Solidux Primasol User manual

Primasol Awning

Technical description

A. General

The Primasol, a sleek design for sun

protection during the day, and ambient

temperature control in the evening.

The Primasol is a retractable awning with a

protective case housing around the fabric

tube. When retracted, the front bar joins

securely with the cassette housing for year

round protection.

The entire design of the awning is laid out for

trouble free, silent, and safe operation.

The awning frame is available in white

(RAL9016) powder coated, or you may

request a special color in accordance with

RAL.

B. Construction of the Awning

1. Support Bar

The main part of the awning frame is the

support bar, which is made from 40x40x2

mm steel sendzimir galvanized and powder

coated. The strong back bar extends the

mounting choices and prevents twisting.

2. Fabric Housing

The housing is assembled from two extruded

aluminum pieces, with a thickness of 2mm.

The bottom and top part of the housing are

tightly snapped together and mounted with

an extruded bracket to the back bar. The

housing is held in place with aluminum side

plates. When the awning is fully retracted,

the front bar closes the housing for the best

protection, and the awning will appear as one

oval shape.

3. Front Bar

The front bar is made out of an extruded

aluminum profile with a wall thickness of 2

mm. It has an oval shape with internal

partitions providing a strong rigid bar to keep

the fabric straight and taut.

4. Side Caps

The front bar end caps and the housing side

caps are made from durable plastic, and are

powder coated to match the colour and

sheen of the aluminum components.

5. Fabric Roller

The Fabric roller is made of a galvanized

steel tube with dimensions of 78x1.25 mm to

prevent deflection from fabric tension.

6. Folding Arms

The profiles of the arms are made of

extruded aluminum profiles with a height of

70 / 65 mm and a sectional thickness of 1.5

mm. The height and oval shape are designed

for premium strength.

The heavy duty arms are assembled with

three strong torsion springs inside the upper

arm profile providing extreme tension for

taut fabric and increasing wind resistance

while ensuring long term durability. The arms

are made with maintenance free stainless

steel cables that are covered with PVC tubing

for easy cleaning and improved aesthetics.

The upper arm, elbow joint, and lower arm

attachment are made by a forged cast

aluminum process to combine highest

strength yield and design requirements.

All parts are powder coated to offer premium

weather resistance and cleaning ability.

7. Slide Support Unit (shoulder)

The arms are connected to the heavy duty

support bar with a slide support unit made of

extruded aluminum for superior strength.

This patented unit allows for adjusting the

pitch of the awning from 0 to 41 Degree.

This allows matching the pitch according to

mounting height available and desired head

room clearance.

8. Front Bar Coupling

The front bar coupling is made from die cast

aluminum with a stainless steel joiner that

swivels on a stainless steel pin. In

accordance with a set screw the pitch of the

front bar can be adjusted. Whatever the

pitch of the awning is, the front bar stays

straight, for better aesthetics and proper

closing of the case.

9. Parts

Various small parts, such as the roller shaft

support, tube support brackets, and hood

brackets, are made from extruded aluminum.

In comparison to cast parts, this increases

the durability of the awning and nearly

eliminates the breaking of the parts. All parts

have rounded edges for smoother

appearance and are powder coated. All

hardware is stainless steel.

10. Drive

The awning can be operated with either a

manual hand crank featuring a smooth bevel

gear system with a ratio of 4.4:1 and a limit

stop to prevent retracting the fabric the

wrong way, or conveniently with a 120 volt

tubular motor mounted in the roller tube.

The motor can be plugged in an outlet or

hardwired and controlled by a switch or

remote system. Sun, wind and motion

controls are available as well as a manual

override option for the motor.

11. Fabrics

The fabric consists of a woven acrylic

material having a weight of approximately

300 g/sq.m, and is sewn together in 120 cm

wide panels.

Swelacryl Fabric: Swelacryl awning fabrics

are made from spun dyed, rot resistant,

polyacrylic fibers, which are highly tear

resistant and ultra colorfast. For durability

and performance, Swela uses quality 8.55

oz/sq. yd (290 g/sq. m) fabric, and employs

a process where the fabric is finished with

DuPont Teflon. This combination means that

Swelacryl fabrics have a water pressure

resistance of 35 mbar (350mm) according

DIN 53886.

Swela Sunsilk Fabric: Swela Sunsilk awning

fabrics are made from specially dyed, light

fast and UV stable polyester yarn, highly

tear resistant and UV stable due to a special

UV absorber. Due to the SNC (Swela Nano

Clean) finish, dirt can be removed just by

rinsing down with water or rain. The water

pressure resistance according to DIN 53886

of 50 mbar (500mm) is much better than

acrylic fabrics. Due to being 30% thinner

than conventional fabrics, there is less

accumulation and drop between seams. It

simply looks nicer.

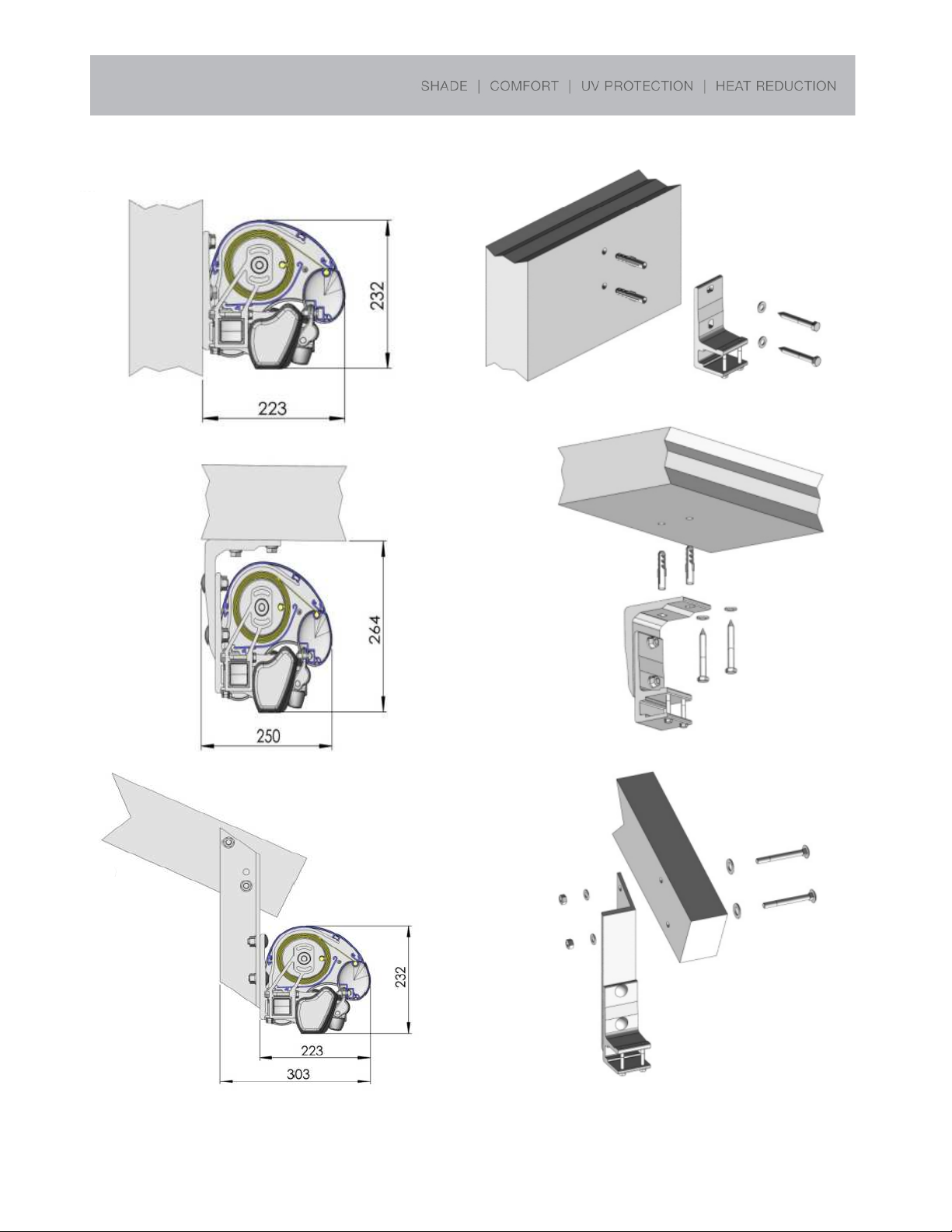

12. Mounting Brackets

There are mounting brackets available for

various mounting options to accommodate

the customer’s situation.

Wall bracket: The wall brackets are made

from extruded aluminum for optimum

strength to ensure that the awning is secure.

Soffit bracket: The soffit brackets are made

from extruded aluminum for optimum

strength. It can be attached to the wall

brackets to mount the awning to the top.

Joist bracket: The joist brackets are made

from extruded aluminum for optimum

strength. It can be attached to the wall

brackets to mount the awning to the joists.

Roof bracket: The roof brackets are made

from steel for optimum strength. The

adjustable angle allows installation on top of

any roof with various slopes.

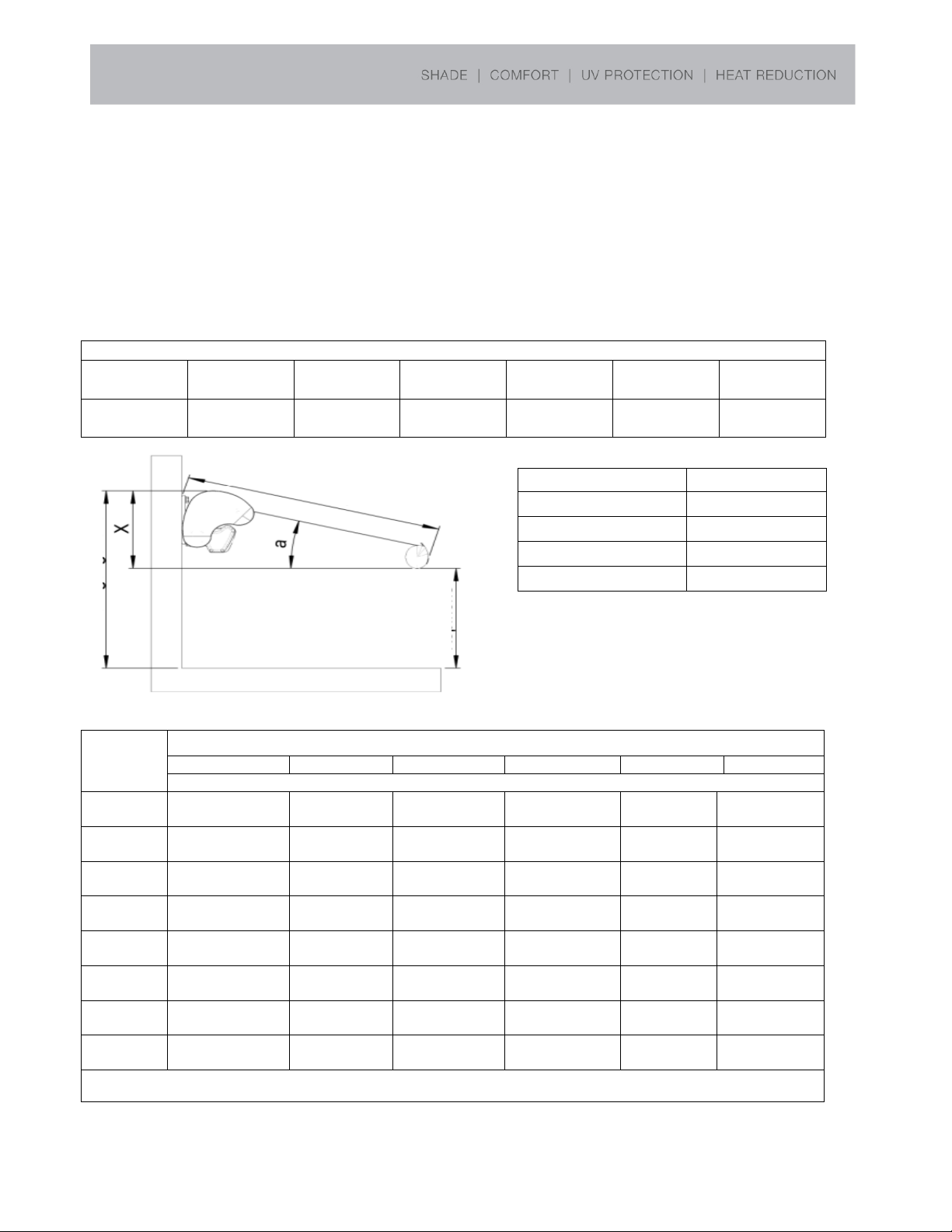

C. Technical Possibilities

The width of the awning is custom made from 7’ ¾” (215 cm) to 23’ (700 cm) (see also minimum

width for projections)

The Projection is available in: 5’ (150 cm), 6’6” (200 cm), 8’2” (250 cm), 10’ (300 cm), 11’6”

(350 cm), and 13’2” (400 cm)

Primasol

Width # of Brackets

<12’ (366 cm) 3

12’ – 17’ (518 cm) 4

17’ – 21’ (640 cm) 5

21’ – 23’ (700 cm) 6

Minimum O erall Awnings Width for Arm Projection

Projection

(cm)

5’

(150)

6’6”

(200)

8’2”

(250)

10’

(300)

11’6”

(350)

13’2”

(400)

Min. Width

(cm)

7’ ¾”

(215)

8’2”

(249)

9’9 ¾”

(299)

11’5 3/8”

(349)

13’1”

(399)

14’8 ¾”

(449)

Projection (cm)

5’ (150) 6’6” (200) 8’2” (250) 10’ (300) 11’6” (350) 13’2” (400)

Pitch

Height X (mm)

5° 10 3/8”

(263)

12”

(306)

13 ¾”

(350)

15 ½”

(394)

17 ¼”

(437)

19”

(481)

10° 15”

(383)

18 ½”

(470)

22”

(557)

25 3/8”

(644)

28 ¾”

(731)

32 1/8”

(818)

15° 19 ¾”

(502)

24 7/8”

(631)

30”

(761)

35”

(890)

40 1/8”

(1020)

45 ¼”

(1149)

20° 24 3/8”

(618)

31”

(789)

37 ¾”

(960)

44 ½”

(1131)

51 ¼”

(1302)

58”

(1473)

25° 28 ¾”

(730)

37”

(942)

45 3/8”

(1153)

53 ¾”

(1364)

62”

(1575)

70 3/8”

(1787)

30° 33”

(838)

42 7/8”

(1088)

52 5/8”

(1338)

62 ½”

(1588)

72 3/8”

(1838)

82 ¼”

(2088)

35° 37”

(940)

48 3/8”

(1227)

59 5/8”

(1514)

70 7/8”

(1801)

82 ¼”

(2088)

93 ½”

(2374)

40° 40 7/8”

(1037)

53 ½”

(1358)

66 1/8”

(1680)

78 ¾”

(2001)

91 3/8”

(2322)

104”

(2644)

Mounting Height = Clear Height + X

Mounting Height

Projection

Cl

ear

Height

Projection

Mounting Brackets

Wall Bracket

Joist Attachment

Soffit Bracket

Installations

Wall Mount

Joist Mount

Soffit Mount

Table of contents