Solgaz GPC-2 User manual

2

Dear Customer,

Congratulations on your reasonable decision to purchase our

ceramic gas panel to be built in all types of kitchen furniture sets.

Our panel can serve as a part of advanced equipment of a

modern kitchen furniture set. Not only is it highly sophisticated,

but it also looks good and is resistant to extreme temperatures. Its

unquestioned advantages include: low operating costs, easy

operation and environmental-friendly parameters, which you will

be able to evaluate in the course of daily use.

Have fun with preparing your perfect tasty meals.

Yours sincerely,

SOLGAZ

The ceramic gas panel-cooker must be connected to a gas

source by an authorized person

(certified installer)

Dear Sir, Dear Madam,

We guarantee that your new gas-fired heating panel will operate correctly.

However, should you have any problems with using this heating panel, our Company Service

will offer you immediate and professional assistance. We want to guarantee full comfort of in

daily use of our product to all those who have put their trust in our company.

3

CONTENTS

1. GENERAL INFORMATION

page

1.1. Application of the plate. . . . . . . . . . …. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2. Technical data of the GPC-2 plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3. Design of the gas plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 4

2. REQUIREMENTS FOR HOB INSTALLATION

2.1. Requirements for rooms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2. Mounting the cooker in kitchen countertop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3. Gas installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4. Electrical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. USE OF THE HOB…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . …. . . . . . . . . . . . 8

3.1. Initial activities, Timer . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2. Switching on and setting the heating power of burners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3. Description of operating condition with intelligent reheating function. . . . . . . . . . . . . . . . . 10

3.4. Switching off the burners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5. Switching the controller lock on and off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6. Residual heat indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7. Choice of pots…. . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.8. Utilization of combustion gas heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.9. Reduction of operating time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. HOB CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1. Cleaning the ceramic panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2. Cleaning the cooker strips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3. Control and supervision over gas, electrical and ventilation systems . . . . . . . . . . . . . 13

5. INSTRUCTIONS FOR THE INSTALLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1. General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2. Adapting the cooker for different type of gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3. Maintenance and inspection of cooker components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6. HANDLING DEFECTS –error signaling . . . . . . . . . . . . . . . . . . . 15

7. CONTROLLER ALARM CONDITIONS SIGNALING. . . . . . . . . . . . . 15

4

GENERAL INFORMATION

1.1. Application of the plate.

The GPC-2 type plate is a ceramic hob with 2 gas burners located underneath. This is the

newest generation of gas hobs where special gas burners controlled by an electronic system process

heat generated through gas combustion into infrared radiation. Radiation infiltrating the ceramic

plate heats the dishes positioned above the hot fields. Hot fields are indicated graphically on the

plate. This hob is provided with touch sensors for controlling its operations. It is fit for building in

a single kitchen countertop or in a combined countertop. It is designed for non-professional (home)

preparation of food and for household use.

Advanced solutions applied in the hob’s construction and design give it a nice esthetical

appearance while ensuring comfortable and safe use.

1.2. Technical data of the GPC-2 hob.

Table. 1

Parameters of the hob

Unit

Type of gas

2E

G20

2Lw

G27

2Ls

G2.350

3B/P

G30

Rated pressure

mbar

20

13

37

Gas nozzle of the f 90 (small) burner

mm

0,75

0,82

1,00

0,43

Gas nozzle of the f 120 (medium ) burner

mm

1,00

1,10

1,35

0,60

Rated heating power of the appliance

kW

≈2,70

Rated heating power of 90 burner

kW

1,07

1,02

0,94

0,93

Rated heating power of 120 burner

kW

1,81

1,72

1,75

1,60

Gas connection

R1/2”

Operating voltage

V

12 V

Power adapter supply voltage

V

230 V/50 Hz

Parameters of the power adapter

12V DC/3,5A

Protection class of the housing

IP- 40

Dimensions (L x W x D)

mm

330x495x110

The entire electrical installation of the hob is supplied with a special power pack and is prepared

as a low voltage system.

In terms of fire risk, the hob is classified as a safe device

1.3 Design of the gas hob

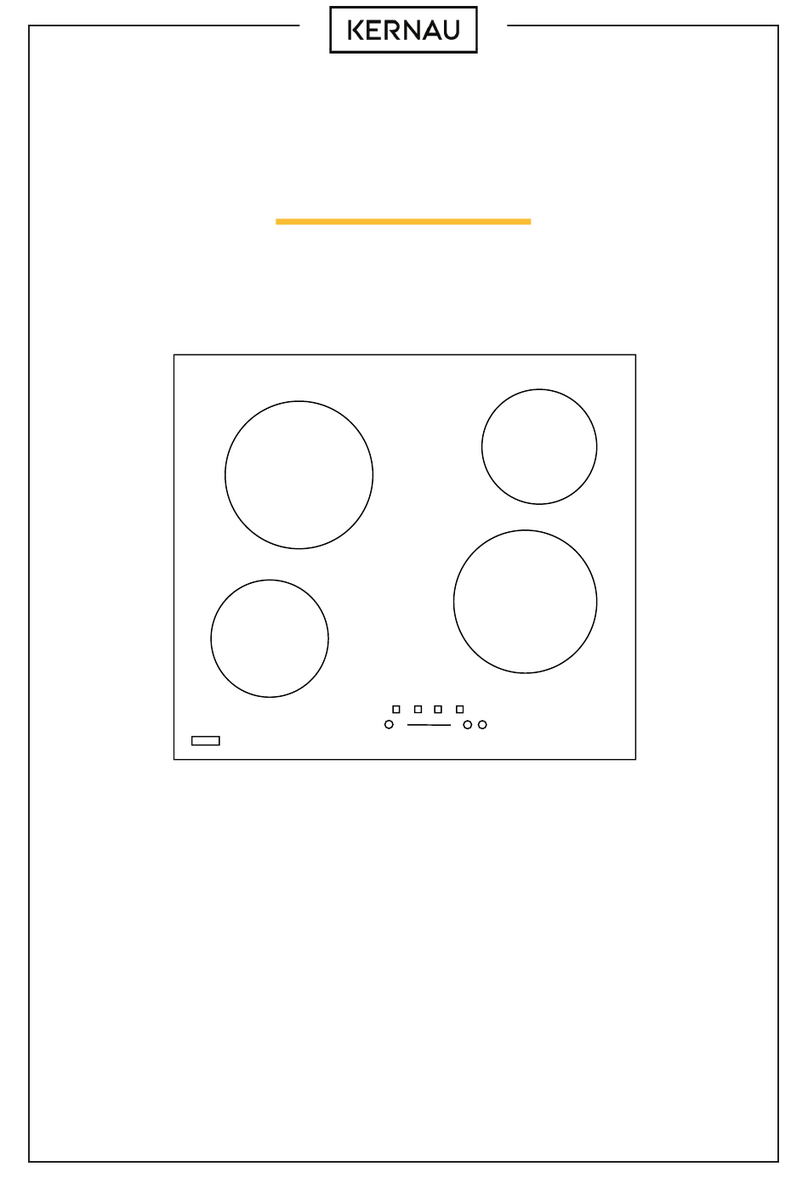

The hob (fig. 1) has two injector gas burners rated as specified in the table above, with a ceramic

insert, equipped with igniting electrodes and ionizing detectors of burning gas. Burners in which

catalytic combustion of gas takes place produce infrared radiation.They are covered with a

ceramic panel with four separate hot fields above the ceramic burners, indicated graphically on the

panel, and one hot pads above combustion gas ducts of gas burners, which do not consume gas.

Because the hob controls must be supplied with 12 VDC power, the hob is supplied from a 12V

power source via a special power pack to be connected to the 230V household system, included

with the delivered hob. Nozzles adapted to commonly used G 20 gas are installed in the delivered

hob by default. The gas source can be a gas network, or a liquid gas cylinder. Through replacing

the working nozzles according to Table 1 and changing the size of air diaphragm according to

Table 3, the user is able to adapt the hob to burning a different type of gas.

A touch control panel is located in the front part of the hob (fig. 1). It is for controlling and

regulating the specific gas burners of the hob. It also displays relevant messages of the cooker

operating conditions.

5

9

2

35 4

1

6 1

87

12V DC

Fig. 1

1–ceramic panel, 2–hot field ø120, 3 –hot field ø90, 4 –hot area, 5–combustion gas outlet, 6–

gas inlet, 7 –controller, 8 –power supply socket, 9 –power adapter

Fig. 2 (control panel –no 7. on fig. 1.)

1–user lock, 2–lock indicator, 3–power setting 4–power setting indicator, 5,6–burner

selection fields 7,8–digital indicator of burner power settings, 9–on/off switch, 10 - –on/off

indicator, 11. timer indicator

6

2. REQUIREMENTS FOR HOB INSTALLATION

All activities related to hob installation and connection to gas and electrical system

should be performed by a certified installer.

NOTE:

Before installing the hob and connecting it to the gas installation, make sure it is adapted

for the right type of gas supply and that this gas corresponds to the gas type given on the

hobs’s rating plate. (by default, cookers are adapted to G 20 gas). Otherwise, adapt the hob

through replacing the nozzles and air diaphragms with the types appropriate for the given

type of gas.

In case of any doubt as to the type of gas supplied via the network, please contact your gas

supplier.

Proceeding in such case is described in details under 5.2 of the instruction.

2.1. Requirements for rooms

The rooms designated for installing the cooker should be dry and airy, with efficient natural

ventilation.

2.2. Installation and assembly in furniture

All activities related to the assembly and connection of the stove to the gas and electric

systems must be performed by an authorized installation technician.

Assembly of the hob in kitchen countertops

Due to the large size of the hob it is not recommended to install it in the countertops of individual

kitchen cabinets. A composite kitchen countertop where the gas hob is to be installed must be

permanently fixed to the cabinets or permanently connected with other elements of the furniture. In

order to place the hob in the kitchen countertop or in a composite countertop, it is necessary to

make an opening in it with the following dimensions, depending on the type of the hob 540x310

mm. If the hob is to be installed over an oven, the opening where the hob is to be installed must be

symmetric.

If the hob is to be placed next to cabinets standing on the countertop or in the corner of the room,

the plate of the gas hob must be placed at least 150 mm away from the side of the cabinet or wall.

The way to install and fix a 2-burner hob is presented in the drawing.

7

310±1

min .150

47 0

40

60 0

+1

min.38

495

33 0

110

48

Fig. 3. Instalation

min. 15 mm

min. 15 mm

1

2

3

Fig.4 Hob with oven arrangement

1 –VENTILATION AIR INLET IN THE BOTTOM PART OF THE SHELF; 2 –VENTILATION AIR INLET

WITH MESH; 3 –AIR

8

500 1

2

140

50

side view front view

Fig. 5 Chart of 8ssembly

1-VENTILATION AIR INLET, 2- VENTILATION AIR INLET WITH MESH

REMARKS:

- Due to the height of the hob, it is impossible to install it over an oven in standard kitchen

cabinets.

- If the kitchen cabinet has a back wall, it is absolutely necessary to cut out ventilation openings in

it, as shown on the drawing.fig. 5,

- Because of the need to assure circulation of air, an air inlet grate should be installed in the skirting

of the cabinet fig. 4.

2.3 Gas supply system

1. GPC-2 have a vertical connector pipe ending with an R1/2”outside thread (ISO 7-R1/2) for

connecting the hob to the gas supply system. It is recommended that the hob be connected to the

gas supply system with a flexible connecting hose with a safety certificate.

2. If the hob is supplied by means of a flexible connecting hose, it is necessary to use an R ½ /G ½

screw-in/screw-on elbow. A cut-off valve must be installed in the system to stop the supply of

gas to the hob, as well as a gas filter preventing the nozzles from clogging due to polluted gas.

3. If the hob is to be supplied with liquid gas from a gas cylinder, a ø10/R1/2” connector pipe is to

be screwed into the gas supply connector pipe, after removing the ½” nipple. A liquid gas

regulating valve needs to be installed on the cylinder valve. The regulating valve is connected

with the hob with a flexible hose for liquid gas (max. length 3 m) with clamps on both ends.

The regulating valve and the flexible hose must have safety certificates.

-The above activities, for the sake of the user’s safety, should be performed by an authorized gas

installation technician!

2.4. Electric system

The control system of the hob is supplied with 12 V direct current through a power supply. In

order to assure correct and safe operation of GPC-2 hobs, it is necessary to provide an electric

socket (230 V/50 Hz) close to the location of the stove in order to connect the hob’s power supply.

The electric socket should have a grounding bolt and cannot be located directly over the hob, at the

distance of less than 10 cm away from the side of the stove and at least 10 cm above the top plane

of the hob plate, away from the area affected by hot fumes exhausted in the back of the hob.

Moreover, it is necessary to provide properly ventilated place for the power supply. In other

places, a special cable to connect the hob with a 12 V DC system will be provided on request.

3. USE OF THE HOB

3.1 The startup of the hob should be performed by an authorized technician in the buyer’s home.

9

The hob can be turned on after it is properly installed in the kitchen cabinet countertop, the type of

gas is verified, and it is connected to the gas and electric supply systems. After the hob is

connected to the gas supply system, it is necessary to checkiif gas does not leak from the

connection.

If an exhaust hood is installed over the hob, then the minimum distance between the hood and the

ceramic plate of the hob may not be less than 750 mm. Before starting the hob, the ceramic plate

should be washed with soft cloth and soapy water or a cleaning agent. After the plate dries, the

burners can be ignited.

After the startup, due to the combustion of protective lubricants, it is necessary to ventilate the

room by opening the window or turning on the mechanical ventilation. This increases the air

exchange in the kitchen and allows the faulty smells to be removed.

Before the hob is started up and the individual burners are ignited, the following must done:

- put the supply cable plug of the power source into the socket of the power supply system and put

the low-voltage 12 V cable ending with a round plug in the hob supply socket. The socket is

located on the bottom of the hob.

- open the gas cut-off valve.

After the hob is connected to the electric system, it is ready for work, which is indicated by a diode

located next to the sensor.

-after the sensor of the main switch is touched with a finger, its indicator is turned off and the hob

is ready to receive instructions. For 5 seconds, all indicators show “0”.If we take no further steps,

after a while the electronic system of the hob goes into a standby mode, the indicators are switched

off and the main switch sensor is turned on again.

- TIMER function, touch a burner selection filed twice (Fig.2, no 5 or 6), touch “+” and “-“ to

select time in minutes (from 1 to 99min.), the burner stops automatically after selected time

3.2. Switching on and setting the heating power of burners.

-NOTE!!!! - do not switch on the hob burners for a prolonged period without filled dishes put

on the hot fields first!!! Otherwise, your device might be damaged.

-When you choose any single burner by touching the controller activating field no 5, or 6, on

fig. 2 and set the power by touching the power setting slider, no 3 fig. 2, within a range

exceeding “0”, the selected burner will go on. This is supposed to happen within less than 5

seconds of enabling the controller via on/off sensor –item on fig. 2. If the delay is longer than

specified above, the burner will not start and the controller will switch to standby mode until

further instruction is received.

-All changes of controller program status are accompanied by short sound signals.

1. To start individual burners of the hob, make sure you do the following:

2.Put a filled dish on the relevant hot field.

3. Touch the on/off sensor no 9 fig. 2. “0” indicators will light up in fields 7, 8. If you touch

the sensor corresponding to the selected burner –fig. 2. again, as needed and as indicated on the

heating panel, you start the second stage of burner setting. Slide your finger along the setting slider

–no 3 on fig. 2 –to set the required power of the heating pad. At that time, the power setting

display –no 4 of fig. 2 –displays a row of diodes and a digital message shows in the previously

selected field, within the range of 0 to 9, showing the power value set. As the row of diodes

extends and the message number displayed increases, the burner power increases as well, and

opposite –if you slide your finger towards the key symbol, you will reduce the power setting. The

row of LEDs will simultaneously become shorter and the numbers displayed are lower, to finally

reach “0”. “9” corresponds to the maximum heating power of the burner, and “0” corresponds to

no power set.

4. After 1 to 3 seconds, the burner will start burning gas (the ceramic insert under the heating plate

will turn red when fully heated).

You may also vary the burner power in a different way. First activate the selected burner (fields

5, 6,of the controller) by touching any location within the power setting control field –no 3 on fig.

10

2. The activated burner’s power will change in increments, to reach the level corresponding to the

touching point. Set the power level using this method within not more than 5 seconds. After 5

seconds of completing the last change of pad power, the control pad of the controller will stop

receiving further instructions, and a new power value of the selected burner will be set as specified

in the preceding step.

Follow the same procedure with each burner.

You may touch the sensors described above at any time to set the desired heating power of burner,

in the range from 1 to 9.

After each change of the selected burner’s power setting, the row of LEDs will light up, then go

off after a short time, with only the modified power setting of the active burner being displayed.

When you have started all burners, their power settings are displayed accordingly and the LED

row –no 4. fig. 2 is off. Burners that have not been switched on in the relevant controller field

corresponding to the burner indicated on the panel will remain off and not light up.

If the burner heating power level is set from 1 to 9, the burner will operate in pulse mode,

meaning that when the burner is not burning gas (several to several tens of seconds in one

cycle), it re-circulates heat from incandescent hearth to heating pad of the ceramic panel, thus

achieving better gas intake efficiency.

At first (cold) run of burner(s), they heat up during several minutes, to switch to pulse

operating mode after that time, depending on the heating power settings.

-TIMER function, touch the burner selection fields twice (Fig.2, no 5,6,7 or 8), touch “+” and “-“

to select time in minutes (from 1 to 99 min.), the burner stops automatically after selected time

3.3. Description of operating condition with intelligent preheating function.

The hob operating status with reheating is a transitory condition for rapid achievement

of target temperature of the active hot field, up to the heating power set. It is signaled by the

decimal point lighting up next to the active burner’s digital indicator (5,6, fig 2).

1. If any level of heating power is set for the given hot field, the controller display will show a

number corresponding to the power setting. With this setting, the operating condition with

automatic reheating function will start automatically. This status is additionally signaled by

decimal point on the display corresponding to the given hot field. It takes up to 18 minutes,

depending on the power setting. Then, the hob’s controller switches to automatic heating cycles.

2. You can change the heating power level of the selected sensor while working with automatic

preheating function using the corresponding sensor and following the procedure described above

under. 3.2.

3. The automatic preheat operating mode of the given burner is automatically controlled by

an electronic system. The user can switch off the function by sliding the finger to “0” power

level and then immediately to any chosen power level (from 1 to 9)

3.4. Switching off the burners.

In order to switch off any of the operating burners, touch the corresponding sensor, then slide

your finger along the slider towards the “key” so that to reduce the burner’s power setting to “0”

(gas supply shutdown). During this operation, the row of LEDs (no 4 fig. 2) showing the power

level goes down and the digits decrease from the level previously set to level “0”. When level “0”

is reached and the controller is ready for restarting, the letter “H” will display after a moment,

indicating that the panel is hot in the location of the burner that has just been shut down.

You may also switch off the entire hob. To do so, touch the main shutdown switch sensor, or

press and hold the power setting slider around zero power for some time, having previously

11

activated the selected sensor for switching down the burner.

All working burners will go off and those just shut down will display the letter “H”.

3.5. Switching the controller lock on and off.

The purpose of controller lock is to secure the hob’s electronic system against accidental

startup or changing the power setting of active burner.

To avoid unauthorized activation (e.g. by a child, a drop of water, or an item being placed on a

working controller), switching off or changing heating power settings of burner(s), use the

controller lock as follows:

-touch the sensor /key/ with your finger –no 1 fig. 2 at least twice in 2 seconds’ time. When

pressed shortly twice, the controller will be locked,

-signaling LED lighting up and a sound signal no 2 fig. 2 indicating the controller lock status, a

long sound signal will be heard simultaneously. The hob controller does not respond to any

instructions except for lock status change.

Proceed in a similar way to deactivate the lock status:

- touch the sensor with your finger (no 1 fig. 2) twice within up to 2 seconds,

-the signal LED (no 2 fig. 2) goes off, the lock is off, and a sound signal is emitted.

3.6. Residual heat indicator.

After a hot field is shut down, it remains hot for a certain time, and the “H” message is

displayed. The above applies to all operating burners being shut down.

Do not touch the hot fields during that time, and do not place heat-

sensitive items on the hot fields, to avoid the risk of burning!

When this indicator goes off, you may safely touch the heating pad.

Cautions –in case of a electricity cut, the residual heat indicator

will go off and the pad may still be hot.

Note: ”H” also refers to the additional hot area, which means that additional hot field (no 5 fig.1)

may be hot as well.

3.7. Choice of pots

To maximize utilization of heat transmitted by infrared radiation emitted by the gas burner,

use appropriate pots that must have:

-diameter similar to hot field size,

-flat bottom of appropriate thickness, min. 4 to 6 mm for stainless steel

dishes.

In addition, the pots must have lids (if allowed by recipe). Make sure the lid does not protrude

outside the dish and condensate does not drip on the ceramic panel. You will thus avoid difficult

stains on the surface of the panel.

12

Cooking time is significantly longer for formed-bottom dishes, as the bottom receives only a

part of infrared radiation emitted by the hot field.

Place the dishes in the middle of graphically indicated hot field before switching on.

To avoid scratching the surface of the hob’s plate, do not move any dishes with materials stuck

to the bottom, like grains of sand or remnants of cleaning agents.

NOTES –for obvious reasons, you are not allowed to:

- use plastic dishes!!!

- use aluminum dishes

- put empty dishes on the hob’s heating fields when a burner is working!!!

Do not put dishes on or do not block the combustion gas outlet grate at the back of the

hob, particularly when it is working !!!

3.8. Utilization of combustion gas heat.

The GPC-2 ceramic gas plate has additional hot field –no 4, which is shown on fig. 1, using

the heat of combustion gas leaving the burner to the outlet grate situated in the rear part of hob.

This hot area can be used for warming up meals that do not require high temperature.

Use of this hot area significantly reduces the hob maintenance costs, as we utilize the heat of

combustion gas emitted from the burner.

Note:

-the additional hot area is hot and you must remember it to avoid getting burnt when touching it.

-do not allow boiling over of prepared dishes and avoid grease splashing on the ceramic plate, as

the food remainders and oil can get burnt.

-

3.9. Reduction of operating time.

To improve operating safety, the hob has a working time limiter for each hot field. The

maximum operating time setting is determined automatically according to recently selected heating

power setting.

If you do not change the heating power level for a long time, then the corresponding hot field is

automatically shut down and the residual heat indicator “H” is activated. However, you can switch

on and use the individual fields at any time, according to operating instructions. These relationships

are given in Table 2.

-

Table 2.

Power setting

0

1

2

3

4

5

6

7

8

9

Maximum heating pad

operating time (hours)

0

10

5

5

4

3

2

2

1

1

13

4. CLEANING AND MAINTENANCE OF THE HOB

REMARK: All the activities related to the cleaning of the ceramic plate must be performed

after the plate cools down to an ambient temperature.

4.1 Cleaning the ceramic plate

When cleaning the ceramic plate, it is necessary to follow the same rules as those for cleaning glass

surfaces. Do not use abrasive or aggressive cleaning agents, scrubbing sand, or sponges with

scratchy surfaces. Using such materials can cause irreparable scratches on the surface of the

ceramic plate.

4.2 Cleaning after each use

- Slight, not-scorched stains should be wiped off with a damp cloth without a cleaning agent.

Using dishwashing liquid may cause bluish discoloration. These persistent stains cannot always be

used at first try, even using a special cleaning agent.

- Sticky stains should be removed with a sharp scrubber. The surface should then be wiped with a

damp cloth with special protective agent.

Removing stains

Light stains, with a pearly color (aluminum residue) can be removed from a cold ceramic plate

with a special cleaning agent. Calcium residues (caused, e.g. by boiling water) can be removed

with vinegar or a special cleaning agent.

When removing sugar, food leavings containing sugar, plastics, or aluminum sheet, one must not

turn off a given heating field! It is necessary to immediately precisely scrape off the leaving (while

they are hot) with a sharp scraper from a hot heating field. After the stain is removed, one may

turn off the stove and clean the cooled ceramic plate with a special cleaning agent.

A cleaning agent must never be applied on a hot ceramic plate

- Cleaning of the hob grids

1.The fume exhaust grids should be cleaned with a damp cloth and a little dishwashing liquid, and

then wiped dry with a cloth.

2.It is not allowed to use abrasive or acidic cleaning agents to clean glass and decorative metal

parts

3.Cleaning should be performed only after the surface to be cleaned is cooled off, the same as in

the case of the ceramic plate.

4.A fume outlet made from enameled steel should be cleaned with sponge, after it cools off.

We take no responsibility for guarantee claims if the ceramic panel of cooker is not

operated properly.

Warning!

If you notice any cracks on the panel’s heating pads, shut down the cooker

immediately and call service.

4.3 Control and supervision over gas, electrical and ventilation systems

To ensure proper and safe operation of your hob, please check the condition of the gas,

electrical and ventilation systems. The scope of inspection should cover:

-checking the technical condition of the aforementioned systems,

notifying the building administrator of any doubt concerning the technical condition of these

installations

14

5. INSTRUCTIONS FOR THE INSTALLER

5.1. General.

Activities related to hob installation, connection to gas and electrical systems and adjusting

hob burners to a different type of gas can only be carried out by a properly trained and

certified worker.

Upon completion of the aforementioned activities, the installer must acknowledge their

completion (list of activities, date, signature and company seal) in the hob guarantee card, which

is the basis for retaining guarantee and warranty rights for the hob. Otherwise, your guarantee

will be voided.

Before commencing hob installation and connection to the gas and electrical systems, the

installer must make sure that:

-the room in which the hob will be used conforms to the requirements of standards (size,

dimensions, location of hob),

the gas and electrical installations are built in accordance with valid standards and regulations

Note:

After installing the hob, the installer must carry out initial startup. During initial startup,

squealing can be heard at combustion gas outlet. This is normal, caused by gas feeding to gas tubes

and burner. It will disappear after first startup.

5.2. Adapting the hob for different type of gas

If the hob needs to be adjusted to a different type of gas than the standard one replace gas

nozzles in all burners with items appropriate for the given type of gas, according to list of nozzles

in the Technical Specifications of these Operating Instructions ( 1.2) and set the volume of input air

with a diaphragm, setting the gap for dimensions as specified in Table 3.

Nozzles can only be replaced by an trained installer

Table. 3

x

12

Gas type

Diaphragm distance from pipe edge –X (mm)

Small burner

Medium-sized burner

Large burner

G20, G27

6

9

no diaphragm

G235

5

8

no diaphragm

3B/P

4

7

no diaphragm

5.3. Maintenance and inspection of hob components

15

If the hob is operated in accordance with these instructions, cleaned and maintained according

to the description presented in clause 4., - then a hob that works properly does not require

inspection.

6. HANDLING DEFECTS –error signaling

Please read the following guidelines before calling the manufacturer’s service technician:

-The reheating hot area heats up but does not glow during operation of the hob.

-Regular bursting noise of spark generator and valve can be heard while starting up the heating

pad before gas is lit.

-Individual hot field may glow with varying power.

These occurrences and sounds are normal in an operating hob.

The burner located under the hot field controls its temperature through switching on and off.

When low heating power setting is chosen for the hot field, the burner will go off for a longer time,

or for a shorter time in case of higher heating power, accordingly.

In case of gas pressure drop in the network or cylinder, the hob will be automatically locked. This

is signaled by the letter “G”.

7. CONTROLLER ALARM CONDITIONS SIGNALING

Alarm messages may display as a result of faults in hob operation, or gas shortage in network.

Identifications of alarm conditions and controller’s signals are given in Table 5.

Table 5.

Reason

Identification

Condition signal

Overheated controller, no

ventilation, or concealed

combustion gas outlet.

Alarm D

Letter “D” on controller display. It

remains until the cooker cools down to

working temperature

Flame presence signal after

switching on the valve

Alarm G

Letter "G” on controller indicators,

showing in the field corresponding to

the burner without flame.

No flame decay signal after

switching off the gas valves.

Flame decay waiting time is 5

seconds.

Spill over alarm.

Alarm C

Alarm E

Letter "C” on the controller display at

the burner where flame decay was not

observed. The controller is locked and

the gas supply is shut down.

A liquid spilled over or any two touch

fields were activated at the same time

(for example when cleaning the glass)

16

Additional information:

The following will be delivered together with your hob:

- Power supply adapter.

Our service center’s phone no.: +48 074 856 52 88

correspondence address: SOLGAZ Sp. z o. o.

58-124 Marcinowice

ul. Spoldzielcza 3

Poland

------------------------------------------------------------------------------------------------------

TYPE: GPC –2 (GPC-2-T)

SERIAL NUMBER…………………………………….

INSTALLERS SIGNATURE…………………………..

DATE:

This manual suits for next models

1

Table of contents

Other Solgaz Hob manuals

Popular Hob manuals by other brands

Electrolux

Electrolux EHB30100 user manual

Siemens

Siemens EF 781 Series instruction manual

Kernau

Kernau KHC 6412 Instruction manual / installation manual

Kuppersbusch

Kuppersbusch EKI3720.1ED Instructions for use and installation

Electrolux

Electrolux EHE 683 Instruction booklet

AEG

AEG IKB6440HFB user manual