Solidator 2.0 User manual

SOLIDATOR 2

DLP 3D PRINTER

USER MANUAL

2

TABLE OF CONTENTS

TABLE OF CONTENTS ................................................................................................................................................. 2

Introduction and Intended Use of Product ............................................................................................................... 3

Safety Instructions ..................................................................................................................................................... 3

Package Contents ...................................................................................................................................................... 4

Selecting a Good Location for Your Solidator Printer................................................................................................ 5

Unpacking the Solidator : .......................................................................................................................................... 6

Initial Commissioning –Machine Setup..................................................................................................................... 7

Calibrate the Solidator............................................................................................................................................... 8

Resin Container Mounting and Airflow Check......................................................................................................... 10

Dry Printing.............................................................................................................................................................. 11

Your first real print................................................................................................................................................... 12

Removing and Cleaning ........................................................................................................................................... 13

Solidator Shutdown Procedure................................................................................................................................ 15

Upload Models......................................................................................................................................................... 16

USB Stick .................................................................................................................................................................. 16

Network Setup......................................................................................................................................................... 16

Description of WLAN Setup and HTML 5 Interface ................................................................................................. 17

Software Setup ........................................................................................................................................................ 19

Technical Specification ............................................................................................................................................ 20

3

Introduction and Intended Use of Product

The Solidator DLP 3D Printer is intended to be used as a 3D object printer that transforms photosensitive liquid

resin into a solid material. Only resins certified for use with the Solidator 3D printer should be used to prevent

damage to the resin container. The Solidator DLP 3D Printer is equipped with a number of security features such

send switches, cover sensor, and chassis that should not be removed or altered to provide safe operating

conditions.

Safety Instructions

Do not tilt the product more than 35 degree when packaged or unpackaged.

Place the Solidator on a strong work surface, one that is capable of supporting 50kg (110lb)

Make sure the Solidator is leveled. Using the installed leveling feet and a water level to

confirm.

Do not modify/trick the cover sensor or end sensors of the Solidator, and do not open the

chassis of the Solidator.

Only use resin certified by tangible engineering for usage with the printer. Use of other

resins will void support, possibly damage the printer, and expose you and the environment

to risks, including extreme heat / fire or gas.

A certified resin is Solidator Professional Resin Transparent Orange R001.

Wear protective nitrile gloves and eye shields when handling resin. Resin can irritate the

skin.

Use protective glasses when handling resin. In case resin is in contact with the eyes, spill

with water for at least 15 minutes and contact a doctor immediately.

Make sure printed objects are cleaned with alcohol and water to ensure no uncured resin

remains. Although the resin does not require a post cure, exposing the printed part to a UV

light source (lamp or sunlight) will quickly remove the tacky surface.

Check the resin containers seal to make sure the film remains intact by cleaning excess resin

carefully before each print. It is recommended that the resin be filtered between prints to ensure

that no particulates are present in the resin.

4

Operate the Solidator 3D printer in a well ventilated and dust free environment to ensure optics

stay clean

Do not place the printer directly under powerful light sources or near a window. The resin material

is highly sensitive to UV light, accidental exposure may cause the resin to cure and cause print

failure or destroy the resin containers film.

Follow the steps shown in the user manual to set up the printer in your environment.

Read the Solidator Professional Resin MSDS, which is available at

https://solidator.blob.core.windows.net/customers/R001_MSDS.pdf

Package Contents

Solidator 3D DLP Printer, including

already Wireless Adapter and RS232

Cable to Projector (already

connected).

Calibration board

Resin container,

Please keep its packaging

for later use

Screws with knobs

Power connector wall socket - male

Power connector female - female

Resin as ordered

Network cable

5

Selecting a Good Location for Your Solidator Printer

When planning where to position the Solidator, you should select a location that fits the follow criteria:

Well ventilated environment (at a minimum forced ventilation on demand), as the resin and alcohol for

cleaning emit an odor.

It is recommended to place the Solidator on a laminated work surface or one that has been

treated to be resistant to household chemicals. To verify that the resin will not damage the work

surface, place a small amount of resin on a small inconspicuous area and verify that the surface is

not damaged.

Note that the Solidator is a Wi-Fi and Ethernet-enabled device, so you can locate it in a room other

than your PC workplace.

Important: There should be no direct sunlight or strong lamp shining in to the Solidator Red Cover

or onto the back side of the Solidator. After you have selected the location to setup your Solidator,

please test the environmental lighting by placing a small amount of resin in a clear container and

expose to the existing lighting. If the resin does cure (solidify), consider either moving the

Solidator to another location or make adjustments to the lighting to minimize interaction with the

resin.

After you selected the location where to put the Solidator, please put small amount of resin in a

small container to test if the resin cures from the light in that room –or not.

6

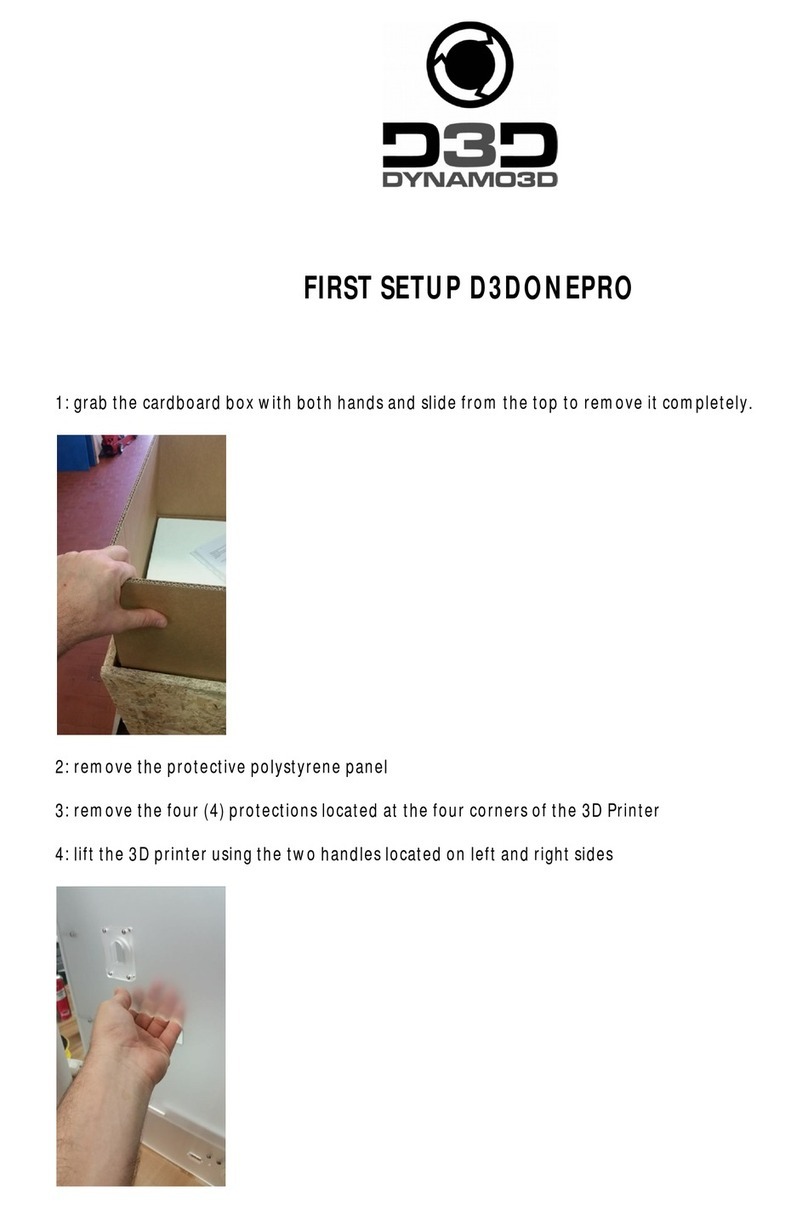

Unpacking the Solidator :

1. Follow all unpacking steps given in this manual

https://solidator.blob.core.windows.net/customers/Unpacking%20Solidator%202.pdf

2. Move the box close to the place on which you plan to use the printer.

3. Use two persons to remove the Solidator from the box, utilizing the grip holes as indicated in

the picture. Do not tilt the printer, and watch the cover glass while moving the printer out!

4. Place the printer on the floor.

IMPORTANT: Use a water level to check the Solidator is leveled. If not already leveled, use the feet

on the Solidator, screwing in and out, to level the Solidator.

Power switch

Power connector

LAN

Wi-Fi adapter

7

Initial Commissioning – Machine Setup

Please follow the instructions. If anything is unclear or not behaving as described, please contact tangible

engineering GmbH immediately before proceeding.

1. Remove the protective film from the red cover and set the cover aside for now.

2. Remove the protective film, if any, from the black body of the printer.

3. Make sure the Power Switch is turned off.

4. Plug in the power cord to the power unit and wall power socket.

8

Calibrate the Solidator

1. Remove the black acrylic sheet that is in the place the resin container will be mounted.

2. Attach the printing platform to the Z-Axis using the knob-screws. Make sure the label is

pointing to the front.

3. Position the resin container in the machine with the resin container label to the front. The

label indicates the correct direction of the resin container. The label must be in the front! This

is very important and must never be done wrong!

If there is no Label, you can still see the correct direction of the container. The min/max fill

lines have to be in the back, one air-entry hole on the left and two air-exit holes on the right,

that’s the correct direction.

4. Turn on the Solidator using the power switch.

5. Within 15 seconds, the Solidator logo should be displayed on the touch screen.

6. Following another 45 seconds, you should see the following screen:

9

If instead you see an error message reading, Calibration Data Mismatch,

please ensure the USB cable on the backside of Display is properly

connected. You will recognize that the Wi-Fi adapter starts blinking blue

once connected correctly. If fixed, just turn off and on again.

7. Select the Setup →calibrate →projector option. This will start the projector and display a

calibration pattern in red. Place the calibration board on top, and check whether the displayed

pattern matches the size of the calibration board outer lines.

Then use the zoom wheel and the focus wheel to adjust the projection. Then remove the

calibration board again.

Note: The projector has a zoom and a focus wheel for projector calibration

Focus

Zoom

6 x M5x10 Torx 25

In delivery state, the focus and the zoom

are fixed. If the focus or zoom does not

appear to be correct, open the printer on

the lower front panel.

10

8. Put the red cover back on the Solidator. Notice that the cover has a magnet inside and that

this magnet needs to sit on inside-rear-right side of the red cover (printer viewed from the

front).

9. Please click on “Setup” and then select Calibrate →Motor, then press Start.

10. After this action, the motor will drive the printing plate to a position that aligns with the top

edge of the resin container. Remove the red cover and confirm that the top of the container

matches the lower edge of the print platform. Then put the red cover back again and press OK

to drive back up.

Resin Container Mounting and Airflow Check

You should wait until the resin container is acclimated to room temperature, when cold it is

possible for the container to deform.

Install the resin container aligning with the full length clamps, tighten the clamps to ensure that

there is no vertical movement of the container.

Next you should check if the there is an air pocket of about 1mm everywhere between the glass

plate and the film of the container. This air pocket is crucial for the machine to work fine.

If you notice an irregular air pocket or if there is any moisture between the glass plate and

the film, using a clean cloth apply gentle pressure to the right side of the resin container

where the two air-exit holes are located. Gently tap the film on the left side of the resin

container until the film is no longer in contact with the glass. Contact customer support, if

problem persists.

11

Dry Printing

1. Go back to the Main Menu and select Print →select the “calibration block”. Then confirm all

checkboxes (although no resin in the resin container) and press Start.

2. Do not be afraid the motor will go slower and be really loud when going down below the resin

container top edge. This is normal. The motor will stop once the printing plate is at the floor of

the resin container. The slow speed avoids bubble formation but results in louder operation.

3. Let it print for a few layers, then pause and abort the print.

12

Your first real print

IMPORANT: Please use safety glasses and nitrile gloves when working with resin and cleaning the objects!

1. Remove the red cover.

2. Remove the resin container and put it on a table. To see if the sealing is still OK after

transport, pour 1.5 liter water into it. Wait for 15 minutes then pour out the water and make

the resin container dry with a soft paper towel.

Note that there is a film above the glass on the floor of the resin container. There should be

no water below the film. If there is water between the glass plate and the film please contact

support.

3. Put the resin container in the Solidator with the Solidator logo at the front left.

The metal container has two partial length lines etched on the back wall, the bottom

line is the minimum fill line and the line approx 8mm above is the maximum fill line.

Pour resin into the container until the resin reaches the maximum fill line.

4. Close the red cover with the magnet on the right side.

Magnetic sensor

Cover magnet

13

5. Now start the print again via touch screen →print →select the “calibration object” and

confirm the check boxes and hit Start.

6. At the end of the print, you should have this object at the print platform.

Please verify that the object has at least 5 pins this indicates correct

sharpness of the projection. If not please try recalibrate the machine

and print again.

Removing and Cleaning

1. Open the screws that fix the printing plate with both hands so the printing plate is settling

down onto the holders evenly. The printing plate can sit in the holders safely.

2. Now you can tilt the platform to the rear and to the front to let resin drip off the platform.

After this you clean the top and bottom of the printing platform using a soft paper towel after

most resin has dripped off. Do not remove the printed object at this stage!

3. The object has been printed without break-off support. That results in clean flat surfaces but

makes it hard to remove. You will need two tools to remove the object from the plate: A

scraper max (1.5mm-thick blade) and a heat gun or hairdryer.

4. First, use the heat gun to heat up the object / printing plate. (We use about 120° C / 248 °F to

do this.) Then, the object becomes softer, and you can remove it from the print plate with the

scraper much easier.

14

5. Clean the object in an alcohol bath, then clean with water. (We use cheap alcohol that sits in a

sealable container. And a water bath in another container.)

6. Now, after you have cleaned the object, let it dry a bit.

7. In the meantime, clean the printing platform to make sure it is free of any residue resin or

cured parts. Also inspect the resin container for any cured resin, if cured resin parts are

floating you need to empty and clean it.

IMPORTANT: The printing platform must be extremely clean. There must be no hard resin

parts on the plates anywhere, as if they fall or get in contact with the resin container floor

they can easily destroy the extremely thin film on the container floor.

8. Mount the printing platform back to the Z-Axis. Note the sticker indicating back and front of

the platform.

IMPORTANT: After each print, check the resin container floor and ensure there are no cured resin

parts in the resin. If needed, you should filter the resin using a funnel and a filter grid, pouring the

resin back in the bottle through the funnel and fine paint filter.

Congratulations, you completed your first print, then cleaned it and the Solidator!

15

Solidator Shutdown Procedure

From the Solidator touch panel, press the power button, the following screen has three options.

Always perform a system shutdown before turning off the main power to the machine.

16

Upload Models

In order to upload models to the Solidator, there are 3 options: Ethernet, Wi-Fi, or USB stick.

USB Stick

To upload files from an USB stick, save the sliced job file to the USB stick, Then, on the Solidator,

plug in the USB stick at the USB slot located in the font, nearby the touch screen. The LED in the

USB stick should light up. If not, the LED stick does not match the Solidator’s USB slot. Wait a few

seconds and click the Jobs/Files menu item to list all jobs. Then, copy a job over to the Solidator.

Later on, you can select the print in the print menu.

Network Setup

If you choose to use Network, you can also use the HTML5 Web Interface. You will be able to

access it using the IP address of the Solidator in your browser, e.g., http://192.168.0.100

Click the Setup Icon in the Main Menu, then select Wi-Fi or LAN and enter the specifics of your

networks as usual.

17

Description of WLAN Setup and HTML 5 Interface

-Over to the Solidator. The file is saved into memory on the Solidator and the print job can be selected in the

future.

-If you choose to use Network, a HTML5 Web Interface is available to load job files.

-You will be able to access the Solidator by entering the IP address of the Solidator in your web browser, e.g.,

http://192.168.0.100

-To determine the IP address of the Solidator via LAN, connect an Ethernet cable to the Solidator and enter

the IP address for your modem/router. Search for devices using the network map.

-Enter the IP address that you have identified into your web browser to access the Web interface.

-To setup the Wi-Fi or Lan settings using the Solidator control panel. Click the Setup Icon in the Main

Menu, then select Wi-Fi or LAN and enter the specifics of your networks as usual.

18

19

Software Setup

1. You can download the software at

https://solidator.blob.core.windows.net/customers/SolidatorStudio-2.0.zip

2. Please install it. You can find the SolidatorStudio.exe in C:\Program Files\tangible

engineering\Solidator\SolidatorStudio.exe afterword.

3. Verify your graphics card works with the Software

3.1.Download this frog model stl file from here: http://www.thingiverse.com/thing:18479

3.2.Start SolidatorSudio.exe from C:\Program Files\tangible engineering\Solidator\SolidatorStudio.exe

3.3.Select File →Load Model and locate the Model.

3.4.Select Print →Save Job.

While slicing a preview of each slice should be displayed. At the end the summary dialog must show a

resin volume which should be 10 ml.

Note: If 0 ml is displayed your graphics card driver needs an update.

More Instructions on how to use the Software are located in the LEARN menu at www.solidator.com

Troubleshooting Graphic Card Drivers and Optimizing Performance

Modern Notebooks often have two graphic cards: Intel HD 3000 / 4000 and a NVIDIA or AMD Radeon card. Intel

HD 3000 is supported under Windows with Driver Version 9.17.10.3517 dated 20.03.2014. Intel HD 4000 is

supported under Max OSX as well as Windows with Driver Version 10.18.10.3621 dated 16.05.2014. NVIDIA and

AMD Radeon needs the latest drivers from nvidia.com or AMD Radeon site.

If your notebook has two graphics cards make sure the better one is used with Solidator Studio. You can find

information on how to do this here under the keyword “switchable graphics” if you search on google also

providing your graphic cards name and details.

20

Technical Specification

Type / Model

Solidator 2.0

Technology

DLP stereolithography, vat polymerization

Build volume

13.22" x 8.26" x 7.87" (336 x 210 x 200 mm )

speed @ 100 micron layer height

2116 cm³ / hour (max)

Resolution enhancement

3D surface smoothing

Voxels in build volume

More than 4.6 billion voxels

Layer height

30 microns to 100 microns

Z-Motor resolution

10 microns (0.000393"/ 0.01 mm)

Minimal feature size XY@336x210mm

0.001" x 0.001" (0.175 x 0.175 mm)

Footprint (W x H x D)

24.1" x 15.7" x 52.5" (640 x 401 x 1380 mm)

Slicing software

Solidator Studio (included)

Support generator

Solidator Studio (included)

Standalone 3D-printing

Yes, no external PC required during print

Touch screen

3.2" touch screen

HTML5 Web interface for mobile and PC devices

Yes

WLAN support for job transfer

Yes

Ethernet support for job transfer

Yes

USB stick / USB Flash drive for job transfer

Yes

Windows operation system support

Yes

Max OSX operating system support

Yes

Linux operating system support

Yes

Voltage

110 V –240 V 50-60 Hz

Operating temperature

64.4 –77 ºF (18 - 25 ºC)

Table of contents

Other Solidator 3D Printer manuals