SolPad SolarIQ 500HD-W-6-4G User manual

1

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

SolPad Load Controller

Installation

Version 1.8 ● 06 February 2020

101 Metro Plaza, Suite 315, CA 95110

www.solpad.com

2

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

Perform all electrical installations in accordance with all applicable local electrical

codes, such as: NPFA 70 (NEC); and ANSI requirements.

WARNING: Incorrect installation and/or operation can cause serious injury or death

to personnel and damage to equipment and/or property. Only qualified personnel are

authorized to install and/or maintain a SolPad device.

WARNING: Use insulated tools to reduce the risk of electrical shock or accidental

short circuits. Remove all jewelry, such as rings, watches, bracelets, etc., when

installing or performing maintenance on the SolPad platform.

WARNING: An electric shock or fire can be fatal to personnel. Inadequately sized

wiring and/or overcurrent protection can cause serious injury or death to personnel

and damage to equipment and/or property.

WARNING: Inadequate grounding methods/conductors can cause serious injury or

death to personnel and damage to equipment and/or property. The grounding

system/conductors must be installed per NEC or CEC requirements.

WARNING: Before servicing a SolPad Load Controller system or replacing any part

of a system you must de-energize the system by flipping the units dedicated circuit

breaker to the off position.

CAUTION: Do not mount or install a SolPad component where is it subject to

physical damage from the surrounding area.

Info: SolPad may choose to revoke any and all warranty of a SolPad system if

visible physical damage due to mishandling, improper installation, or electrical arcing

is present on any component associated with the installation process.

3

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

Table of Contents

1. Special Section: Connecting Loads .......................................................................................... 6

1.1 About this section ............................................................................................................ 6

1.2 Connection Examples ....................................................................................................... 6

20A / 120V Circuit Connection ................................................................................................ 6

................................................................................................................................................. 6

Water Heater Connection (30A / 240V) ................................................................................. 6

Clothes Dryer Connection (30A / 240V) ................................................................................. 7

Pool or Spa HEATER (30A / 240V) ........................................................................................... 7

Pool or Spa PUMP (30A / 240V) .............................................................................................. 8

HVAC – Air Handler (30A / 240V) ............................................................................................ 8

HVAC – Control via low voltage; A/C Compressor and Fan are controlled ............................ 9

HVAC Connection – A/C and Heat Control via low voltage – Fan is not controlled ............... 9

Electric Kitchen Range controlled with 50-amp breaker ...................................................... 10

2. The SolPad Load Controller ................................................................................................... 11

2.1 Introduction.................................................................................................................... 11

2.2 SolPad Load Controller Product Line .............................................................................. 11

6 Relay Load Controller: SolarIQ 500HD-W-6-4G ................................................................. 11

12 Relay Load Controller: SolarIQ 500HD-W-12-4G ............................................................. 11

24 Relay Load Controller: SolarIQ 500HD-W-24-4G ............................................................. 11

32 Relay Load Controller: SolarIQ 500HD-W-32-4G ............................................................. 11

2.3 Tools and Materials ........................................................................................................ 12

Recommended Materials ...................................................................................................... 12

Recommended Tools ............................................................................................................ 12

2.4 Unpacking – What you will find in the box .................................................................... 12

................................................................................................................................................... 13

Loose Parts ............................................................................................................................ 13

2.5 System Components and Descriptions .......................................................................... 14

SolPad CPU – CompuLab ....................................................................................................... 14

4

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

Power Supply ........................................................................................................................ 15

MOTES – Marvel of Tiny Engineering ................................................................................... 15

4G High Gain Antenna / RS485 Adapter / Wi-Fi Antenna .................................................... 16

2.6 Relay Descriptions .......................................................................................................... 17

................................................................................................................................................... 17

20 Amp SPDT 240vac Relays ................................................................................................. 17

30 Amp DPDT 240vac Ice Cube Relays .................................................................................. 17

50 Amp DPDT 240vac Open Frame Relays ........................................................................... 18

3. Installation ............................................................................................................................ 19

Installation Steps ................................................................................................................... 19

3.1 Mounting the Enclosure ................................................................................................. 19

3.2 Source Power for the System ......................................................................................... 20

3.3 Connectivity and Accessories ......................................................................................... 20

4G, Wi-Fi, RS485 .................................................................................................................... 21

3.4 Installation of Current Transducers (CTs) ...................................................................... 22

Mains / Grid Power ............................................................................................................... 23

Battery Max Customers with AC Coupled Batteries ............................................................. 24

Battery Max Customers with DC Coupled Batteries ............................................................. 25

Demand Customers with Solar ............................................................................................. 25

................................................................................................................................................... 26

3.5 Connecting Loads ........................................................................................................... 26

............................................................................................................................................... 26

Populate the Cover Label ...................................................................................................... 26

3.6 Power up the Load Controller ........................................................................................ 27

3.7 Installer Checklist ........................................................................................................... 28

3.8 System Verification, Test & Turn-up .............................................................................. 28

4. FAQ’s ..................................................................................................................................... 30

What is Demand? .................................................................................................................. 30

How do utilities charge for demand? ................................................................................... 30

Can you explain On Peak and Off Peak? ............................................................................... 30

What does a SolPad demand management system do? ...................................................... 30

5

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

My clothes dryer turns on and tumbles but does not heat up, is my dryer broken? .......... 30

What systems and appliances does the SolPad system typically control? ........................... 31

6

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

1. Special Section: Connecting Loads

1.1 About this section

This ‘Connecting’ section is located at the front of the guide to serve as an easy-to-find

reference offering examples for certain use cases. Before beginning a SolPad Load

Controller installation you must read the entire guide and carefully follow each step.

THESE CONNECTIONS EXAMPLES ARE NOT TO BE CONSIDERED AS DETAILED WIRING

DIAGRAMS. ANY INSTALLATION WITH A SOLPAD LOAD CONTROLLER MUST BE COMPLETED

IN ACCORDANCE WITH ALL APPLICABLE LOCAL ELECTRICAL CODES BY A

LICENSED ELECTRICIAN.

1.2 Connection Examples

20A / 120V Circuit Connection

To control a typical 120v circuit in a residence, you’ll

interrupt the line conductor at the breaker and land

it on the relay in the load controller.

In the electric panel, interrupt the load’s L1

conductor and run it to the normally closed

(N.C.) contact on the 20-amp relay.

Run a second conductor from the relay’s

COM terminal back to the circuit breaker.

See 20-amp SPDT Relay information in section 2.6

Water Heater Connection (30A / 240V)

Water heaters are often low priority items for

control and among the first to shed. For each

water heater, disconnect one leg from the circuit

breaker.

In the electric panel, interrupt either the

L1 or L2 conductor and run it to the

normally closed (N.C.) contact on the 30A

relay.

Run another conductor from the relay’s

COM terminal back to the circuit breaker.

See 30 Amp DPDT Relay information in section 2.

7

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

Clothes Dryer Connection (30A / 240V)

Disconnect the leg which supplies the heating

element ONLY, so the motor and controls are still

allowed to run. Determine the correct leg through

trial and error. Disconnect one leg from the circuit

breaker, and then test the dryer. If you the motor

and controls work but there is no heat, the correct

leg has been disconnected.

Some heaters have 220V motors which are trickier,

but if eliminate the heat, you have disconnected

the correct leg.

In the electric panel, interrupt L1 or L2

(whichever is the heating element leg) and

run it to the normally closed (N.C.) contact

on the 30A relay.

Run another conductor from the relay’s COM terminal back to the circuit breaker.

See 30 Amp DPDT Relay information in section 2.6

Pool or Spa HEATER (30A / 240V)

As with Clothes Dryers, you want to disconnect the

leg suppling the heating element ONLY. Determine

which leg is which is through trial and error.

Disconnect one leg from the circuit breaker, and

then test the heater. If you the motor and controls

work but there is no heat, the correct leg has been

disconnected.

In the electric panel, interrupt L1 or L2

(whichever is the heating element leg) and

run it to the normally closed (N.C.) contact

on the 30A relay.

Run another conductor from the relay’s

COM terminal back to the circuit breaker.

NOTE: Advise the customer once wiring is complete that reprogramming of their Pool or

Spa timer may be required, and to take into account the “On-Peak” periods when doing so.

See 30 Amp DPDT Relay information in section 2.6

8

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

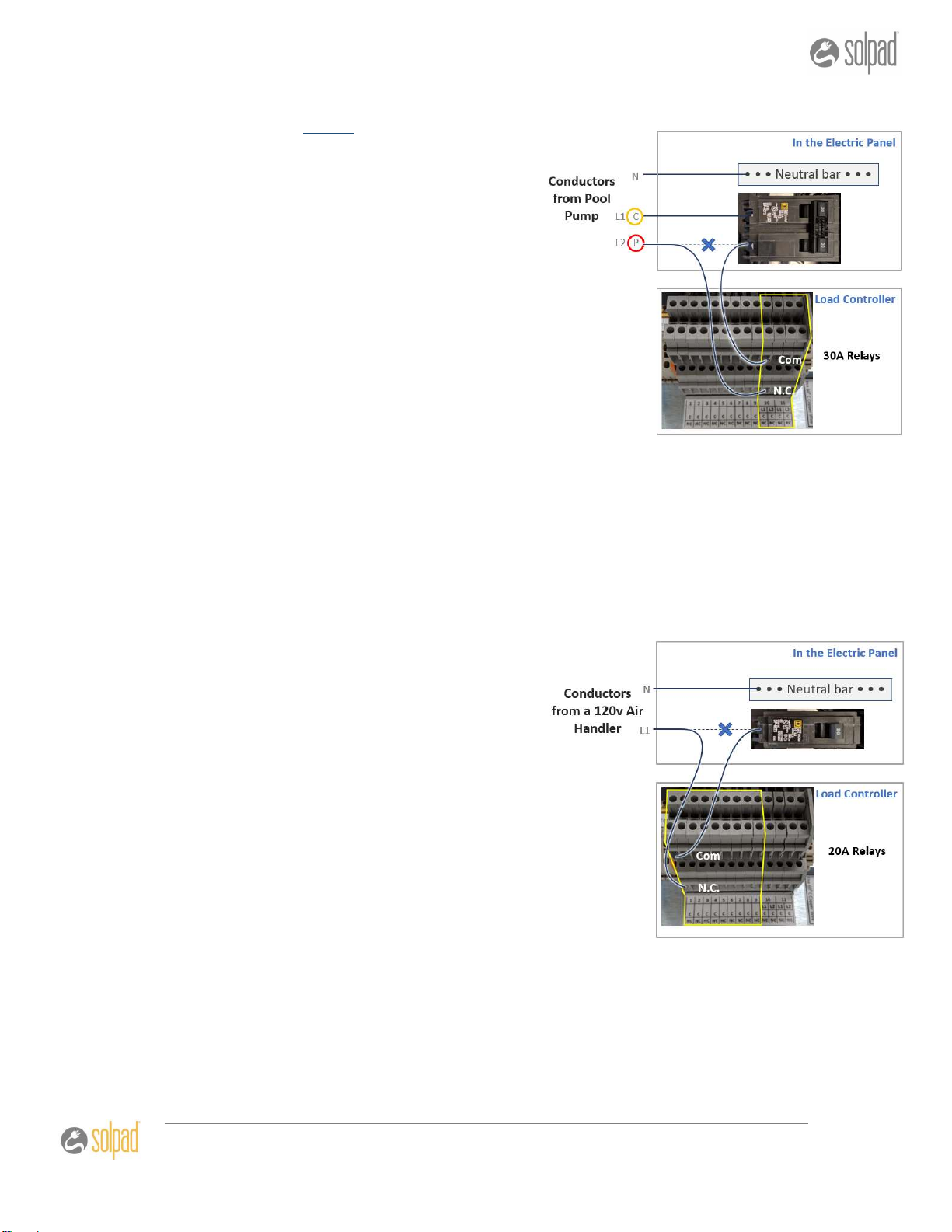

Pool or Spa PUMP (30A / 240V)

As with Clothes Dryers, you want to disconnect

the supply leg which breaks the pump ONLY.

Determine the proper leg to control by trial and

error. Disconnect one leg from the circuit

breaker, and then test the pump. If you the

controls work but there is no pumping, the

correct leg has been disconnected.

In the electric panel, interrupt L1 or L2

(whichever is the pumping element leg)

and run it to the normally closed (N.C.)

contact on the 30A relay.

Run another conductor from the relay’s

COM terminal back to the circuit

breaker.

NOTE: Advise the customer once wiring is complete that reprogramming of their Pool or

Spa timer may be required, and to take into account the “On-Peak” periods when doing so.

See 30 Amp DPDT Relay information in section 2.6

HVAC – Air Handler (20A / 120V)

Air Conditioners and Air Handlers are normally

high priority items for control, and typically the

last or next to last to shed. In this configuration

the Line between the unit and the breaker is

interrupted.

In the electric panel, interrupt the load’s

L1 conductor and run it to the normally

closed (N.C.) contact on the 20-amp

relay.

Run a second conductor from the relay’s

COM contact back to the terminal on

the circuit breaker.

See 20-amp SPDT Relay information in section 2.6

9

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

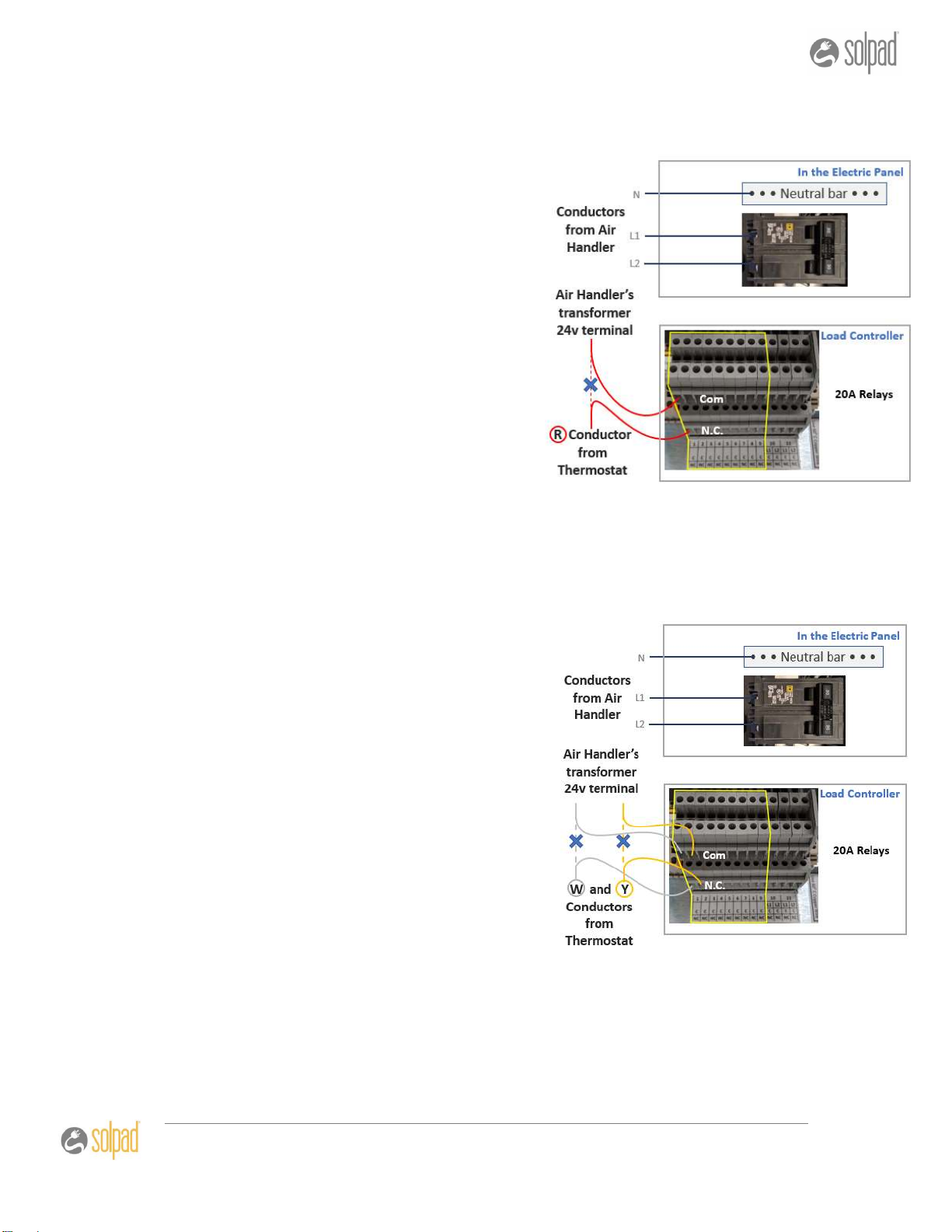

HVAC – Control via low voltage; A/C Compressor and Fan are

controlled

Air Conditioners can be controlled through their

low voltage thermostat wires. In this

configuration you’ll interrupt the red conductor

running from the thermostat to the unit’s

internal transformer.

The red (R) conductor from the

thermostat needs to be disconnected

from the air-handler transformer’s 24v

terminal. Run this conductor instead to

the normally closed (N.C.) contact on

the 20-amp relay.

Run another conductor from the relay’s

COM terminal to the 24v terminal on

the air-handler’s transformer.

See 20-amp SPDT Relay information in section 2.6

HVAC Connection – A/C and Heat Control via low voltage – Fan is not

controlled

For this configuration you’ll interrupt the white

(W) and yellow (Y) conductors that run from the

thermostat to the air handling unit.

For the W conductor to control heat:

Run the W conductor from the

thermostat to the normally closed (NC)

terminal on a 20-amp relay.

Run a second conductor from the relay’s

COM terminal to the heat terminal on the

air handler unit.

For the Y conductor to control cool:

Run the Y conductor from the thermostat

to the normally closed (NC) terminal on a second 20-amp relay.

Run a second conductor from the relay’s COM terminal to the heat terminal on the

air handler unit.

NOTE: this takes 2ea 20-amp relays. See 20-amp SPDT Relay information in section 2.6

10

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

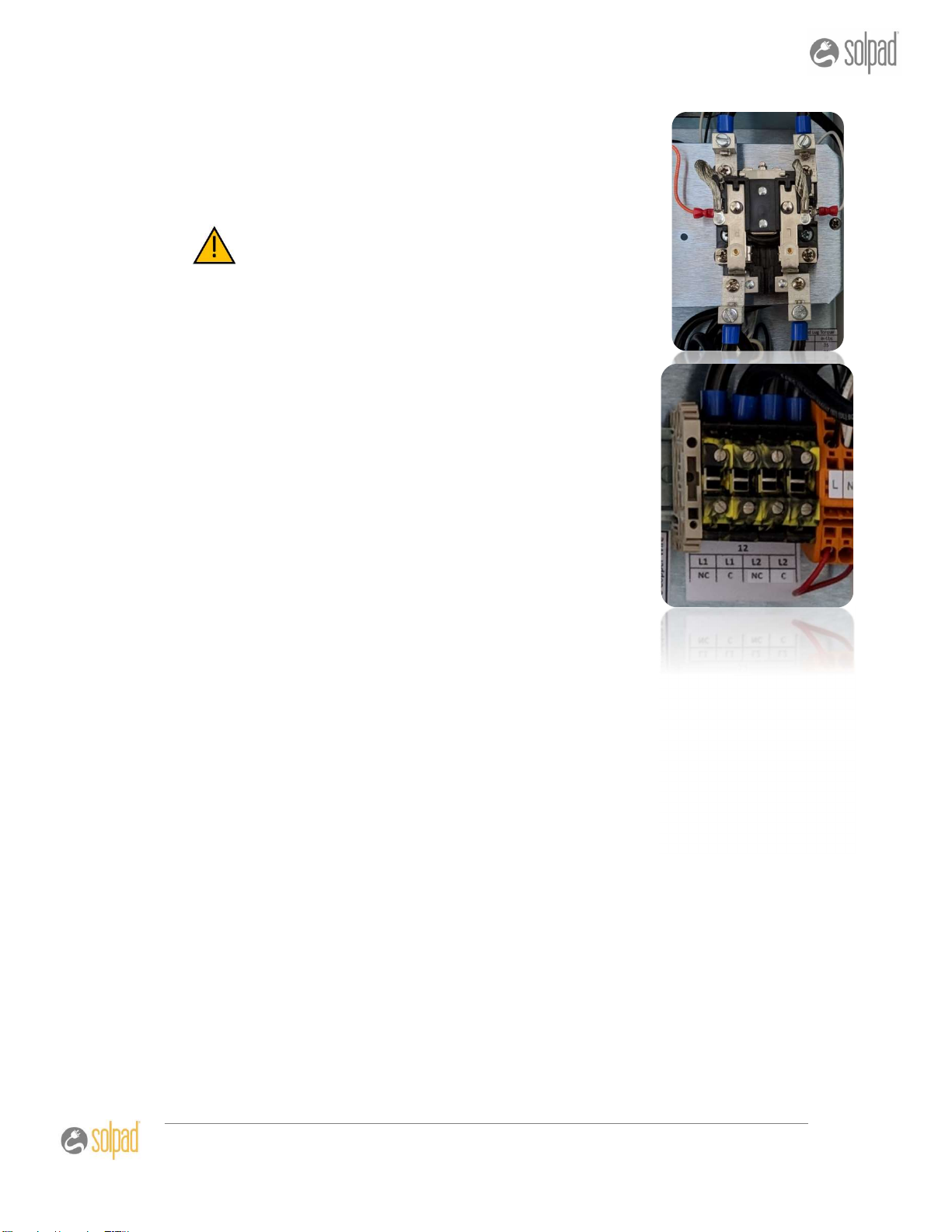

Electric Kitchen Range controlled with 50-amp breaker

For this configuration you’ll interrupt

both L1 and L2.

The 50-amp relay terminals are located

on the yellow terminal block.

Interrupt L1 and L2 coming from

the range, and land them on their

respective ‘NC’ terminals on the

50-amp relay block.

Then run new L1 and L2

conductors from their respective

‘C’ terminals back the two-pole

breaker in the panel.

See 50 Amp DPDT 240vac Open-frame Relay information in section 2.6

11

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

2. The SolPad Load Controller

2.1 Introduction

Congratulations on your purchase of the SolPad Load Controller

This system was designed using our 4 decades of experience to provide you with an

accurate, reliable and flexible system for you to control your electrical demand and power

use. This manual covers an overview of the product, safety information, installation

instructions, for a variety of models with slight variations.

**IMPORTANT NOTE: This Energy Management System is to be installed by a professional

electrician.

2.2 SolPad Load Controller Product Line

SolPad carries four different Load Controller options to cover a variety of customer needs.

6 Relay Load Controller: SolarIQ 500HD-W-6-4G

Control six circuits using:

(4) 20A relays

(2) 30A relays

12 Relay Load Controller: SolarIQ 500HD-W-12-4G

Control t12 circuits using:

(4) 20A relays

(2) 30A relays

(1) 50A relay

24 Relay Load Controller: SolarIQ 500HD-W-24-4G

Control 24 circuits using:

(19) 20A relays

(4) 30A relays

(1) 50A relay

32 Relay Load Controller: SolarIQ 500HD-W-32-4G

Control 32 circuits using:

(26) 20A relays

(4) 30A relays

(2) 50A relay

12

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

2.3 Tools and Materials

While this is not intended to be an exhaustive list of materials and tools required, it is

intended to provide you with the items that are often necessary (and not on hand) to

complete a typical installation and not included with the system as purchased.

Recommended Materials

1. CTs for the Main Service.

2. CTs for PV production monitoring.

3. 15amp dedicated breaker for EMS power source.

4. 18/2 or 18/4 Stranded, Unshielded control cable (for CTs).

5. 18/4 Stranded, Shielded Wire (for use with Rogowski Coil or other 4-20ma

applications).

6. CT Kit – Provides installer with CT options should the supplied CTs not fit.

7. Mounting hardware for the enclosure based on site requirements.

8. 14ga and 10ga stranded conductor.

9. Wire nuts or multitaps for above.

10. 1” minimum EMT, and necessary connectors based on site requirements

Recommended Tools

1. Voltage meter and Amp Meter for CT Calibration.

2. Laptop Computer with TeamViewer v11 preloaded.

3. CAT5 patch cable to connect Laptop to CPU.

4. Small instrument screw drivers for terminating CT conductors on the MOTES.

5. Stepper or Unibit for mounting the 4G high gain antenna.

2.4 Unpacking – What you will find in the box

Before opening the box, inspect the box itself for signs of damage as that will require further

inspection of the contents to ensure components are damage free.

13

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

Even though the system is fully tested before shipment and the enclosure is carefully

packaged to protect the electrical components inside during shipment, wires and plugs may

come loose during shipping. Check all terminals and wires to ensure they are properly

seated. Push down on the terminals to make sure they’re secure, lightly tug on the wire

connections to make sure they won’t fall out during installation. Also, make sure the relays

are all firmly seated in the black relay bases located on the middle-right side of the panel.

The enclosure may come with a small white cardboard box or zip lock bag that contains

accessories necessary to complete the installation. The CPU may come already installed on

the din-rail on the top left of the panel as shown above, or inside the accessory box.

Loose Parts

For an IQ 500HD-W-6-4G, the following accessories

will be included

1ea - 4G high gain antenna

1ea - Adapter for the 4G antenna

1ea – 4-amp Circuit Breaker

1ea - Wi-Fi antenna

14

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

2.5 System Components and Descriptions

The SolPad 500HD series Energy Management Systems consist of the following components;

A. CPU

B. Power supply

C. MOTES

D. Slave Relays

E. 30-amp DPDT relays

F. 50-amp relay

G. 30-amp relays underneath mezzanine

H. Terminal block for CT’s

I. Terminal block for 20-amp relays

J. Terminal block for 30-amp relays

K. Terminal block for 50-amp relays

L. 4-amp breaker/AC power terminals

SolPad CPU – CompuLab

The CPU has ports on three of the four

sides. There will be an external IP labeled

on the side that doesn’t have any ports.

CPU features: Ethernet Port, USB ports,

Micro SD card slot, 4G antenna port,

RS485, Wi-Fi antenna, power input port

15

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

Power Supply

The Power Supply on the top-right of the panel inside the enclosure converts 120VAC to DC

voltages for the components in the system.

MOTES – Marvel of Tiny Engineering

The MOTEs are micro-controllers that exchange information with the CPU, and send

intermediate commands to the relays. The MOTEs are designated by a version number and

physical position. In the image below, the mote on the left is version “R1.1” (R for

Residential) and “/1” for the first position in the layout.

The first MOTE’s inputs (I-1, I-2, I-3, I-4) are used for the grid power CTs, while the second

MOTE is for the solar power or production CTs. Using jumpers, the input type can be

changed between 0-10V, 4-20mA, and 10K Ohms. The standard system uses 0-5V CTs, and

no jumper is required for any 0-5v input. The jumpers are installed on the left-hand side of

the MOTE.

16

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

The 8 outputs (O-1, O-2, O-3, O-4) between the motes are what send signals to the relays to

turn devices on/off. In Residential systems, only six outputs are used in conjunction with

relays to accommodate different load sizes, (O-1-3 on each.) The diagram below shows how

the layout is wired to cover the ranges.

4G High Gain Antenna / RS485 Adapter / Wi-Fi Antenna

The last three components are shown in the image below. The high gain antenna with

adapter that will be mounted on the exterior of the enclosure and the to the top SMA port,

the RS485 adapter, and Wi-Fi antenna mounted to the bottom SMA connector.

17

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

2.6 Relay Descriptions

20 Amp SPDT 240vac Relays

These relays are intended for use with 120v circuits landed on

breakers of 20-amps or less.

Each relay has two terminals: The lower is a ‘N.C.’ (normally closed)

terminal and the upper is a COM (common) terminal.

Each relay comes pre-wired to phoenix

terminals mounted on a DIN rail

Your load controller contains between 4-26 of

these relays depending on your model.

30 Amp DPDT 240vac Relays

The relay comes pre-wired to a set of phoenix terminals mounted on

a DIN Rail.

Each 30-amp relay has two positions on the terminal block (A and B).

A and B each have two terminals: The lower is a ‘N.C.’ (normally

closed) terminal and the upper is a COM (common) terminal.

To control one leg of a two-pole circuit (which

is usually all that is required) you’ll use the two

‘A’ terminals for that relay.

You can make use of the unused side (‘B’

terminals) to control a second circuit, but two

circuits on a single relay WILL BE CONTROLLED

TOGETHER.

18

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

50 Amp DPDT 240vac Open Frame Relays

When using the 50-amp relay to control an electric range,

both L1 and L2 need to be interrupted and run through the

relay.

FAILURE TO ADDRESS THE ITEMS BELOW COULD RESULT

IN THE RELAY HEATING UP AND FAILING.

All lug connections to the relay terminals MUST be

properly torqued AND VERIFIED AT INSTALLATION

COMPLETION

All lug set screws must be properly torqued AND

VERIFIED AT INSTALLATION COMPLETION

Both legs of the load must be connected to the relay.

Do not put different loads on one relay (IE: L1 from load

#1 on one leg of the relay, and L1 from Load 2 on the

other leg)

19

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

3. Installation

These instructions are intended only as GENERAL GUIDELINES to be used in conjunction with

local and national electrical and building codes. This unit should be installed and serviced by

qualified persons only. Install the system in 6 steps. Steps 3 - 5 can be performed

simultaneously, or in any order, however step 6 cannot be completed until after they are all

complete.

Installation Steps

1. Mount the enclosure

2. Source power for the system

3. Connectivity and Accessories

4. Installation of Current Transducers (CTs)

5. Connecting Devices to be Controlled

6. Power Up the Load Controller

7. System Verification, Test and Turn-up

The Installation technician will be required to supply some of the items necessary to

complete the installation as noted in the “Recommended Material” and Recommended

Tools sections.

**IMPORTANT NOTE: This Energy Management System is to be installed by a

professional electrician.

3.1 Mounting the Enclosure

Choose where to mount the enclosure.

The Enclosure is best mounted near:

The Source of Power

Where the CTs will be installed - Main Grid Power, Dedicated Loads, and Solar

Power CTs

Where devices to be controlled - Devices are typically intercepted for control at the

breaker panels but will sometimes require wire going to the device location.

The enclosure has four holes pre-drilled for mounting and should be used to secure the

enclosure according to local code and with the appropriate fasteners based on site

conditions.

20

101 Metro Plaza • Suite 315 • San Jose, CA 95110 • (800) 801-4186 © 2020 SolPad Inc.

After the Enclosure is mounted, go through all the terminals on the panel and make sure

they are all pushed in, the 16amp relays are properly seated, and then go to all the wire

connections and make sure none of them come loose by pulling the wire lightly.

3.2 Source Power for the System

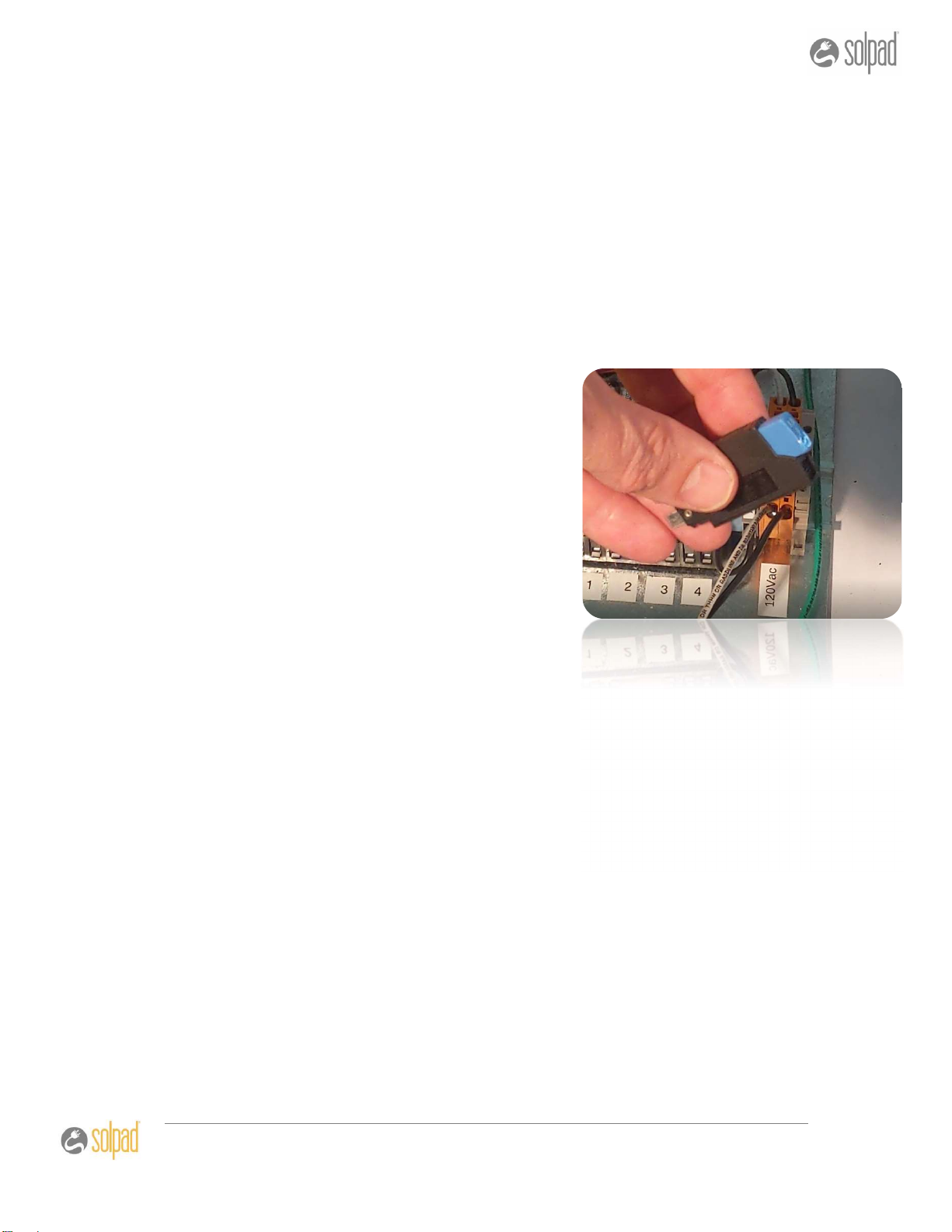

The SolPad EMS needs an independent power source of

120VAC with a ground.

Power the load controller from a dedicated 15amp breaker

Terminate the conductors from the 15A breaker powering the

load controller as follows:

A. Land the ground wire on the ground lug (A in picture).

B. Land the Neutral (white) in the orange terminal labeled

‘N’ (B in picture)

C. Land the Line (black) in the orange terminal labeled ‘L’

(B in picture)

Make sure the wires can be lightly pulled on without coming

out.

D. Insert the 4A breaker as shown (C) in the grey terminal

block labeled LBK.

Keep the dedicated 15-amp breaker switched off until the

remaining installation steps are completed

3.3 Connectivity and Accessories

The SolPad Load Controller has several means of connection depending on the options

purchased.

1. 4G T-Mobile internal Cellular Modem (KORE secure-AWS servers) Preferred

2. Wi-Fi - Connect to the system through the local Wi-Fi independent of public

internet.

This manual suits for next models

3

Table of contents

Popular Controllers manuals by other brands

Honeywell

Honeywell CP-UL1012S installation instructions

Johnson Controls

Johnson Controls M9106-AG 2N0 Series installation instructions

AMFLOW

AMFLOW A6 quick start

Jandy

Jandy Jandy Pro Series Installation and operation manual

Velleman

Velleman Vellight LEDC25 user manual

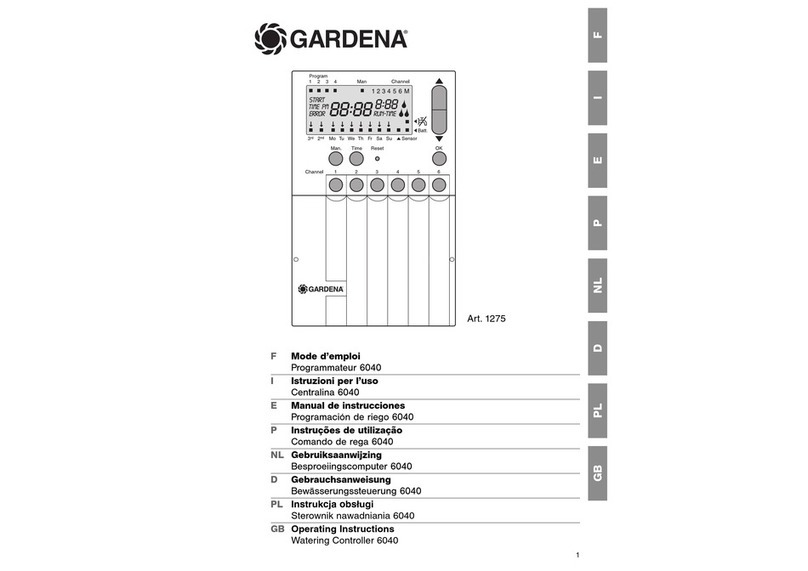

Gardena

Gardena Watering Controller 6040 operating instructions