SolaX Power X3-PRO G2 Series User manual

614.00630.02

X3-PRO G2 Series

User Manual

8 kW - 30 kW

SolaX Power Network Technology (Zhejiang) Co., Ltd.

Copyright Declaration

The copyright of this manual belongs to SolaX Power Network Technology (Zhejiang) Co., Ltd. Any

corporation or individual should not plagiarize, partially or fully copy (including software, etc.),

and no reproduction or distribution of it in any form or by any means shall be allowed. All rights

reserved. SolaX Power Network Technology (Zhejiang) Co., Ltd. reserves the right of final

interpretation.

ADD.: No. 288 Shizhu Road, Tonglu Economic Development Zone,

Tonglu City, Zhejiang Province, China.

TEL.: +86 571-56260011

E-mail: info@solaxpower.com

Contents

1 Note on this Manual

1.1 Scope of Validity

1.2 Target Group

1.3 Symbols Used

2 Safety

2.1 Appropriate Usage

2.2 Important Safety Instructions

2.3 Explanation of Symbols

2.4 EC Directives

3 Introduction

3.1 Basic Features

3.2 Terminals of Inverter

3.3 Dimension

4 Technical Data

4.1 DC Input

4.2 AC Output

4.3 Efficiency, Safety and Protection

4.4 General Data

5 Installation

5.1 Check for Transport Damage

5.2 Packing List

5.3 Installation Precaution

5.4 Installation Steps

5.5 Connection of the Inverter

5.6 Run the Inverter

6 Operation Method

6.1 Control Panel

6.2 LCD Function & Operation

Contents

01

03

03

03

03

04

04

06

09

10

11

11

11

12

13

13

14

15

16

17

17

17

18

19

24

38

39

39

40

1.1 Scope of Validity

This manual is an integral part of X3-PRO G2 Series. It describes the

assembly, installation, commissioning, maintenance and failure of the

product. Please read it carefully before operating.

Note: “X3” means three phases. ”PRO” means product series name. “8K”

means rated output power is 8 kW. ”G2” means this product is the second

generation machine of the series. “2D” means two strings of MPPT and with

DC switch. “3D” means three strings of MPPT and with DC switch.

Keep this manual at where it is accessible all the time.

1.2 Target Group

This manual is for qualified electricians. The tasks described in this manual

only can be performed by qualified electricians.

1.3 Symbols Used

The following types of safety instructions and general information appear in

this document as described below:

1 Notes on this Manual

7 Troubleshooting

7.1 Trouble Shooting

7.2 Routine Maintenance

8 Decommissioning

8.1 Dismantling the Inverter

8.2 Packaging

8.3 Storage and Transportation

8.4 Waste Disposal

Notes on this ManualContents

03

02

54

54

57

58

58

58

58

58

59

9 Disclaimer

* Warranty Registration Form

X3-PRO-20K-G2(2D)

X3-PRO-25K-G2(3D)

X3-PRO-17K-G2(3D) X3-PRO-20K-G2(3D)

X3-PRO-30K-G2(3D)

X3-PRO-8K-G2(2D) X3-PRO-10K-G2(2D) X3-PRO-12K-G2(2D)

X3-PRO-15K-G2(2D) X3-PRO-17K-G2(2D)

X3-PRO-15K-G2(3D)

Danger!

“Danger” indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Warning!

“Warning” indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Caution!

“Caution” indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Note!

“Note” provides tips that are valuable for the optimal operation

of your product.

2 Safety

2.1 Appropriate Usage

The X3-PRO G2 Series are PV inverters which can convert DC power from PV

generators to AC power and feed it into the public grid.

Surge protection devices (SPDs) for PV installation

Over-voltage protection with surge arresters should be provided

when the PV power system is installed.

The grid connected inverter is fitted with SPDs in both PV

input side and MAINS side.

Induced surges are the more likely cause of lightning damage in majority of installations,

especially in rural areas where electricity is usually provided by long overhead lines.

Surges may be induced on both the PV array conductors or the AC cables

leading to the building.

Specialists in lightning protection should be consulted in the actual application.

Using appropriate external lightning protection, the effect of a direct lightning

strike into a building can be mitigated in a controlled way, and the lightning

current can be discharged into the ground.

Installation of SPDs to protect the inverter against mechanical damage and

excessive stress include a surge arrester in case of a building with external

lightning protection system (LPS) when separation distance is kept.

To protect the DC system, Surge Protection Device(SPD type2) should be fitted

at the inverter end of the DC cabling and at the array located between the

inverter and the PV generator, if the voltage protection level (VP) of the surge

arresters is greater than 1100V, an additional SPD type 3 required surge protection

for electrical devices.

►

05

04

SafetySafety

Anti-Islanding Effect

►

Islanding effect is a special phenomenon that grid-connected PV

system still supplies power to the nearby grid when the grid loss

happened in the power system. It is dangerous for maintenance

personnel and the public.

X3-PRO G2 series provide Active Frequency Drift(AFD) to prevent

islanding effect.

Lightning will cause a damage either from a direct strike or from surges due to a

nearby strike.

To protect the AC system, surge protection devices (SPD type2) should be

fitted at the main incoming point of AC supply (at the consumer’s cutout),

located between the inverter and the meter/distribution system; SPD (test

impulse D1) for signal line according to EN 61632-1.

All DC cables should be installed to provide as short a run as possible, positive

and negative cables of the string or main DC supply should be bundled

together. Avoiding the creation of loops in the system. This requirement for

short runs and bundling includes any associated earth bundling conductors.

Spark gap devices are not suitable to be used in DC circuits once conducting,

they won’t stop conducting until the voltage across their terminals is typically

more than 30 volts.

Electricalgrid

Electricmeter,

bidirectional Solax

three phase meter

(optional)

Load

PVarray

DCDistribution

Box

Household

DistributionUnits

X3-PRO G2 series Inverter

ACDistribution

Box

Warning!

2.2 Important Safety Instructions

Danger!

Danger to life due to high voltages in the inverter!

All work must be carried out by qualified electrician.

The appliance is not to be used by children or persons with

reduced physical sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given

supervision or instruction.

Children should be supervised to ensure that they do not play

with the appliance.

Caution!

Possible damage to health as a result of the effects of

radiation!

Do not stay closer than 20 cm to the inverter for a long time.

Note!

Grounding the PV generator.

Comply with the local requirements for grounding the PV

modules and the PV generator. SolaX recommends connecting

the generator frame and other electrically conductive surfaces

in a manner which ensures continuous conduction and

ground these in order to have optimal protection of system

and persons.

Warning!

Ensure input DC voltage ≤Max. DC voltage. Over voltage

may cause permanent damage to inverter or other losses,

which will not be included in warranty!

Warning!

Authorized service personnel must disconnect both AC and

DC power from X3-PRO G2 series before attempting any

maintenance or cleaning or working on any circuits connected

to the X3-PRO G2 series.

Prior to the application, please read this section carefully to ensure correct

and safe application. Please keep the user manual properly.

Use only attachments recommended or sold by SolaX. Otherwise may result

in a risk of fire, electric shock, or injury to person.

Make sure that existing wiring is in good condition and that wire is not

undersized.

Do not disassemble any parts of inverter which are not mentioned in

installation guide. It contains no user-serviceable parts. See Warranty for

instructions on obtaining service. Attempting to service the X3-PRO G2

Series inverter yourself may result in a risk of electric shock or fire and will

void your warranty.

Keep away from flammable, explosive materials to avoid fire disaster.

The installation place should be away from humid or corrosive substance.

Authorized service personnel must use insulated tools when installing or

working with this equipment.

PV modules shall have an IEC 61730 class A rating.

Never touch either the positive or negative pole of PV connecting device. Strictly

prohibit touching both of them at the same time.

The unit contains capacitors that remain charged to a potentially lethal voltage

after the MAINS and PV supply have been disconnected.

Hazardous voltage will present for up to 5 minutes after disconnection from

power supply.

CAUTION - RISK of electric shock from energy stored in capacitor. Never operate

on the solar inverter couplers, The MAINS cables, PV cables or the PV generator

when power is applied. After switching off the PV and Mains, always wait for 5

minutes to let the intermediate circuit capacitors discharge before you unplug

DC and MAINS couplers.

When accessing the internal circuit of solar inverter, it is very important to wait 5

minutes before operating the power circuit or demounting the electrolyte

capacitors inside the device. Do not open the device before hand since the

capacitors time to sufficiently discharge! require

Measure the voltage between terminals UDC+ and UDC- with a multi-meter

(impedance at least 1Mohm) to ensure that the device is discharged before

beginning work (35VDC) inside the device.

Safety Safety

0706

Do not operate the inverter when the device is running.

Risk of electric shock!

Caution!

Danger of burn injuries due to hot enclosure parts!

During operation, the upper lid of the enclosure and the

enclosure body may become hot.

If necessary, touch the lower temperature enclosure lid during

operation.

Warning!

Warning!

PE Connection and Leakage Current

• All inverters incorporate a certified internal Residual Current Device(RCD) in

order to protect against possible electrocution and fire hazard in case of a

malfunction in the PV array, cables or inverter. There are 2 trip thresholds for

the RCD as required for certification (IEC 62109-2:2011). The default value for

electrocution protection is 30 mA, and for slow rising current is 300 mA.

• If an external RCD is required by local regulations, check which type of RCD is

required for relevant electric code. It recommends using a type-A RCD. The

recommended RCD values is 100 mA or 300 mA unless a lower value is required

by the specific local electric codes. When required by local regulations, the use

of an RCD type B is permitted.

High leakage current!

Earth connection essential before connecting supply.

• Incorrect grounding can cause physical injury, death or equipment malfunction

and increase electromagnetic.

• Make sure that grounding conductor is adequately sized as required by safety

regulations.

• Do not connect the ground terminals of the unit in series in case of a multiple

installation. This product can cause current with a d.c. component. Where a residual

current operated protective (RCD) or monitoring (RCM) device is used for protection

in case of direct or indirect contact, only an RCD or RCM of type B is allowed

on the supply side of this product.

For United Kingdom

• The installation that connects the equipment to the supply terminals shall

comply with the requirements of BS 7671.

• Electrical installation of PV system shall comply with requirements of BS 7671

and IEC 60364-7-712.

• No protection settings can be altered.

• User shall ensure that equipment is so installed, designed and operated to

maintain at all times compliance with the requirements of ESQCR22(1)(a).

For Australia and New Zealand

• Electrical installation and maintenance shall be conducted by licensed

electrician and shall comply with Australia National Wiring Rules.

0908

2.3 Explanation of Symbols

This section gives an explanation of all the symbols shown on the inverter and

on the type label.

Symbols on the Inverter

Symbol Explanation

Operating Display.

An error has occurred, please inform your installer immediately.

Symbols on the Type Label

Safety Safety

Symbol Explanation

CE mark.

The inverter complies with the requirements of the applicable

CE guidelines.

RCM remark.

Beware of hot surface.

The inverter can become hot during operation. Avoid contact

during operation.

Danger of high voltages.

Danger to life due to high voltages in the inverter!

Danger.

Risk of electric shock!

Observe enclosed documentation.

The inverter can not be disposed together with the household waste.

Disposal information can be found in the enclosed documentation.

Do not operate this inverter until it is isolated from mains

and on-site PV generation suppliers.

Danger to life due to high voltage.

There is residual voltage in the inverter which needs 5 min to

discharge.

• Wait 5 min before you open the upper lid or the DC lid.

TUV certification.

Compliant with UKCA standards.

Compliant with UKNI standards.

RoHS certificate

The inverter complies with the requirements of Restriction of

Hazardous Substances.

Warning!

2.4 EC Directives

This chapter follows the requirements of the European low voltage directives,

which contains the safety instructions and conditions of acceptability for the

endues system, which you must follow when installing, operating and

servicing the unit. If ignored, physical injury or death may follow, or damage

may occur to the unit. Read this instructions before you work on the unit. If

you are unable to understand the dangers, warnings, cautions or instructions,

please contact an authorized service dealer before installing. Operating and

servicing the unit.

The Grid connected inverter meets the requirement stipulated in Low

Voltage Directive (LVD) 2014/35/EU and Electromagnetic Compatibility (EMC)

Directive 2014/30/EU. The unit is based on:

EN 62109-1:2010 ; EN 62109-2:2011 ; IEC 62109-1(ed.1) ; IEC62109-2(ed.1)

EN 61000-6-3:2007+A:2011 ; EN 61000-6-1:2007 ; EN 61000-6-2:2005

In case of installation in PV system, startup of the unit (i.e. start of designated

operation) is prohibited until it is determined that the full system meets the

requirements stipulated in EC Directive (2014/35/EU,2014/30/EU, etc.)

The grid connected inverter leave the factory completely connecting device

and ready for connection to the mains and PV supply ,the unit shall be

installed in accordance with national wiring regulations. Compliance with

safety regulations depends upon installing and configuring system correctly,

including using the specified wires. The system must be installed only by

professional assemblers who are familiar with requirements for safety and

EMC. The assembler is responsible for ensuring that the end system complies

with all the relevant laws in the country where it is to be used.

The individual subassembly of the system shall be interconnected by means

of the wiring methods outlined in national/international such as the national

electric code (NFPA) No.70 or VDE regulation 0107.

3 Introduction

3.1 Basic features

Thanks for your purchasing with SolaX X3-PRO G2 Serial inverter. The X3-

PRO G2 Series inverter is one of the finest inverters on the market today,

incorporating state-of-the-art technology, high reliability, and convenient

control features.

Advanced DSP control technology.

Utilize the latest high-efficiency power component.

Optimal MPPT technology.

- 2/3 MPP Tracking.

- Wide MPPT input range.

Advanced anti-islanding solutions.

IP66 protection level.

Max. efficiency up to 98.5%. EU efficiency up to 98.0%.

THD<3%.

Safety &Reliability: transformerless design with software and hardware

protection.

Export control.

Power factor regulation.

Friendly HMI.

- LED status indications.

- LCD display technical data, human-machine interaction through press

key.

- PC remote control.

- Upgrade through USB interface.

- Pocket WiFi/LAN/4G monitoring.

3.2 Terminals of inverter

10 11

Safety Introduction

A B C D

EF

G

Warning!

Only authorized personnel is allowed to set the connection.

3.3 Dimension

Ø

Dimension

4 Technical Data

4.1 DC Input

Max. recommended DC power [W]

Max. DC voltage [V]

Norminal DC operating voltage [V]

Operating voltage range [V]

MPPT voltage range@full load [V]

Max. input current [A]

Max. short circuit current [A]

Start input voltage [V]

No. of MPP trackers

Strings per MPP tracker

DC disconnection switch

0

12000

1100

650

160-980

350-850

32/32

40/40

200

2

A:2/B:2

12 13

Introduction Technical Data

X3-PRO-8K-G2(2D)

Model X3-PRO-10K-G2(2D) X3-PRO-15K-G2(2D)

15000

1100

650

160-980

350-850

32/32

40/40

200

2

A:2/B:2

18000

1100

650

160-980

350-850

32/32

40/40

200

2

A:2/B:2

22500

1100

650

160-980

400-850

32/32

40/40

200

2

A:2/B:2

Max. inverter backfeed current to

the array [mA]

Yes

Object

A DC switch

PV connector

Dongle port for

COM

B

C

D

E

F

Description

RS485

AC connector

Pocket WiFi /LAN (optional) /4G (optional)

482.00 mm

417.00 mm

186.00 mm

417.00 mm

X3-PRO-12K-G2(2D)

Ground connection port

G

25500

1100

650

160-980

400-850

32/32

40/40

200

2

A:2/B:2

X3-PRO-17K-G2(2D)

Max. recommended DC power [W]

Max. DC voltage [V]

Norminal DC operating voltage [V]

Operating voltage range [V]

MPPT voltage range@full load [V]

Max. input current [A]

Max. short circuit current [A]

Start input voltage [V]

No. of MPP trackers

Strings per MPP tracker

DC disconnection switch

0

22500

1100

650

160-980

400-850

32/32/32

40/40/40

200

3

A:2/B:2/C:2

X3-PRO-15K-G2(3D)

Model

X3-PRO-20K-G2(2D)

X3-PRO-25K-G2(3D)

30000

1100

650

160-980

400-850

32/32

40/40

200

2

A:2/B:2

30000

1100

650

160-980

400-850

32/32/32

40/40/40

200

3

A:2/B:2/C:2

37500

1100

650

160-980

500-850

32/32/32

40/40/40

200

3

A:2/B:2/C:2

Max. inverter backfeed current to

the array [mA]

Yes

X3-PRO-20K-G2(3D)

45000

1100

650

160-980

500-850

32/32/32

40/40/40

200

3

A:2/B:2/C:2

X3-PRO-30K-G2(3D)

25500

1100

650

160-980

400-850

32/32/32

40/40/40

200

3

A:2/B:2/C:2

X3-PRO-17K-G2(3D)

4.2 AC Output

Nominal AC power [VA]

Max. apparent AC power [VA]

Rated grid voltage [V]

Rated AC frequency [Hz]

Nominal AC current [A]

Max. AC current [A]

THDi

Displacement power factor

Feed-in phase

8000

8800

12.2/11.6

13.2

Model

10000

11000

15.2/14.5

16.0

<3%

0.8 leading-0.8 lagging

Three-phase

50/60

12000

13200

18.2/17.4

19.3

15000

16500

22.8/21.8

24.2

4.3 Efficiency, Safety and Protection

MPPT efficiency

Euro efficiency

Max. efficiency

Safety & Protection

Over/under voltage protection

DC isolation protection

Grid protection

DC injection monitoring

Back feed current monitoring

Residual current detection

Anti-islanding protection

Over temperature protection

ARC protection

SPD protection

99.90%

97.70%

98.20%

99.90%

97.70%

98.20%

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Optional

Type II

Model X3-PRO-8K-G2(2D)

X3-PRO-10K-G2(2D)

X3-PRO-15K-G2( 2D)

X3-PRO-12K-G2(2D)

99.90%

97.80%

98.30%

X3-PRO-25K-G2(3D)

X3-PRO-30K-G2(3D)

99.90%

98.00%

98.50%

14 15

99.90%

97.80%

98.30%

99.90%

97.80%

98.30%

Technical Data

Technical Data

X3-PRO-17K-G2(2D) X3-PRO-20K-G2(2D)

17000

18700

25.8/24.7

27.5

Nominal AC power [VA]

Max. apparent AC power [VA]

Rated grid voltage [V]

Rated AC frequency [Hz]

Nominal AC current [A]

Max. AC current [A]

THDi

Displacement power factor

Feed-in phase

15000

16500

22.8/21.8

24.2

Model

20000

22000

30.3/29.0

33.6

<3%

0.8 leading-0.8 lagging

Three-phase

20000

22000

30.3/29.0

33.6

X3-PRO-15K-G2(3D) X3-PRO-25K-G2(3D) X3-PRO-20K-G2(3D)

25000

27500

37.9/36.3

41.8

30000

30000

45.5/43.5

45.5

X3-PRO-30K-G2(3D)

X3-PRO-17K-G2(3D) X3-PRO-20K-G2(3D)

3~/N/PE, 220/380 V, 230/400 V; 3~/PE, 380 V, 400 V

50/60

3~/N/PE, 220/380 V, 230/400 V; 3~/PE, 380 V, 400 V

X3-PRO-8K-G2(2D) X3-PRO-10K-G2(2D) X3-PRO-15K-G2(2D) X3-PRO-12K-G2(2D) X3-PRO-17K-G2(2D) X3-PRO-20K-G2(2D)

17000

18700

25.8/24.7

27.5

X3-PRO-17K-G2(3D)

X3-PRO-15K-G2( 3D)

4.4 General Data

Dimension (W/H/D)[mm]

Dimension of packing (W/H/D)[mm]

Net weight [kg]

Gross weight [kg]

Installation

Operating temperature range [℃]

Storage temperature [℃]

Storage/Operation relative humidity

Altitude [m]

Ingress protection

Isolation type

Protective class

482x417x186

590x530x315

Wall-mounted

-30~+60 (Derating at 45)

-30~+60

0%~100%, condensation

4000(>3000 derating)

IP66

Transformerless

5 Installation

5.1 Check for Transport Damage

5.2 Packing List

Make sure the inverter is intact during transportation. If there are some

visible damages, such as cracks, please contact your dealer immediately.

Open the package and fetch out the product, check the accessories at

first. The packing list is shown as below.

Object

X3-PRO G2 series inverter1A

ABE

B

C

D

E

G

H

I

J

K

1

8/12

8/12

9

5

1

1

1

Bracket

PV terminal (positive*4 , negative*4 for two strings,

positive*6 , negative*6 for three strings)

(Expansion bolt, Gasket, Self-tapping screw)*3

Product manual

Quick installation guide

Quantity Description

Technical Data Installation

Model

L1

Pocket WiFi /LAN (Optional) /4G (Optional)

G

K L

M

24.5 28

28.5 32

H

N

5

Meter (Optional)

1

M N

PV pin contact (positive*4 , negative*4 for two strings,

positive*6 , negative*6 for three strings)

Terminal block*1, RJ45 connector*1,

F

F4

1

X3-PRO-8K-G2(2D)

X3-PRO-10K-G2(2D) X3-PRO-15K-G2 (2D) X3-PRO-12K-G2(2D) X3-PRO-30K-G2(3D) X3-PRO-25K-G2(3D)

26

30

24.5

28.5

16 17

IJ

OT terminal*5

Terminal cover*5

X3-PRO-20K-G2(2D)

X3-PRO-17K-G2(2D)

26

30

Terminal sleeve*1, R-type terminal*1

CD

X3-PRO-20K-G2(3D)

X3-PRO-17K-G2(3D)

27.5

31.5

Noise level

Night-time consumption

Over voltage category

Pollution degree

Cooling concept

Communication interface

Standard warranty [year]

I

<3 W

III(MAINS), II(PV)

II

X3-PRO G2 Series 8 kW-30 kW

M5 inner hexagonal screw

AC waterproof cover

X3-PR O G2 Seri es

User Manual

8 kW - 30 kW

Copyright Declaration

The copyright of this manual belongs to SolaX Power Network Technology (Zhejiang) Co., Ltd. Any

corporation or individual should not plagiarize, partially or fully copy (including software, etc.),

and no reproduction or distribution of it in any form or by any means shall be allowed. All rights

reserved. SolaX Power Network Technology (Zhejiang) Co., Ltd. reserves the right of final

interpretation.

28

32

Natural cooling Smart fan cooling

<35 dB <55 dB <58 dB

X3-PRO-15K-G2(3D)

Meter, USB, RS485_Modbus, WiFi / LAN (Optional)/4G (Optional), DRM (Optional)

5 (10 optional)

Inverter Topology Non-isolated

5.3 Installation Precaution

Please avoide direct sunlight, rain exposure, snow laying up during installing and

operating.

X3-PRO G2 Series inverter is designed for outdoor installation (IP66).

Make sure the installation site meets the following conditions:

Not in direct sunlight.

Not in areas where highly flammable materials are stored.

Not in potential explosive areas.

Not near the television antenna or antenna cable.

Not higher than altitude of about 4000 m above sea level.

Not in environment of precipitation or humidity.

Be sure the ventilation is good enough.

The ambient temperature in the range of -30℃ to +60℃.

The slope of the wall should be within ±5°.

5.4 Installation Steps

Preparation

Ø

Below tools are needed before installation.

Installation Installation

The wall hanging the inverter should meet conditions below:

1. solid brick/concrete, or strength equivalent mounting surface;

2. Inverter must be supported or strengthened if the wall’s strength isn’t

enough(such as wooden wall, the wall covered by thick layer of decoration)

Type

Machine Installation Tools

Tool equipment

Bit Φ10

Name Image

Hammer

drill

Outer

hexagonal

wrench

Torque

screwdriver

Name Image

Utility knife

Diagonal

pliers

Multifunction

terminal

crimping

tool (RJ45)

Multimeter

Marker

Tape

measure

Protective

glasses

Safety

gloves

Individual

Protection

Tools

Rubber

hammer

OT

terminal

press clamp

0.5mm²~10mm²

Wrench

Screwdrivers

Inner

hexagonal

wrench

Crimping

Tool

Crosshead M5

DC Voltage

Range ≥1100 VDC

Wire

stripper

18 19

≥300 mm

≥300 mm

≥300 mm≥300 mm 300 mm

300 mm

300 mm

300 mm

300 mm

Position Min Distance

Left

Right

Up

Down

Forward

Reserved space dimensions of

installation

5.4.1 Installation Space Requirements

Reserve enough space when installing inverter (at least 300 mm) for heat

dissipation.

The distance of installation space for multiple inverters is as follows:

Step 1: Fix the bracket to the wall.

Ø

First find the expansion screws and the bracket in the accessory bag, as

shown below:

a) Mark the holes on the wall with a marker.

b) Drill holes at the marked points to a depth of at least 60 mm.

a)

5.4.2 Mounting

20 21

≥300 mm

≥300 mm

Expansion bolts, Gasket, Self-tapping screws Bracket

b)

Φ10 Drill

(Depth: 60 mm)

Installation Installation

60.00 mm

Step 2: Hang the inverter on the bracket.

c) Insert expansion bolts into the holes, use rubber hammer to knock the

expansion bolts into the wall.

d) Insert the self-tapping screws into the gaskets and use the outer hexagon

wrench to tighten them.

c)

Expansion bolts

Rubber hammer

d)

Self-tapping

screw

Outer hexagonal wrench

Gasket

Step 3: Tighten the inverter and bracket.

Ø

f ) Use the inner hexagonal wrench to tighten the inner hexagonal screw on

the right side of the inverter.

e)

f )

Inner hexagonal wrench

(Torque :1.2±0.1 N·m)

Installation Installation

22 23

e) Hang the buckle of the inverter to the corresponding position of the

bracket;

Ø

5.5 Connection of the Inverter

PV String Connection

Ø

X3-PRO G2 series inverter have three couples of PV connectors which can be

connected in series into 3-strings PV modules. Please select photovoltaic

modules with good performance and quality assurance. The open circuit voltage

of the module array should be less than the maximum PV input voltage specified

by the inverter, and the operating voltage should be within the MPPT voltage

range.

Table 3 Max. DC Voltage Limitation

Max. DC Voltage 1100 V

Warning!

The voltage of PV modules is very high and dangerous , please

comply with the electric safety rules when connecting.

Warning!

Do not ground the positive or negative pole of the

photovoltaic module!

Note!

Please follow the requirements of PV modules as below:

Same type; Same quantity; Identical alignment; Identical tilt.

In order to save cable and reduce the DC loss, we suggest

installing the inverter near PV modules.

5.5.1 The Main Steps to Connect to the Inverter

Inverter+BMU

Installation Installation

Model

Danger!

Danger to life due to high voltage on DC conductors.

when exposed to sunlight, the PV array generates dangerous DC

voltage which is present in the DC conductors. Touching the DC

conductors can lead to lethal electric shocks.

Do not cover the PV modules. Do not touch the DC conductors.

Connection Steps

X3-PRO-8K-G2(2D)

X3-PRO-10K-G2(2D)

X3-PRO-15K-G2 (2D)

X3-PRO-12K-G2(2D) X3-PRO-25K-G2(3D)

24 25

X3-PRO-30K-G2(3D)

Step 1. Turn off the DC switch, connect the PV module, prepare a 2.5-4 mm PV

cable, and find the PV (+) terminals and PV (-) terminals in the package.

PV cable PV pin contacts Negative terminals

Positive terminals

Step 2. Use a wire stripper to strip 7 mm insulation layer from the wire end.

7.0 mm

Wire stripper

Step 3. Tighten the cable with the insulation layer stripped and insert it into

the pin contact (see Figure 1), make sure all wires are inserted into the pin

contact (see Figure 2).

Figure 1

Figure 2

Positive PV

pin contact Negative PV

pin contact

X3-PRO-17K-G2(2D)

X3-PRO-20K-G2(3D) X3-PRO-17K-G2(3D)

X3-PRO-20K-G2(2D)

X3-PRO-15K-G2 (3D)

PV+

PV-

Step 5. Divide the PV terminal into 2 parts - the plug and the fastening

head. Insert the cable through the fastening head and the corresponding

plug. Note that the red and black lines correspond to different plugs.

Finally, force the cable pair into the plug, there will be a "click" sound,

which indicates that the connection is completed.

Step 6. Tighten the fastening head and insert into the corresponding

positive and negative (PV+/PV-) ports of the inverter.

Step 4. Tighten the PV pin contact and the wiring harness to make

the connection tight without looseness.

Crimping Tool

Negative

Positive

Positive

Negative

PV+

PV+

PV- PV-

The following is the location of the inverter's positive and negative (PV+/PV-)

ports.

Schematic diagram of the inverter PV connected.

Installation Installation

26 27

Connection Steps

Grid Connection

Ø

X3-PRO G2 series inverter are designed for three phase grid. Rated grid voltage

is 230 V, frequency is 50/60 Hz. Other technical requests should comply with

the requirement of the local public grid.

Micro-breaker should be installed between inverter and grid, any loads should

not be connected with inverter directly.

Note: Check the grid voltage and compare with the permissive voltage range

(refer to technical data).

a) Disconnect the circuit-bricker from all the phases and secure against re-

connection.

b) Select appropriate cable and prepare to strip the wires:

- Strip 82 mm of insulation from the cable end.

- Use the stripping pliers to strip 12 mm of insulation from wire ends as below.

Table 4 Cable and Micro-breaker recommended

Incorrect Connection between Load and Inverter

L1, L2, L3 Cable

PE, N Cable

4-5 mm²

Model

5-6 mm²

*The parameters have some differences because of different environment and material. Please

choose appropriate cable and micro-breaker according to the local conditions.

5-6 mm² 8-10 mm² c) Fetch the AC waterproof cover from the carton.

e) Strip 82 mm of insulation from the cable ends by using the stripping

pliers.

Micro-breaker 16 A 32 A 50 A

2.5-5 mm² 3-6 mm² 3-6 mm² 3-6 mm²

X3-PRO-8K-G2(2D) X3-PRO-10K-G2(2D) X3-PRO-15K-G2(2D)

X3-PRO-12K-G2(2D) X3-PRO-30K-G2(3D) X3-PRO-25K-G2(3D)

20 A 25 A

3-6 mm² 3-6 mm²

6-8 mm²

5-6 mm²

40 A

10 mm²

63 A

3-6 mm²

28 29

L1 L2 L3 N PE

f ) Crimp the wire ends by using the wire crimper.

12 mm

Stripping pliers Stripping pliers

Crimp

82 mm

70 mm

12 mm

12 mm

70 mm

70 mm

Wire crimper

g) Pull one terminal cover each over conductors L1, L2, L3, N and the

grounding conductor. The terminal cover must be below the stripped

conductor section.

h) Use the OT terminal crimping tool to press OT terminals.

Installation Installation

X3-PRO-17K-G2(2D)

X3-PRO-20K-G2(3D)

X3-PRO-20K-G2(2D)

X3-PRO-17K-G2(3D)

strip length

L1

L2

L3

82 m m

12 m m

d) Unscrew the fastening nut of the AC waterproof cover and remove the

sealing rings. Select appropriate number of the sealing rings according to

the outer diameter of the cable. Let the cable pass through the fastening

nut, the sealing ring(s) and the waterproof cover in sequence.

a

b

Diameter(mm) Sealing ring(s)

a

a+b12~18

18~25

diameter

X3-PRO-15K-G2(3D)

j) Align the waterproof cover and tighten the four screws with an inner

hexagonal wrench.

Torque:1.2 0.1 ±N·m

Torque:0.1 1.2± N·m

k) Tighten the waterproof fastening head.

Installation Installation

Mains cable (AC line cable) shall be short-circuit protected and thermal overload

protected.

Always fit the input cable with fuse. Normal gG (US:CC or T) fuses will protect the

input cable in short circuit situation. They will also prevent damage to adjoining

equipment.

Dimension the fuses according to local safety regulations, appropriate input

voltage and the related current of the solar inverter.

The rated short-circuit breaking capacity of the above protective device shall be

at least equal to the prospective fault current at the point of installation. See

section technical data of this manual for details.

2 2

AC output cable: Cu; L1,L2,L3, N+PE: 3*5.0 mm +2*5.0 mm for 8 kW and 3*6.0

mm +2*6.0 mm for kW/12 kW/15 kW and 3*8.0 mm +2*6.0 mm for 17 kW/20

2 2 2 2

10

2 2

kW and 3*10.0 mm +2*6.0 mm for 25 kW/30 kW @40 ambient temperature ℃

with a max length of 5 m, with operating time of the fuses is less than 5 seconds,

installation method B2 according to 60204-1:2006, annex D: cable in conduit EN

cable trunking system, number of loaded circuit only one. Use H07 (cord RNF

designation 60245 66) for an ambient temperature of 40℃ or less and use IEC

90℃ wire for ambient temperature between 40℃ and 60℃.

Selection of Fuses and Cables

30 31

L1 L2 L3 N PE

i) Tighten the screws of the wire ends with a screwdriver.

1. For condition differing from those mentioned above,

dimension the cables according to local safety regulations,

appropriate input voltage and the load current of the unit.

(You can choose a thicker cable but the fuses must be rated

according to the rating of the cable.)

2. Fuses must be approved by Notified Body.

Note!

Therefore the current-carrying capacity of the components and sub-assemblies

provided in the end-use system (connectors, cables, junction box, switchgear,

etc.) and the reverse current PV modules shall be considered based on the

feedback current and reverse current. The direct current (DC) circuit breaker or

fuse between each solar generator and inverter shall be provided based on

solar inverter input ratings.

Select DC cables based on the above inverter back-feed current and ISC PV

rating and Vmax ratings.

32 33

Installation Installation

Earth Connection

Ø

Tighten the ground screw with an inner hexagonal wrench as shown in

the figure below. (φ5 inner hexagonal screw. Torque:1.2±0.1 N·m)

5.5.2 Communication interface

This product has a series of communication interfaces: such as

WiFi/LAN/GPRS, RS485/Meter, DRM and USB for upgrading for human

and machine communication. Operating information like output voltage,

current, frequency, faulty information, etc., can be delivered to PC or

other monitoring equipment via these interfaces.

1.WiFi /LAN (Optional) /4G(Optional)

This inverter provides a WiFi/LAN connecting port(the Dongle port) which

can collect information from inverter including the status, performance and

updating information to the monitoring website via connecting Pocket WiFi

(Pocket LAN can be purchased from the supplier for optional if needed).

Connection steps:

Please check the Pocket WiFi user manual for more details.

This is a communication interface for engineers to adjust the inverter.

a. RS485

b. Meter (Optional)

1.Monitor the energy to grid and from grid throughout the whole day.

2.Achieve the export control function with a higher accuracy.

Electrical

grid

Electric meter,

bidirectional three-phase

meter

Load

X3-PRO G2 series inverter

A meter can communicate with the X3-PRO G2 series inverter through this

interface, then you can:

The smart meter must be authorized by SolaX, any third party or

non-authorized meter may not match with the inverter.

SolaX will not take the responsibility if the unauthorized meter is

unavailable.

2.RS485/Meter

Please see the Quick Installation Guide for three-Phase Meter for details.

Meter Connection Steps:

Household Distribution

Units

Note!

Installation Installation

34

3.RJ45 Connection Steps:

(1) Prepare RJ45 connector and a communication cable.

(2) Strip the insulation from the communication cable.

(3) Let the communication cable pass though the waterproof connector

with RJ45, then insert it into the RJ45 connector following the PIN definition

rule.

(4) Crimp the RJ45 connector with the crimping plier.

(5) Insert the cable into the COM port of the inverter, and tighten the

waterproof connector.

a. DRM is provided to support several demand response modes by giving

control signals as below.

1

8

DRM, Dry Contact, Heat Pump Controller Steps:

Pin

Definition

123 4 5678

X

X X X REF GEN DRM0

Pin

Definition

123 4 5678

Dry Contact+ X X

Pin

Definition

123 4 5678

X

XHeat Pump Controller+

X X

X X

b. Dry Contact is provided to control the closing and breaking of switches by

giving control signals as below.

c. Heat Pump Controller is provided to draw heat from the surroundings and

transfer it to the object to be heated by sending control signals as below.

Dry Contact-

Heat Pump Controller-

1. Prepare RJ45 connector and a communication cable.

2. Strip the insulation from the communication cable.

3. Let the communication cable pass though the waterproof plug, then

insert it into the RJ45 connector following the PIN definition rule.

4. Crimp the RJ45 connector with the crimping plier.

5. Insert the cable into the COM port of the inverter, and tighten the

waterproof plug.

Connection Steps:

X X

X X

X X

35

The PIN denitions of RS485/Meter interface are as below.

12

Pin

Definition

123 4 56

485A 485B 485A 485B meter A meter B

Installation Installation

4. Upgrade

The inverter system can be updated through an U-disk.

1) Please contact our service support to get the update file, and extract

it into your U-disk as the following file path:

Make sure the directory is in accordance with above form strictly!

Do not modify the program file name! Or it may cause the inverter

to stop working!

Make sure the input voltage is more than 200 V (in good illumination

condition), or it may result in failing during updating.

“update\ARM\ ”;618.xxxxx.00_MICPROG2_ARM_Vx.xx_xxxxxxxx.usb

“update\DSP\618.xxxxx.00_MICPROG2_DSP_V usb”.x.xx_xxxxxxxx.

Upgrade Steps:

Note: Vx.xx is version number, xxxxxxxx is file completion dates.

2) Make sure the DC switch is off and the AC is disconnected with grid.

If the Pocket WiFi is connected to the port, please remove the Pocket WiFi at

first.

3) Then insert the U-disk into the Dongle port on the bottom of the inverter.

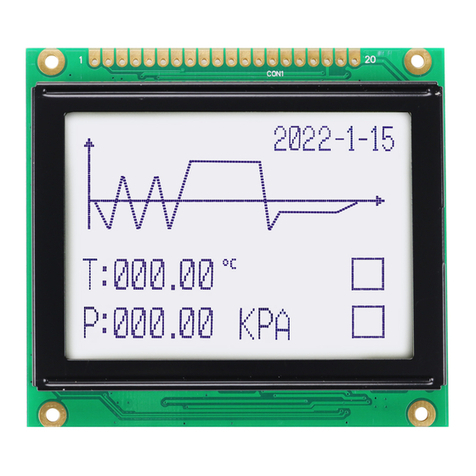

Then turn on DC switch and connect the PV connector, the LCD will show a

picture as below.

During updating, don’t turn off the DC switch or disconnect the

PV connector. If the updating stopped due to PV power failure,

do not unplug the U-disk. When the PV power recovers, the

update will continue. If the updating stopped due to other

reasons, reinsert the U-disk to continue the update.

4) Press the “Up” and “Down” button to select ARM or DSP. Then long press

“Down” and select the correct update file to confirm the update. ARM and

DSP shall be updated one by one.

Update

ARM

DSP

5) After the upgrade is completed, please remember to turn off the DC

switch or disconnect the PV connector, then pull off the U-disk, and connect

the Pocket WiFi back.

36 37

Other manuals for X3-PRO G2 Series

1

This manual suits for next models

19

Table of contents