PICASO 3D Designer XL User manual

INTRODUCTION

1

Dear Customer,

We are happy to welcome you among the owners of Designer XL. Your 3D printer has a

user-friendly interface and up-to-date printing control functions. Therefore, it can be used

both by experienced engineers and those who are just discovering the world of additive

technologies.

3D printing is a sophisticated process that involves many factors. We have prepared

a detailed User Manual to make your interaction with the printer as easy, intuitive, and

safe as possible. It describes all main components, 3D printer’s functions, and menu

settings; the principles and fundamentals of working with various materials, as well as

recommendations for using the device. Key information is highlighted with frames:

This Manual uses hyperlinks for quick and easy access to sections.

Please, read the entire User Manual before using Designer XL. For any technical issues,

The pictures used herein are part of the product’s graphical image and may differ from the actual

appearance of the device.

The description of the menu contents, the list of errors, and the device’s features may vary depending

on the 3D printer rmware version used.

The manufacturer is not responsible for any actions deviating from those described in this Manual.

This frame highlights important warnings about working with Designer XL.

This frame highlights notes and useful references for working with Designer XL.

We wish you success in the implementation

of your ideas and projects!

INTRODUCTION

2

SAFETY AND PRECAUTIONS

HOW DESIGNER XL WORKS

X PLATFORM

EQUIPMENT SPECIFICATIONS

WORKPLACE

STARTER KIT

MAIN COMPONENTS OF DESIGNER XL

POWER CONNECTION

DESIGNER XL MENU

CONTROL DURING PRINTING

BUILD PLATE AUTO-LEVELING

FILAMENT LOADING

PRINTING

FILAMENT UNLOADING

CONNECTION TO PC

NOZZLE REPLACEMENT

SET UP Z-OFFSET

CALIBRATION OF THE CLEANING SYSTEM

PRINTER FIRMWARE UPDATE

ERROR LIST

PRINT SPEED MODES

REMOVING AND REPLACEMENT THE HEATING UNIT

QUESTIONS AND ANSWERS

58

58

UNPACKING 11

18

26

41

PRINTER CONTROL

BASICS OF WORKING WITH Designer XL

SERVICE FUNCTIONS

4

6

8

10

12

13

14

17

19

24

27

29

34

37

39

42

44

46

49

50

53

56

58

How does the DESIGNER XL notication system work?

What is the debug screen?

INTRODUCTION

3

How to nd the printer serial number?

What operations can I perform during printing?

What is the material prole?

How to create a new prole?

How to store and dry lament?

What is a printlist?

What should I do if there is no lament ow and/or I hear clicks in

the printhead?

What shall I do if the lament cannot be loaded?

What shall I do if the spool has run out, and how to replace it

during printing?

What printer parts are consumable?

What type of USB drives can I use?

Why shall I calibrate the cleaning system?

Why does DESIGNER XL often pause for a short time?

Why are magnets of different sizes?

What kind of service is required for the printer?

59

59

59

60

62

63

64

65

65

66

66

66

66

66

67

SAFETY AND PRECAUTIONS

4

Designer XL complies with European Parliament Directives 2014/35/EU on low-

voltage equipment and 2014/30/EU on electromagnetic compatibility.

Do not use Designer XL to store foreign objects. Foreign objects in the printer’s

working area can damage Designer XL’s components.

Do not use Designer XL to heat up food or other items.

Do not expose Designer XL to external temperature effects and/or liquids, gases,

electric and/or magnetic elds, which can damage the device’s electronic or

mechanical components.

Do not use the 3D printer in a humid or dusty environment. Follow the requirements

for the workplace.

During its operation, the device may produce a specic smell of molten lament.

This is a feature of the printing process. We recommend using the 3D printer in a

well-ventilated area. Do not leave the working printer unattended.

Designer XL is not intended for use by the disabled, unless they are supervised by a

person who is responsible for their safety.

It is forbidden to use Designer XL by persons under the inuence of alcohol, drugs

and/or other intoxicants.

Handle the 3D printer carefully — it includes electronic components and mechanical

parts that can be damaged if hit or dropped.

Some 3D printer’s parts operate at a high temperature. To avoid burns, be careful

not to touch heated surfaces while printing and servicing the device. Wait at least

10-15 minutes for the unit’s heating elements to cool down before opening the lid.

SAFETY AND PRECAUTIONS

5

Some 3D printer’s parts are moving. To avoid personal injury and device

malfunction, do not interfere with the movement of the 3D printer units during its

operation.

Do not use non-original spare parts and do not attempt to repair it on your own:

this can lead to device failure.

Do not seek third party’s advice on the operation of the 3D printer. Our ocial

contact details are:

HOW DESIGNER XL WORKS

6

Designer XL operates under the FFF technology (fused lament fabrication). The principle

of the technology is to melt a thermoplastic polymer lament and to build a layer-by-layer

model based on a previously prepared task.

HOW DESIGNER XL WORKS

7

Designer XL is a 3D printer which is in the X platform-based product line. When you master

it, you will able to work with any devices based on the X platform.

To get started, you need a 3D model in one of the following formats: .stl, .obj, .3ds or .amf.

The model should be uploaded into the software on a personal computer (PC) — Polygon X

(supplied free of charge), which converts it to a printing task le in .plgx format with a set

of control commands to operate PICASO 3D printers. To start printing on Designer XL,

you should save the .plgx le to a USB stick (supplied in the starter kit). File recording can

be made remotely using Polygon X via Ethernet connection.

.plgx

Designer

X PLATFORM

8

X Platform is a complex of software and hardware solutions for 3D devices by PICASO 3D

designed for additive manufacturing purposes.

End-of-Filament and Filament Flow Control systems with built-in

sensors detect the lament availability and the ow. Based on the data

obtained, Designer XL carries out self-testing and, in case of an abnormal

situation due to the lament absence or uneven ow, automatically starts

the problem-solving algorithm. If the abnormal situation persists, the

printing process is suspended and the printer waits for user’s actions.

Example: the lament is run short of on the spool or broke off during the

printing: Designer XL pauses its operation, reports lack of material, waits

to lament reloading and continues printing.

If the nozzle is completely or partially clogged during printing, the

material ow is stopped or impeded: Designer XL will detect a change

in the uniform ow, pause printing, and start an automatic nozzle high-

temperature cleaning algorithm. If the nozzle cleaning is successful,

printer continues printing; otherwise, printing is paused, and Designer XL

informs the user about the problem.

The Prole System stores parameters for working with materials in the

printer memory. The prole settings are used to control the layer time,

which allows to maintain surface high quality when printing small models;

as well as to control the temperature of radiators, which allows to avoid

overheating of the lament above the thermal barrier and protects the

material in the feed channel from degradation. To start printing , the user

selects a material prole based on the lament loaded. The prole system

provides for using one and the same task in .plgx format to print with any

thermoplastic lament used without preparing a new printing task.

X PLATFORM

9

Printer status can be monitored both from the printer display and through

the local network via Ethernet network connection. There is one software

used to control all X Platform devices — Polygon X. When connecting

several printers via a LAN router, you can monitor all connected printers

and control the printing process on one window tab of Polygon X.

Integrated high-speed print modes. Before the printing starts, the user

selects a speed mode in accordance with the expected result. It provides

for one and the same task in .plgx format being printed at different

speeds without preparing a new printing task.

The notication system allows to dene the device status remotely, even

on a PC screen when working via network.

An adaptive air circulation system uses data from material proles to

create optimal conditions for printing and to avoid the temperature

gradient inside the 3D printer chamber.

The printing surface control system in most cases provides for possibility

to detect the weakening of adhesion of the printed model to the platform

or the presence of a foreign object when printing the current layer in a

timely manner. If an item comes unstuck or the printed layer has a wrong

shape, the printer will pause printing until the user’s intervention.

The nozzles height control system (only for PRO-series printers)

automatically allows for the difference in the height of nozzles relative

to each other in case of dual-material printing and makes an appropriate

amendment to the platform height. This system allows to reach high

quality of dual-material printing.

EQUIPMENT SPECIFICATIONS

10

PRINTING

Printing technology

Fused Filament Fabrication (FFF)

Build Volume

360 x 360 x 610 mm

(14 x 14 x 24 inch)

Extruder maximum printing

temperature

410 ºC (770 F)

Heated bed maximum temperature

150 ºC (302 F)

Print speed

up to 100 cm3/h

Minimum Layer Thickness

10 microns (0.01 mm)

Layer Resolution

0.01 – 0.8 (depending on the

nozzle diameter)

ELECTRICITY

Networking

220 ± 15%, 50 Hz (option 110 ± 15%, 60 Hz)

Maximum Power Consumption

1.3 kW

Interfaces

Ethernet, USB 2.0 (USB stick in starter kit)

PRINTING MATERIALS

Formax (ABS + CF), Ultrax (PA + CF),

PEEK, PA, PC, TPU, TPE, PP, ASA, SBS,

PETG, ABS, PLA, PVA, HIPS and others

PHYSICAL

CHARASTERISTICS

WITHOUT BOX

Printer dimensions

985 x 645 x 565 mm

Weight

75 kg

MECHANICS

Casing

Aluminium composite

Frame

Steel (3 mm)

Heated bed construction

Aluminium, glass

Guides

XY rail (steel)

Z cylindrical (steel)

FEATURES

Primary systems

Filament Flow Control

End-of-Filament Sensor

First Layer Control

Built-in Prole System

Network Printing

Additional features

Filament drying mode

Printer status notication system

Auto-control workability of all systems

Surface print control system

Table Leveling

Auto-leveling

Pozitioning Resolution

11 x 11 x 1.25 microns

Filament diameter

1.75 ± 0.1 mm

Nozzle diameter

0.2 – 0.8 mm (0.5 in starter kit)

SOFTWARE

Software

Polygon X

File Types

*.stl, *.obj, *.3ds, *.amf, *.plgx, *.ppf,

*.ppl, *.plgs

UNPACKING

WORKPLACE

12

The workplace for 3D printer installation must satisfy the following requirements:

Leave the 3D printer unpacked at the prepared workplace for at least 24 hours — do not

plug it to power supply prematurely.

Ambient temperature: 15 to 30 ºC (59 to 86 F).

Relative humidity: 30 to 65%.

Atmospheric pressure: 720 to 790 mm Hg.

Ventilation availability

Solid horizontal surface to withstand at least 30 kg load.

Lack of direct sunlight on the 3D printer.

Power supply 220 V ± 15% (50 Hz) with grounding.

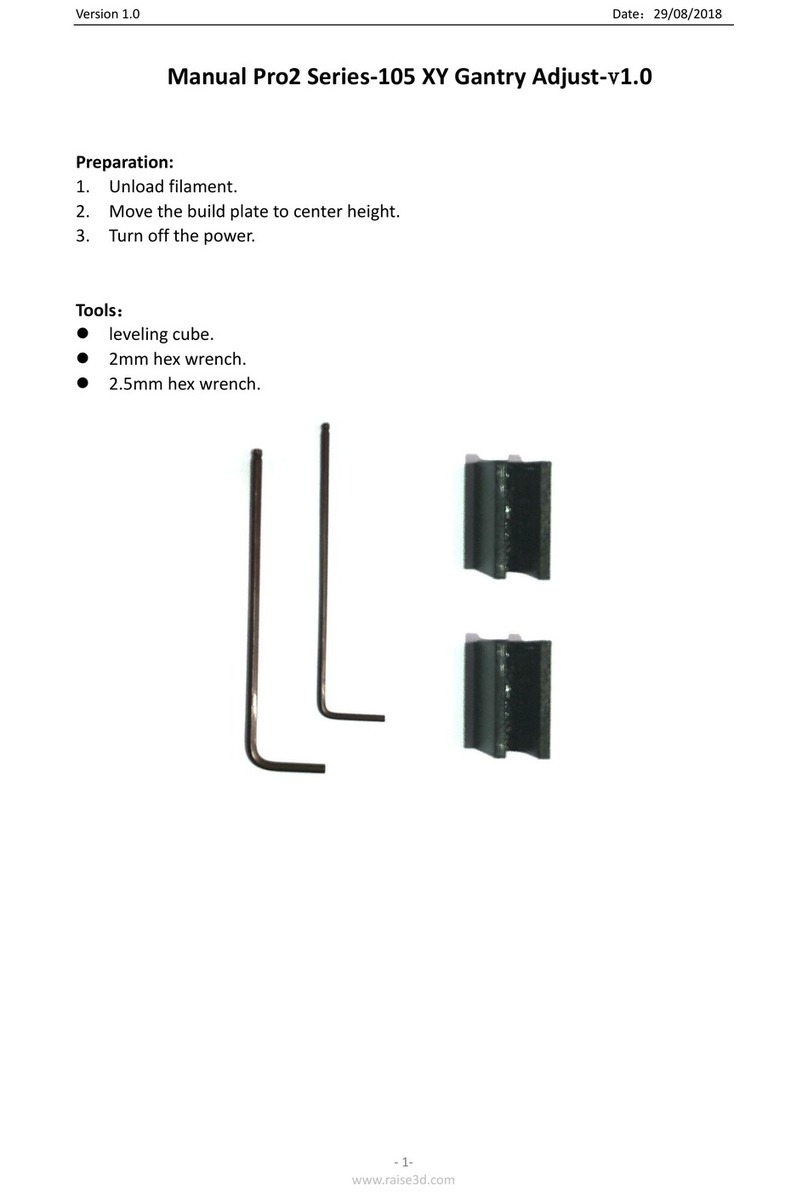

STARTER KIT1

13

Examine the starter kit. It must comprise:

If there are any discrepancies or lack of a transportation part and ties, please take

forget to include the serial number of your 3D printer.

Available in the Designer XL:

Toolkit:

Power cable

Filament spool

Adhesion glue

0.5 mm steel nozzle

Temperature unit 400

8 mm glass

Screwdriver Torx TX-TR

Slotted screwdriver

Nippers

Box cutter

Pliers

Nozzle change key

Hex key 1.5

Hex key 2

Hex key 2.5

USB drive

0.5 mm steel nozzle

1 The type and conguration may be changed by the manufacturer without user’s consent, which shall

not affect the declared device specications.

MAIN COMPONENTS OF DESIGNER XL

14

Front view

Front door

Chamber

circulation fan

Glass ejector

Build plate with

glass

Top lid

Display

Joystick

USB-A

port

MAIN COMPONENTS OF DESIGNER XL

15

Side rear view

Side door

Motherboard box

Container

Power button

Power adapter

connector

Ehernet port

USB-B

port

Chamber

cooling fan

Drivers cooling

fan

MAIN COMPONENTS OF DESIGNER XL

16

Inside view

Printhead (PH)

Cleaner

Nozzle

Filament feed

tube

PH cooling fan

Model cooling

fan

Printhead (PH)

Cable-chain

POWER CONNECTION

17

Make sure all plastic locking clip parts and ties are removed. Take the printhead (PH)

into your hands and make sure that it moves freely. Plug the power cable into the power

adapter connector against the stop then plug it into a power socket 220 V ± 15%, 50 Hz or

110 ± 15%, 60 Hz (in compliance with used electricity network standard).

Switch the power button to position 1 — the display and lighting turns on, the printer

beeps.

We recommend to keep the original box and pallet for further possible transportation of

the printer.

Never plug the Designer XL into a power socket without grounding2.

2 PrinterName has a heating components with a 220 V supply. Also it equipped a residual-current

device (RCD), which secure the safety only if the socket has a ground.

PRINTER

MANAGEMENT

DESIGNER XL MENU

19

The 3D printer is controlled through the display menu3. To navigate through the menu

items, rotate the joystick clockwise or counterclockwise: the joystick does not have an

extreme position. To select a menu item, press the joystick.

PRINT

FILAMENT

Files

Displays folders and les in .plgx, .gcode4 formats in the USB stick inserted to the

printer . Allows to select a le to start printing.

Filament loading

Starts algorithm for lament loading in the PH using the ow motor along with

heating up the nozzle to the operating temperature in compliance with the settings

of the selected prole.

Filament unloading

Starts the algorithm for lament unloading out of the PH using the ow motor at the

unloading temperature in compliance with the settings of the selected prole.

Filament replacement

Alternately runs lament unloading and loading algorithms.

Hot unloading

Starts the algorithm for lament unloading out of PH using the ow motor with

heating the nozzle up to the operating temperature in compliance with the settings

of the selected prole.

Printlists

Displays a list of tasks in the active printlist5with ability of browsing all printlists

uploaded to a USB drive, to alternately start printing (tasks in the printlists folder).

3 The Menu Interface may vary depending on the rmware in use on the 3D printer.

4 .plgx is a print task le prepared by the Polygon X, adapted for printing on X Platform printers; .gcode is a

print task le prepared by third-party slicers. When printing such tasks, some features of X Platform printers

are inactive.

5 Printlist is a list of tasks for alternate printing. It is prepared by the Polygon X software in .ppl format with

network connection available.

This manual suits for next models

1

Table of contents

Other PICASO 3D 3D Printer manuals