14

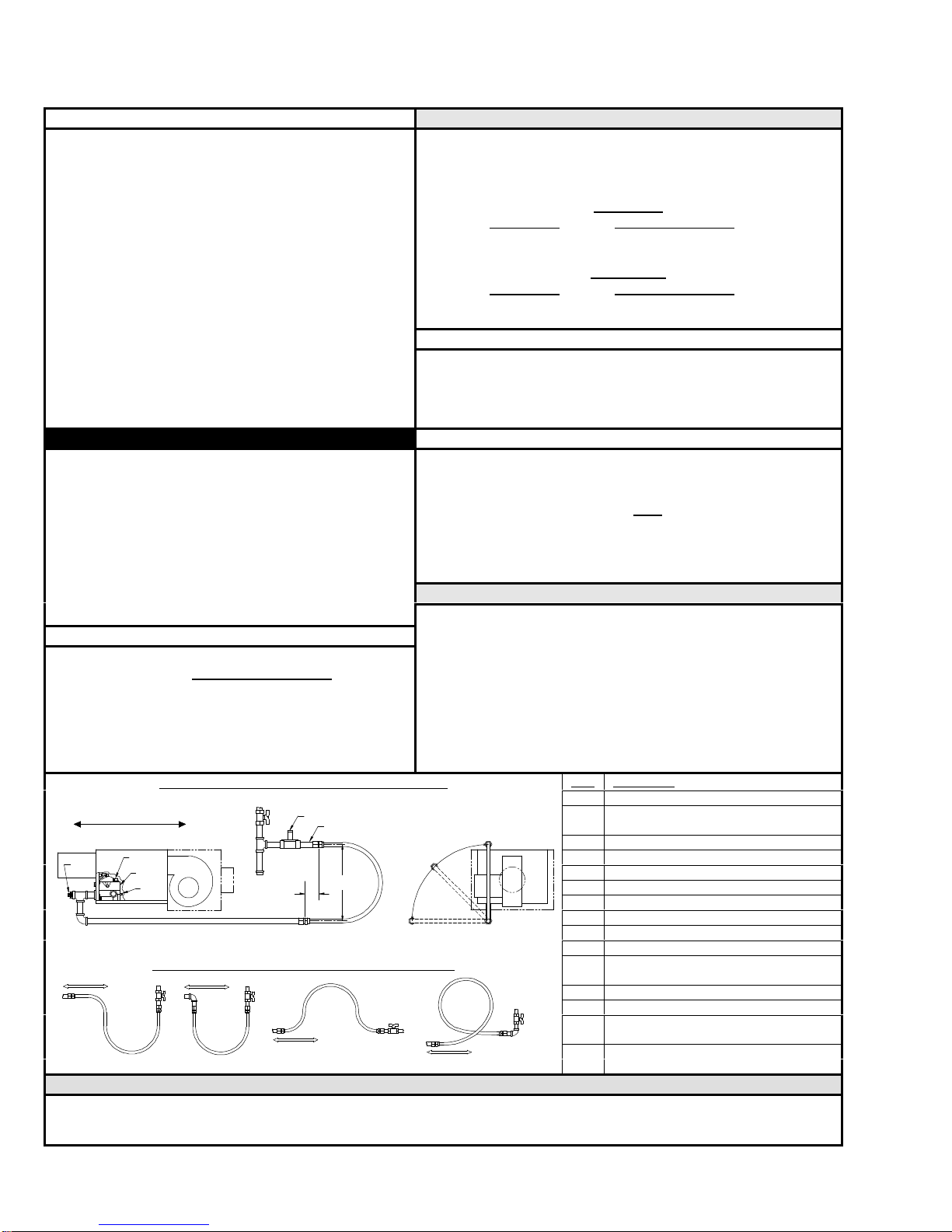

A

A

A

A

MP

RA

WA

LB

J

K

IP

A

FH

E

D

G

GAS SUPPLY AND GAS PRESSURE

GAS SUPPLY PIPING INLET GAS PRESSURE

•Inlet gas pressure must be measured on the inlet side of the

valve at the inlet test point (IP). Remove plug from the inlet

test point, connect to manometer.

•Inlet gas pressure must conform to the following:

MINIMUM

GAS TYPE INLET PRESSURE

Natural 6” WC (15 cm WC)

LP/Propane 11” WC (28 cm WC)

MAXIMUM

GAS TYPE INLET PRESSURE

Natural 14” WC (35 cm WC)

LP/Propane 14” WC (35 cm WC)

IMPORTANT

•Gas piping must be installed in accordance with

local codes and/or the National Fuel Gas Code,

ANSI Z223.1 / NFPA 54-latest edition.

•All pipe connections must have pipe joint compound,

resistant to LP/propane gas action.

•Piping must have drip leg and a ground joint union.

•Local codes may require shut-off cock ahead of the

drip leg.

•Use only agency approved flexible gas connector

furnished with heater. See WARNING.

•Use swing or swivel joint in addition to rigid piping if

local codes prohibit use of a flexible gas connector.

•Installer provide 1/8” NPT plugged tapping for inlet

test point connection immediately upstream of gas

connection to heater.

•Isolate regulators, flexible gas connectors, and

heaters during high-pressure leak testing.

•All gas lines must be purged of air before startup.

•Inlet gas pressure at inlet test point (IP) cannot be more than

14 inches of Water Column (WC) (35 cm WC) (1/2 PSI),

confirmed by actual field test. (Heater on or off).

WARNING HIGH GAS PRESSURE

•When inlet gas pressure is greater than 14 in. WC (35 cm

WC) a positive lockout type high-pressure regulator must be

installed in the gas line ahead of the heater.

•High-pressure regulators will NOT turn off the flow of gas.

•Always check local codes for gas venting requirements for

high-pressure regulators.

•An over-pressure protection device (OPD) may be required in

certain jurisdictions.

MANIFOLD GAS PRESSURE

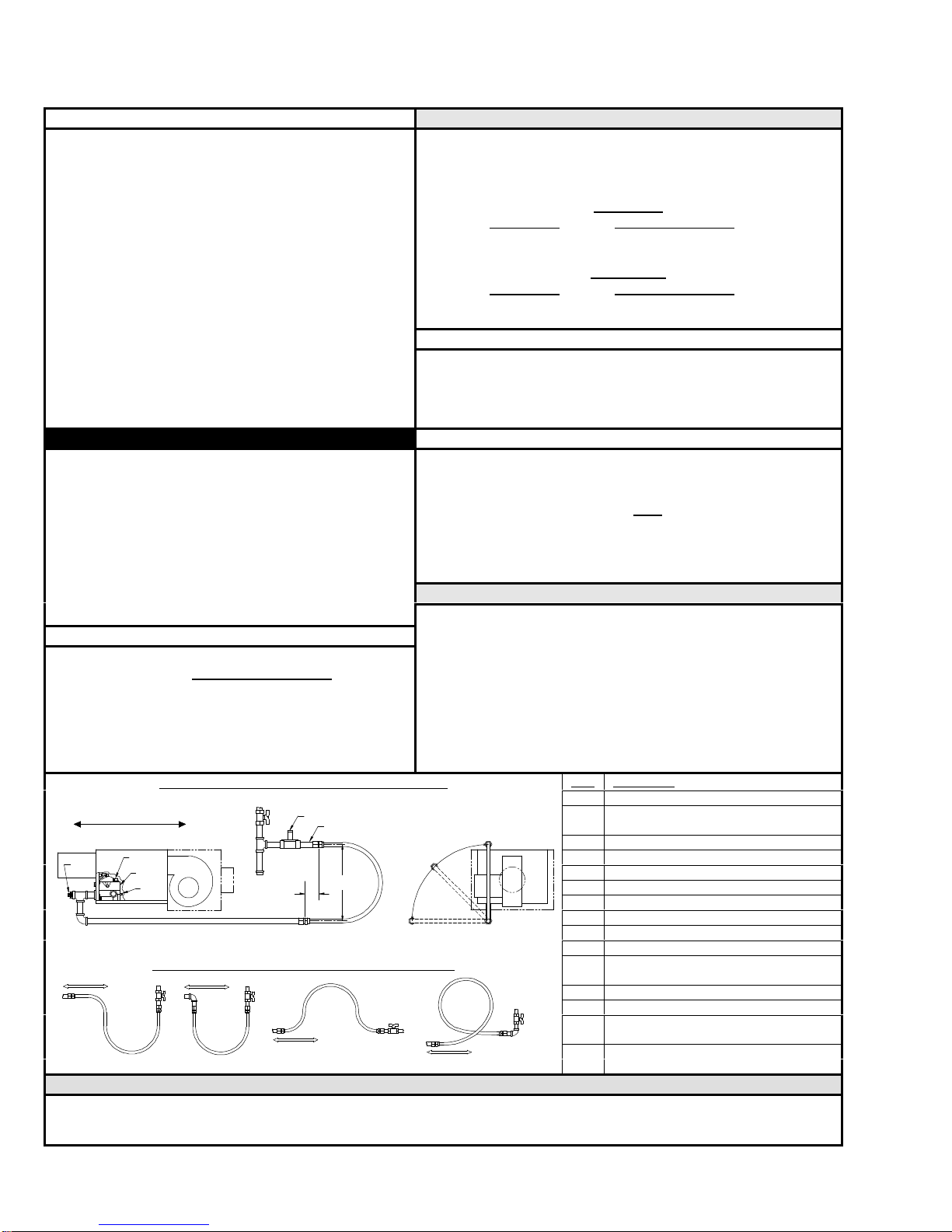

•Connector must be installed in a “ ” configuration.

Use only the 24” (61 cm) or 36” (91 cm) long

connector of 1/2” (13 mm) nominal ID that was

furnished with the heater.

•Stress from expansion and contraction of heater

may cause excessive wear on the gas connection.

•For a heater 20 feet (6.1 m) long, heater tubes can

expand up to 1.1” (28 mm).

•It is important to maintain dimensions on drawing

below.

GAS PRESSURE MEASUREMENTS

•Use only a water or red oil manometer to make

measurements --- NOT A DIAL GAUGE.

•Make measurements and adjustments when this

heater and ALL other gas burning equipment

connected to the same gas meter are operating at

maximum capacity.

•Set inlet pressure first. Fluctuations in inlet pressure can

alter manifold pressure coming out of the gas valve.

•See drawing below for manifold pressure adjustment location.

•Loosen set screw, or remove plug form manifold test point

(MP); connect to manometer.

•Remove the slotted cap screw covering the manifold

adjustment.

•Turn adjustment screw clockwise to increase pressure or

counterclockwise to decrease pressure.

•Manifold Pressure setting is 3.5” WC (8.9 cm WC).

GAS CONNECTOR – CORRECT POSITIONS Item Description

AHeater movement

BGas supply nipple must be parallel to

heater movement

CHard piping

DFlexible gas connector

E3” (7.62 cm) maximum displacement

F12” (30 cm)

GVertical (as shown at left) – end view

HAlternate positions okay – end view

JGas cock shut-off (by others)

KDrip leg

GAS CONNECTOR – INCORRECT POSITIONS LRegulator required when pressure

exceeds 14” (35 cm) WC (by others)

IP Installer provide inlet test point

MP Manifold test point

RA Robert Shaw or Sit valve manifold

pressure adjustment

WRONG WRONG WRONG WRONG WA White Rodgers valve manifold pressure

adjustment

CAUTION

Excessive torque on the burner gas inlet pipe or manifold may cause damage to burner. Always use two (2) wrenches when

making pipe connections. Check for leaks with non-corrosive gas leak detection fluid. DO NOT USE FLAMES! Thoroughly

rinse with clean water to remove leak detection fluid.