the connection cable assembly and the

earth cable are laid correctly and avoid coil windings (see

illustrations on the left).

Menu level

1

2 cycles

4 cycles

Super 4 cycles

Spot welding

External

1

5

43

2

Select requested parameter and adjust by handwheel

Voltage ACTUAL value

Converted power

Wire feed

Sheet thickness preview

Current ACTUAL value

Current preview

Arc fine adjustment

Voltage preview

CAUTION: In synergy mode all other parameters will be auto-

matically adapted in the background.

Functions in the menu level:

• Turn handwheel: select

• Press handwheel: activate

Wire feed as

reference vari-

able

LED description

LED : Ready for operation

LED :Welding

LED : Failure

Press the

handwheel:

Open the job quick

memory menu

Save current setting:

- Select job No. (S1-S5)

- Press handwheel for 2 seconds

Delete welding job:

- Select job to be deleted

- Press handwheel for 4 seconds

Press

the handwheel

LED off:

Fine adjustment -

arc length

LED on:

Fine adjustment -

arc dynamics

Measured value display

5

Arc fine

adjustment

4

Adjust welding capacity

3

Select operating

mode

2

Brief instruction Basic settings for commissioning

For detailed information,

please refer to the operating manual!

7

Block 3c MASTER Plus Operating panel

Content

1. Structure and function ............................................................................ 9

1.1 Operating panel........................................................................................................ 9

1.2 Display.........................................................................................................................10

1.3 Hold value display..................................................................................................10

1.4 Description of operating modes .....................................................................11

1.4.1 Definition 2-cycles .............................................................................................11

1.4.2 Definition 4-cycles .............................................................................................11

1.4.3 Definition Super-4-cycles................................................................................11

1.4.4 Definition Spot welding/Interval................................................................11

1.4.5 Definition External ............................................................................................11

1.5 Description of processes.....................................................................................12

1.5.1 TIG Welding...........................................................................................................12

1.5.2 Electrode Welding..............................................................................................12

1.5.3 MIG/MAG Welding ............................................................................................12

1.6 Description of processes in MIG/MAG process.........................................12

1.7 Description of additional functions ..............................................................14

1.7.1 Duo Pulse...............................................................................................................14

1.7.2 Clean Start.............................................................................................................15

1.7.3 Diagnosis ...............................................................................................................15

2. Operation.................................................................................................. 16

2.1 Operating concept of the operating modes ..............................................16

2.1.1 Operating mode 2-cycles................................................................................16

2.1.2 Operating mode 4-cycles................................................................................17

2.1.3 Operating mode Super-4-cycles..................................................................18

2.1.4 Operating mode Spot welding/Interval ..................................................19

2.2 Configuration of characteristic curve...........................................................19

2.2.1 Adjust secondary parameters ......................................................................20

2.2.2 Restore original secondary parameters...................................................20

2.2.3 Parameter of operating modes "2-cycles" and "4-cycles" .................20

2.2.4 Additional parameters of operating mode "Super-4-cycles"..........21

2.2.5 Additional parameters of operating mode "Spot Welding/Inter-

val".............................................................................................................................21

2.3 Save and load job....................................................................................................22

2.3.1 Rapid memory access.......................................................................................22

2.3.2 Space management..........................................................................................23

3. Configuration operating panel............................................................. 27

3.1 Language ...................................................................................................................27

3.2 Basic settings ...........................................................................................................28

3.2.1 Basic screen...........................................................................................................28

3.2.2 2-cycles start and end crater program .....................................................28

3.2.3 Fine adjustment .................................................................................................28

3.2.4 Control voltage mode.......................................................................................29

3.2.5 External selection of process ........................................................................29

8MA_QN_MP

3.2.6 Reset to factory setting....................................................................................29

3.3 General configuration..........................................................................................29

3.3.1 Automatic Hold display...................................................................................29

3.3.2 MHW 405 TQ ........................................................................................................30

3.3.3 Cooling water pump.........................................................................................30

3.3.4 Job continuation.................................................................................................31

3.4 Compensation of the external welding circuit ........................................31

3.4.1 For software version x.05 or higher ...........................................................31

3.4.2 For software version x.10 or higher ...........................................................32

3.5 Process monitoring ...............................................................................................32

3.6 Cooling water monitoring .................................................................................34

3.7 Sense technology ...................................................................................................35

3.8 QWD PushPull..........................................................................................................35

3.9 Lock/unlock functions..........................................................................................36

3.9.1 Access management ........................................................................................37

3.9.2 User management and PAK ..........................................................................38

3.10 PC adaptation ..........................................................................................................43

3.11 Options .......................................................................................................................43

3.12 Activation code........................................................................................................43

9

1. Structure and function

1.1 Operating panel

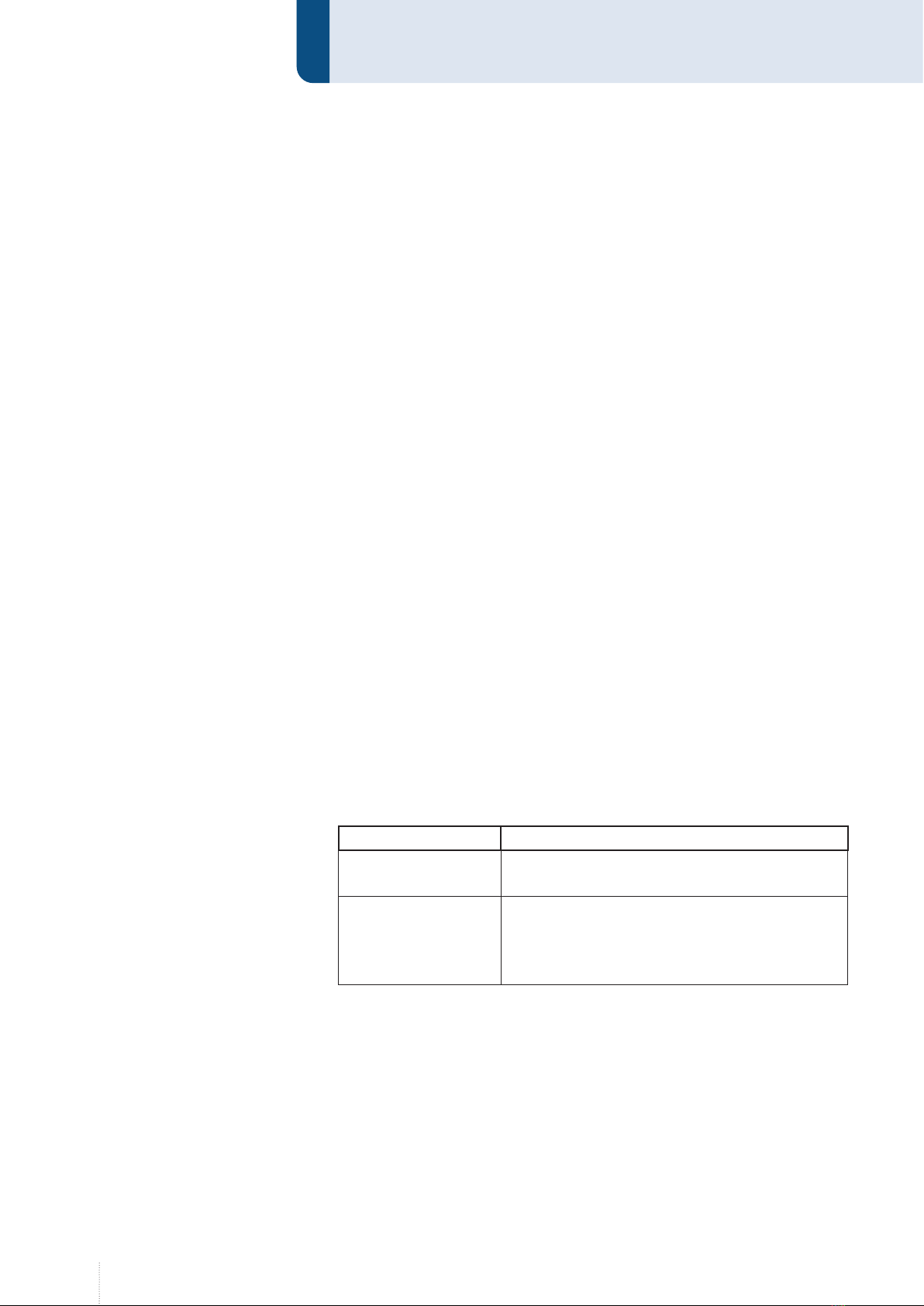

Item Designation Function

Selection key Op-

erating modes

2 cycles, 4 cycles, Super-4 cycles, Spot weld-

ing, External

Job key Load, save, delete job

Hold key Actual value display: m/min, mm, V, kW

Display hold values

Rotary knob left Quick save selection (Jobs), setting the

capacity

Menu button Welding settings: Basic and secondary

parameters

Rotary knob right Fine adjustment, dynamics

Key button

Actual value display: A, ASet (power pre-

view), fine calibration or dynamic, VNomi-

nal (in Syn-Off mode), lock/unlock

12

3 4 5 6 7

Illustration 50. Master Plus Operating Panel

1

2

3

4

5

6

7

10 MA_QN_MP

Structure and function

1.2 Display

Item Designation Function

Process Display active processes

Operating mode Display active operating mode

Function lock Display locked functions active

Job number Display active job/rapid memory

Status display

LED:

Green - Welding power source switched on

Blue - Welding process runs

Red (blinking) - Error message

Red/blue (alternating) -

Error message while welding

Main display Display of the welding measurement values

Fine adjustment

LED on: Rotary knob (6) adjusts the dynamic

LED off: Rotary knob (6) adjusts the arc

length

1.3 Hold value display

The hold value display shows the averaged values for the last weld for

10 seconds. To activate the hold value display, press the Hold button until

the display changes.

After the welding process, the hold display will automatically be displayed

for 5 seconds. This function can be deactivated in the configuration menu

under "General".

Illustration 51. Master Plus Display

8

12

9 10 11

13 14

8

9

10

11

12

13

14

11

1.4 Description of operating modes

The following operating modes can be selected:

• 2 cycles

• 4 cycles

• Super 4 cycles

• Spot welding/Interval

• External

1.4.1 Definition 2-cycles

Operating mode 2-cycles is provided for short manual welds. You can find

additional information in the chapter 2.1 on page 16.

1.4.2 Definition 4-cycles

Operating mode 4-cycles is provided for short manual welds. You can find

additional information in the chapter 2.1 on page 16.

1.4.3 Definition Super-4-cycles

Operating mode Super-4-cycles is provided for longer standard manual

welding tasks. The operating mode allows working with different main

parameters for the so-called power continuation. The power continuation

is ensured by shortly pressing the torch button. You can find additional

information in the chapter 2.1 on page 16.

1.4.4 Definition Spot welding/Interval

The spot function allows spot welding for a defined time. You can find

additional information in the chapter 2.1 on page 16.

1.4.5 Definition External

This function is intended for automated or robotic operation.

The various signals are selected via the automation interface of the

welding power source.

12 MA_QN_MP

Structure and function

1.5 Description of processes

The following welding processes will be described hereunder.

1.5.1 TIG Welding

The process is provided with a Lift Start ignition.

• Use the left rotary knob to select the welding current.

The displays for wire diameter and shielding gas are hidden.

1.5.2 Electrode Welding

All common stick electrodes can be welded in operating mode Electrode.

If you selected the process Electrode, the right display shows "Aset". The

displays for the wire diameter and the material thickness are masked

out. You can now select the required welding current by means of the left

rotary knob.

By pressing the left rotary knob the open circuit voltage is switched on. The

status display is lit blue. By pressing the left rotary knob again or changing

into another operating mode the open circuit voltage is switched off.

1.5.3 MIG/MAG Welding

This process is divided into pulse-free and pulsed MIG/MAG welding pro-

cesses with and without synergy function, see following chapter.

1.6 Description of processes in MIG/MAG process

The following MIG/MAG welding processes can be selected at the welding

power source:

Process Function

Control Weld

(MAG normal)

Control Weld is a synergy-guided, pulse-free MAG

normal welding process.

Synergy Off

This MAG normal welding process is synergy-in-

dependent. The parameters for the wire feed and

welding voltage must be set individually using

the rotary knob.

13

Process Function

Rapid Weld (modified

Control Weld)

This is a modified standard characteristic curve

of "Control Weld". A very concentrated arc,

ensuring a very deep penetration, is generated.

Rapid Weld characteristic curves are available for

the following material-gas-wire combinations.

• Normal, Fe, 92% Ar, 8% CO2 wire 1,0 mm

• Normal, Fe, 92% Ar, 8% CO2 wire 1,4 mm

• Normal, Fe, 82% Ar, 18% CO2 wire 0,8 mm

• Normal, Fe, 82% Ar, 18% CO2 wire 1,0 mm

• Normal, Fe, 82% Ar, 18% CO2 wire 1,2 mm

• Normal, Fe, 82% Ar, 18% CO2 wire 1,6 mm

• Normal, Fe, 91% Ar, 4% O2 , 5% CO2 wire 1,2 mm

• Normal, Fe, 91% Ar, 4% O2 , 5% CO2 wire 1,4 mm

• Normal, Fe, 91% Ar, 4% O2 , 5% CO2 wire 1,6 mm

Vari Weld (I/I-Pulse)

The Vari Weld process is an I/I-controlled pulsed

arc.

The welding settings are selected for the

MIG/MAG welding process "Vari Weld" so an

extremely low spatter pulsed arc is created

without further fine adjustment (arc length and

dynamic).

The welding current does not depend on the

distance between torch and workpiece. Arc seam

tracking is not possible in connection with a

ROMAT robot application.

Speed Weld (U/I

Pulse)

The Speed Weld process is a U/I-controlled

pulsed arc.

The MIG/MAG welding process "Speed Weld"

is especially suitable for high welding speeds

and is ideal for joining sheet metal parts from

0,1 … 5 mm.

The welding current depends on the distance

between torch and workpiece. Arc seam tracking

in connection with a ROMAT robot application is

possible.

14 MA_QN_MP

Structure and function

1.7 Description of additional functions

The following additional functions are available in the selection menu for

the basic and secondary parameters.

Function Condition

Duo Pulse only if the selected characteristic curve offers this func-

tion

Clean Start only if the selected characteristic curve offers this func-

tion

Diagnosis

1.7.1 Duo Pulse

A second weld parameter set is generated from the set basic value by

means of the Duo Pulse (Aluplus) function. This can be greater or less than

the basic value. By means of a defined frequency there is a switch-over

between the two parameter sets. The appearance of the weld seam surface

is formed by the defined change of parameters. During root welding,

defined cool-down times are reached depending on the setting.

If the "Duo Pulse" function is activated, the following additional changes

are available in the menu secondary parameters.

Parameters Value range

"DuoPulse modulation" Correction value (+/- 99)

"DuoPulse frequency" Correction value (+/- 99)

Menu button

1

Illustration 52. Selection menu for basic and secondary parameters

1

15

1.7.2 Clean Start

Clean Start is a special ignition routine which ensures a reliable and low

spatter arc ignition. The complete ignition routine runs in the millisecond

range.

1.7.3 Diagnosis

The machine model, performance class, data set number, the current

version of the selected synergy characteristic curve and the software

versions of the modules connected to the CAN bus are displayed in this

menu. The "Data set number" identifies the entire characteristic curve data

set. The "Characteristic curve number" identifies the current characteristic

curve.

Welding power sources are compatible with the operating panel with a

software version of x.08 and higher.

16 MA_QN_MP

Operation

2. Operation

2.1 Operating concept of the operating modes

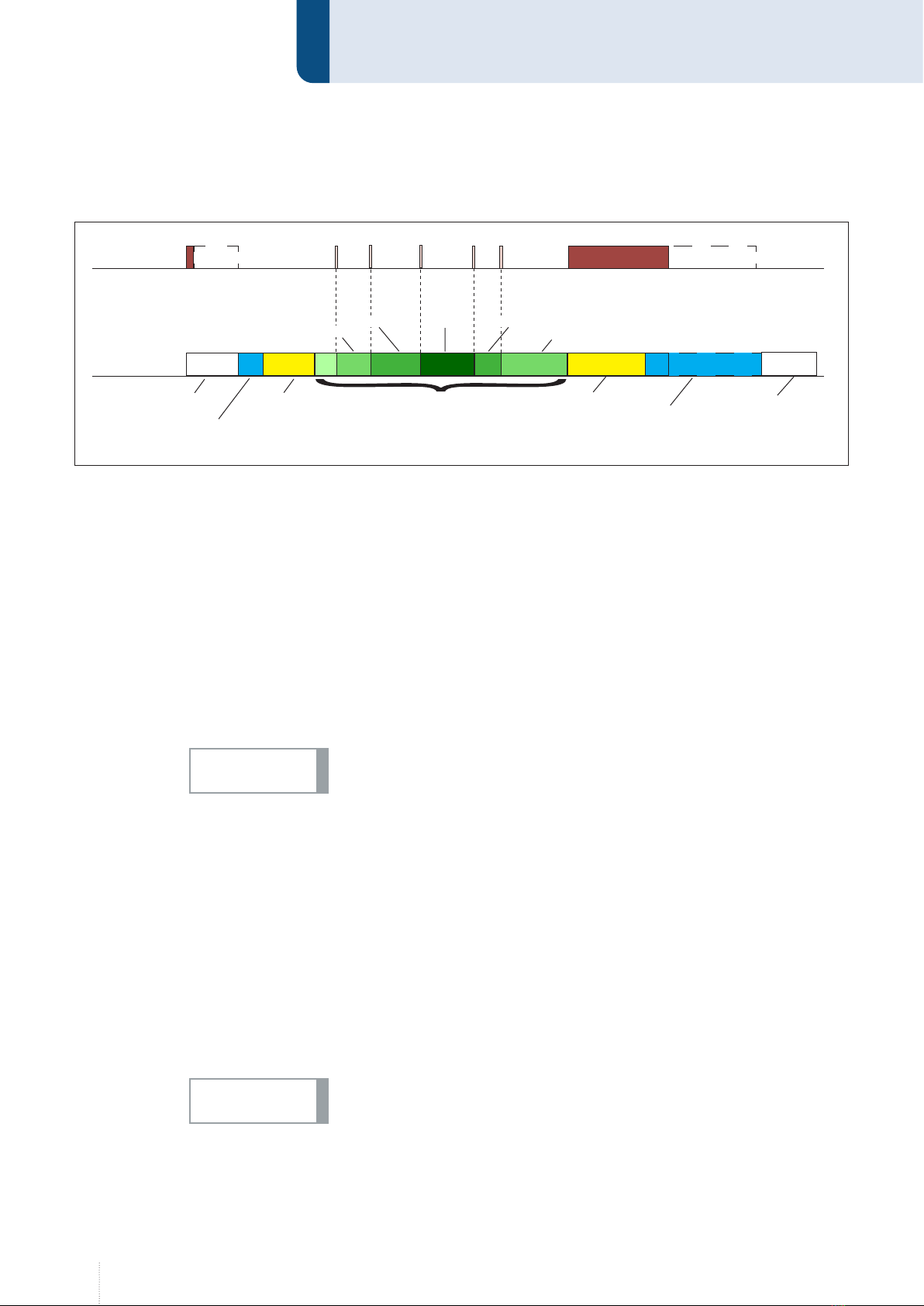

2.1.1 Operating mode 2-cycles

1st cycle --> Press and hold torch button

• Solenoid valve for shielding gas opens

• Weld voltage is applied on wire electrode

• Wire feed starts with reduced speed (inching-in)

• Arc ignites, weld current flows

• Wire feed switches to the preset speed

2nd cycle -->Release torch button

• Wire feed stops

• Weld voltage switches off after expiration of the "burnback time“

• Arc extinguishes

• Solenoid valve closes after expiration of the "gas post-flow time“

Torches

Keystroke

Welding time

Start time:

3 sec

Gas pre-flow +

inching in

Wire burnback +

gas post-flow

End crater

filling time:

3 sec

Upslope

1 sec

Downslope

2 sec

Main power

1 s

3 s 2 s 3 s

17

2.1.2 Operating mode 4-cycles

1st cycle --> Press and hold torch button

• Solenoid valve for shielding gas opens

• Weld voltage is applied on wire electrode

• Wire feed starts with reduced speed (inching-in)

• Arc ignites, weld current flows

• Wire feed switches to the preset speed

2nd cycle -->Release torch button

• The start program is executed with the adjusted parameters and then

switches via a programmable time function ("Up-Slope") into the main

program.

3rd cycle --> Press and hold torch button

• Change from main program to the end program via a time function

("Down-Slope").

4th cycle --> Release torch button

• Wire feed stops

• Weld voltage switches off after expiration of the "burnback time“

• Arc extinguishes

• Solenoid valve closes after expiration of the "gas post-flow time“

Torches

Keystroke

Welding time

Start time:

1 sec

Gas pre-flow +

inching in

Wire burnback +

gas post-flow

End crater

filling time:

3 sec

Upslope

3 sec

Downslope

2 sec

Main power

3 s1 s 2 s 3 s

18 MA_QN_MP

Operation

2.1.3 Operating mode Super-4-cycles

1st cycle --> Press and hold torch button

• Solenoid valve for shielding gas opens

• Weld voltage is applied on wire electrode

• Wire feed starts with reduced speed (inching-in)

• Arc ignites, weld current flows

• Wire feed switches to the preset speed

2nd cycle -->Release torch button

• The start program is executed with the adjusted parameters and then

switches via a programmable time function (Up-Slope) into the main

program.

If the start time in the program menu is set to "Torch", releasing the torch

button switches to the main program.

(optional) Power continuation --> Tap torch button

• Depending on the configuration of the "Step modulation" and "Num-

ber of steps" parameters, the power and wire feed speed are increased

or reduced with each press of the button on the torch. You can find ad-

ditional information in the chapter “2.2 Configuration of characteristic

curve”.

3rd cycle --> Press and hold torch button

• A time function (down-slope) switches from the main program to the

end program and the end parameters are executed.

4th cycle --> Release torch button

If the end crater filling time parameter is set to "Torch", the end param-

eters will not be executed until the torch button is released.

• Wire feed stops

• Weld voltage switches off after expiration of the "burnback time“

• Arc extinguishes

• Solenoid valve closes after expiration of the "gas post-flow time“

3 s

0 +4 +42 s

Torches

Keystroke

Welding time

Start time:

1 sec

End crater filling

time:Torch

Upslope

2 sec

Downslope

3 sec

Main power

Step modulation +2

Number of steps: 3

1 s +6

+2 +2 Torch

Gas pre-flow +

inching in Burnback +

Gas post-flow

Step 1

Step 1 Step 2 Step 3 Step 2

NOTICE!

NOTICE!

19

2.1.4 Operating mode Spot welding/Interval

Press and hold torch button

• Solenoid valve for shielding gas opens

• Weld voltage is applied on wire electrode

• Wire feed starts

• Arc ignites, weld current flows

• Welding process stops automatically after expiration of the defined

time.

Release torch button during the spot time

• The welding process is immediately stopped

2.2 Configuration of characteristic curve

The QINEO welding power sources always use the existing synergic

characteristic curves. These default values can be adjusted in the secondary

parameters menu.

2 s

Torches

Keystroke 1 s 3 s

2 s 2 s

1 s

Welding time

Menu button

1

Illustration 53. Selection menu basic (left) and secondary parameters (right)

1

20 MA_QN_MP

Operation

2.2.1 Adjust secondary parameters

1. Press the menu button.

2. Using the left rotary knob, select the menu for the secondary

parameters for the characteristic curve and confirm it by pressing the

knob.

3. Select the desired parameter by turning the left rotary knob and con-

firm your selection by pressing the knob.

4. Turn the rotary knob to change the default value and confirm the

correction value by pressing the knob.

5. To exit the menu, select the exit symbol by turning the rotary knob and

confirm by pressing the knob.

The correction values will be added to the original values. The parameters

of the original characteristic curve will not be changed.

2.2.2 Restore original secondary parameters

1. Press the menu button.

2. Using the left rotary knob, select the menu for the secondary

parameters for the characteristic curve and confirm it by pressing the

knob.

3. Set the correction value to "-0-".

4. To exit the menu, select the exit symbol by turning the rotary knob and

confirm by pressing the knob.

2.2.3 Parameter of operating modes "2-cycles" and "4-cycles"

• Gas pre-flow Correction value (Off, +/- 99)

• Inching-in Correction value (+/- 99)

• Start program (time) Correction value (Off, +/- 99)

• Start program (power) Correction value (+/- 99)

• Upslope Correction value (Off, +/- 99)

• Main power Absolute value (m/min)

• Downslope Correction value (Off, +/- 99)

• End crater prog. (time) Correction value (Off, +/- 99)

• End crater prog. (power) Correction value (+/- 99)

• Wire burnback Correction value (+/- 99)

• Gas post-flow Correction value (Off, +/- 99)

NOTICE!

Table of contents

Other Cloos Welding System manuals

Popular Welding System manuals by other brands

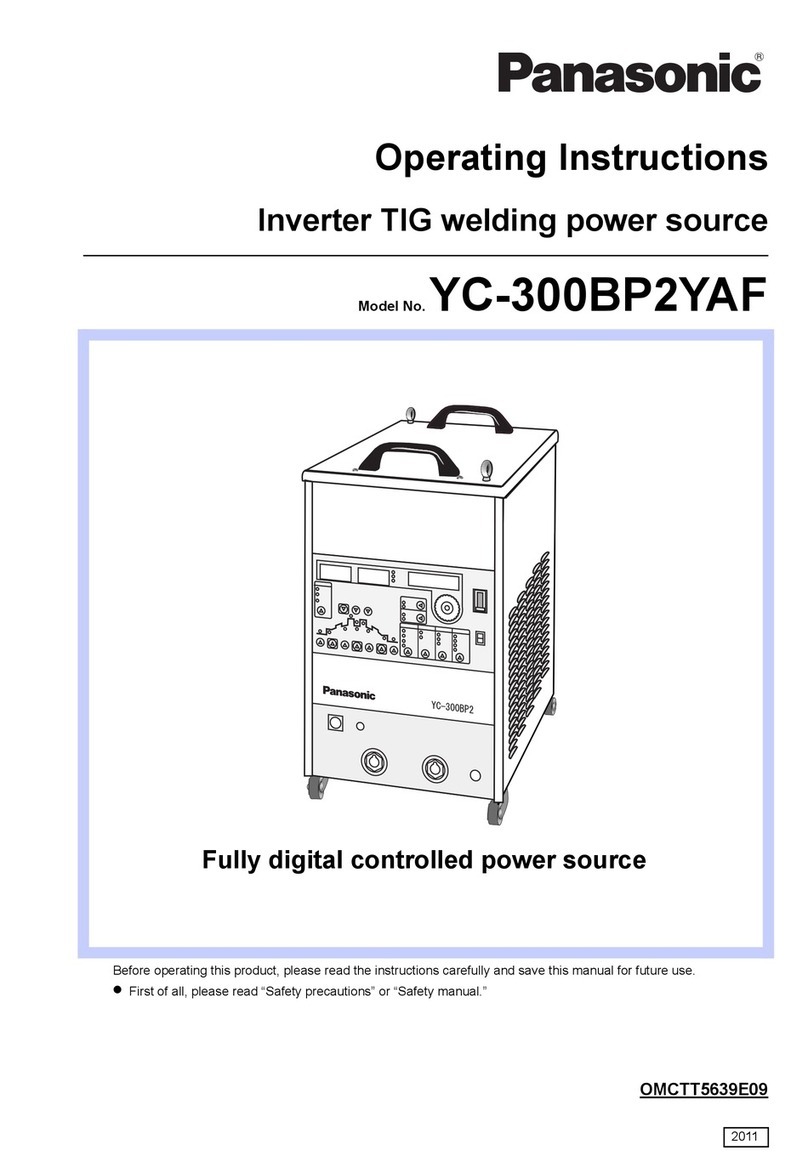

Panasonic

Panasonic YC-300BP2YAF operating instructions

Lincoln Electric

Lincoln Electric CV ADAPTER IM309-D Operator's manual

Cebora

Cebora MONO STAR MIG 1620/M instruction manual

Draper

Draper MW180AT instructions

Lincoln Electric

Lincoln Electric INVERTEC IM526-B Operator's manual

Miller

Miller ARC PAK 350 owner's manual