Solar Electronics 7054-1 User manual

INTRUCTION MANUAL

FOR

MODEL 7054-1

SPIKE GENERATOR

March 10, 1971

Revised: June 11, 1976

Revised: March 9, 2007

Revised: June 30, 2009

Solar Electronics Company

A Division of A. T. Parker, Inc.

10866 Chandler Boulevard

North Hollywood, California 91601

Telephone: (818) 755-1700 Fax: (818) 755-0078

Solar Electronics Company

2 of 22

4

4

6

7

7

7

8

9

9

10

10

10

11

11

11

11

11

13

15

15

16

16

17

17

18

TABLE OF CONTENTS

1.0 Application…………………………………………………………………………...

2.0 Description…………………………………………………………………………..

3.0 Specifications……………………………………………………………………….

4.0 Operation………………………………………………………………………….....

4.1 General…………………………………………………………………........

4.2 Interconnections for Parallel Injection…………………………...........

4.3 Interconnections for Series Injection………………………….............

4.4 FUNCTION Switch…………………………........…………………………

4.5 Pulse Positioning…………………………........………………………….

4.6 Repetition Rate…………………………........………………………….....

4.7 Spike Amplitude…………………………........…………………………...

4.8 Amplitude with Low Impedance Loads…………………………..........

4.9 Pulse Shape…………………………........…………………………..........

5.0 Maintenance and Calibration…………………………......................................

5.1 Equipment

Required…………………………........................................+

5.2 Preliminary Procedure.........................................................................

5.3 Voltage Check......................................................................................

5.4 Trigger Waveform................................................................................

5.5 Check and Adjustment of Maximum Amplitude................................

5.6 Check and Adjustment of Frequency Calibration.............................

5.7 Check and Adjustment of Range of Pulse.........................................

5.8 Check and Adjustment of Range of Pulse.........................................

5.9 Check of Single Pulse Function.........................................................

5.10 Compare Waveforms on 2K Ω50 W Resistors................................

6.0 Parts List…………………………........................................……………………..

Solar Electronics Company

3 of 22

4

5

13

14

7

8

8

9

12

12

17

Oscilloscope Plots, Illustrations and Images

Oscilloscope Plots

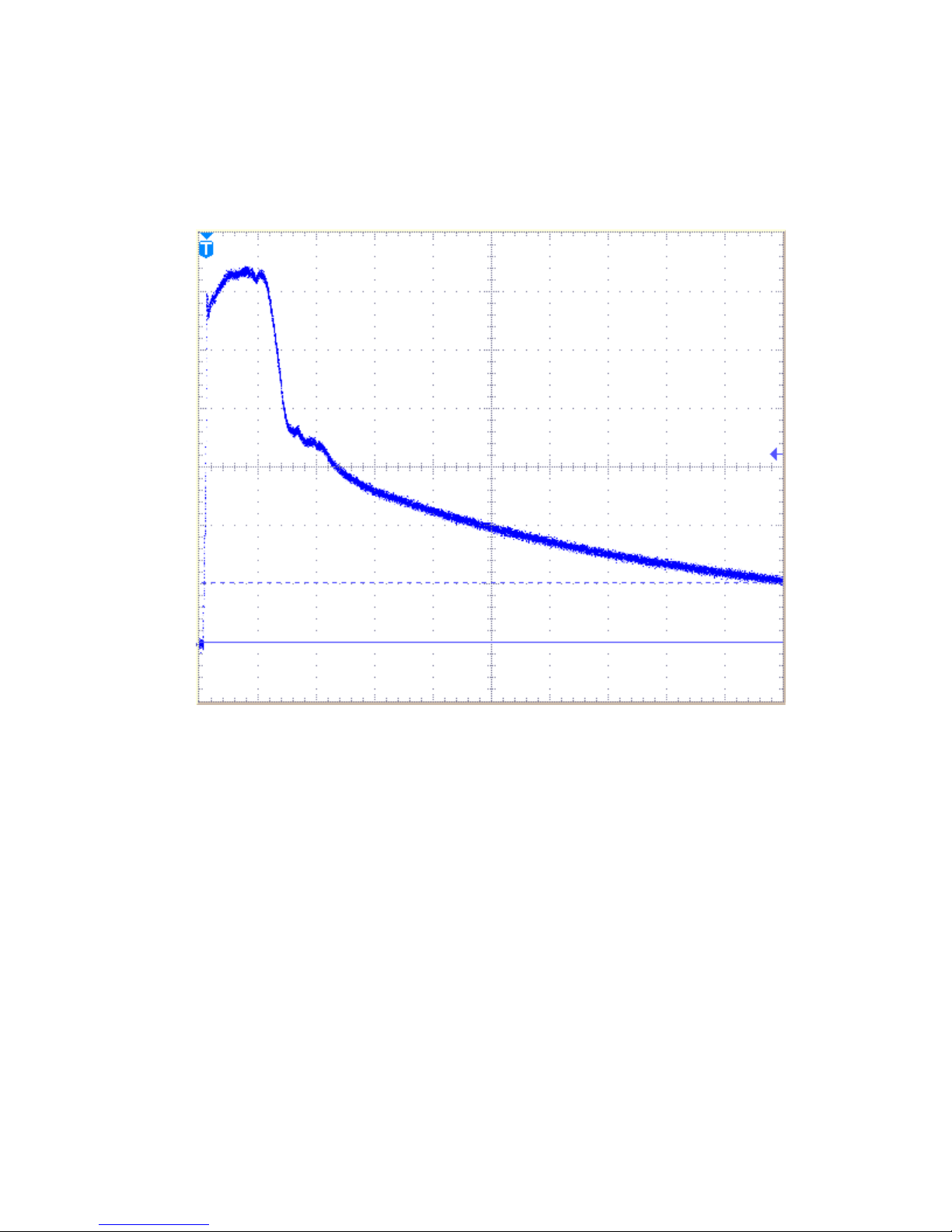

Figure 1 – Pulse Shape with 5 ΩLoad on Either Series or Parallel Output…………...

Figure 2 – Pulse Shape with 0.5 ΩLoad on Either Series or Parallel Output…………

Figure 9 – Waveform at output of Q5, Amplitude at zero…………………………………

Figure 10 – Waveform at output of Q5, Amplitude at maximum………………………...

Illustrations

Figure 3 – Parallel Injection on DC Line……………………………………………………..

Figure 4 – Series Injection on AC Line……………………………………………………….

Figure 5 – Series Injection on DC Line, Measuring 7054-1 Spike Only………………...

Figure 6 – Setup for Pulse Position Test on 400 Hz Line…………………………………

Images

Figure 7 – Printed Circuit Board Reference Designators…………………………………

Figure 8 – Adjustment Sliders and Measurement Point…………………………………..

Figure 11 – 2K Ω50 W Resistors……………………………………………………………...

Solar Electronics Company

4 of 22

1.0 Application

The model 7054-1 Spike Generator was specifically designed for screen room use in

making conducted transient susceptibility tests as required by MIL-STD-826A, MIL-STD-

461A/462 and other RFI/EMI specifications.

2.0 Description

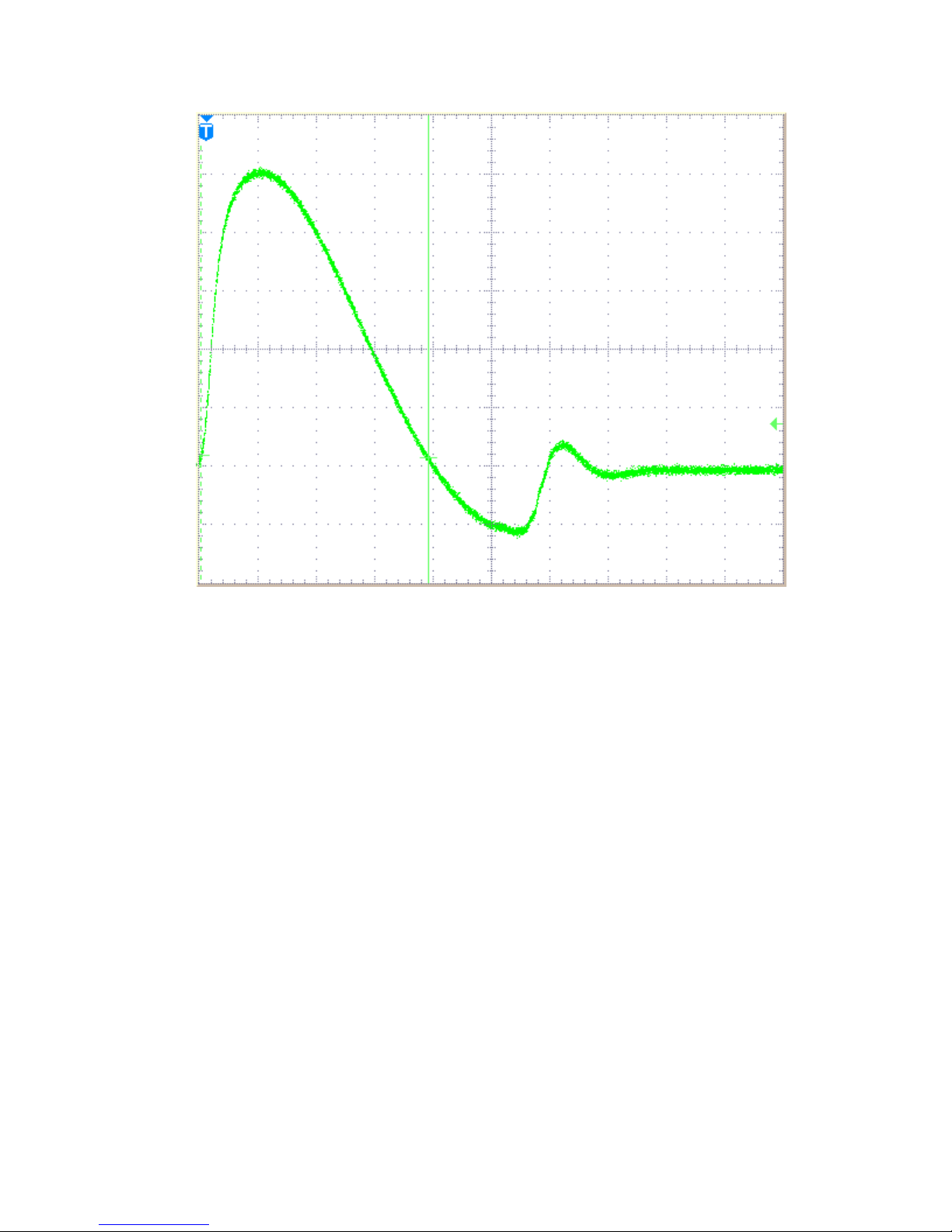

The model 7054-1 Spike Generator provides a transient pulse (spike) with amplitude

adjustable up to 600 V peak. Using parallel injection into a resistive load, the output

transient closely follows an idealized curve with less than 1 µs rise time and falling to

10% of full voltage in approximately 10 µs. See Figure 1 and 2. The repetition rate is

adjustable from 0.8 pulses per second (pps) to 10 pps.

10 20 30 40 50 60 70 80 90

Vertical: 20 V/div

Horizontal: 10 µs/div

Frequency: 10 pps

Amplitude: 100 V peak into 5 Ωload

Figure 1 – Pulse shape with 5 Ωload on either series or parallel output

120

0

20

40

60

80

100

Am

p

litude, Volts

Microseconds

Solar Electronics Company

5 of 22

2 4 6 8 10 12 14 16 18

Vertical: 20 V/div

Horizontal: 2 µs/div

Frequency: 10 pps

Amplitude: 100 V peak into 0.5 Ωload

Figure 2 – Pulse shape with 0.5 Ωload on either series or parallel output

A FUNCTION switch allows either recurring spikes at a selected rate or provides for

single spikes by a panel-mounted push button. The FUNCTION switch also provides for

synchronization with 60 Hz* or 400Hz lines.

When synchronizing with AC lines, the PULSE POSITION knob allows for phase

adjustment of the spike to position it anywhere on the AC sine wave.

The PARALLEL output terminals provide for injection of the spike in parallel with the

load. The SERIES output terminals provide connections for series injection. The output

terminals are isolated from the chassis and the AC line.

100

-20

0

20

40

60

80

Am

p

litude, Volts

Microseconds

Solar Electronics Company

6 of 22

3.0 Specifications

Spike Repetition Rate

Continuously adjustable from 0.8 pps to 10 pps

Spike Amplitude

Continuously adjustable from 5 V to 600 V peak

Spike Duration

Output falls to 10% of full voltage in approximately 10 µs with a 5 Ωload on the

SERIES output terminals

Rise Time

Less than 1 µs into 5 Ωresistive load

Spike Shape

Ringing characteristic as per Figure 1 and Figure 2

Phase Adjustment

Adjustable from 0° to 360° on 60 Hz* or 400 Hz lines

Internal Impedance

Approximately 0.5 Ω

Power Line Current in Series Injection Mode

Handles 25 A RMS at power frequencies or DC

Power Requirement

115 V 60-400 Hz, 1.6 A**

Size

19” rack panel, 7” high x 12-3/4” deep, less projections

Weight

US: 36 lb.; Metric: 16.3 kg.

Solar Electronics Company

7 of 22

4.0 Operation

4.1 General

Parallel Injection is most often used for DC lines. Series injection is always used on AC

lines. CAUTION! DO NOT CONNECT OUTPUT OF SPIKE GENERATOR IN

PARALLEL WITH AC LINES. ALTHOUGH SERIES INJECTION CAN BE USED ON

EITHER AC OR DC LINES, PARALLEL INJECTION MUST NOT BE USED ON AC

LINES SINCE SEVERE DAMAGE TO THE SPIKE GENERATOR WILL RESULT.

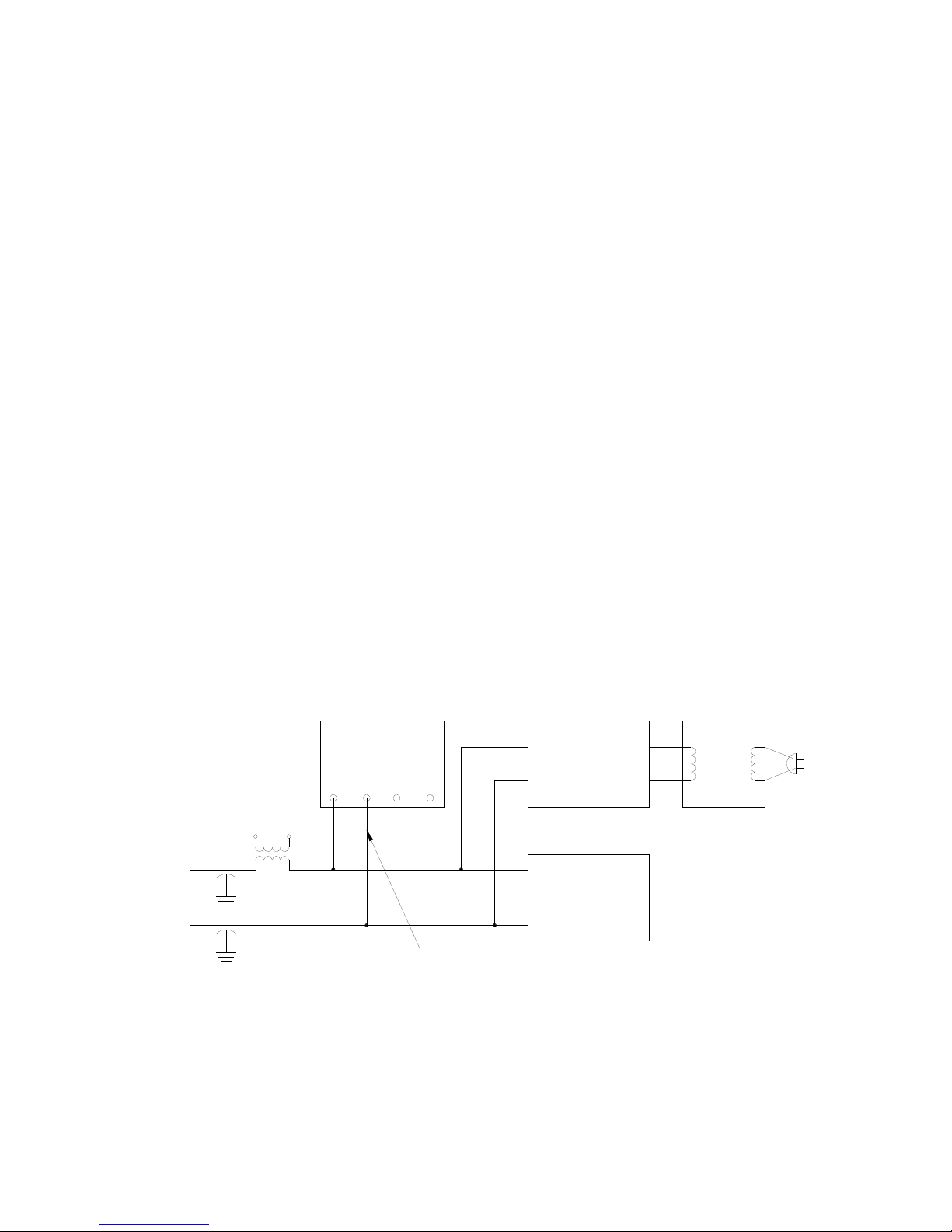

4.2 Interconnections for Parallel Injection

As shown in Figure 3, connect the oscilloscope to the terminals marked PARALLEL.

Also connect these terminals to the DC input power leads of the equipment under test.

Take precautions to prevent grounding the load through the case of the oscilloscope.

Use a Solar type 7032-1 Isolation Transformer or equivalent at the power input to the

oscilloscope. All output terminals on the Spike Generator are isolated from the case of

the unit.

When parallel injecting the spike into a DC line, it is desirable to use an inductor in series

with the power source so that the spike is applied to the test sample without the R.F.

shunting effect of the power source impedance. The secondary of Solar Type 6220-1A

Audio Isolation Transformer is well suited for this application and is capable of carrying

50 A of test sample current.

Solar

7054-1

Oscilloscope

Solar

7032-1

Isolation

Transformer

Test Sample

A.C.

D.C. Line

Solar

6512-106R

10 µF

Solar

6220-1A

FIGURE 3 - PARALLEL INJECTION ON D.C. LINE

Parallel

Output

Parallel Series

Solar Electronics Company

8 of 22

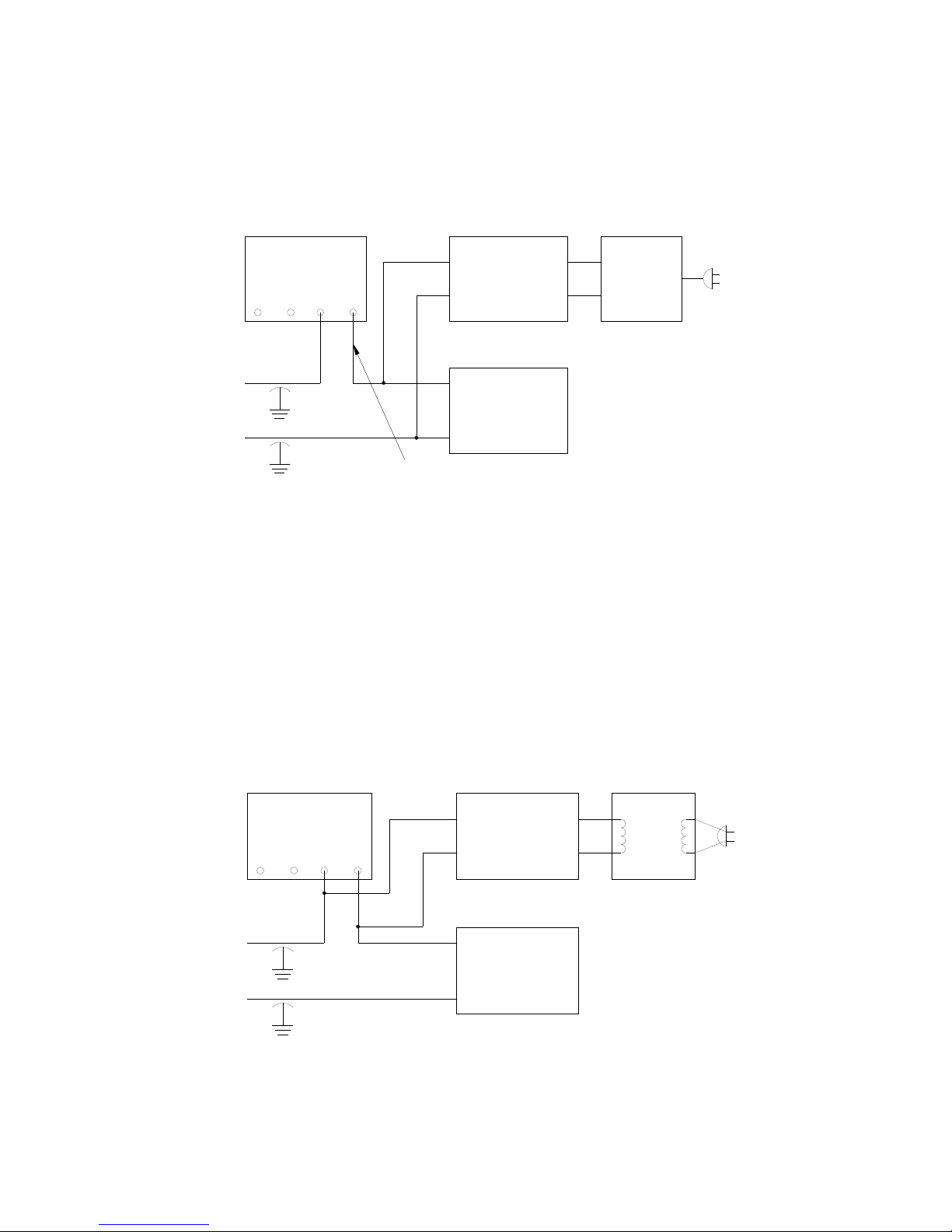

4.3 Interconnections for Series Injection

For series injection, connect the output terminals marked SERIES in series between the

power source and the test sample as shown in Figure 4. It is recommended that the

injection be in series with the ungrounded side of the power line.

Solar

7054-1

Oscilloscope

Solar

7032-1

Isolation

Transformer

Test Sample

A.C.

A.C. Line

Solar

6512-106R

10 µF

Series

Output

FIGURE 4 - SERIERS INJECTION ON A.C. LINE

Parallel Series

The series connection is capable of handling 25 A RMS or DC This connection inserts

approximately 75 µH in series with the test sample. The power frequency voltage drop

across this reactance is 4.75 V at 25 A, 400 Hz.

The oscilloscope should be connected across the SERIES output terminals to indicate

the shape and magnitude of the spike being injected into the circuit. See Figure 5.

However, the spike as it appears on the AC waveform into the test sample is best seen

by connecting the oscilloscope across the power input leads to the test sample, as

shown in Figure 4. Precautions must be taken to avoid grounding the hot side of the

power line through the case of the oscilloscope.

Solar

7054-1

Oscilloscope

Solar

7032-1

Isolation

Transformer

Test Sample

A.C.

D.C. Line

Solar

6512-106R

10 µF FIGURE 5 - SERIES INJECTION ON D.C. LINE

OSCILLOSCOPE MEASURING 7054-1 SPIKE ONLY

Parallel Series

Solar Electronics Company

9 of 22

4.4 FUNCTION Switch

This control enables the operator to select from three functions. In the extreme left,

SINGLE PULSE position, it provides for pushbutton operation of single transients. The

FREQUENCY P.P.S. position selects the variable repetition rate function. The last two

FUNCTION switch positions select pulse positioning on 60Hz and 400Hz AC power

signals respectively.

4.5 Pulse Positioning

With the equipment connected for series injection on AC lines, as shown in Figure 4,

place the FUNCTION switch in 60 Hz* or 400 Hz SYNC position as required. The power

cord of the Spike Generator must be connected to the same power source as the test

sample.

However, when operating on a 400 Hz power line for the pulse position test, it is

necessary to connect the blower fan to the standard 60 Hz* line. See figure 6. This is

accomplished by removing the parallel blade connector, P1, from its socket (adjacent to

the fuses on the rear panel) and connecting it to a primary power source of 115 V 60

Hz*.

Connect the oscilloscope across the power input to the test sample. Avoid grounding the

hot side of the line through the case of the oscilloscope. A power line isolation

transformer such as Solar type 7032-1 is suggested at the power input to the scope, as

shown in figures 4 and 6.

Oscilloscope Sola

r

7032-1

Test Sample

400

Hz

Line

Sola

r

6512-106R

10 µF

Series

Output

FIGURE 6 - SETUP FOR PULSE POSITION TEST ON 400 Hz LINE

115 V

400 Hz

Line

P1

Sola

r

7054-1

Parallel Series

115 V

60 Hz

LINE

Solar Electronics Company

10 of 22

The PULSE POSITION control in conjunction with the polarity reversing switch will

enable phase shift of the injected spike through 360° as observed on the oscilloscope.

The phase reversing switch at the bottom of the panel will allow adjustment of the spike

position to the positive half cycle or the negative half cycle of the power line sine wave.

Due to the phase difference existing, the knob position corresponding to the voltage zero

crossover will differ from one test sample to another.

When synchronizing on a 60 Hz* line, the spike appears on every 8th sine wave of the

power frequency. On a 400 Hz line, the spike appears on every 64th sine wave. The

spike position, however, is the same on each sine wave on which the spike appears.

This periodic injection of the spike is due to the 7.5** pps rate on 60 Hz* lines and a rate

of 6.2 pps on 400 Hz lines. (In this equipment, the repetition rate must be kept below

10 pps to allow time for the charging of the capacitors which provide the energy for the

spike.)

CAUTION: WHEN OPERATING ON A 400 HZ POWER LINE, DO NOT LEAVE THE

FUNCTION SWITCH IN THE 60 HZ POSITION FOR PROLONGED PERIODS SINCE

IT MAY CAUSE OVERHEATING OF THE POWER SUPPLY.

Upon completion of the 400 Hz pulse positioning test, reinsert the parallel blade

connector into the mating socket. This connector should remain in this position for all

other uses of the Spike Generator.

4.6 Repetition Rate

The calibration of the knob in pps is reasonably accurate (approximately ±10%) at all

panel markings. For applications where the exact rate is important, it may be measured

on the time base scale of the associated oscilloscope. The rate is independent of load

conditions.

4.7 Spike Amplitude

The amplitude of the spike is adjustable from approximately 5 V to 600 V peak by means

of the AMPLITUDE knob. The calibration of this scale is most accurate at 100 V with a

resistive load greater than 5 Ωand with a repetition rate of 10 pps. For adjustment of

amplitude into unknown loads, the knob must be adjusted while watching the spike

amplitude on an oscilloscope with calibrated vertical amplitude.

4.8 Amplitude with Low Impedance Loads

Since the internal impedance of the Spike Generator is of the order of 0.25-1.0 Ω, the

amplitude into a matched load will be one half that of the open circuit amplitude. This

characteristic enables the operator to estimate the load impedance when it is

approaching the internal impedance of the generator.

Solar Electronics Company

11 of 22

4.9 Pulse Shape

When unloaded or connected to a purely resistive load, the spike shape is approximately

that of Figure 1. For low impedance or reactive loads, the shape is modified in terms of

load. Figure 2 indicates the spike shape when connected to a 0.5 Ωresistive load.

5.0 Maintenance and Calibration

Periodically make the following tests to verify the performance of the Spike Generator.

Make any adjustments required to bring the performance within the specified limits.

5.1 Equipment Required

The following equipment is required for the tests and adjustments described below:

1. Variac, 105-135 V, 60 to 400 Hz,* capable of handling 2 A

2. AC voltmeter, range suitable for measuring line voltage at 60 ** and 400

Hz

3. Calibrated oscilloscope

4. DC voltmeter

5. Single phase 400 Hz power source, capable of supplying 2 A

6. 5 Ωresistor, ±10%, ≥20 W

7. 6 V, 400 Hz transformer

5.2 Preliminary Procedure

Be sure the line cord of the Spike Generator is disconnected from the primary source.

Remove screws in top cover and in bottom cover.

Connect the variac to a 115 V 60 Hz* power source. Plug the Spike Generator into

output of variac. Connect the voltmeter across the variac output and maintain 115 V***

input to Spike Generator throughout the test.

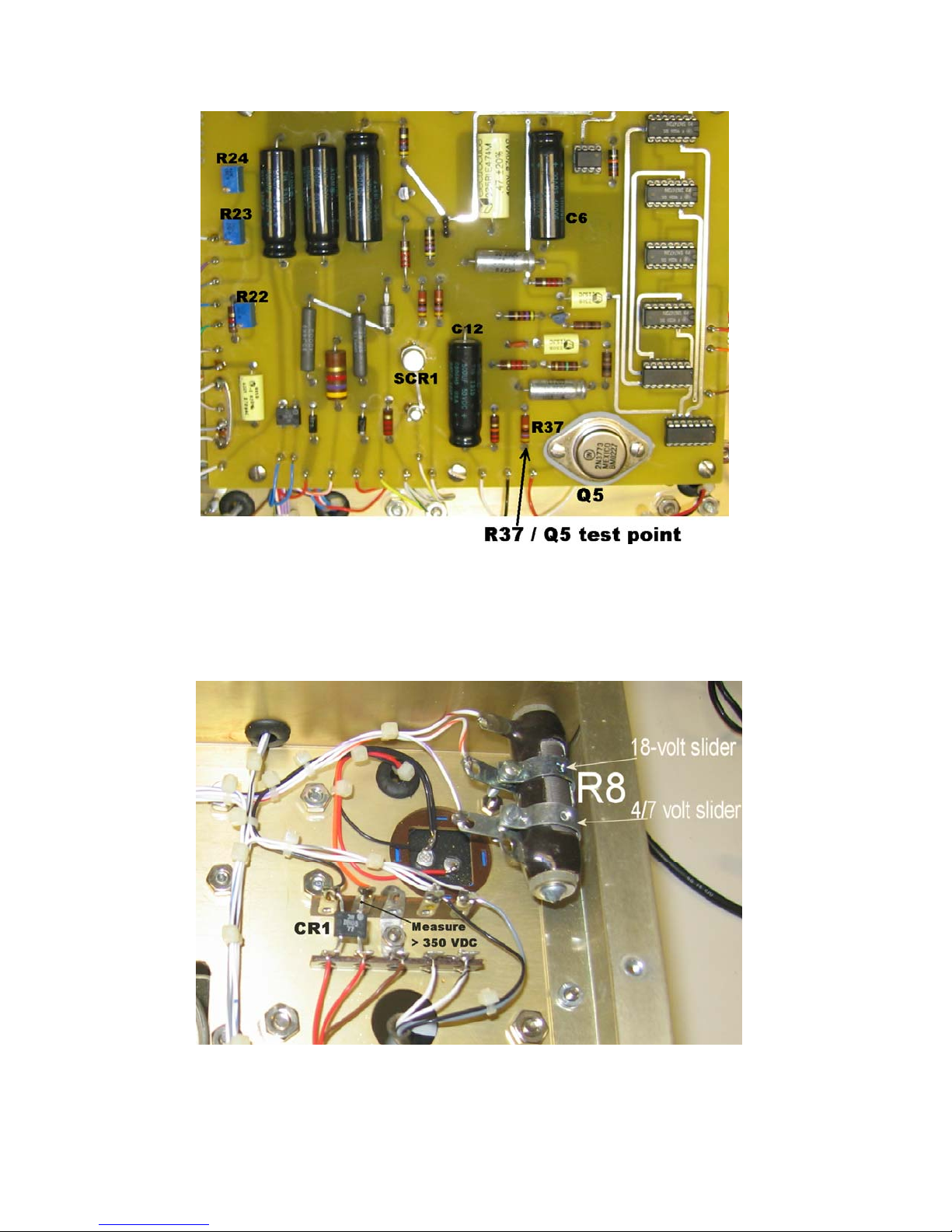

5.3 Voltage Check

DC voltage across the 500 µF capacitor C6, should be 4 V ±10% for older 7054-1's or 7

V ±10% for more recent 7054-1's. Voltage across the 500 µF capacitor C12 should be

18 V DC ±10%. See Figure 7. If necessary, adjust the sliders on R8 shown in Figure 8

to obtain these voltages.

Solar Electronics Company

12 of 22

FIGURE 7- PRINTED CIRCUIT BOARD REFERENCE DESIGNATORS

The DC voltage out of rectifier CR1 should be at least 350 V for rightmost rotation of the

knob. See Figure 8 for CR1 measurement point.

FIGURE 8- ADJUSTMENT SLIDERS AND MEASUREMENT POINT

Solar Electronics Company

13 of 22

5.4 Trigger Waveform

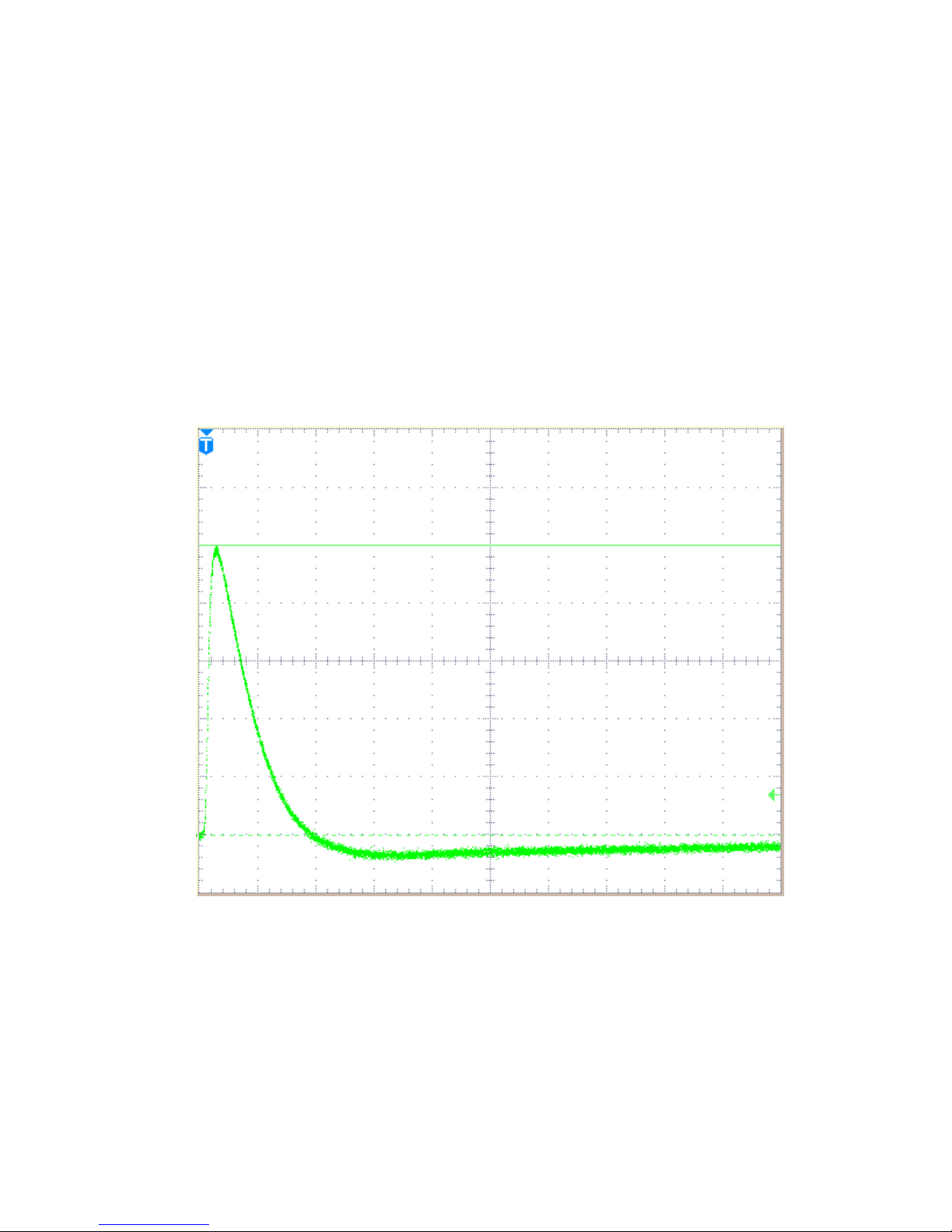

Connect the oscilloscope across R37 at the output of Q5 in Figure 7. The common lead

of the oscilloscope may be left on the negative end of C6 or C12. With the FUNCTION

switch at FREQUENCY P.P.S., the frequency at 10 pps, the AMPLITUDE knob at zero,

the waveform should be similar to that of Figure 9.

20 40 60 80 100 120 140 160 180

Vertical: 2 V/div

Horizontal: 20 µs/div

FIGURE 9 – Waveform at output of Q5, Amplitude at zero

With the AMPLITUDE knob adjusted for maximum output, the waveform of Figure 9 will

be modified due to kickback from the SCR firing and will resemble that of Figure 10.

10

-2

0

2

4

6

8

Am

p

litude, Volts

Microseconds

Solar Electronics Company

14 of 22

20 40 60 80 100 120 140 160 180

Vertical: 2 V/div

Horizontal: 20 µs/div

FIGURE 10 – Waveform at output of Q5, Amplitude at maximum

10

-2

0

2

4

6

8

Am

p

litude, Volts

Microseconds

Solar Electronics Company

15 of 22

5.5 Check and Adjustment of Maximum Amplitude

To check and, if required, adjust the maximum amplitude, proceed as follows:

Connect the 5 Ωresistor across the SERIES output terminals on the Spike Generator.

Connect oscilloscope input to SERIES output terminals on the Spike Generator.

Adjust oscilloscope controls to display 600 V peak at 10 pps.

Turn Spike Generator on.

Set FUNCTION switch to the FREQUENCY P.P.S. position.

Set FREQUENCY P.P.S. knob to 10.

Rotate AMPLITUDE control to the leftmost position.

Oscilloscope should display peak amplitude of at least 600 V.

On the oscilloscope, verify that the pulse reaches peak amplitude in less than 1 µs and

decays to zero in 8-14 µs.

Adjust AMPLITUDE control until oscilloscope displays 100 V peak.

Verify that AMPLITUDE knob indicates 100. If it does not, loosen set screws and move

knob on shaft to indicate 100 when oscilloscope displays peak amplitude of 100 V.

NOTE: All other tests and adjustments will be made at 100 V amplitude.

5.6 Check and Adjustment of Frequency Calibration

To check and adjust the frequency calibration, proceed as follows:

Place the 5 Ω20 W or greater resistor on the SERIES output terminals and connect the

oscilloscope across it.

Set FUNCTION switch to FREQUENCY P.P.S. and the rate to 10.

Set oscilloscope sweep for 20 ms/div and set vertical amplifier to 5V/div.

There should be a pulse on every 5th division on the oscilloscope grid and a total of 3

pulses.

If necessary, adjust 5K potentiometer, R22, in Figure 7, until a pulse appears at each

major division on the oscilloscope, with a total of 10 pulses. With the oscilloscope sweep

adjusted for 0.1 sec/div, this display corresponds to a frequency of 10 pps.

Solar Electronics Company

16 of 22

5.7 Check and Adjustment of Range of Pulse Position Control at 60 Hz

To check and adjust the range of the PULSE POSITION control at 60 Hz*, proceed as

follows:

Set FUNCTION switch on Spike Generator to 60~SYNC.

Set oscilloscope sweep for 1 ms/div, automatic sweep triggered to the positive (+) half of

the line cycle.

Rotate PULSE POSITION control on Spike Generator. One pulse should appear on

oscilloscope. If more than one pulse appears, replace SCR1 in Figure Sissy

When the PULSE POSITION control is rotated over its full range, the pulse should move

8 ½ ** divisions on the oscilloscope grid. If necessary, adjust potentiometer R23, in

Figure Sissy, until the PULSE POSITION control moves the pulse 8 ½** oscilloscope

divisions over its full range.

5.8 Check and Adjustment of Range of Pulse Position Control at 400 Hz

To check and adjust the range of the PULSE POSITION control at 400 Hz, proceed as

follows:

Connect a variac to 115 V*** 400Hz power source. Maintain 115 V *** output from the

variac throughout the following tests.

Connect a 6 V, 400 Hz transformer to the external trigger input to the oscilloscope. The

transformer must use the same power source as the Spike Generator.

Turn on the Spike Generator and set the FUNCTION switch to 400~SYNC, and the sync

phase switch (marked + and -) to +.

Set the oscilloscope sweep for 0.2 ms/div, automatic sweep, external trigger. The

oscilloscope should display a single pulse.

Rotate PULSE POSITION control clockwise and counterclockwise so pulse travels

across the display.

The pulse should travel 6¼ divisions.

If necessary, adjust R24, in Figure Sissy, until the pulse travels 6¼ divisions.

Solar Electronics Company

17 of 22

5.9 Check of Single Pulse Function

To check generation of a single pulse, proceed as follows:

Set the FUNCTION switch to the leftmost position to SINGLE PULSE.

Press the pushbutton switch several times. Observe that each time the switch is

depressed a pulse appears on the oscilloscope.

When this test is completed, return the Spike Generator to operation from a 60 Hz*

primary source.

5.10 Compare Trigger Waveforms

See Figure 11. Prepare the oscilloscope to measure around 300 volts. Connect a scope

probe ground lead to the 7054-1 chassis. Turn the 7054-1 on. Set the AMPLITUDE

knob to maximum. Set the FUNCTION knob to FREQUENCY P.P.S.. Set the repetition

rate knob to 10 pps. Being careful not to touch any component leads with your hand,

probe the top terminal of each of the eight indicated 2K Ω50 W resistors to verify that

the waveforms are about the same on each resistor.

FIGURE 11- 2K Ω50 W RESISTORS

Solar Electronics Company

18 of 22

6.0 Parts List

Reference

Designator Description

B1 Filter Muffin Fan, Rotron

C1 Capacitor, 0.1 µF 400 V GMV, Mylar Foil, 250B

C2 Capacitor, 500 µF 50 V DC, Electrolytic

C3 Capacitor, 80 µF 450 V DC, Sprague TVL-1735

C4 Capacitor, 500 µF 50 V DC, Electrolytic

C5 Capacitor, 270 pF, DM, Mica

C6 Capacitor, 500 µF 50 V DC, Electrolytic

C7 Capacitor, .33 µF 200 V 5%, Metalized Mylar, 210B

C8 Capacitor, 500 µF 50 V DC, Electrolytic

C9 Capacitor, .22 µF 200 V 5%, Metalized Mylar, 210B

C10 Capacitor, .15 µF 200 V 5%, Metalized Mylar, 210B

C11 Capacitor, .033 µF 200 V 5%, Metalized Mylar, 210B

C12 Capacitor, 500 µF 50 V DC, Electrolytic

C13 Capacitor, 1 µF 200 V 10%, Metalized Mylar, 210B

C14 Capacitor, 50 µF 25 V, Sprague TE-1209

C15 Capacitor, 1 µF 200 V 10%, Metalized Mylar, 210B

C16 Capacitor, .01 µF 150 V, Disc

C17 Capacitor, 50 µF 25 V, Sprague TE-1209

C18 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C19 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C20 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C21 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C22 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C23 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C24 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C25 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C26 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C27 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C28 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C29 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C30 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C31 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C32 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C33 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C34 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C35 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C36 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C37 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

Solar Electronics Company

19 of 22

C38 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C39 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C40 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C41 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C42 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C43 Capacitor, .33 µF 100 V GMV, Metalized Mylar, 210B

C44 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C45 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C46 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C47 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C48 Capacitor, 2 µF 600 V, Cornell-Dubilier DYR-6200

C49 Capacitor, .22 µF 400 V, GMV, Mylar Foil, 250B

C50 Capacitor, 10 µF 1000 V, Cornell-Dubilier, T10100

C51 Capacitor, 10 µF 1000 V, Cornell-Dubilier, T10100

CR1 Diode Quad, Motorola MDA-920-7

CR2 Not Used

CR3 Diode, 1 A 200 V, Diodes DI-72

CR4 Diode, 1 A 200 V, Diodes DI-72

CR5 Diode Bridge, 1 A 100 V, Motorola MDA-920-3

DS1 Pilot Light, Eldema EG01-RCB-NE2E 100K

F1 Fuse, 115 V: 2 A

F2 Fuse, 115 V: 2 A

FL1 Line Filter, Solar

IC1 Integrated Circuit, Motorola MC-890P

IC2 Integrated Circuit, Motorola MC-890P

IC3 Integrated Circuit, Motorola MC-890P

IC4 Integrated Circuit, Motorola MC-890P

IC5 Integrated Circuit, Motorola MC-892P

J1 Jack, 2 wire AC

J2 Jack, Banana Type

J3 Jack, Banana Type

Solar Electronics Company

20 of 22

L1 Toroid, Solar 705408

L2 Toroid, Solar 705408

L3 Toroid, Solar 705408

L4 Toroid, Solar 705408

L5 Toroid, Solar 705408

L6 Toroid, Solar 705408

L7 Toroid, Solar 705408

L8 Toroid, Solar 705408

P1 Plug, 2 Wire AC

P2 Plug, 3 Wire AC

Q1 Transistor, Motorola 2N3904

Q2 Transistor, Motorola 2N3904

Q3 Unijunction Transistor, Motorola 2N2647

Q4 Transistor, Motorola 2N3905

Q5 Transistor, Motorola 2N3773

R1 Resistor, Part of DS1 (Add 150K 1/2 W for 230 V)

R2 Resistor, 100 Ω50 W WW, Ohmite

R3 Resistor, 2K Ω50 W WW, Ohmite

R4 Resistor, Dividohm, 1 K Ω50 W WW, Ohmite

R5 Resistor, 4 K Ω4 W WW, Ohmite

R6 Resistor, 4.7 K Ω1 W 10%, Ohmite

R7 Resistor, 1.2 K Ω5 W WW, Ohmite

R8 Resistor, 150 Ω25 W WW, Ohmite, Dividohm

R9 Resistor, 2.2 K Ω1/2 W 10%

R10 Resistor, 1.2 K Ω1/2 W 10%

R11 Resistor, 12 K Ω1/2 W 10%

R12 Resistor, 8.2 K Ω1/2 W 10%

R13 Resistor, 27 K Ω1/2 W 10%

R14 Resistor, 10 K Ω1/2 W 10%

R15 Resistor, 220 Ω1/2 W 10%

R16 Resistor, 3.3 K Ω1/2 W 10%

R17 Resistor, 1.2 K Ω1/2 W 10%

R18 Resistor, 1.2 K Ω1/2 W 10%

R19 Resistor, 1.2 K Ω1/2 W 10%

R20 Resistor, Variable 50 K Pot

R21 Resistor, Variable 50 K Pot

R22 Resistor, Variable 5 K Trimpot, Bourns 3067P

R23 Resistor, Variable 5 K Trimpot, Bourns 3067P

R24 Resistor, Variable 20 K Trimpot, Bourns 3067P

Table of contents

Other Solar Electronics Portable Generator manuals