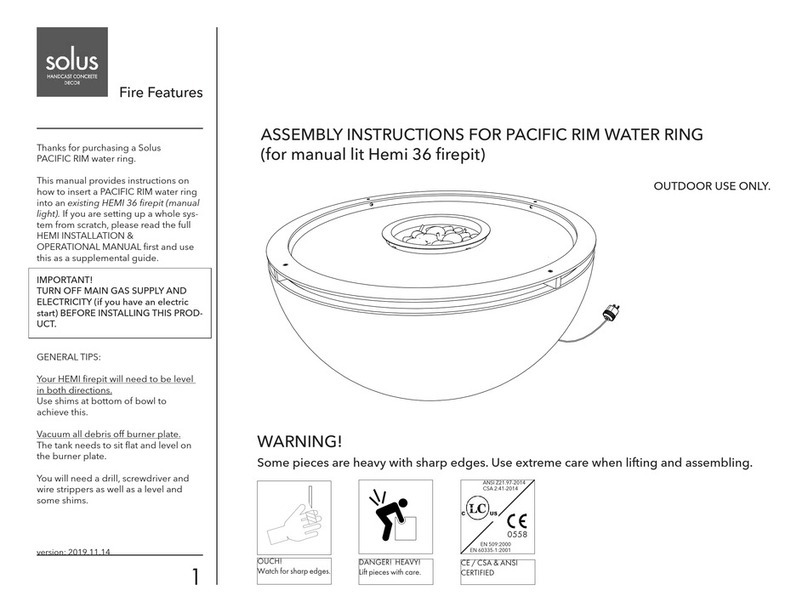

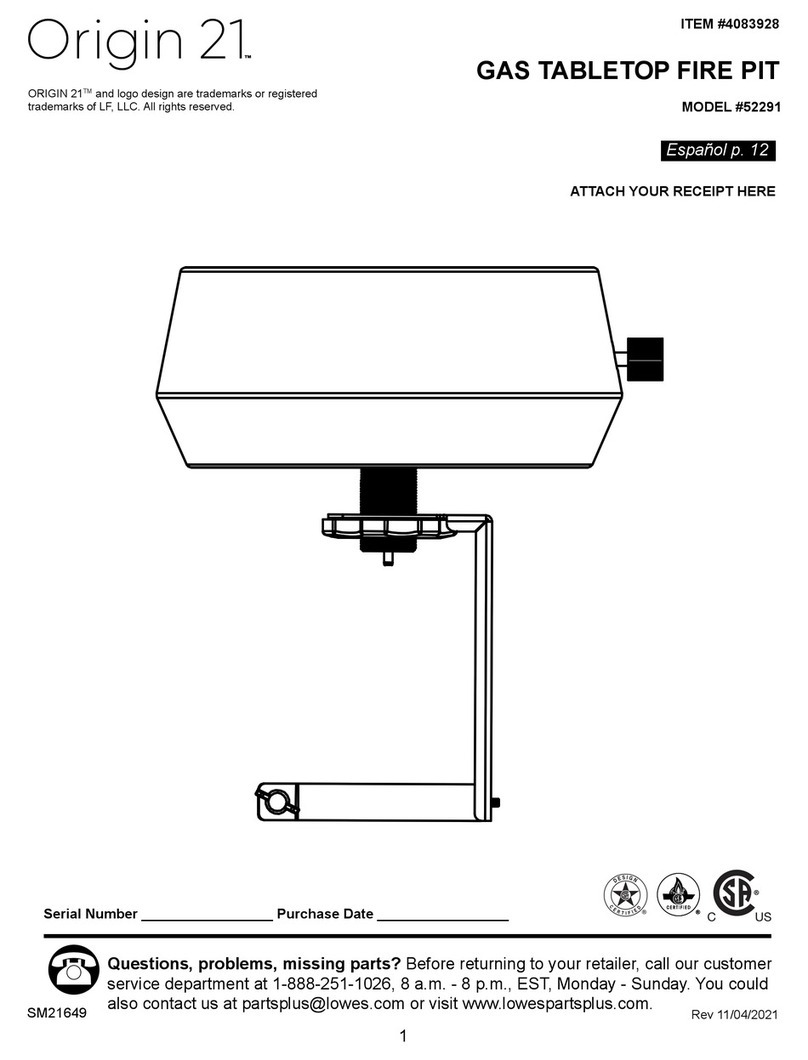

Solus Hemi 26 User manual

fire pit installation and user manual

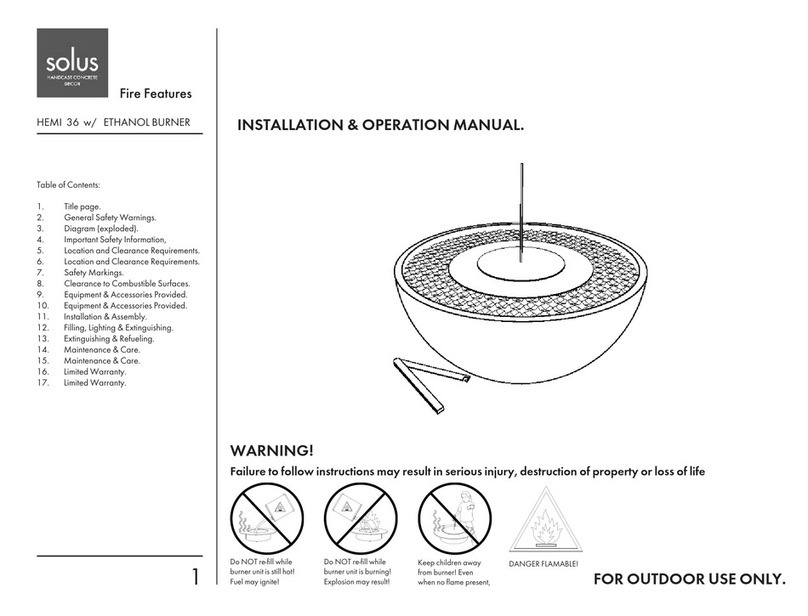

C O N T E N T S

Standards

Page 2

Product Ratings

Page 2

Product Warnings

Page 3

Location of the Fire Pit

Page 6

Fire Pit Clearances

Page 7

Unpacking

Page 7

General Lifting Guide

Page 8

Installation and Operation

Page 10

Media Installation

Page 16

General Care and Maintenance

Page 18

End of the Season Checklist

Page 21

Start of the Season Checklist

Page 22

Troubleshooting

Page 23

Warranty Information

Page 25

Parts List

Page 27

Optional Accessories

Page 28

Product Registration

Page 31

January 2022

This user manual contains information that is critical to the installation and

operations of your Solus Fire Pits. For safety, please follow these instructions carefully.

This fire pit conform to the following standards:

ANSI Z21.97 – 2004 / CSA 2.41 -2017

Outdoor Decorative Gas Appliance

CSA 2.17-2017

Gas-Fired Appliances For Use at High Altitudes

CE BS EN 498:2012

Specification for Dedicated Liquefied Petroleum Gas Appliances

CE BS EN 509:2001 + A1 : 2003 + A2: 2004

Decorative Fuel-Effect Gas Appliances

Made in Canada by Solus Decor Inc.

Building C-109 Braid Street, New Westminster, BC Canada V3L5H4

1.877.255.3146 www.solusdecor.com

PRODUCT RATINGS

GAS RATINGS

Natural Gas (NG)

Inlet Gas Pressure : 7 ”W.C. (17.4mbar) (0.25 PSi)

Manifold Gas Pressure :

Burner Ratings Minimum Manifold Pressure Requirement

60,000 BTU (17.58kW) 3.5”W.C. (8.7mbar) (0.12 PSi)

73,500 BTU (21.39kW) 3.5”W.C. (8.7mbar) (0.12 PSi)

108,000 BTU (31.65kW) 2.5”W.C. (6.2 mbar) (0.09 PSi

ELECTRICAL RATINGS

North America

: 120vAC, 60Hz, 1.5 Amp

Operating Ranges : 108vAC - 132vAC

UK/EU :

230vAC, 50Hz, 1.5 Amp

Operating Ranges : 220vAC - 240vAC for

UK/EU

WARNINGS:

Consistent

Inlet Gas Pressure

is required to avoid weak pilot flame and burner dropouts.

Stable

Voltage Supply

is required to avoid ignition module lockout.

Page 2 of 32

PRODUCT WARNINGS

DANGER: If you smell gas:

1) Shut off gas to the appliance.

2) Extinguish any open flame.

3) If the odor continues, keep away from appliances and immediately call the gas

supplier or fire department.

WARNING: For Outdoor Use Only

WARNING: Only Licensed Gas Fitters and Electricians are allowed to install and

perform repair services on this fire pit

WARNING: This Fire pit should be inspected before use and at least once annually by a

qualified technician.

WARNING: This manual contains information critical to the safe installation and

operation of the fire pit

WARNING: Never alter product or configuration in any way

WARNING: Fuel line sizing and or/regulations are the responsibility of the installer and

must be able to supply the stated Product Ratings.

WARNING:Testing for leaks after installation is the responsibility of the installer.

WARNING: All fire pits must have a gas shutoff outside of the exterior of the fire pit

to allow for emergency shut off and maintenance.

Page 3 of 32

WARNING: All fire pits with an electric start system, must have an electrical shut off

(wall switch or breaker) on the exterior of the fire pit or on an adjacent wall to allow for

emergency shutdown and maintenance.

WARNING: Improper installation, adjustment, alteration, service, or maintenance can

cause injury or property damage. Read the installation, operating, and maintenance

instructions thoroughly before installing or servicing this equipment

WARNING: Improper installation, adjustment, alteration, service, or maintenance can

cause injury or property damage. Read the installation, operating, and maintenance

instructions thoroughly before installing or servicing this equipment

WARNING: Improper installation, adjustment, alteration, service, or maintenance can

cause injury or property damage. Read the installation, operating, and maintenance

instructions thoroughly before installing or servicing this equipment.

WARNING: Do not use this fire pit if any part of it has been under water. Call a

licensed technician to inspect the fire pit and replace the parts under water as

necessary

WARNING: Do not store or use gasoline or other flammable near the fire pit.

WARNING: It is the installer’s responsibility to ensure a safe installation and to

educate the end user about proper operation. Leave this manual with the end user

WARNING: FOR REMOTE CONTROL USE: To prevent accidental start-up from

unwanted RF signals it is the responsibility of the end user to turn off power to the

electric outlet for the remote control receiver when the fire-pit is not in use via wall

switch or breaker.

WARNING: This fire pit is not intended to be a starter for wood or any other

combustibles.

WARNING: Select a location where the fire pit can be attended during operation.

Never leave an operating fire pit unattended or by someone not familiar with its

operation or emergency shut off locations.

WARNING: Both children and adults should be alerted to the hazards of high surface

temperatures and should stay away to avoid burns and clothing ignition.

WARNING: Young children should be carefully supervised when they are in the area

of the fire pit.

WARNING: Clothing or other flammable materials should not be placed on or near a

fire pit.

Page 4 of 32

WARNING: This fire pit emits very high temperatures - Combustibles must be located

far enough away that there is no risk of ignition.

WARNING: All Solus vessels for Natural and Liquid Propane Gas are vented at the

bottom. The ventilation allows for heat and/or residual fuel to escape. The vents also

function as a drain to prevent water build-up. These vents must not be blocked or

tampered with at any time. Failure to follow this instruction may result in the fire-pit

overheating or explosion. Overheating could also lead to heat damage to internal

components.

WARNING: The interior void space of the Solus vessel surrounding the gas valve and

electrical box cannot be filled with any material (gravel, crushed rock, concrete, etc.) to

allow for proper ventilation.

WARNING: Solus concrete vessels are HEAVY. Use care and caution during lifting,

positioning and repositioning to prevent injury, damage to fire pits and damage to

property. Some Fire Pits will require 2 or more people to lift; some may require 4 or

more people. The Fire Pit must be evenly supported and level – Shim appropriately as

required.

WARNING: The fire pit must be serviced annually by a professional certified in your

jurisdiction.

WARNING: Installer must confirm the appliance is built for the appropriate gas used –

natural gas or LP. Do not use natural gas appliances with LP or LP appliances with

natural gas. Refer to the label on the appliance.

WARNING: To prevent damage, unhook the fire pit from the gas supply for pressure

leak tests.

WARNING: Gas Plumbing Connections: Use only joint compound or tape that is

resistant to all gases. Apply joint compound to all male pipe fittings only- DO NOT use

on FLARED fittings. Be sure to tighten every joint securely.

WARNING: An LP-cylinder not connected for use shall not be stored in the vicinity of

this or any other appliance

Page 5 of 32

LOCATION OF THE FIRE PIT

All Solus Decor fire pits are intended and designed for Outdoor Use Only.

Stable Surface

The Solus fire pit vessel must be placed on a stable and flat surface. Select a location with good

drainage that allows easy access for installation and maintenance of the fire pit.

Consider the location with less unfavorable winds

Solus Burner is designed to withstand 10MPH (16.0934KPH) wind speed. Consider purchasing a

Solus WindShield if the location is prone to severe and unpredictable wind activities like open

beachfront spaces or high rise building patios and balconies.

Page 6 of 32

Gas Shut Off

All Fire pits must have a gas shut-off mechanism located outside of the appliance. This gas shut-off

mechanism must be accessible for emergency shut-off and maintenance. Please note that the Key

Ball Valve outside the vessel of this firepit is not a shut-off mechanism. This Key Ball Valve is used

to regulate the flame height and flame intensity.

Electrical Shut Off

All Fire pits with electronic ignitions must have an External shut-off switch (ON/OFF switch or timer)

near the fire pit. This electrical switch/timer must be accessible for emergency shut-off and

maintenance.

Timer must have a Manual ON/OFF Button.

Please refer to the local electrical and

building codes prior to installation of the switch.

FIRE PIT CLEARANCES

Horizontal Clearance

Concrete vessels must be at least 16 inches (0.5 meter) away from any combustible structure and/or

materials.

Vertical Clearance

Clearance between the burner and any structure overhead must be at least 77 inches (1.95 meter)

from any combustible structure and/or materials.

UNPACKING

Page 7 of 32

The fire pit will arrive in an exquisite crate, fully foamed padded. Carefully inspect the crate for

damages during delivery. Open the crate immediately if any damages are observed. Document the

damages through photographs and report to Solus Decor at once.

Crate Check

Customers are required to report any crate damages within 24 hours of receiving the crates.

Contents Check

Furthermore, it is the customer's responsibility to check it’s contents within 48 hours from receipt

of the shipment to check for content damages.

Solus is not responsible for damages reported beyond these timelines.

GENERAL LIFTING GUIDE

WARNING:

These concrete products are heavy and bulky. Moving these concrete products may require multiple

people. Refer to the table on the next page.

Please note that only Hemi 36 and 48 bowls are provided with straps that act like a carrying

harness.

Page 8 of 32

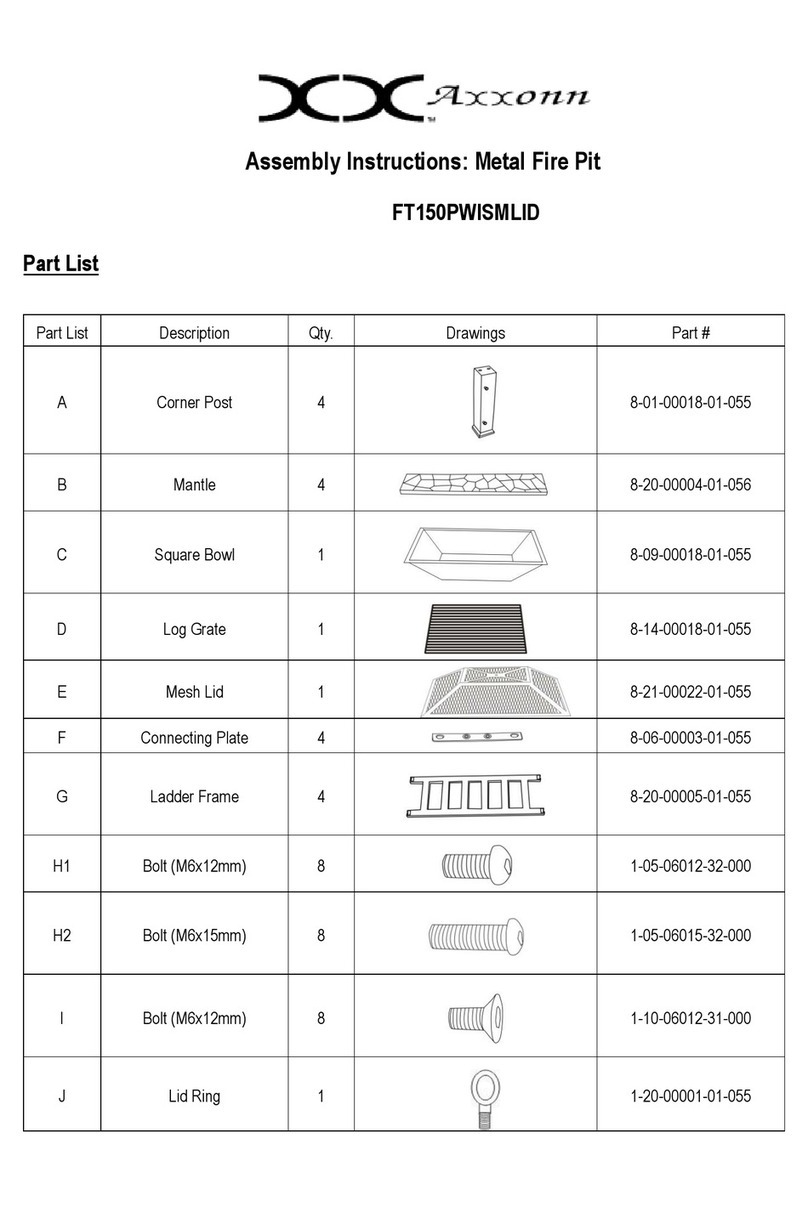

Product Type

Lbs

Kgs

Number of Person Needed to Lift

Hemi 26

81

37

2

Hemi 36

156

71

2 (Strap Attached)

Hemi 48

317

144

4 (Strap Attached)

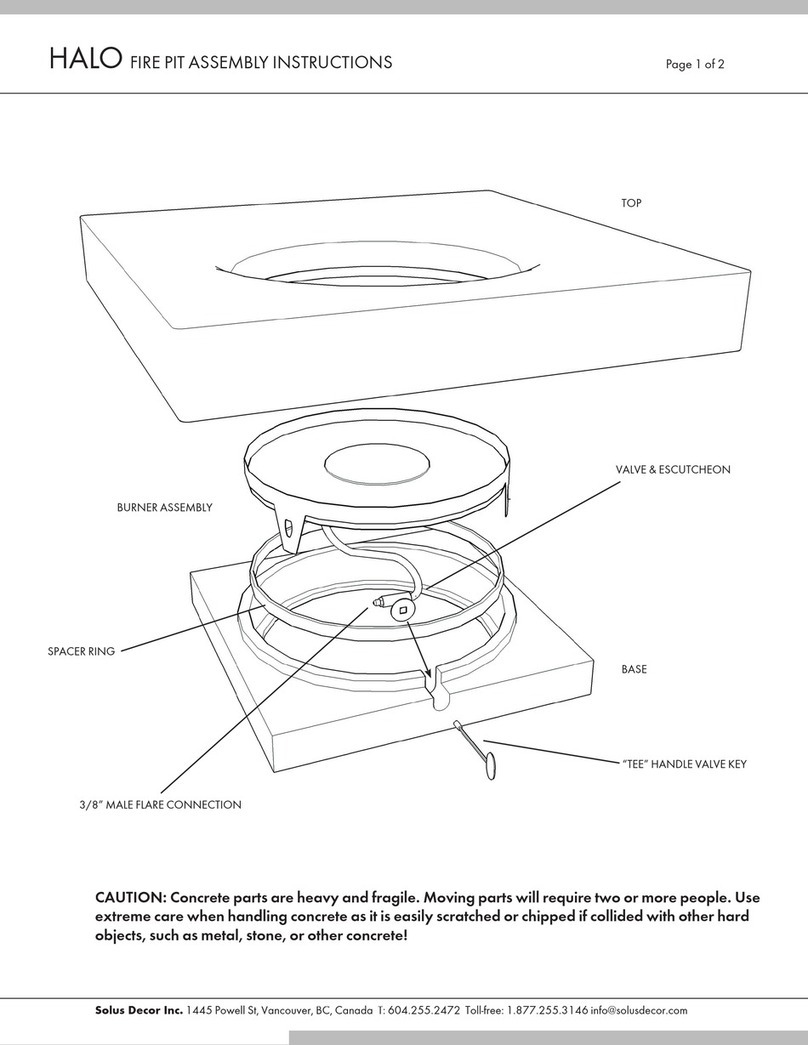

Halo 36 Low Base

76

35

2

Halo 36 Low Top

244

111

2-3

EHA 36 Box

230

105

2-3

EHA 36 Top

244

111

2-3

Halo Low 48 Base

75

34

2

Halo Low 48 Top

526

239

5

EHA 48 Box

230

105

2

EHA 48 Top

526

239

4-5

Fire Table Base

74

34

2

Fire Table Box

243

110

2-3

Fire Table Top

134

61

2

Firebox 30

243

110

2-3

Firecube with Lid

156

71

2

Tavolo Base

75

34

2

Tavolo Box

243

110

3-4

Tavolo Top

410

186

4

Linear

148 per slab

67 per slab

2

Page 9 of 32

INSTALLATION AND OPERATION

WARNING:

Installation and repair must be done by Licensed Gas Fitters. The fire pit must be inspected before

use and at least checked or serviced annually by a qualified service technician. Cleaning may be

required frequently as necessary. When a fire pit is not in use, an all-weather cover or metal top

must be used to avoid water and moisture build-up and to protect the fire pit from environmental

hazards.

●

Fire Pit Ratings :

Check the Output BTU Ratings of the fire pit and ensure the

following requirements are followed.

Gas Rating (NG) :

Inlet Gas Pressure : 7 ”W.C. (17.4mbar) (0.25 PSi)

Manifold Gas Pressure :

Burner Ratings Minimum Manifold Pressure Requirement

60,000 BTU (17.58kW) 3.5”W.C. (8.7mbar) (0.12 PSi)

73,500 BTU (21.39kW) 3.5”W.C. (8.7mbar) (0.12 PSi)

108,000 BTU (31.65kW) 2.5”W.C. (6.2 mbar) (0.09 PSi

Electrical Rating

North America

:120vAC, 60Hz, 1.5 Amp

Operating Ranges : 108vAC - 132vAC

EU/UK : 230vAC, 50Hz, 1.5 Amp

Operating Ranges : 220vAC - 240vAC for EU/UK

●

Inlet Pressure :

This is the input gas pressure coming from the main gas line

going to the fire pit. Reading must be taken only after all other gas appliances

on the main supply are on and running at full capacity.

●

Manifold Pressure:

This is the pressure at the manifold when the burner is on.

Page 10 of 32

●

Gas Requirement :

Consistent

Inlet Gas Pressure

is required to avoid weak

pilot flame and burner dropouts.

THIS IS AN ABSOLUTE PRIORITY

.The

reading must be recorded and written on the installer’s card and must be given

to the owner/end user. Owner’s must keep this card for future use and

servicing.

●

Electrical Requirement :

Stable

Voltage Supply

is required to avoid ignition

module lockout.

Page 11 of 32

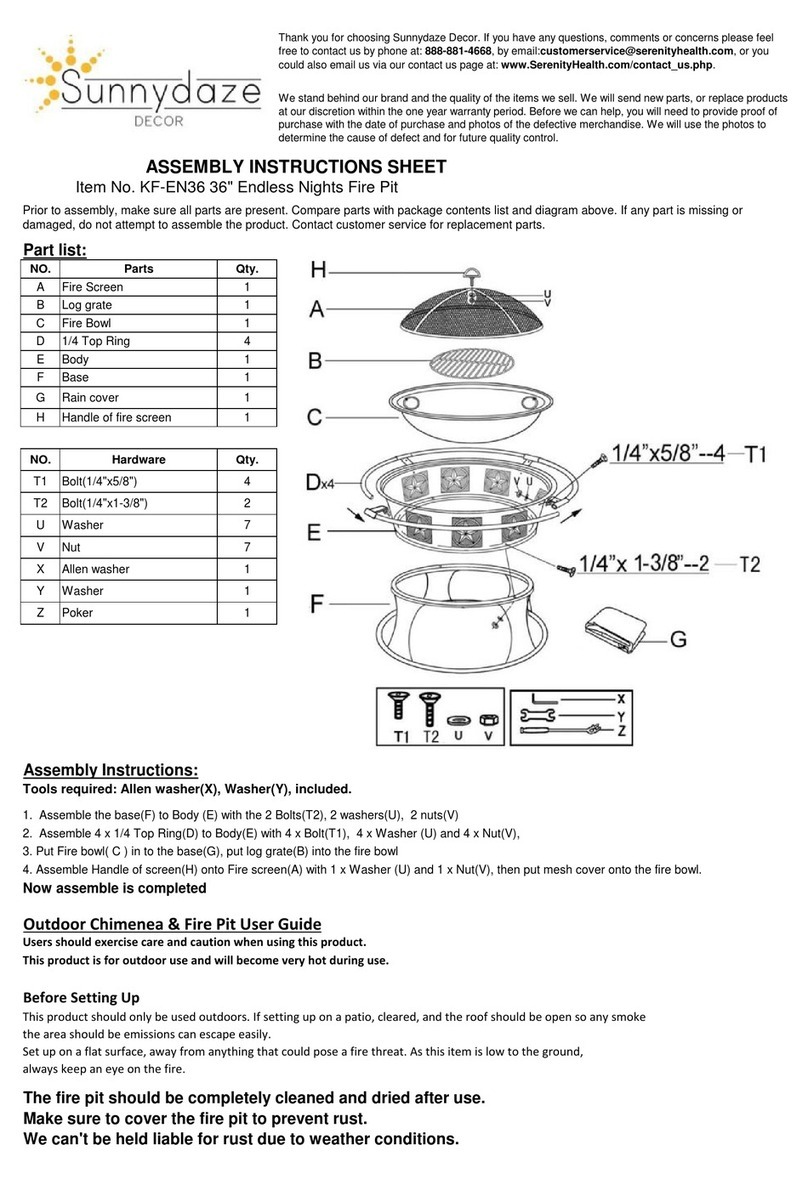

Locate all the components

●Installer’s Package

●3” Valve Keys

●1/2” Yellow Flex Line

●Auto Burner Assembly with Dual Gas Valve

●Concrete Bowl – Ball Valve

Page 12 of 32

Gas Connection

●Make sure that the gas shut-off valve (emergency shut-off valve) of the appliance is

closed when connecting the gas lines.

●Locate the Ball Valve inside the concrete bowl/vessel. This valve is supplied with flared

fitting at both ends.

●Connect the one end of the yellow flex gas line (supplied) to the one end of the Ball Valve

and the other end to the Dual Solenoid Gas Valve (underneath the burner assembly).

●Connect the end of the NG main supply line to the end of the Ball Valve.

●Test all gas piping and connections for leaks after gas connections

●Do not use an open flame to check for leaks.

Electrical Connection

●Make sure the electrical switch/timer is off.

●In the Electronic Box, take the cover screws off to access the electronic panel.

●Run the supply line from the shut-off switch/timer through the pre-drilled holes at the

bottom of the box.

●Follow the wiring diagram on the next page.

Page 13 of 32

Operation

Turning ON the Electronic Ignition System - NG

○Read instructions very carefully.

○Remove any covers prior to operation.

○Confirm that the gas shut-off valve (emergency shut-off valve) is open.

○Locate the Ball Valve and the electrical shut-off switch/timer.

Page 14 of 32

Ignition

By using the 3” Key (supplied), fully open the Ball Valve freely by turning the shaft

counter-clockwise. Turn on the electrical shut-off switch/timer (not supplied) to initiate

electronic ignition operation. The sparker will try to ignite the pilot for about 7 seconds

until it is lit. Once the pilot is lit, the thermosensor is heated and sends a signal to the

main gas valve to initiate release of gas to the main burner. Fully purged gas lines will

light up the burner manifold immediately.

Purging the line

Failure of the system to detect gas flow and flame after the first ignition cycle will

result in the system going to stand-by mode. Sometimes, due to in-activity and not being

used, bleeding or purging of air out of the lines is needed to encourage gas flow. To do

this, the system needs to be restarted several times until the whole gas line is saturated

with gas. To restart the system, turn on the electrical switch and initiate the ignition

process. Once the sparker stops igniting the pilot, turn the switch off, and then on again

to initiate another ignition cycle. Do this until the pilot is lit and the burner manifold

starts to gather flame.

Flame Adjustment

Adjust the flame height and intensity by turning the Ball Valve using a 3” key

(provided). Turn the key clockwise to decrease and turn anti-clockwise to increase flame

height. Please note that the Ball valve must be fully open prior to ignition and must be

fully closed when not in operation.

Turning OFF the Electronic Ignition System - NG

○Turn the electrical switch/timer off

○Shut the Ball Valve off by turning the shaft clockwise using the 3” Key

○Close the gas shut-off valve (emergency shut-off valve).

○Allow the burner to cool down before installing the cover, if available.

WARNINGS:

Consistent Inlet Gas Pressure is required to avoid weak pilot flame and burner dropouts.

Stable Voltage Supply is required to avoid ignition module lockout.

Page 15 of 32

MEDIA INSTALLATION

WARNING:

Do not install any refractory stones (decorative river rocks) or lava rocks that are not supplied by

Solus Decor. Landscape stones and other natural materials may explode when heated

.

WARNINGS:

Do not dump media over the burner and or the nozzles.

Keep the pilot cage free and clear of any refractory stones and lava rocks.

Page 16 of 32

WARNING:

Improper media installation may cause regressed pilot flame, burner ignition issue or can damage the

thermocouple and thermosensor.

Lava Rock Bed

Cover the entire burner plate with lava rock. Add enough layers of lava rocks until it reaches the

underside of the burner.

Do not cover the nozzles with lava rocks.

Make sure no dust or other

particles are inside the nozzles prior to lighting. When a fire pit is equipped with a Pilot Assembly,

make sure that there are no lava rocks inside the pilot cage.

Refractory Stone Placement

A small pool of decorative river rocks should be placed on and around the burner. Make sure that no

rocks are blocking any of the burner nozzles. Rearrange these stones around to deflect flame into a

natural appearance, this is referred to as Flame Sculpting.

Page 17 of 32

GENERAL CARE AND MAINTENANCE

KEEP THE FIRE PIT COVERED WHEN NOT IN USE

Ensure that gas and power (when applicable) are shut off and the fire pit is cool before performing

any service and maintenance.

We recommend that a qualified service technician performs the following maintenance procedure at

the beginning of each fire pit season.

Cleaning the Burner Nozzles

Periodic check, inspection and cleaning of the burner assembly is recommended. This is to avoid

unusual and unwanted flame behaviour as well as ignition failure. To clean the burner nozzles,

remove the refractory stones and lava rocks to allow access to the burner. Use a scotch green pad

or 320 grit sandpaper or a brush to scrape soot and remove any dust, spider web or any particles.

To check for nozzle clogs, use a small paper clip or needle and carefully insert in the burner nozzles.

Remove any clogs if any.

Page 18 of 32

Cleaning of Pilot Assembly

A clean and clear pilot assembly is important to the operation of the fire pit. Pilot not lighting, gas

valve not opening, gas flow not initiating, flame dropouts, to name a few are common occurrences

of a dirty and un-maintained pilot assembly. Hence regular inspection and maintenance is

recommended.

Components of the Pilot Assembly

1. Pilot Nozzle

Remove the pilot cage carefully. By using a knife or any sharp blade, remove any build-up along the

1/16” slit of the nozzles. Purge the debris or dust off using compressed air or using a vacuum

cleaner.

Page 19 of 32

2. Inlet Orifice

The Pilot Orifice can be removed from the bottom of the pilot assembly (bottom of burner plate)

using a 7/16 wrench. Clean the two (2) tiny holes on top of the Inlet Orifice and ensure that you can

see through the 2 tiny holes.

3. Thermosensor

Use a scotch green pad or 320 grit sandpaper to buff and clean the tip of metal stem of the

thermosensor

Page 20 of 32

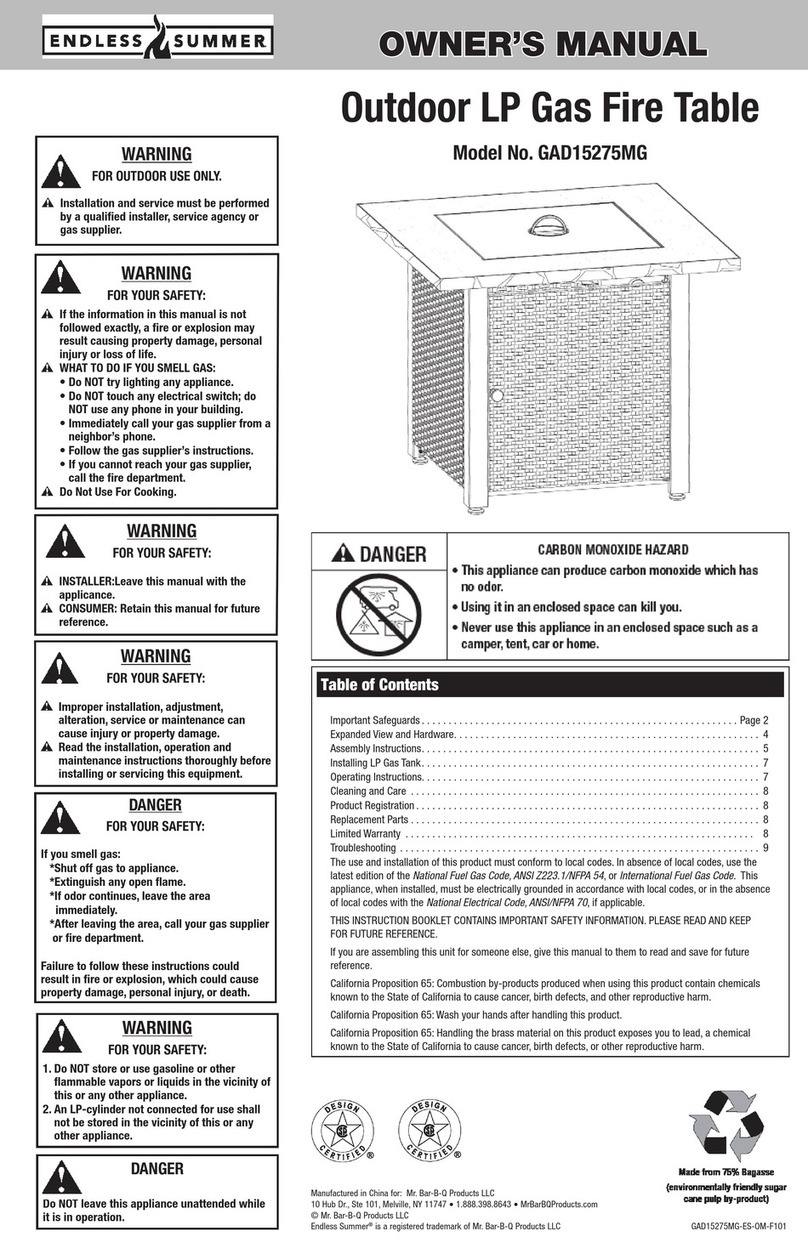

This manual suits for next models

19

Table of contents

Other Solus Outdoor Fireplace manuals

Popular Outdoor Fireplace manuals by other brands

Endless Summer

Endless Summer GAD15275MG owner's manual

Axxonn

Axxonn FT150PWISMLID Assembly instructions

Masport

Masport MAWSON ONE Assembly & Usage Instructions

Cosi

Cosi Cosiflow square User and installation instructions

Sunnydaze

Sunnydaze KF-EN36 Assembly instruction sheet

Sunnydaze Decor

Sunnydaze Decor FSN-700 manual