Solgaz GNC-4 User guide

Sp. z o.o.

solgaz.eu

Assembly and instruction manual for

GAS CERAMIC HOB

to be built-in

GNC - 4

WARNING!

For your safety, please read the notes and suggestions presented further in this instruction

manual.

2

The gas hob can be connected to the gas source only by an installer

with qualifications to work with gas appliances.

This device is not to be connected to exhaust pipes.

The device should be installed and connected in accordance with applicable legal

regulations.

Warning!

If the hob's glass plate breaks, stop using it immediately

and contact the service department.

Please also be careful when handling the hob:

- do not touch, do not move metal grates or burner components

during use or immediately after. This can cause burns.

- do not place metal grids on the glass outside of their designated place (near the

burner). Grate assembly components can scratch the glass plate of the hob.

We guarantee the correct operation of the purchased gas hob.

However, if there are any problems related to the use of the device, our Support Department

will provide you with fast and professional help. We want to guarantee all those who have

trusted us full comfort in everyday use

of our product.

This device is labelled in accordance with European Directive 2002/96/EC on used electrical

and electronic equipment. After its period of use, the device cannot be thrown away with

other household waste. The user is required to return it to an entity engaged in the collection

of waste electrical and electronic equipment.

DEAR SIR OR MADAM

3

Thank you for your trust and purchase of the Solgaz automatic gas hob.

Our technology is sure to inspire you to better cooking each day thanks to the

hob's aesthetics, convenience and safety.

Sincerely,

SOLGAZ

TABLE OF CONTENTS:

1. GENERAL INFORMATION AND SAFETY INSTRUCTIONS............................................................................4

1.1. PURPOSE OF THE DEVICE............................................................................................................................. 4

1.2. TECHNICAL SPECIFICATIONS OF THE HOB ........................................................................................................ 4

1.3. HOB CONSTRUCTION.................................................................................................................................. 5

2. REQUIREMENTS FOR HOB INSTALLATION ............................................................................................... 6

2.1. REQUIREMENTS FOR ROOMS ....................................................................................................................... 6

2.2. INSTALLATION OF THE HOB IN A KITCHEN CABINET COUNTERTOP ......................................................................... 7

2.3. GAS SYSTEM............................................................................................................................................. 8

2.4. ELECTRICAL SYSTEM................................................................................................................................... 9

3. TIPS FOR THE INSTALLER ......................................................................................................................... 9

3.1. GENERAL INFORMATION............................................................................................................................. 9

3.2. Adapting the hob to another type of gas ........................................................................................ 9

3.3. Maintenance and inspections of hob elements............................................................................. 10

4. USING THE HOB..................................................................................................................................... 10

4.1. INITIAL ACTIVITIES ................................................................................................................................... 10

4.2 HOB CONTROL PANEL ................................................................................................................................... 11

4.3. STARTING THE HOB.................................................................................................................................. 11

4.4. WORK PROGRAMMES AND HOB FUNCTIONS ................................................................................................. 11

4.4.1. Residual heat indicator.................................................................................................................. 12

4.4.2. Standard operating mode ............................................................................................................. 12

4.4.3. Water boiling function................................................................................................................... 12

4.4.4. Flame size stabilisation function ................................................................................................... 13

4.4.5. Booster function ............................................................................................................................ 13

4.4.6. Timer function ............................................................................................................................... 14

4.4.7. Pause function –Stop'n go ............................................................................................................ 14

4.4.8. Turning the controller lock on and off ........................................................................................... 15

4.5. SELECTION OF POTS AND PANS................................................................................................................... 15

5. HOB CLEANING AND MAINTENANCE..................................................................................................... 15

5.1. REGULAR CLEANING................................................................................................................................. 16

5.2. INSPECTION AND SUPERVISION OVER GAS,ELECTRICAL AND VENTILATION SYSTEMS. ............................................. 16

6. PROCEDURE IN CASE OF FAILURES, ERROR SIGNALS ............................................................................. 17

7. WARRANTY CARD FOR THE GNC-4 GAS CERAMIC HOB ......................................................................... 19

4

1. GENERAL INFORMATION AND SAFETY INSTRUCTIONS

1.1. Purpose of the device

GNC type hobs are hobs for in-built installation, designed for preparation of dishes

and use in households. The gas burners are equipped

with temperature sensors, which assure maximum user safety and automatic, precise

operations. GNC belongs to a generation of gas hobs, whose burners are controlled

electronically and the device has

sensor-based control. The hob is designed for in-built installation in the countertop of a

single kitchen cabinet or in a composite countertop.

1.2. Technical specifications of the hob

Parameter

Unit

Value

Type and group of supplied

gas

2E

2Lw

2Ls

2L

3B/P

3P

3P

G20

G27

G2,350

G25

G30

G31

G31

Nominal connection

pressures

mbar

20

20

13

25

37

37

30

Thermal power of all 4

burners

kW

7.4

Gas stream of all 4 burners

g/h

~740

(This value applies only to liquefied gases)

Power of individual burners

Large burner

kW

2.8

Nozzle diameter

mm

1.31

1.49

1.90

1.35

0.85

0.90

0.90

Medium burners

kW

1.8

Nozzle diameter

mm

1.05

1.25

1.49

1.05

0.70

0.75

0.79

Small burner

kW

1.0

Nozzle diameter

mm

0.79

0.90

1.05

0.85

0.50

0.55

0.57

Gas connection

on the underside of the hob with an R1/2 internal pipe thread

Voltage and power supply

230 V/50 Hz -12V DC 4.5 A 60 VA

Protection rating

IP40

Device class

II

Hob dimensions

(W x D x H)

mm

580 x 500 x 67 (the dimensions include the protruding cover for

engines), grid above the hob - 55

WARNING!

Please bear in mind that stepper motors placed under the hob's glass plate control the size of

the flame and may be audible during adjustments. When the burner is turned on and the gas

ignited, a regular sound (knocking) can be heard. These are normal phenomena

and sounds of a working hob.

5

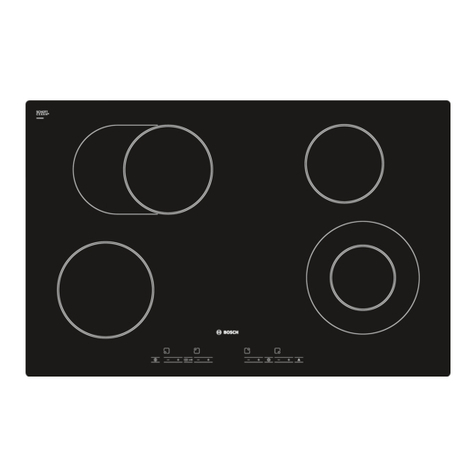

1.3. Hob construction

The ceramic plate (Fig. 1) features 4 special open gas burners,

of which the 3 largest are equipped with temperature sensors. Burner operations are controlled

electrically via a stepper motor. Built-in temperature sensors allow you to program a

constant cooking temperature, boil water and protect the burner from working without a

pot or pan.

The control units are powered with 12 V DC provided through a power supply from a 230 V

mains supply. The power supply is provided as a set with the purchased hob.

It is also possible to purchase an additional auxiliary power supply that allows the hob to

work in the absence of mains electricity. This is available on special order.

Gas can be sourced from the gas transmission system or a cylinder with liquefied gas.

The front part of the hob features a touch control panel. It enables control and monitoring

of individual burners and selection of operating modes.

Fig. 1 GNC hob

1 –ceramic glass plate, 2 –control panel, 3, 4, 5, 6 –cast iron grates for burners,

7, 8, 9, 10 –burner rings, 11, 12, 13, 14 –burner caps,

15, 16, 17, 18 –ignition electrode, 19, 20, 21 –thermal electrode (temperature sensor)

6

Fig. 2 Side view (from the right) of the GNC hob

1 –thermal electrode (temperature sensor), 2 –cast iron grates for burners, 3 –burner caps,

4–ignition electrode, 5 –burner body,

6 –burner ring, 7–hub body

2. REQUIREMENTS FOR HOB INSTALLATION

All activities related to the assembly and connection of the hob to the gas

and electrical distribution systems must be performed by a licensed installer qualified to

work with gas.

Warning:

Before installing and connecting the gas hob, check whether the hob is suited for the

type of gas that is to be used and whether it is compatible with the type of gas indicated on

the name plate of the hob. In case of incompatibility, do not perform assembly.

Warning:

The hob can be adapted to a different type of gas only by a licensed installer

qualified to work with gas. If in doubt about the type of gas supplied through your gas

distribution network, please contact the local gas distributor.

2.1. Requirements for rooms

Rooms in which the hobs are installed should be dry and airy, and offer efficient

natural ventilation due to the emission of exhaust fumes and heat. Assure good ventilation

of the kitchen, keep open natural ventilation openings or install mechanical ventilation

equipment (hood with mechanical removal).

Prolonged, intense use of the device may require additional ventilation: opening

windows or more effective ventilation, e.g. increasing the efficiency of mechanical

ventilation, if such is used.

The legal basis for determining the suitability of a room

in a building for installation of a gas hob is the Regulation of the Minister of Infrastructure on

the technical conditions that should be met by buildings and their location. (Journal of Laws

No. 75 as of 12.04.2002 Chapter 7, as amended.)

If a range hood is installed above the hob, the minimum distance between the

ceramic glass plate and the hood should not be less than 600 mm. We recommend a

7

distance of

750 mm.

The hob is not adapted for connecting to exhaust gas pipes. It should be installed and

connected in a manner compliant with current installation regulations.

2.2. Installation of the hob in a kitchen cabinet countertop

The countertop, in which the gas hob is installed must be screwed in permanently to

the cabinets or permanently connected with other furniture elements. In order to install the

hob in the countertop of a kitchen cabinet or a composite countertop, prepare a 540 x 480

mm opening. If the hob is installed above an oven, the opening for the hob should be made

symmetrically.

When the hob is installed next to cabinets standing on the countertop or in a corner

between walls, maintain a distance of at least 150 mm from the side of the cabinet or wall

corner.

The hob is fixed to the countertop using a self-adhesive gasket. We do not

recommend a different fixing method, using silicone in particular.

We recommend removing the rear wall of the cabinet in order to ensure better

ventilation under the hob. This also applies to installations with an oven.

A partition below the base of the hob is not required.

Fig. 3 GNC hob dimensions

Fig. 4 Installing the hob without an oven

1–Ventilation opening under the countertop: 2 –Air intake grille

8

Fig. 5 Installing the hob over an oven

1–ventilation opening in the lower shelf; 2–free space between the shelf and the back of the cabinet (air

flow); 3 –ventilation opening under the countertop

2.3. Gas system

The GNC –4 gas hob has a vertical connection terminated with an internal R ½"

thread (ISO 7-R1/2). It is recommended to connect the hob to the gas distribution system by

means of a flexible hose with a safety certificate.

The system used for supplying the hob from the gas distribution system should be

equipped with a cut-off valve.

The gas hob uses a mesh gas filter, which is responsible for capturing and removing

mechanical impurities. It assures appropriate flow in the system

and efficient operation. No maintenance or cleaning is required.

If the hob is supplied with liquefied gas from a gas cylinder, connect it using a

ø10/R1/2" connector screwed onto the gas inlet. On the cylinder valve, install a regulator for

liquefied gases. Connect the regulator with the hob using a flexible hose suitable for

liquefied gases (with a maximum length up to 3 m) with bands attached at both ends.

The regulator and flexible hose must have a safety certificate.

It is the user's responsibility to replace fittings

with a limited period of use.

The gas connection should be routed in such a way that there are no bends

with a radius smaller than 150 mm and that it does not come into contact with heated

elements of the hob's housing and other devices (e.g. oven).

The flexible hose that supplies the hob should be mounted in such a way that it does

not touch the moving parts of the housing section (e.g. drawer) and does not pass through a

space with insufficient dimensions.

For reasons of user safety, installation of the hob must be performed by a gas

appliance installer!

9

Please note:

Laws in force in Poland prohibit the connection of gas appliances to LPG cylinders in

buildings with a gas distribution system

(Journal of Laws No. 75 Chapter 7).

2.4. Electrical system

In order to ensure correct and safe use of the hob, an electrical power supply (230

V/50 Hz) needs to be run to the vicinity of the hob for connecting the power supply unit.

The electrical socket should be equipped with a protective pin and cannot be placed

directly above the hob or at a distance smaller than 10 cm from the side of the hob and at

least 10 cm above the upper plane of the hob, and absolutely outside the area where hot

exhaust gases flow out of the burners. A properly ventilated space needs to be provided for

the power supply unit.

The power supply cable from the mains electrical system and the power cable to the

hob should be run in such a way that they do not come into contact with heated parts of the

hob or heat generating devices installed beneath.

3. TIPS FOR THE INSTALLER

3.1. General information

Only a trained and authorised installer may perform activities related to assembly,

connection of the hob to the gas

and electrical distribution systems, and adjusting the burners to another type of gas.

Before proceeding to the assembly and connection of the hob to the gas and electric

systems, the installer should check that:

- the room, in which the hob will be used, meets the requirements of current

regulations (volume, dimensions, hob location),

- the gas and electric systems are made in accordance with applicable standards

and regulations.

The employee performing the installation must, after completing all activities,

confirm their performance (list of activities, date, signature and company stamp) in the

hob's warranty card, which is the basis for the warranty and statutory warranty of the

purchased hob. Otherwise, the warranty card is invalid.

After installation, the installer must perform the first start-up. At the first start-up

of the hob, the burner may ignite after a longer time. This is a normal phenomenon, caused

by gas filling the pipes and the burner itself. This disappears after the first start-up.

3.2. Adapting the hob to another type of gas

If it is necessary to adapt the hob to a different type of gas than the one for which it

was prepared by the manufacturer at the factory, all gas nozzles in burners need to be

replaced with such appropriate for the particular gas (in accordance with data in the table in

10

point 1.2).

It is also necessary to replace the hob's solenoid assembly and modify the controller

software. This procedure can only be performed by an authorised service centre.

3.3. Maintenance and inspections of hob elements

When operated in accordance with this instruction manual, and cleaned

and maintained, a properly working hob does not require inspections.

4. USING THE HOB

4.1. Initial activities

After installing the hob in accordance with point 2.:

- place the burner body (item 5, fig. 2) in the hob's body (item 7, fig. 2) paying

attention that it is evenly (horizontally) placed,

- place the burner cap (item 3, Fig. 2) centrally on the burner ring; be careful when

placing caps on burners with a temperature sensor (item 1, Fig. 2),

- place grids (item 2, Fig. 2) on the hob's glass plate, making sure that the metal pins

fit the openings in the glass,

- insert the plug of the power supply cable into the mains power socket

and place the 12 V low voltage cable ended with a circular plug in the power socket of the

hob (it is located on the bottom of the device, in the lower right corner, under the control

panel),

- open the cut-off valve on the gas supply line to the hob,

- once connected to electrical power, the hob will start its calibration mode. The

timer section of the display will show "00" and horizontal signs will appear above the

burners' sensors. Once the markings above the sensor of the upper right burner disappear, a

blinking calibration symbol will appear. When this disappears, the hob enters standby mode

and is ready for use. This is signalled by an indicator light (item 1, Fig. 6). Stepper motors can

be heard during calibration (knocking).

When the hob is used for the first time, open a window and assure air access to the

room. This will ensure better air exchange in the kitchen, allowing unpleasant odours to

escape.

11

4.2 Hob control panel

Fig. 6 Control panel –item 2. from Figure 1.

1–switch indicator, 2 –lock indicator, 3 –hob on/off switch,

4–hob panel lock, 5,6,7,8–digital indicators of the set burner power,

9–timer indicator, 10, 11, 12, 13 –burner selection fields, 14 –increasing power,

15 –reducing power, 16 –timer switch, 17 –booster function switch,

18 –boiling function switch, 19 –stop'n go function on/off switch, 20 –power level stabiliser function switch

4.3. Starting the hob

To start the hob, after completing the initial steps from point 4.1., touch the main

sensor switch (item 3, Fig. 6) with your finger. The switch indicator goes out (item 1, Fig. 6)

and the hob is ready to accept commands. All four field indicators (item 5, 6, 7, 8 in Fig. 6)

show "0000" for 6 seconds. If no further action is taken, after that time the hob goes into

standby and indicators turn off, with only the switch sensor remaining lit. The switch can be

used to turn off the hob at any time, even with the lock activated.

4.4. Work programmes and hob functions

The GNC hob can work in different modes, which allow comfortable, precise and safe

cooking. All changes in the way burners work are introduced through the control panel. The

size of the flame and the power output of the burners are controlled automatically.

The hob will turn off automatically after 4 hours of operation without any changes of

settings, if there are pots or pans on the burners. In case there are no pots or pans on the

medium or large burners, it will switch off when the safety temperature limit is reached,

which is lower than the self-ignition temperature of edible oil. This is aimed at protecting

the hob's components from overheating and ensuring user safety.

The smallest burner is not equipped with a temperature sensor. The set temperature and

boiling functions are not available in its case.

12

This burner will not turn off, if there are no pots or pans, however, the other burners will.

Please pay special attention to this.

Descriptions for starting and using each of the available work modes are shown

below:

4.4.1. Residual heat indicator

When a burner is turned off, its elements and the grate remain hot. To protect the

user against accidental burns, an "H" is displayed over the sensor of the turned off burner.

Only once it turns off is it safe to touch elements of the burner, grates and glass in this area.

4.4.2. Standard operating mode

A specific, constant power/flame size can be set for each of the burners.

After a burner is selected using its sensor (items 10, 11, 12, 13), use the + and –

sensors (items 14, 15) to choose power on a scale from 1 to 9, where each level contains 3

adjustment levels. This allows precise adjustments, with a total of 25 different flame sizes.

Burner power is pre-set to 5 to facilitate quick selection of more or less power.

Holding the + or - sensor can speed up the adjustment, as it then jumps a full level (3

levels of adjustment simultaneously).

The burner is turned off by a double tap on the corresponding sensor.

Despite setting the same power level on the two medium-sized burners, the flame

sizes may differ slightly. This does not indicate incorrect operation of the hob, as this

phenomenon results from the independent construction of both burners.

4.4.3. Water boiling function

This programme makes it possible to automatically boil water and turn off the burner

once finished.

For the function to work properly, please follow the instructions below:

- use a kettle/vessel with a lid, a thin bottom and 0.5 l to 3 l capacity,

- the water should be at room temperature when the programme is switched on,

- do not interrupt the programme,

- do not add or pour out water.

Pay attention and maintain the above parameters because a change or interruption of the

programme (e.g. using the stop'n go function) can reduce the precision and boiling time.

The boiling mode is started by selecting the burner using the appropriate sensor

(items 10, 12, 13) and touching the programme sensor (item 18). Medium burners start at

level 9, the large burner at 5, with field indicators (items 5, 7, 8) displaying horizontal lines

rising from the bottom up. The hob uses temperature sensors to automatically cut off the

gas supply after the water boils. The programme allows it to boil for a short time to ensure

that the water is cooked and sterilised. The boiling time is also dependent on the material

parameters of the pot or pan, altitude A S L, ambient temperature and type of gas used.

To turn off the boiling function, touch the sensor field of the burner (items 10, 12, 13)

used in this mode and after selecting, touch the boiling mode sensor (item 18). The burner

13

will return to continuous operation in manual mode.

A burner with the boiling programme activated cannot use the timer, booster and

flame size stabilisation modes. You can use the stop'n go (pause) function, but this may

disrupt the programme, as per the above. You can also use the control panel lock function.

4.4.4. Flame size stabilisation function

This function allows you to maintain the set power level for the prepared dish (range:

from 40 to 220. This gives a total of 181 settings). Power levels indicate the temperature, but

due to the properties of various vessels, the type of gas, ambient temperature, food density,

etc., the obtained results may differ from the actual temperatures in the pot or pan. The

flame's power is automatically

and smoothly maintained at one level by stepper motors.

The function applies only to burners equipped with a temperature sensor.

If the temperature increases too quickly or exceeds the set safety threshold, the flame is

reduced or even extinguished. In case of the temperature being too low in relation to the set

power, the hob automatically increases the flame.

The mode is started by activating a given burner with its sensor (items 10, 12, 13) and

touching the function sensor (item 20).

The digital display (item 9) will show a power indication symbolising the temperature,

which the hob will aim to achieve. The value is raised or lowered by means of the +and –

sensors (items 14, 15).

After 6 seconds, the temperature indicator will be switched off and a small letter "c"

will appear on the indicator field of the burner, for which the function is activated.

In the event of a change in power level, the flame size is adjusted in real time.

To exit the power level stabilisation function, touch the sensor for the field (items 10,

12, 13), for which the function is activated and touch the function sensor (item 20).

After switching off the function or after an exit, the hob will set the burner output to the one

used currently in stabilisation mode.

4.4.5. Booster function

This function allows immediate and automatic setting of the selected burner's

maximum power. It can be used when the power level stabilisation programme is activated

and the burner is working as standard. The function does not work in the water boiling

mode.

To use the function, touch the sensor of any working burner

(items 10, 11, 12, 13) and then the booster function sensor (item 17). At this moment, the

hob will set the maximum power on the burner for 3 minutes. The display for the burner

using the booster function will be marked with the letter "P" and a dot in the lower right

corner of the burner display (items 5, 6, 7, 8).

The function can be switched off before the lapse of 3 minutes by changing the

14

programme on a given burner or by touching the booster function sensor (item 17) for the

selected burner.

4.4.6. Timer function

The programme allows automatic shutdown of the hob. The working time can be set

within a range from 1 to 99 minutes.

The programmes work on every selected cooking zone and are independent of each

other.

When the timer is working, changes can be made to the hob's work mode.

Completion of the timer programme is signalled with a visual (the power level of the

turned off burner will start to flash) and audio signal.

Once switched off, the message "H" remains.

To take advantage of the function, touch the sensor of any working burner (items 10,

11, 12, 13, Fig. 6)and then the timer function sensor (item 16, Fig. 6).

Above the row of burner power displays (items 5, 6, 7, 8, Fig. 6) a function display will

appear (item 9, Fig. 6), which will show "00". In 6 seconds, set a time in minutes using the +

and - sensors (items 14 and 15, Fig. 6) within a range from 1 to 99. After this time the burner

will be turned off. When the timer function is on, the burner display will be marked with a

blinking dot in the lower right corner of the display (items 5, 6, 7, 8).

You can see the time remaining in minutes until the the burner is turned off and

change this value at any moment. To check the remaining time/make a change, touch the

burner sensor with the active timer function (items 10, 11, 12, 13) and then the timer

function sensor (item 16). The timer display (item 9) will show the remaining time set until

the burner is turned off.

The function can be switched off by changing the work programme or turning off the given

burner. You can also activate the timer function by setting the working time and then

the work programme when starting the hob.

4.4.7. Pause function –Stop'n go

The pause function can be used at any time during cooking. It allows you to stop the hob and

later return, with the previously set programmes and heating levels.

At least one burner of the hob must be working. When you touch the pause sensor

(item 19, Fig. 6) markings will light up in the indicator locations and the operation of the

hob will be suspended for up to 15 minutes for all cooking zones. When the pause function is

on, it is only possible to use control panel lock sensors (item 4, Fig. 6)

and on/off sensors of the hob (item 3, Fig. 6)

The pause function is turned off by touching the function sensor (item 19, Fig. 6). At

that moment the indicators of previous settings will light up again and the hob will continue

to operate.

If the function is not switched off after 15 minutes from its activation, the hob will

turn off.

15

4.4.8. Turning the controller lock on and off

The controller lock protects the hob against accidental starting or a change in the

power of the working burners.

In order to prevent uncontrolled starts, switching off or changing the burner's power, use

the controller lock, which is done as follows:

Touch the sensor (key) with your finger item 4 Fig. 6. Pressing and holding it for 5

seconds will cause the controller to lock, the indicator diode to switch on and an extended

audio signal to sound.

To unblock the hob controller, follow a similar procedure:

Touch the sensor with your finger item 4 Fig. 6 and hold for 5 seconds, the indicator

diode item 2 Fig. 6 switches off, the hob controller is unlocked and an audio signal can be

heard.

4.5. Selection of pots and pans

To ensure optimum use of the heat generated by the flame from the gas burner, use

appropriate pots and pans. They must have:

- a flat bottom,

- a bottom diameter larger than the diameter of the burner.

In addition, the pots and pans are to be covered with lids (if permitted by the recipe).

Also ensure that the lid does not protrude beyond the cookware, so that condensate does

not drip onto the glass plate of the hob. This way, you will avoid difficult to remove stains.

Do not use such cookware on the hob that extends significantly beyond the heating

area edges. In addition, the diameters of the bottom of the pots and pans placed on the

large and small burners

at the front of the hob, should not exceed 22 cm. Failure to comply with this may cause the

control panel to overheat and increase the risk of burns to the user.

Cookware should be placed centrally on the grate above the centre of the burner

before it is switched on. The minimum diameter of the cookware should not be smaller than

the diameter of the flame crown of a particular burner.

Pay special attention not to accidentally damage the temperature sensors that protrude

above the grate, e.g. by moving a pot over the surface of the grates without lifting it or by

carelessly placing cookware on the hob.

NOTES - for obvious reasons:

do not use plastic dishes,

do not put empty cookware on the hob's cooking zones,

do not place textiles near lit burners.

5. Hob cleaning and maintenance

In the event of incorrect care for the hob's ceramic glass plate

and burner elements, our warranty responsibilities are void.

16

The ceramic plate, grates and burner elements are wear elements

and wear out when the hob is used.

Warning!

If you notice cracks on the glass plate, immediately stop using the hob and call

customer support.

Cleaning guide at www.solgaz.eu/czyszczenie

5.1. Regular cleaning.

For cleaning ceramics, we recommend products shown at www.solgaz.eu/srodki-

czystosci/ (however, it is forbidden to clean metal parts with such products, in particular the

black aluminium strip, in which the exhaust grilles are located). These products remove all

dirt from the ceramic plate, while being safe for it. If you notice any invasive effects when

other products are used, stop immediately. We are not responsible for damages due to use

of chemicals other than those we recommend.

The hob can be cleaned only once it has cooled down to ambient temperature.

Use gently acting fluids to clean enamel surfaces (grates and all burner components).

Do not use strong abrasive cleaning agents, such as powders containing an abrasive,

abrasive pastes, abrasive stones, pumice, wire cleaners, etc.

Clean the hob regularly after each use. Do not allow the top to become dirty, in

particular avoid burns that happen during cooking.

▪remove light, unburned spots with a damp cloth without a cleaning agent.

▪use a sharp scraper to remove tightly attached spots. Then, wipe the surface with a

damp cloth and a special cleaning agent. Persistent stains cannot always be removed

during the first cleaning, even when a special cleaning agent is used.

It is best to let the cleaning agents dry and then wipe them off wet. Never apply cleaning

agents to hot elements of the hob. Any remaining cleaning agent should be wiped off with a

damp cloth before the hob is heated up again. Otherwise, they may have a corrosive effect

on varnished and metal elements of the hob.

Enamel grids are dishwasher safe.

5.2. Inspection and supervision over gas, electrical

and ventilation systems.

To ensure proper and safe operation of the purchased hob, check the condition of

the gas, electrical and ventilation systems, which should include:

-checking the technical condition of the above-mentioned systems,

-submitting comments to the building administrator in case of any doubts regarding their

technical condition.

17

6. PROCEDURE IN CASE OF FAILURES, ERROR SIGNALS

IMPORTANT:

Before calling the manufacturer's service technician, please read the following tips:

Please bear in mind that stepper motors placed under the hob's glass plate control

the size of the flame and may be audible during adjustment. When the burner is switched on

and when the gas is ignited, a regular sound (knocking) can be heard. These are normal

phenomena and sounds of a working hob.

Alarm messages may be shown in case of problems in the hob's operation or lack of gas in

the distribution system or cylinder.

The names of alarm states and the manner in which they are signalled by the controller are

given in the table below.

Cause

Name

Status signal

No flame signal, burner not

working despite the gas

valve being open

Alarm G

The letter "G" appears on controller

indicators in the zone of the burner, in

which no flame appeared, and a pulsating

sound plays

No flame extinguished signal

when the gas valves are

turned off. The waiting time

for the flame to disappear is

5 seconds.

Alarm C

The letter "C" on the controller display for

the burner, for which the flame's

extinguishing was not noted. The controller

is blocked, the gas supply is shut off. A

pulsating sound appears.

Overheated controller, no

ventilation or a covered

exhaust outlet.

Alarm D

The letter "D '' appears on the controller's

display. It remains until the equipment has

cooled down to operating temperature.

Simultaneous pressing of

several sensors on the

control panel or its flooding.

Alarm E

The letter "E" appears on the controller's

display and a pulsating sound is emitted.

Alarm states signalled by the hob controller inform the user about incorrect operation of

the equipment. If the gas hob functions incorrectly, please stop using it and contact us

between 8 am and 6 pm through our:

Support Centre:

tel. 515 020 434

Customer service office:

tel. 515 020 420

We provide a power supply unit together with the hob.

18

Manufacturer's declaration

The manufacturer hereby declares that this product meets the essential requirements of the

European directives listed below

Directive 2006/95/EC Low voltage electrical equipment

Directive 2004/108/EC Electromagnetic compatibility

Directive 2009/142/EC on essential requirements for appliances burning gaseous fuels, and

was marked with

Connection certificate

The gas ceramic hob has been properly connected to an active gas distribution system or gas

source.

Installation

address……………………………………………................................................................................

date of installation ................................... qualifications No……………………………

stamp and signature

of the installer ..............................

19

7. WARRANTY CARD FOR THE GNC-4 GAS CERAMIC HOB

factory No………………....... date of manufacture..............................

WARRANTY CONDITIONS

In order to assure safe use and for this warranty to remain valid, the gas ceramic hob must

be installed by an installer qualified for working on gas systems. Installation at the place of

use is done at the user's expense.

The gas ceramic hob is intended only for household use.

The product should be used according to the Instruction Manual provided with the

product and powered using the power supply from the manufacturer.

The manufacturer assures correct operation of the product for a period of 24 months

counting from the date of purchase.

A defect in the product will be remedied within 14 business days from submission of a

service request, with the warranty period extended by the time from the submission date

to the moment the user receives a defect-free product . In particularly justified cases,

when the repair must be performed

at the manufacturer's headquarters, the complaint will be resolved within 21

business days. A device that is to be repaired should be complete, in

its original packaging and secured for transport, supplied together with the warranty

and power supply. The user should clean the hob of any dirt caused by use. The

shipping costs are covered by the warrantor.

The warrantor is released from liability under the warranty in the case of defects:

◦caused by incorrect use

◦resulting from alterations and repairs performed by the user

◦resulting from improper parameters of the gas supplied to the hob or connection to a

different gas supply than that set at the factory.

◦in case of a lack of relevant entries in the warranty card.

◦in the event of loss of warranty

◦when a power supply other than that suggested by the manufacturer is used

◦damage to the ceramic plate and enamelled components resulting

from use is not covered by the warranty.

During the warranty period the buyer has the right to request replacement of faulty

equipment with such that is free from defects, if according to the decision of the person

representing the warrantor or acting on its behalf, a defect occurs in the equipment

that is impossible to remove. We reserve the right to forego replacement, if

mechanical or chemical damage, or other indications of incorrect use or

maintenance are found. Replacement does not apply in the case of purchase of a

discounted product or one without original seals.

20

Should the complaint be deemed unjustified due to the absence of a defect or its

occurrence as a result of improper use, the warrantor refuses to perform a free warranty

repair by providing written justification of its position. In this case, a paid repair is

possible after costs are determined and accepted by the interested parties.

Adaptation of the device for use with a different gas than set at the factory is not

considered a warranty repair. In selected cases such work is performed by an authorised

installer. A description of the procedure is provided in the instruction manual.

This warranty card is valid, if the device was installed by a properly

qualified person. It cannot contain deletions, unreadable entries

or corrections.

Please send requests for warranty repairs to our Technical Support

in any form, together with an address, the serial number and a short description of

the fault. The support employee will indicate the appropriate service centre for

your place of residence. Contact details for the manufacturer's technical support are

provided at the end of the warranty document and on the website of the warrantor

www.solgaz.eu.

After the warranty period, the manufacturer performs paid repairs, once the scope and

costs of the repair are agreed with the interested party.

No duplicate or copy is issued in case the warranty card is lost.

Warranty service is only valid within Polish territory.

The warranty is valid along with proof of purchase within Poland.

In matters not covered by this Warranty Card, the law in force shall apply, in particular the

provisions of the Act of 30.05.2014 on consumer rights published in the Journal of Laws of 2014

item 827, and the provisions included in Art. 577 to 581 par.1 of the Civil Code

Table of contents

Other Solgaz Hob manuals

Popular Hob manuals by other brands

Weller

Weller WHP 1000 operating instructions

Siemens

Siemens EA 746 Series instruction manual

Indesit

Indesit PI 604GB operating instructions

Hotpoint Ariston

Hotpoint Ariston PCN 751 T/IX/HA operating instructions

Candy

Candy PL2D40NX User instructions

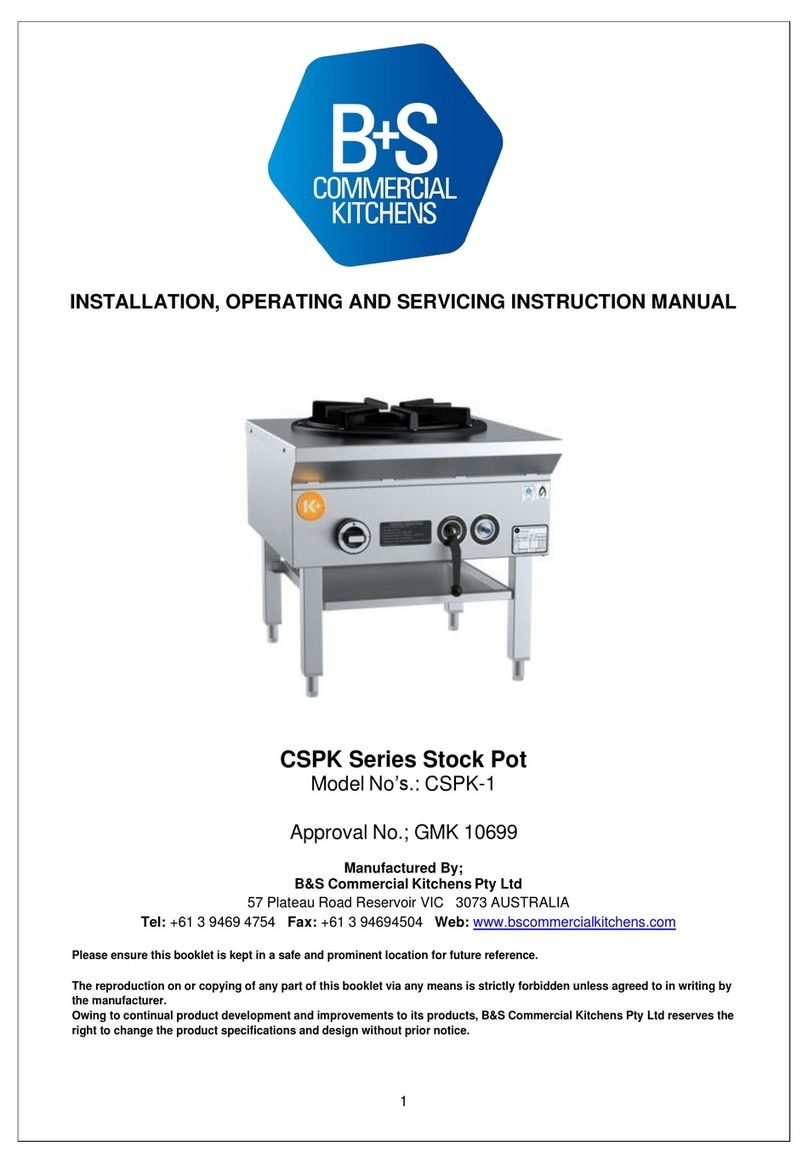

B+S

B+S CSPK Series Installation, operating and servicing instruction manual