Soltec CFM-Lite User manual

CFM-Lite Installation Manual

1/ 64

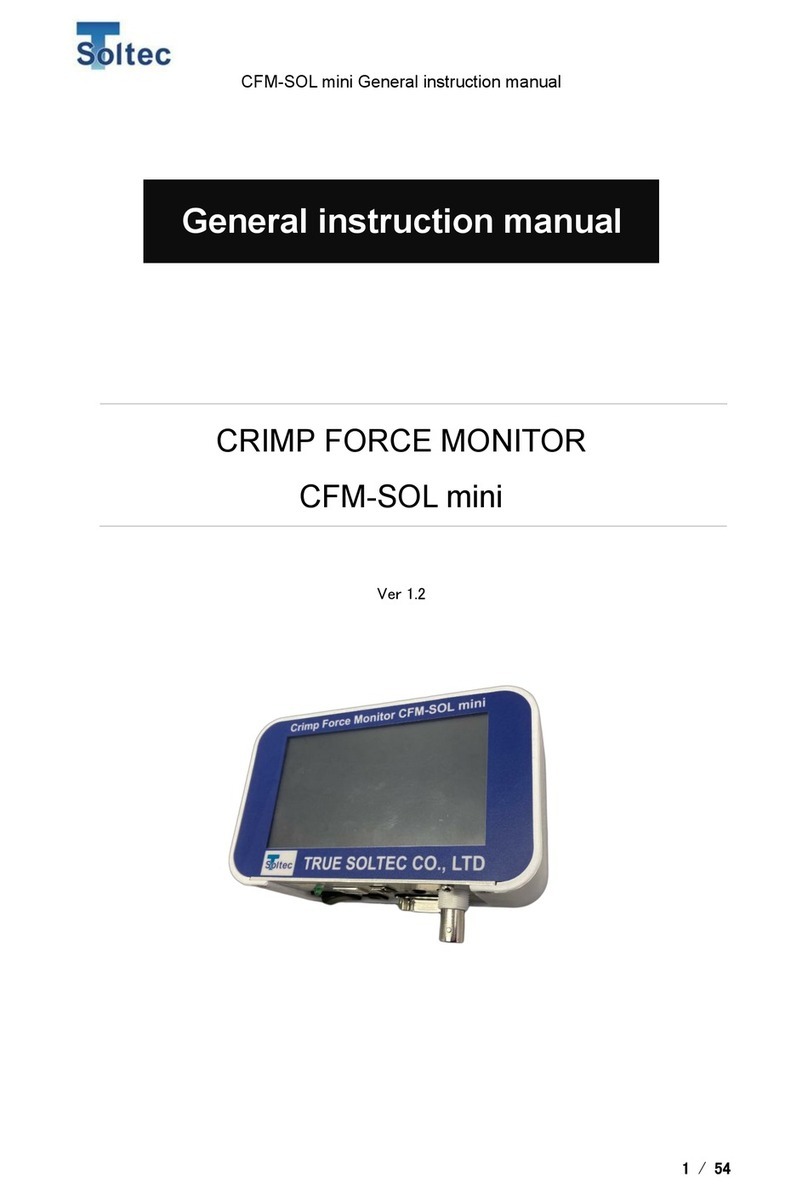

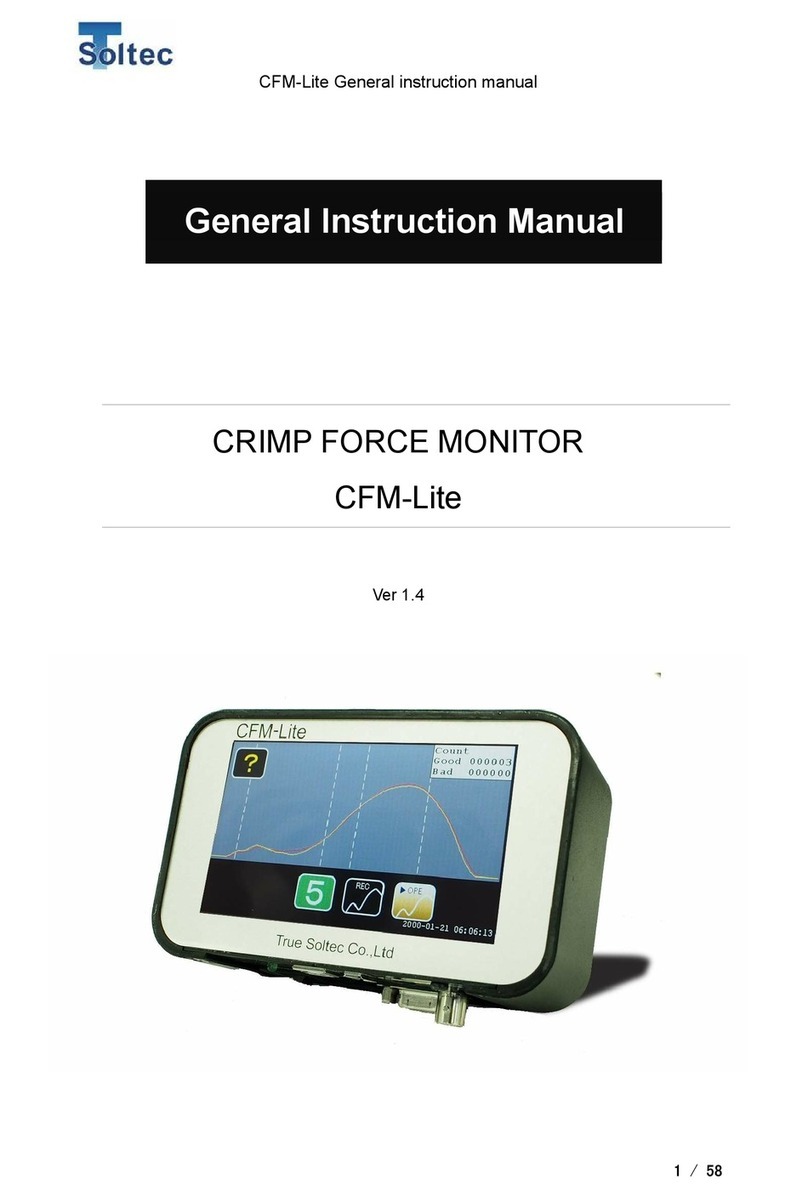

Crimp Force Monitor

CFM-Lite

Ver 1.1

CFM-Lite Installation Manual

CFM-Lite Installation Manual

2/ 64

Update history

Version number

Date

Updated by

Detail

Version 1.0

2017.10.24

Masato Sato

Version 1.1

2018.12.14

Masato Sato

1.1 & 2.1

description for

dongle is updated.

CFM-Lite Installation Manual

3/ 64

CONTENTS

1. Overview ......................................................................................................................... 5

1.1. The main unit, standard accessories and optional accessories.............................. 5

1.2. Connection of accessories....................................................................................... 9

1.3. Main specifications of the unit.................................................................................. 9

1.4. Terms explanation.................................................................................................. 10

1.5. Input and Output.................................................................................................... 12

1.6. Signal interface...................................................................................................... 14

1.6.1. External trigger input ...................................................................................... 14

1.6.2. External RESET.............................................................................................. 15

1.6.3. External TEACH ............................................................................................. 15

1.6.4. STOP signal.................................................................................................... 16

1.6.5. EJECT............................................................................................................. 18

1.7. PC communication................................................................................................. 18

1.8. AC Power adaptor.................................................................................................. 18

1.9. BNC........................................................................................................................ 18

1.10. USB memory...................................................................................................... 18

1.11. Sensor................................................................................................................ 19

2. Installation..................................................................................................................... 21

2.1. First of all : opening the box................................................................................... 21

2.2. Packed parts.......................................................................................................... 22

2.3. PSS sensor installation.......................................................................................... 24

2.3.1. How to set on the machine : example............................................................ 24

2.3.2. Procedure of setup the sensor....................................................................... 25

2.4. Wiring of interlock signal (Stop signal) for the machine........................................ 31

2.5. Lay out of the cables of sensor and I/O................................................................. 39

2.6. How to set up mounting bracket for the main unit................................................. 42

2.7. How to install PC software..................................................................................... 48

2.8. Let’s get started...................................................................................................... 53

3. Other installation ........................................................................................................... 55

3.1. Proximity sensor installation.................................................................................. 55

3.2. Base plate and sensor preload.............................................................................. 57

3.3. Eject signal connection.......................................................................................... 58

3.4. How to set up the insulation plate for PSS sensor. ............................................... 59

CFM-Lite Installation Manual

5/ 64

1. Overview

This manual guides you the way how to install the system successfully.

1.1. The main unit, standard accessories and optional accessories

Front

Rear

All are operated via the touch panel in the front. Only the power switching button is

located at the bottom.

Bracket set

holes (M5)

CFM-Lite Installation Manual

6/ 64

Bottom

FG (Frame Ground) must be connected firmly to the earth via e.g. the earth terminal of

the table tap, crimping machine, the formal earth terminal prepared by the factory in

order to prevent the external noise.

Accessories

Packed together

Non packed together

CFM-Lite main unit

PC software (available by download from PC web

site)

Sensor : Standard is PSS type,

optionally available is FTW or

FTC model.

General instruction manual and Installation manual

(available by download from PC web site)

BNC cable for sensor

PC (user preparation)

I/O cable for control

USB-AB type cable (user preparation)

AC adaptor

USB memory (user preparation)

Dongle key (optional item)

Mounting bracket

Basic instruction manual (print)

Power switch

USB-B type port for

USB-AB cable

USB-A type

port for USB

memory

Dongle key port

AC adaptor

port

Sensor input

D-sub 9 pin port

for I/O cable

Power LED

FG

Serial No. seal

CFM-Lite Installation Manual

7/ 64

Photos of packed items:

BNC cable

1.5 m long BNC cable connects the

force sensor and CFM-Lite main unit.

I/O cable

1.5 m long Input and Output cable

with D-sub 9 pins connector for

connecting CFM-Lite and the machine

control

Dongle key (optional)

This key blocks selected operations

from unwanted hand of operators

PSS sensor

Force detection is made by measuring

the machine body’s elongation. See

sensor details at 1.11. Sensor

ACAdaptor

Noise proof type adaptor is prepared.

Caution: Do not use other low costAC

adaptors in the market.

Mounting bracket

Standard bracket for mounting the

main unit: 170mm long body can be

set by the triangle base plate (M5).

CFM-Lite Installation Manual

8/ 64

Photos of non-packed together

PC is to be normal type in the market.

USB cable is available in the market, too.

USB cable (AB type)

B connector

A connector

CFM-Lite Installation Manual

9/ 64

1.2. Connection of accessories

1.3. Main specifications of the unit

Outer dimensions

W 137mm x H 84mm x D 50mm

Analog sensor

signal

Resolution 12bit

Max sampling rate 20kHz

Sensor

FTW series (ring type force sensor, cable output, 0.1 to 10 ton)

PSS series (piezo strain sensor, high /middle / low sensitivity

models)

FTC series (ring type force sensor, connector output, 2 or 4 ton)

I/O cable

“Refer to 1.5. Input and Output”

USB

communication

1) PC communication (USB2.0)

2) USB data memory (max 64GB saved)

Power

Adapter Tec made, model ATM012T-W240U

(Input 100~240V AC、Output 24V DC・0.5A)

Other all AC adaptors are out of warranty if trouble should happen.

Operating

temperature

0~40 degrees C, Humidity 90% or lower but no dew

Circumstances

RoHS regulation is performed.

Dongle

key

BNC cable

PSS sensor

USB-AB cable

AC adapter

I/O cable

CFM-Lite Installation Manual

10 / 64

1.4. Terms explanation

Crimp Force Monitor = CFM : CFM monitors cable’s terminal crimping is

monitored by using a force sensor. Every crimped force data is compared with

the standard (= good ) force data (reference force curve) to judge if it is a good

crimping or defect.

Operation = OPE.: It is a mode of CFM-Lite. It controls data if it is good or bad.

Production is done under OPE mode.

TEACH: It is a mode of CFM-Lite. Before starting production, two good crimp

data will create the reference force curve by which next coming all data can be

judged. This mode teaches the standard; therefore we say it as “Teach”.

Tolerance : Data deviation from the standard is expressed by percentage %. The

acceptable limit of + tolerance value and –tolerance value will be setup for

controlling good and defect data.

Parameters : Only selected parameters can be accessed by touching the front

panel of the main unit.All the others can be precisely conditioned by selecting

parameters by PC software.

Trigger : This word is used in broad sense. We mean it as the start timing of

force signal getting. There are two ways of triggering; one is the automatic

trigger “Auto Trigger” CFM-Lite detects the right force level to start getting

automatically, and the other is the external switch trigger which is made by a

high response type sensor set on the crimping machine monitoring the machine

ram motion. Normally the automatic trigger can work. However bad machine

conditions and poor material quality will make force data very unstable. In such

cases, we should recommend you to use the external trigger. Consult with us or

our agent.

Stop signal : CFM-Lite outputs stop signal when it detects a defect crimp. It locks

the machine not to re-start production until the operator checks it and remove

the cause. The stop signal line is often connected in series to the foot switch

circuit of manual press.

CFM-Lite Installation Manual

11 / 64

Eject signal: For more advanced machines using automatic running system will

use this signal as the confirmation of good crimp completion. The machine will

receive this pulse signal to take the next cycle.

CFM-Lite Installation Manual

12 / 64

1.5. Input and Output

Input and Output circuit

1) +24Vout

2) TRIGGER

3) RESET

4) TEACH

5) STOP_NC

6) STOP_COM

7) STOP_NO

8) EJECT

9) GND

10) FG(Shell)

11) FG(Shell)

I/O

DSUB 9pin

CFM-Lite Installation Manual

13 / 64

I/O pin assignment

PIN No.

Description

Wire color

1

Power

24V(output)

Orange/Black 1

2

TRIGGER

External trigger input

Orange /Red 1

3

RESET

External reset input

Yellow/Black 1

4

TEACH

External teach input

Yellow/Red 1

5

STOP

Stop signal (N.O)

Green/Black 1

6

STOP

Stop signal (COM)

Green/Red 1

7

STOP

Stop signal (N.C)

Gray/Black 1

8

EJECT

Eject output

Gray/Red 1

9

GND

Ground

White/Black 1

CFM-Lite Installation Manual

14 / 64

1.6. Signal interface

See “1.5 Input and Output”

1.6.1. External trigger input

A high speed optical switch will make the pin 2 (TRIGGER) and pin 9 (FND) shorted

for triggering. But, if the automatic trigger mode is selected, this signal is ignored.

This trigger timing is expressed as HIGH to LOW change. The system demands

Low period longer than 10m seconds.

The measurement starts from (3) and ends at (4). Internally the system gets margin

area 10% each for left and right sides.

Triger level (1)

[Diagram] Signal exceeding the trigger level

Trig. Signal

(Switch ON)

Force

Force monitor start (2)

Force measurement (3)

Force monitor stop (4)

Triger level

(set by PC)

CFM-Lite Installation Manual

15 / 64

It monitors for 100msec. to confirm that force curve exceeds the trigger level.

If it cannot confirm such exceeding of the trigger level, the force curve with peak

of at (2) –(3) period is obtained.

1.6.2. External RESET

RESET signal release errors of data error, sensor error and TEACH error. It is the

external resetting, which will be sent from the press machine or external switching

box. To make it ON, pin 3 (RESET) and pin 9 (GND) should be short circuited.

When the system operates without error, this RESET signal is ignored. Caution:

make the low time (short-circuited) longer than 10msec. for sure.

1.6.3. External TEACH

TEACH signal starts teaching. It is the external TEACH signal from the machine.

Make pin 4 (TEACH) and pin 9(GND) short circuited to set ON. When the CFM is

already in TEACH mode, this signal is ignored. Caution: make the low time (short-

circuited) longer than 10m sec. for sure.

Triger Signal

[Diagram] Signal not exceeding the trigger level

Triger level

(set by PC)

Force

Force monitor start (2)

Force measurement (3)

CFM-Lite Installation Manual

16 / 64

1.6.4. STOP signal

STOP signal stops operation of machine. There are normally open (NO) signal and

normally close (NC).

NO:

When the main unit is turned on, it keeps the relay contact opened.

NC:

When the main unit is turned on, it keeps the relay contact closed.

The below is the relay contact circuit. It shows the normal mode. When it should

happen error, the mode is reversed, namely the NO contact is closed and NC

contact is opened.

Stop signal contact

5

STOP

(N.O)

GRN/BLK 1

6

STOP

(COM)

GRN/RED 1

7

STOP

(N.C)

GRY/BLK 1

Normally open NO

Normally close NC

Common COM

CFM-Lite Installation Manual

17 / 64

Contacts condition

Pin 5(STOP (N.O))

Pin 7(STOP (N.C))

Power OFF

Close

Open

TEACH

Open

Close

OPE

Open

Close

Tolerance setting

Close

Open

Parameter screen (PC)

Close

Open

Error happens

Close

Open

Ordinary manual type press control has no special connector for external stop

signal. Therefore, we recommend you to break the foot switch circuit for CFM stop

signal in serial so that the foot switch can be locked at the error detection. See “2.4

Interlocking signal (STOP) for press machine”.

Foot Switch

CFM-STOP

Machine

CFM-Lite Installation Manual

18 / 64

1.6.5. EJECT

EJECT signal is output to a semi-automatic machine which has the electrical control

functions to receive the eject-pulse signal as the confirmation of good crimp and start

the next press cycle. The eject pulse width is 100m sec. It is possible to select Eject

output at good crimping or bad crimping as a parameter. Normally Pin 8 (EJECT) and

9(GND) is open (= HIGH). When EJECT is output, it becomes LOW and maintain

100ms and returns to HIGH. See “3.3 Eject signal connection”.

1.7. PC communication

See [1.3 main unit specifications]

1.8. AC Power adaptor

See [1.3 main unit specifications]

1.9. BNC

BNC cable is used for the sensor connection. Use only ours.

1.10. USB memory

Force curve is kept in the USB memory. When it is inserted to the USB port, data is

automatically stored in time order.

Machine is

crimping

Eject output

100mSec pulse

Force curve

Pulse width = 100ms

Eject is output within 100ms when the unit is set as short measurement

mode (measurement max. 100ms).

Eject is output within 500ms when the unit is set as long measurement

mode (measurement max. 500ms)

Lower dead point

CFM-Lite Installation Manual

19 / 64

1.11. Sensor

Piezoelectric strain sensor, PSS50

PSS50 is provided as standard accessory. It can be screwed to machine body easily.

Refer to “2.3 PSS sensor installation”for details. It’s sensitivity is 90mV/μST. The

μST is called as micro-strain, a physical term expressing how micron meter

elongated per 1 meter long base material. This sensor outputs high voltage in

proportion to applied elongation. Namely, when the machine body strains at

crimping, PSS sensor output proportional voltage to its elongation.

Other PSS series sensors: PSS100, PSS25

PSS100 is of 160mV/μstrain for highly rigid type press machines.

PSS 25 is of 40mV/μstrain for low rigid machines.

* For selection of right PSS model, please consult with us. They are all same size.

Only the sensitivity is classified.

Sensitivity 90mV/μstrain(PSS-50)

Rated strain limit 50μstrain (physical overload is 400μstrain)

Low cut frequency About 0.1Hz

Linearity 3FS %

Output impedance 100Ωor lower

Base noise 500μVrms or lower

Carrier base voltage 11V±1V

Recommended set torque 7~10N-m

Max. allowable torque 10N-m

Net weight About 73g

Power Voltage 24~27V, constant current2~10mA

Operating principle Sharing, piezoelectric effect

Sensor casing Stainless steel

Connector Miniature type, No.10-32UNF

Set screw M6 type set screw, flat head、φ6.4mm

Operating temperature range -20~60 degreeC

CFM-Lite Installation Manual

20 / 64

Other sensors are also available.

When your press has no space to put PSS sensor or you prefer to receipt of the

force directly –not via machine’s distortion, you can choose our ring type

piezoelectric force sensors.

FTW series are cable output type, ranging from 100kg, 500kg, 1ton, 2ton, 2.5

ton, 5ton and 10ton.

FTC series are connector output type, ranging 2ton and 4 ton.

In order to receive the crimping force, the sensor must be set in the applicator’s base

plate or the machine ram. Usually we recommend to put the FTW sensors in the

base plate, which will be designed and fabricated by us. You will consult with us or

our agent for sensor selection, location of sensor, jig design and installation. It must

be done before issuing your purchase order.

As for the base plate type installation of FTW sensors, refer to “3.2 base plate and

sensor preloading”.

Sensor model

(max load)

FTW05(500kg)

FTW20(2t)

FTW255(2.5t)

FTW50(5t)

FTW100(10t)

[FTW]

They are

sandwiched in

the base

plates

110t

Ex.FTW20 cable output

FTC208(2t)

FTC408(4t)

[FTC]

They are

pinched in the

ram adaptor.

Sensor cable

must be routed

carefully not

for breakage

Ex.FTC208 connector output

[Connection]

Sensor Pre-amp. BNC cable

4 ± 0 . 0 0 5

φ 1 8 . 9

φ 6 . 4 1 3 . 9

3 0 1 8 . 1

φ 2 . 3 L = 2 0 0

10t

7 . 8 7 ± 0 . 0 2 5

0 . 2

0 . 1 5

φ 1 6 . 5 1

φ 6 . 3 8

1 9 . 5

φ 7

Connection

cable

Other manuals for CFM-Lite

1

Table of contents

Other Soltec Monitor manuals

Popular Monitor manuals by other brands

Fujitsu

Fujitsu SCALEOVIEW C17-7 user manual

Dell

Dell 2407WFP - UltraSharp - 24" LCD Monitor user manual

Dell

Dell E157FPT Environmental Data Sheet

Fujitsu

Fujitsu Plasmavision PDS4208W-B user manual

Advan

Advan AMM15TK3 Operation manual

Samsung

Samsung 400FP-2 - SyncMaster - 40" LCD Flat Panel... user manual