Solar Fabrik Professional 54 User manual

Play it safe

Installation guide solar modules

Professional

Vision

Professional, Vision

2 1408TU0710

Technical modifications and modifications of the product design are reserved. The technical information

at the time of production of the product are valid.

© Solar-Fabrik AG, Freiburg, 2014

DIN EN ISO 9001

Quality management system

DIN EN ISO 14001

Environmental management system

BS OHSAS 18001

Occupational health and safety management system

Status: 07.08.2014 / Document number: 1408TU0710

Professional, Vision 3

Vision 54 | frameless

Professional 60

Vision 60

Professional 54

1408TU0710

Installation guide

Professional, Vision

4

1408TU0710

Safety information

JGeneral safety information

The operation and maintenance of a PV system

require a substantial level of technical knowledge.

Therefore, any work on the system may only be

carried out by qualified and authorized personnel.

Make sure to read these mounting instructions

carefully before installing, commissioning

or servicing the PV system and keep these

instructions in a well accessible location. Failure to

comply with these safety instructions may result in

personal injury and product damage. Please keep

children away!

We strive to be the leader in innovation and

research, while continuing to improve our

products.

For this reason we reserve the right to make

changes to this installation guide without prior

notice.

JImportant safety instructions

The use of these modules must comply with

original design purposes. The modules should not

be altered technically. When mounting, make sure

that the valid local building regulations, standards

and accident prevention regulations are adhered

to. Make sure that all required safety instructions

for the mounting and operation of any further

system components are also adhered to.

JWarning: Extreme Danger

due to electrical shock!

Solar modules generate electricity. When exposed

to light, a voltage occurs, which can be dangerous

and life-threatening. Even though the individual

modules generate a relatively low voltage of

50 V DC, the voltage will accumulate as soon as

several modules are connected in series. Modules

connected in parallel result in accumlation

of the currents. Although the fully insulated

plug contacts are designed to protect against

accidental contact, the following instructions must

be followed when handling the solar modules in

order to avoid combustion, spark formation and,

above all, fatal electrical shocks:

XNever insert electrically conducting pieces into

the plugs and sockets!

XDo not wear metallic jewelry during

mechanical and electrical installation!

XKeep the tools and work area dry! Only install

solar modules and wires with dry plugs and

sockets!

XMaintain utmost caution and care! When

working on the wires, always use both tools

and gloves which are insulated!

XDo not disassemble the modules! Never

remove parts or name plates fitted by the

manufacturer! Only use flawless modules! Do

not treat the back side of the modules with

sharp objects, paints or adhesives!

XDo not expose modules to artificially

concentrated sunlight

It is absolutely necessary that the wiring of the

modules is only carried out by qualified and

authorized personnel!

Professional, Vision

5

1408TU0710

JWarning:

Danger due to high voltage!

Even in disconnected condition the inverter can

retain high voltages, which is a major shock

hazard. Therefore:

XBe very cautious when working with the

inverter and wires!

XAfter switching off the inverter as well as

before working on the inverter, make sure to

regulate the time intervals as recommended

by the manufacturer so that the high voltage

components can be discharged!

Make sure to adhere to the assembly regulations

of the inverter manufacturer!

JWarning:

Danger due to electric arc!

The solar modules generate a direct current when

exposed to light. When opening a closed circuit,

e.g. disconnecting the direct current wire from the

loaded inverter, a fatal electric arc may occur.

XNever disconnect the solar generator from the

inverter while the inverter is connected to the

grid!

XMake sure to use only flawless wire

connections! Connect wires seamlessly and

keep them free from dirt!

JElectrical installation

The solar modules are designed for use in PV

systems of application class A and are approved

for operation in systems with dangerous direct

current (more than 120 V DC in accordance

with EN 61730) and power. PV modules of this

application class are approved for operation in

installations with unrestricted access. Professional

and Vision modules from Solar-Fabrik AG, which

are qualified under EN 61730 and have been

properly installed, meet the requirements of

protection class II.

Safety information

J Transport, temporary storage

and safe unpacking

The modules are sensitive technical components,

which must be handled with utmost care.

Therefore, be particularly careful during transport

and temporary storage and leave the modules in

the package until they are used. Always lift and

carry the module with both hands and never carry

by means of the junction box.

Do not drop the modules or place them down

clumsily on a hard floor and/or on the module

corners. Do not place any objects on the modules.

Do not stack the modules without protection.

Avoid deflection of the modules. Do not walk on

the modules. Do not treat with sharp objects and

keep all electrical contact areas clean and dry.

For docum

entation purposes, the serial number should

be noted. If required, the modules should be

temporarily stored in a dry, ventilated room.

Clean, non-slip gloves must be worn during all

transport and installation work to prevent cut

injuries from the panel edges. Contamination

of the solar glass with fingerprints must also be

avoided, as this may damage the special coating

on the glass.

Please pay special attention to the warnings on

the package as well as on the enclosed unpacking

instructions!

Professional, Vision

6

1408TU0710

Installing the module

JMake sure that the installation is

carried out safely:

Protect yourself and other persons from falling,

do not carry out the installation in heavy winds

and eliminate the risk of falling objects as much

as possible. Secure the work area in order to avoid

the endangerment or injury of persons.

JObserve the allowable maximum

mechanical loading:

Do not exceed the maximum mechanical loading

and make sure to consider location-specific

loads such as wind or snow. Remember that the

module might sag when loaded under certain

circumstances. In order to avoid damaging the

module by pointed or uneven structures, do not

place fasteners or cable ties between the rear of

the module and the cross section.

JEnsure that the modules are

grounded properly:

Under the terms of Solar-Fabrik AG, grounding of

the module frame (if present) and the mounting

rack is not required for fault-free operation.

To reduce the risk of electric shock (e.g. due to

static charge) as far as possible, Solar-Fabrik AG

recommends to ask an experienced installer to

carry out a proper grounding. If an external

lightning protection system has been already

installed, the PV system has to be integrated

in the existing lightning protection concept

by a specialist. Country-specific standards and

regulations must be observed.

The grounding connections between the modules

must be checked and accepted by a qualified

electrician. Furthermore, the main grounding may

only be connected by a qualified electrician.

In the USA and Canada, a grounding method

approved by Underwriters Laboratories (UL) is

obligatory.

To provide proper grounding, an optimal electrical

conductivity is required. For this purpose,

grounding holes are provided at the rear of the

module frame (if present).These grounding holes

are marked by a stamped ground symbol.

Connect the grounding terminal only to the provided and

marked grounding holes at the rear of the module frame.

Grounding symbol:

For grounding we recommend the Solklip

grounding terminal with integrated thread-

cutting screw, (UL 467 approved, UL number

E69905), manufactured by Tyco Electronics.

Observe the additional instructions at www.

tycoelectronics.com. These grounding terminals

accommodate 4 mm² (AWG 12) and 6 mm²

(AWG 10) stripped solid copper wires. The wires

must not be cut, notched or scratched. No further

preparation is required.

Professional, Vision

7

1408TU0710

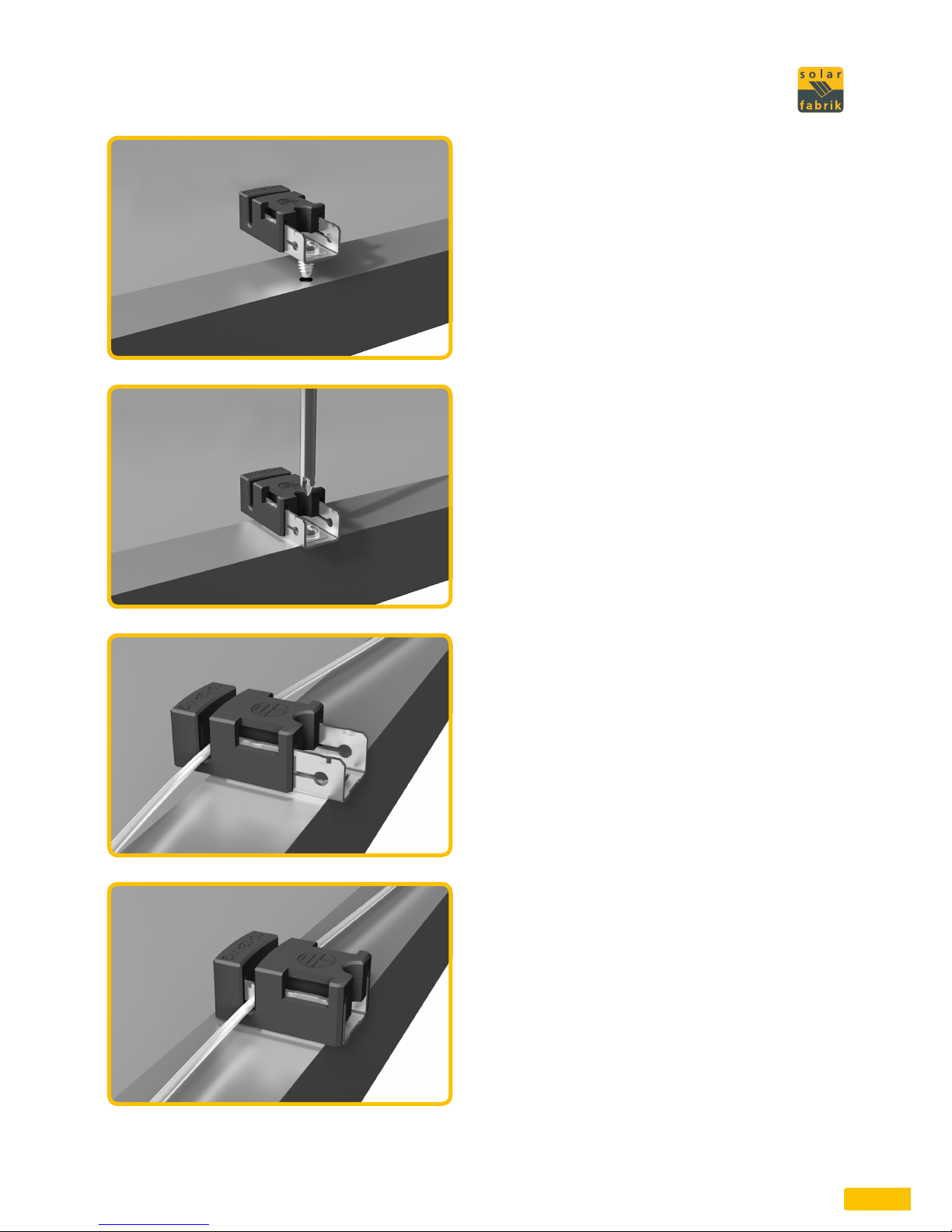

JMounting of grounding terminal

on frame

The grounding terminal must be placed on the

frame in such a way that the screw touches the

grounding hole. Using a screwdriver, install the

screw into the grounding hole until its head is

flush with the base and the base is flush with the

frame.

Then, turn the screw another quarter or half turn.

The thread-cutting screw should be torqued by

20.4 lb in and 24,8 lb in (2.3 and 2.8 Nm).

JWire placement

Insert the cable into the wire slot. Then push in

the wire on both ends into the slot. (The wire slot

will cause the wire to be slightly curved as shown.)

JTermination

The slider must be engaged (slider covers the

base). Using cable clamps, move the slider over

the base until it covers the base. This terminates

the wire. To open the slider a slotted screwdriver

can be used.

Professional, Vision

8

1408TU0710

Installing the module

JEnsure comprehensive fire

protection:

The installation of on-roof systems may influence

the fire safety of a building. Improperly installed

systems can present even more of a danger in

the case of fire. Therefore, the modules of an

on-roof system must always be installed over

a fire-resistant surface. As the module is not

regarded as explosion-proof it must not be

installed near inflammable gases and vapors e.g.

close to gas containers, painting installations or

gasoline stations. Furthermore, the module must

not be installed next to open fire and flammable

materials.

JMake sure that the surroundings

are suitable:

The module is designed for use in temperate

climate. Make sure that after installation

the module is neither subjected to artificially

concentrated sunlight, immersed in water or

continuously splashed with liquids. By all means

make sure that the module is not subjected to

abnormal chemical exposure. Therefore, due

to the expected emissions, installation in the

immediate vicinity of production facilities is not

recommended. Exposing the module to extreme

levels of salt or sulphur may lead to corrosion.

JThe correct installation situation

It is very important that the module fulfills the

technical requirements of the overall system.

Therefore, care must also be taken that the

module is not exposed to any negative mechanical

or electrical influence from other system

components. Only connect modules with the

same rated current in series and modules with

the same rated voltage in parallel. The modules

may only be operated at the allowable system

voltage; operation at a higher voltage is not

recommended.

JThe correct location for installation:

The module must not be installed as overhead

glazing or vertical glazing, e.g. on a facade.

Beside the module itself, the mounting system

must also be suited to the expected conditions

at the location of installation (snow, wind) and

withstand them easily. The bottom side of the

module frame (if present) features holes for

draining precipitation water. Make sure during

installation that these holes retain their function.

For portrait mounting, the junction box may be

mounted facing up or down on the underside

of the module. This applies to the Professional

60 series. Otherwise, the junction box must be

mounted facing upwards on the underside of the

module.

JYield maintenance through optimal

alignment and inclination:

We advise you to familiarize yourself with the

appropriate alignment and inclination of the

modules prior to installation in order to ensure

an optimal system yield. The ideal conditions for

the generation of electricity are accomplished

when the sun rays reach the generator surface

perpendicularly. For modules connected in a

series, make sure that all modules have the same

alignment and inclination in order to avoid

performance losses.

Professional, Vision

9

1408TU0710

JInstall the module in an area

free of shade:

Even a low degree of shading will have a negative

effect on the system yield. Therefore, the system

must be installed in a location without shading.

The module should never be shaded completely

during the whole year and be exposed to direct

sunlight for several hours per day even in less

favorable periods of the year.

JEnsure an appropriate ventilation

on back:

By an appropriate ventilation on the back, an

accumulation of heat with adverse effects on the

performance can be avoided.

JSecure attachment

To ensure that modules are installed correctly,

make sure to securely attach the modules at least

four points. Framed PV modules can be clamped

on both the short and long sides. Frameless Vision

modules must be clamped on the long sides and

cannot be installed with arbitrary clamp types.

Only special laminate clamps from Solar-Fabrik

AG may be used to mount the modules. Use of

unauthorised laminate clamps will render the

product and performance warranty void.

NOTE for Vision series:

The detailed installation instructions in the

separate installation manual must be observed, in

addition to the notes appearing here.

Professional, Vision

10

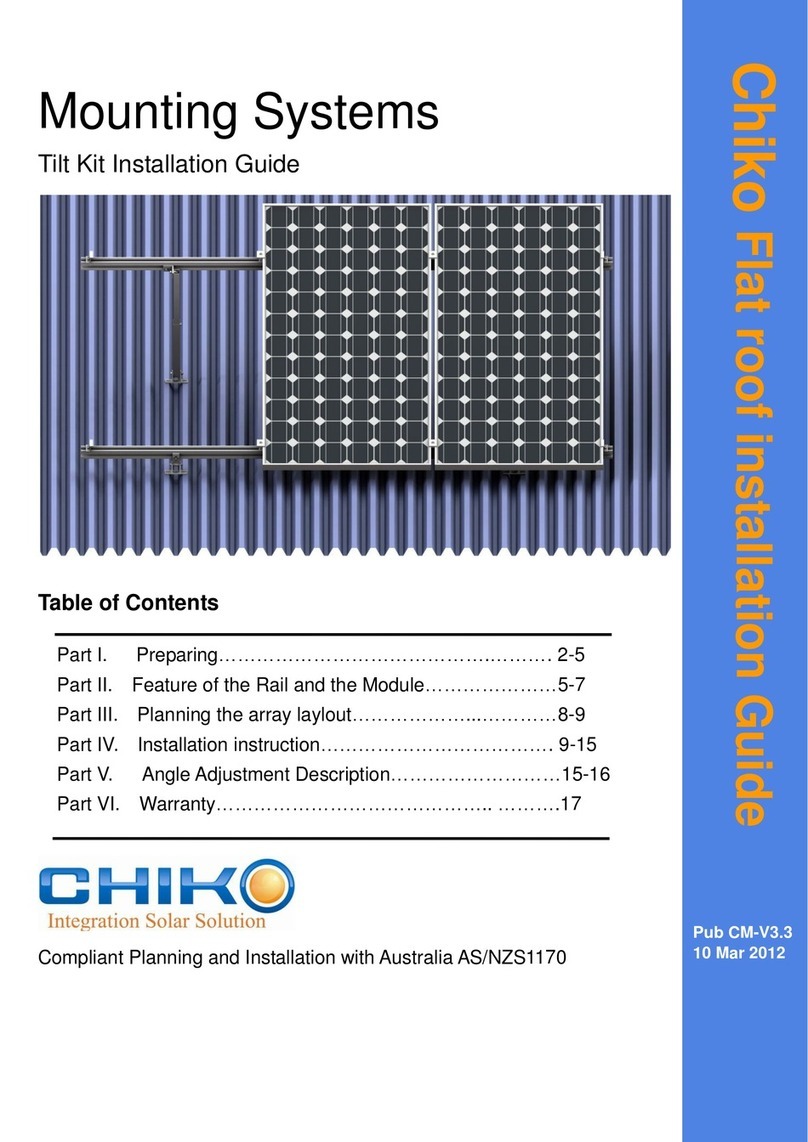

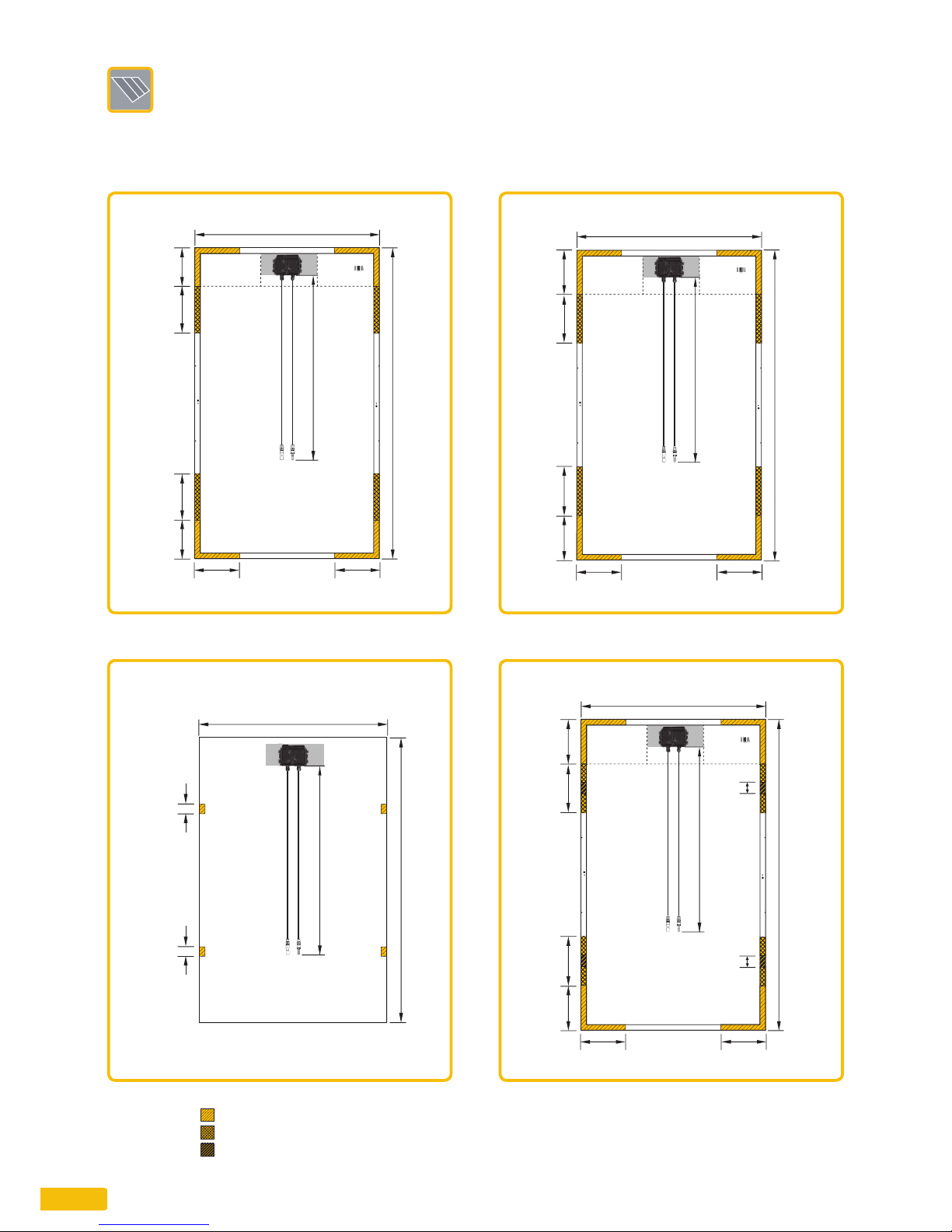

Vision 54 | frameless

L

+

C

3

983

1496

1000

Vision 54

375 ± 20375 ± 20

Professional 60

L

+

C

3

990

1660

240240-500

240 240-500

240 240

1000

Professional 60

Vision 60

L

+

C

3

990

340-400340-400

1677

240240-500

240 240-500

240 240

1000

Vision 60

Professional 54

L

+

C

3

990

1503

210210-460

210 210-460

240 240

1000

Professional 54

1408TU0710

Installing the module

JClamping areas

375 ± 20

(central

clamping

point)

375 ± 20

(central

clamping

point)

Approved up to 2,400 Pa

Approved up to 5,400 Pa

Approved up to 6,600 Pa

Clamping areas:

Professional, Vision 111408TU0710

JNote:

Pay attention to the maximum load-bearing

capacity of the modules, with consideration of

wind and snow load zones, the terrain category

and the height of the building.

JInstallation data:

There are several methods to connect the modules

to substructure: by clamping the modules from

the front (example A) or by bolting the modules

from the back (example B) using the provided

attachment holes.

Use a torque wrench for installation. The required

tightening torque for the above samples is

14.8 lb ft (20 Nm). Use M6 bolts made of V2A.

Only use the provided holes for installation.

If any further holes are drilled, the warranty

will no longer apply. For laminates, use the

explicit installation instructions contained in the

installation manual of the selected mounting

system. Always use appropriate corrosion-proof

fixing materials for installation.

Example A: Clamping wing

Example B: Direct bolting

Professional, Vision

12 1408TU0710

Installing the module

JProper wiring

Never open the connection box! The modules

are already fitted with all necessary wires and

connectors.

JEnsure correct wiring:

The integrated connection cables are UV resistant.

The conductor cross-section of the connection

cables is 4 mm². For wiring, the connection cables

are fitted with prefabricated connectors, which

are protected against reverse polarity.

Keep the total area of all conductor loops as

low as possible in order to reduce the voltages

due to indirect lightning strikes. Always carry

out a careful final check of the wiring prior to

commissioning the generator. If the measured

open circuit voltage diverges from the default

value, a wiring error has occurred. Check for

correct polarity.

Merge the connectors together correctly:

Connectors may only merged together when

dry. Also make sure that a gap-free connection is

possible.

In order not to exceed the max. system voltage at

-10 °C, the 54-cell Professional and Vision modules

must not be connected in series with more than

24 modules. With the Professional and Vision 60

modules, max. 22 modules may be connected

in series. Additionally, the requirements of the

inverters must be observed.

When connecting the modules in parallel, a

corresponding overcurrent protection must be

used. This can be achieved with direct current

fuses, which prohibit return currents greater than

12 A.

Furthermore, the connection requirements and

design regulations of the inverter manufacturer

must be observed.

JOnly use suitable materials:

The system may only be wired using special

solar wires and suitable connectors. It is very

important that all necessary materials are in a

flawless electrical and mechanical condition. Only

use single core wires and chose an appropriate

conductor size in order to minimize the voltage

drop. For further connections of the modules only

appropriate cables with a minimum conductor

cross-section of 4 mm² must be used.

JProtect the wires from adverse

environmental effects:

Only use UV-resistant cable ties for the

attachment of the wires to the mounting system.

Protect the exposed wire from possible damage,

e.g. by routing it in plastic tubes. Avoid direct

exposure to sunlight.

Under usual and expected conditions, a PV

module can generate a higher current and/or

higher voltage as stated with the standardized

test conditions. For this reason, the Isc and Uoc

values specified on the module must be multiplied

by a factor of 1.25 to determine the rated voltage

values of conductors, fuse values and the size

of control systems connected to the PV module

output.

JMake sure connectors are mounted

correctly

To ensure that connectors of the same model are

used, it is permitted to sever the module cable just

before the module connector plug and mount one

of the other connectors approved by Solar-

Fabrik AG.

The KSK4 connector (manufactured by Kostal) is

approved for use by Solar-Fabrik AG.

Additional connectors upon request. Consult your

Solar-Fabrik AG sales representative if you have

any questions.

The connector must be installed according to the

mounting instructions provided for the connector.

Note that all work must take place on the ground

when attaching the module connector.

Always make sure that the module is disconnected

from the generator field while carrying out work.

Make sure that the photoactive side of the

module remains face down while work is carried

out to ensure that voltage is kept at an absolute

minimum.

The full product warranty for the module remains

valid as long as all mounting instructions are

followed and the installation is carried out by a

specialist technician.

It is not permitted to combine incompatible

connectors from different manufacturers.

Combining connectors from different

manufacturers will render the product warranty

void.

Professional, Vision 131408TU0710

JMaintenance and cleaning

Usually, the modules are automatically cleaned

by rain. With an inclination of more than 15° the

modules generally need no additional cleaning. In

the case of severe contamination, we recommend

that the modules are cleaned with ample water

and without cleaning agents.

In the case of severe contamination, we

recommend cleaning with plenty of water with

a low lime content. Please do not use a nozzle

attachment, and ensure that only moderate

water pressure is used. Using cleaning products

and scratching cleaning devices will damage the

special anti-reflective coating and render the

product and performance guarantees void. Under

no circumstances may contaminants be scratched

or rubbed off without moisture. Damage to the

highly efficient anti-reflective surface may change

the visual appearance of the module surface and

result in decreased performance.

Use of automatic cleaning machines for solar

energy systems is at your own risk, and is not

authorised by Solar-Fabrik AG in any way.

Inspect the installation on a regular basis and

check it for

Xsecure fixing and corrosion-free condition of all

mountings

Xsecure connection, cleanliness, integrity and

corrosion-free condition of all wire connections

Xtransition impedances of the potential

equalization

JInformation about liability and

revision level of the instructions

If any of the instructions given in the user

information are not adhered to, Solar-Fabrik

AG will not guarantee the availability and

functionality of the modules. Since the compliance

with the said safety instructions as well as

the conditions and methods for installation,

operation, usage and maintenance of the modules

cannot be checked or monitored by Solar-Fabrik

AG, Solar-Fabrik AG does not accept any liability

for damage due to improper use, incorrect

installation, operation, usage or maintenance.

The text and the figures of this installation guide

comply with the state of technology at the time of

printing.

Subject to alterations.

Professional, Vision

14 1408TU0710

Notes

Professional, Vision 151408TU0710

Play it safe

Solar-Fabrik AG

Munzinger Str. 10

79111 Freiburg

Deutschland

Telefon +49 (0)761 4000-0

Telefax +49 (0)761 4000-199

www.solarfabrik.de

Status: 07.08.2014 / Document number: 1408TU0710

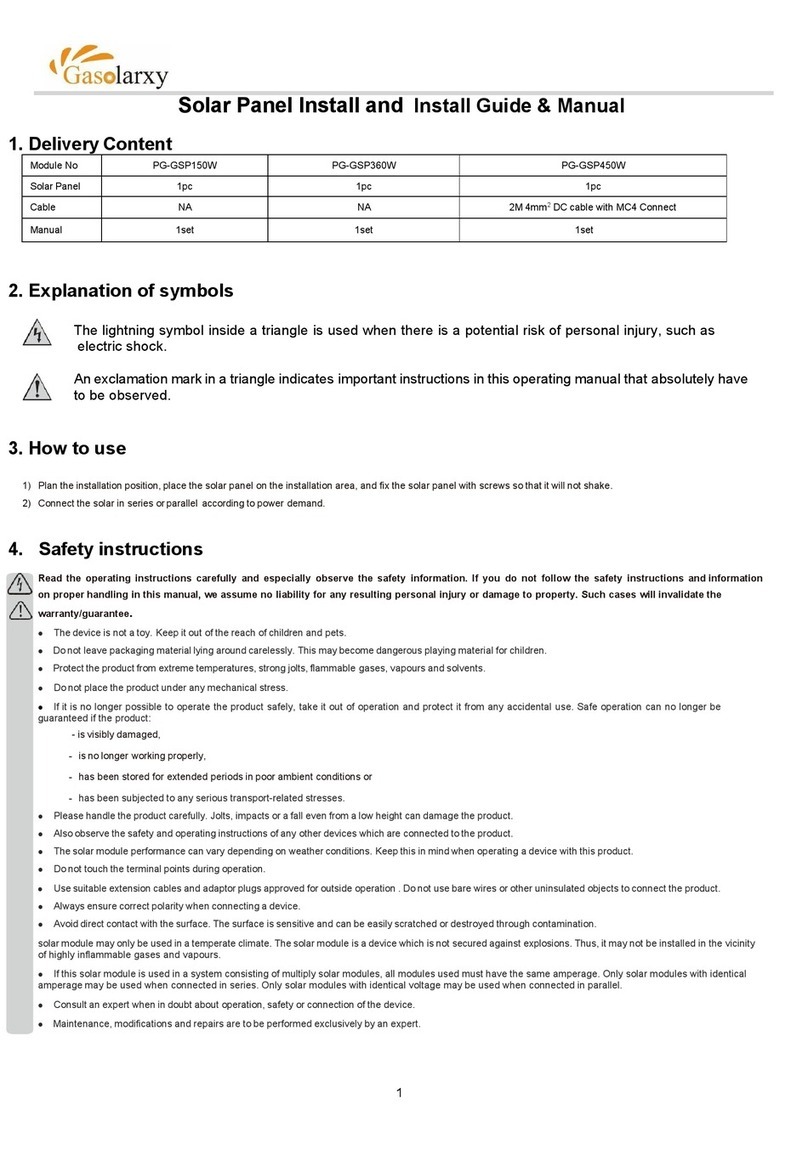

This manual suits for next models

3

Table of contents

Other Solar Fabrik Solar Panel manuals

Popular Solar Panel manuals by other brands

BenQ

BenQ PM245P01 Series installation guide

NEO TOOLS

NEO TOOLS 90-143 user manual

AEROCOMPACT

AEROCOMPACT CompactPITCH XM-P Assembly instructions

Viessmann

Viessmann VITOVOLT 200 5458 installation instructions

Solibro

Solibro SL2 Operation manual

LEJ LINE

LEJ LINE LSK-JC-2V Installation and maintenance manual