Solwave 180MWAS12T User manual

Commercial Microwave

SERVICE MANUAL

Models

16400049

180MWAS12T

180MWAS18T

180MWAS21T

Table of Contents

Safety Information......................................................................................................2-4

Installation.................................................................................................................... 6

Specifications............................................................................................................... 7

Owner’s Information................................................................................................. 9-10

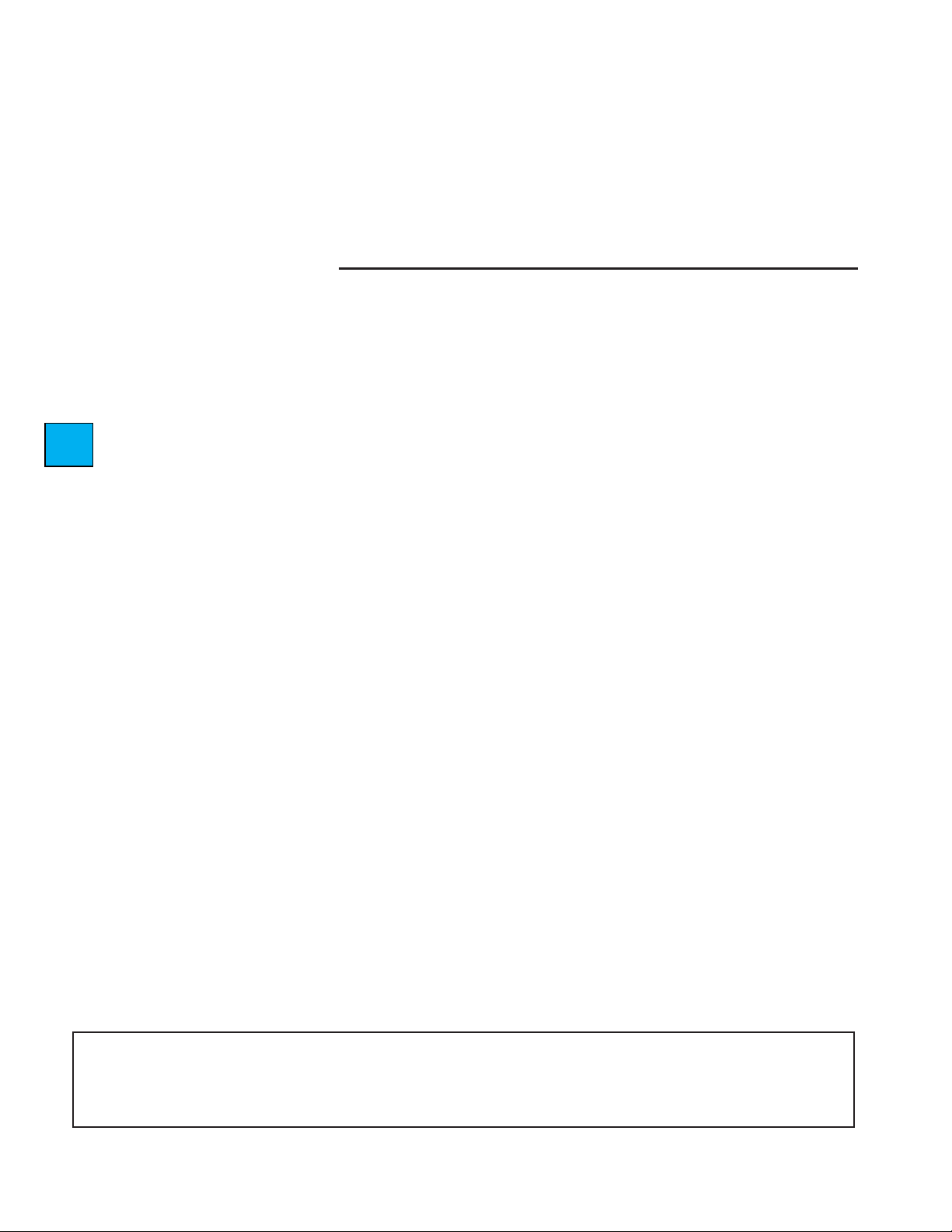

Components Locations. ..............................................................................................12

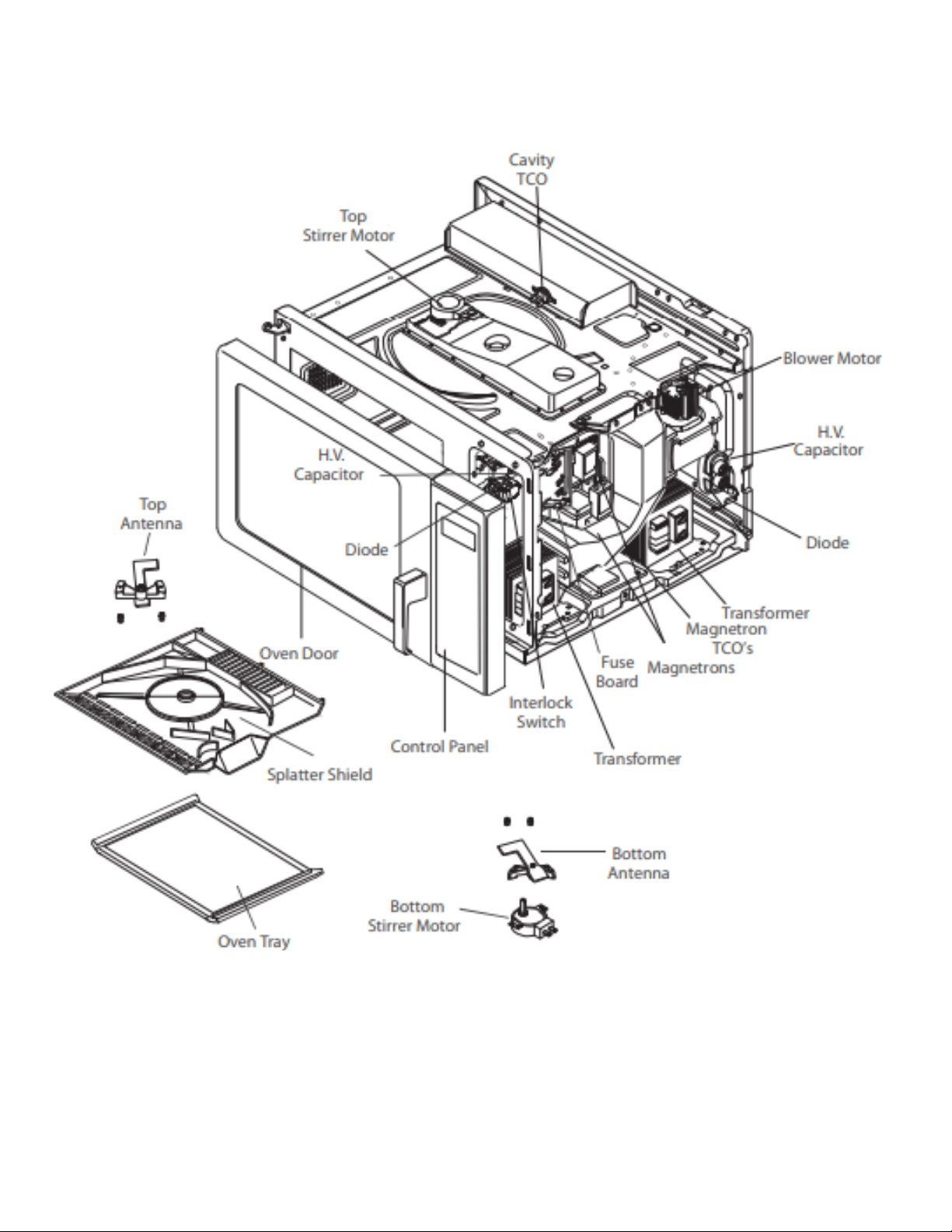

Disassembly.............................................................................................................. 14-15

Performance Testing Procedures. ...............................................................................17

Component Testing Procedures .............................................................................19-20

Error Codes. .............................................................................................................. 20

Service Test Mode . ................................................................................................... 20

Troubleshooting. ......................................................................................................... 22

Schematic / Wiring Diagrams.................................................................................24-25

1

1

Safety Information

2

Safety Information

!

WARNING

Read the following information to avoid possible exposure to microwave energy:

The basic design of the Microwave Oven makes it an inherently safe device to both use and service.

However,there are someprecautions whichshouldbefollowedwhen servicingthemicrowaveto maintainthis

safety. These are as follows:

1.

Always operate the unit from an adequately

grounded outlet. Do not operate on a two-wire

extension cord.

2.

Before servicingtheunit(ifunitisoperable)

perform the microwave leakage test.

3.

Theovenshouldneverbeoperatedifthedoordoes

not fit properly against the seal, the hinges or hinge

bearings are damaged or broken; the choke is

damaged, (pieces missing, etc.); or any other

visible damage can be noted. Check the choke

areato ensurethat this area is clean andfree ofall

foreignmatter.

4.

If the oven operates with the door open and

producesmicrowaveenergy, take thefollowing

steps:

A.

Tell the user not to operate the oven.

B.

ContactSOLWAVE immediately.

5.

Alwayshavetheovendisconnectedwhentheouter

case is removed except when making the "live"

tests called for in the Service Manual. Do not

reach into the equipment area while the unit is

energized. Make all connections for the test and

check them for tightness before plugging the cord

into theoutlet.

6.

Always ground the capacitors on the magnetron

filter box with an insulated-handle screwdriver

before working in the high voltage area of the

equipment compartment. Some types of failures

will leave a charge in these capacitors and the

discharge couldcause areflex actionwhich could

make you injure yourself.

7.

Always remember that in the area of the

transformer there is HIGH VOLTAGE. When the

unit is operating keep this area clear and free of

anything which could possibly cause an arc or

ground, etc.

8.

Do not for any reason defeat the interlock

switches there is not valid reason for this action

at any time.

9.

IMPORTANT: Before returning a unit to a

customer, be sure to check for proper switch

interlock action.

10.

The MicrowaveOven shouldnever be

operated with any components removed and/or

bypassed orwhen any ofthe safety interlocksare

found to be defective, or when any of the seal

surfacesaredefective,missing,ordamaged.

11.

All microwave ovens meet all requirements

ofthe radiation control for Healthand SafetyAct of

1968. Due to measurement uncertainties, the

maximum leakage for the field will be 4mw/cm2.

12.

To ensure that the unit does not emit excessive

microwave leakage and to meet the Department

ofHealthand HumanServicesguidelines,check

theovenformicrowaveleakageusingamicrowave

oven leakage meter that complies with US

GovernmentCDRH/ FDA/ DHHSrequirements

and or any other local government requirements.

The maximum leakage level allowed by

manufacturer

is 4mw/cm 2.

13.

If servicer encounters an emission reading

over

4mw/cm2, the servicer is to cease

repair and contact SOLWAVE

immediately for further direction.

SOLWAVE will contact the proper

Government Agencyuponverificationof

thetestresults.

3

Recognize this symbol as a SAFETY message

!

WARNING

When using electrical equipment, basic safety precautions should be followed to reduce the risk of burns,

electrical shock, fire, or injury to persons including the following.

1. READ all instructions before using equipment.

2. READ AND FOLLOW the specific

“PRECAUTIONS TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE

ENERGY” on this page.

3. This equipment MUST BE GROUNDED. Connect

only to properly GROUNDED outlet. See “

GROUNDING / EARTHING INSTRUCTIONS”.

4. Install or locate this equipment ONLY in

accordance with the installation instructions in

this manual.

5. Some products such as whole eggs and sealed

containers—for example, closed glass jars—are

able to explode and SHOULD NOT be HEATED

in this oven.

6. Use this equipment ONLY for its intended use as

described in this manual. Do not use corrosive

chemicals or vapors in this equipment. This type

of oven is specifically designed to heat, cook,

or dry food. It is not designed for industrial or

laboratory use.

7. As with any equipment, CLOSE SUPERVISION

is necessary when used by CHILDREN.

8. See door cleaning instructions

9. DO NOT heat baby bottles in oven.

10. Baby food jars shall be open when heated and

contents stirred or shaken before consumption, in

order to avoid burns.

11 DO NOT operate this equipment if it has a

damaged cord or plug, if it is not working properly,

or if it has been damaged or dropped.

12. This equipment, including power cord, must be

serviced ONLY by qualified service personnel.

Special tools are required to service equipment.

Contact nearest authorized service facility for

examination, repair, or adjustment.

13. DO NOT cover or block louvers or other openings

on equipment.

14. DO NOT store this equipment outdoors. DO NOT

use this product near water – for example, near a

kitchen sink, in a wet basement, a swimming pool,

or a similar location.

15. DO NOT immerse cord or plug in water.

16. Keep cord AWAY from HEATED surfaces.

17. DO NOT let cord hang over edge of table or

counter.

18. For commercial use only.

PRECAUTIONS TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

A. DO NOT attempt to operate this oven with the door open since open door operation can result in harmful

exposure to microwave energy. It is important not to defeat or tamper with the safety interlocks.

B. DO NOT place any object between the oven front face and the door to allow soil or cleaner residue to

accumulate on sealing surfaces.

C. DO NOT operate the oven if it is damaged. It is particularly important that the oven door close properly and

that there is no damage to the:

1. door (bent)

2. hinges and latches (broken or loosened)

3. door seals and sealing surfaces.

D. The oven should not be adjusted or repaired by anyone except properly qualified service personnel.

4

To avoid personal injury or property damage, observe the following:

1. Do not deep fat fry in oven. Fat could overheat

and be hazardous to handle.

2. Do not cook or reheat eggs in shell or with

an unbroken yolk using microwave energy.

Pressure may build up and erupt. Pierce yolk

with fork or knife before cooking.

3. Pierce skin of potatoes, tomatoes, and similar

foods before cooking with microwave energy.

When skin is pierced, steam escapes evenly.

4. Do not operate equipment without load or food

in oven cavity.

5. Microwave popcorn should not be popped in

oven.

6. Do not use regular cooking thermometers in

oven. Most cooking thermometers contain

mercury and may cause an electrical arc,

malfunction, or damage to oven.

7. Do not use metal utensils in oven.

8. Do not use aluminum foil in oven

9. Never use paper, plastic, or other combustible

materials that are not intended for cooking.

10. When cooking with paper, plastic, or other

combustible materials, follow manufacturer’s

recommendations on product use.

11. Do not use paper towels which contain nylon or

other synthetic fibers. Heated synthetics could

melt and cause paper to ignite.

12. Do not heat sealed containers or plastic bags in

oven. Food or liquid could expand quickly and

cause container or bag to break. Pierce or open

container or bag before heating.

13. To avoid pacemaker malfunction, consult

physician or pacemaker manufacturer about

effects of microwave energy on pacemaker.

14. An authorized servicer MUST inspect equipment

annually. Record all inspections and repairs for

future use.

To avoid risk of fire in the oven cavity:

a. DO NOT overcook food. Carefully attend oven

when paper, plastic, or other combustible

materials are placed inside the oven to facilitate

cooking.

b. Remove wire twist-ties from paper or plastic

bags before placing bag in oven.

c. If materials inside the oven ignite, keep oven

door CLOSED, turn oven off and disconnect

the power cord, or shut off power at the fuse or

circuit breaker panel.

d. DO NOT use the cavity for storage. DO NOT

leave paper products, cooking utensils, or food

in the cavity when not in use.

WARNING

Liquids such as water, coffee, or tea are able to

be overheated beyond the boiling point without

appearing to be boiling due to surface tension of the

liquid. Visible bubbling or boiling when the container

is removed from the microwave oven is not always

present. THIS COULD RESULT IN VERY HOT

LIQUIDS SUDDENLY BOILING OVER WHEN A

SPOON OR OTHER UTENSIL IS INSERTED INTO

THE LIQUID. To reduce the risk of injury to persons:

i) Do not overheat the liquid.

ii) Stir the liquid both before and halfway through

heating it.

iii) Do not use straight-sided containers with narrow

necks.

iv) After heating, allow the container to stand in the

microwave oven for a short time before removing

the container.

v) Use extreme care when inserting a spoon or

other utensil into the container.

WARNING

5

Model Specifications

Installation

·

Unpacking the oven

·

Radio Interference

·

Oven Placement

Specification

·

Input- Power Source

·

Output- Power Source

·

Power Consumption

·

Cavity Dimension

·

Weight

2

6

Installation

Unpacking Oven

• Inspect oven for damage such as dents in door or

dents inside oven cavity.

• Report any dents or breakage to source of purchase

immediately. Do not attempt to use oven if damaged.

• Remove all materials from oven interior.

• If oven has been stored in extremely cold area, wait a

few hours before connecting power.

Radio Interference

Microwave operation may cause interference to radio,

television, or a similar oven. Reduce or eliminate

interference by doing the following:

• Clean door and sealing surfaces of oven according to

instructions in Owner’s Manual.

• Place radio, television, etc. as far as possible

from oven.

• Use a properly installed antenna or cable on radio,

television, etc. to obtain stronger signal reception.

Oven Placement

• Do not install oven next to or above source of heat,

such as pizza oven or deep fat fryer. This could cause

microwave oven to operate improperly and could

shorten life of electrical parts.

• Do not block or obstruct oven filter. Allow access for

cleaning.

• Install oven on level countertop surface.

A- Allow at least 2 in / 5.1 cm of clearance

around top and sides of equipment.

Proper air flow around equipment cools

electrical components. With restricted

air flow, oven may not operate properly

and the life of electrical parts is

reduced.

B -There is not an installation clearance

requirement for the back of the oven

C – Allow at least 1 in / 2.54 cm clearance

around sides of oven

•Oven stacking is allowed using stacking

bracket located on oven back panel top hinge

side corner

•Using stacking brackets on back panel of

ovens remove screws from stacking brackets

and reattach them to back panel between both

ovens securing them together using back

panel screws

7

Specifications

Power Source

Voltage AC

120V

208-240V

208-240V

Amperage

16A

20A

20A

Frequency

60 Hz

60 Hz

60 Hz

Single Phase, 3

wire grounded

Yes

Yes

Yes

Plug Configuration /

Cord

NEMA 5-20

NEMA 6-20

NEMA 6-20

Power Output

Nominal

microwave

energy

(IEC705)

1200W

1800W

2100W

Minimum

temperature rise

12°F / 6.5°C

18°F / 7.7°C

21°F / 11.5°C

Operating

Frequency

2450 MHz

2450 MHz

2450 MHz

Power

Consumption

16A

13.5A

15.5A

Cook Condition

Microwave

2000W

2800W

3200W

Dimensions

Cabinet

Width

21 3/4” (551)

21 3/4” (551)

21 3/4” (551)

Height

14 3/8” (365)

14 3/8” (365)

14 3/8” (365)

Depth

21” (533)

21” (533)

21” (533)

Cavity Dimensions – 1.2 cu ft

Width

14 1/8” (359)

14 1/8” (359)

14 1/8” (359)

Height

8 7/8” (226)

8 7/8” (226)

8 7/8” (226)

Depth

16 1/4” (413)

16 1/4” (413)

16 1/4” (413)

Weight

Crated

71 lbs. (32 kg)

77 lbs. (35 kg)

77 lbs. (35 kg)

Uncrated

66 lbs. (30 kg)

70 lbs. (32 kg)

70 lbs. (32 kg)

Models 180MWAS12T 180MWAS18T 180MWAS21T

8

Owner’s Information

Clean Filter

Control Panel

·

Manual Operation

·

Programming Items

User Options

·

Changing Options

3

9

Owner’s Information

CLEAN FILTER

This oven displays

CLEAN FILTER

at user

defined intervals. When the message

displays SOLWAVE recommends

cleaning the air filter thoroughly.

Cleaning the air filter will not shut off

the message.

The message will stop displaying

automatically after 24 hours. Depending

on microwave use and environmental

conditions, the filter may need to be

cleaned more frequently. Once the

frequency is determined, set the option

for

the appropriate time frame.

Preprogrammed

Pads

To cook food

using preprogrammed

cooking sequences:

1. Open oven door and place food

in oven. Close door.

2. Press desired pad.

3. Oven begins to cook.

4. At end of cooking cycle oven

beeps and shuts off.

X2

Programming

(if equipped)

To change the cooking factor:

1. Open oven door.

2. Press and hold pad 1 for

approximately 5seconds.

3. Press pad to bereprogrammed.

4. Press the QTY 2X pad.

5. Press a numbered pad to

change the cookingfactor.

• Cooking factor can be set from

10% to 100%.

• Default is 80%.

• Pad 5 would changethe

cooking factor to 50%.

6. Press START pad tosave

changes.

Electronic Control

Manual Operation

To cook food using a specific entered time and power level:

1. Open oven door and place food in oven. Close door.

2. Press TIME ENTRY pad and enter cooking time.

3. Press a power level pad to change power level if desired (some

models).

•

COOK LEVEL

displays with the power setting.

4. If stage cooking is desired, press TIME ENTRY pad and repeat steps

2 through 4, (some models).

5. Press START pad.

6. At end of cooking cycle oven beeps and shuts off.

Programming Items

1. Open oven door.

2. Press and hold pad 1 for approximately 5 seconds.

3. Press pad to be reprogrammed.

4. Enter cooking time by using the number pads.

5. Press a power level pad to change power level ifdesired.

6. If stage cooking is desired, press TIME ENTRY pad.

• Display briefly shows the stage number.

• Display changes to cook time and power level for the next stage.

7. Enter cook time and power level as in steps 4 and 5 (some models).

• To enter another cooking stage for that pad, press TIME ENTRY pad

again.

• Up to four different stages can be programmed (some models).

8. Press START pad to set new programming changes to the pad.

NOTE:

To discard changes, press STOP/RESET pad or close oven door.

X2 Pad (if equipped)

1. Open oven door and place food in oven. Close door.

2. Press QTY 2X pad.

3. Press desired preprogrammed pad or pad sequence.

4. Oven begins cooking. Displayed cooking time is the total of original

cooking time and added 2X time.

The switching operation of this microwave oven can cause voltage fluctuations on the supply line. The operation of this oven under

unfavorable voltage supply conditions can have adverse effects. This device is intended for the connection to a power supply system

with a maximum permissible system impedance Zmax of

0.2 Ohms

at the interface point of the user’s supply. The user has to

ensure that this device is connected only to a power supply system which fulfills the requirement above. If necessary, the user

can ask the public power supply company for the system impedance at the interface point.

7

10

DO NOT power spray

No metal pans

Options such as single or double digit programming, beep volume, and

maximum cooking time can be changed to suit individual preferences.

To change options:

1. Open oven door.

• If door is closed or RESET pad is pressed before programming is complete,

changes are discarded and microwave exits programming mode.

2. Press and hold pad 2 for approximately 5 seconds.

• This begins options mode.

• Microwave will beep and 0P: displays.

3. Press number pad that controls option to be changed.

• See table below for options.

• Current option will display.

4. Press number pad again to change the option.

• Each time pad is pressed, option will change.

• Match code displayed with code for desired option.

5. Press START pad to save changes.

• To change additional options, repeat steps 3 and 4.

• Changes appear after door is closed or STOP/RESET pad is pressed.

Numbered Pads

Display

Options

1

End of Cycle Beep

OP:10

OP:11

OP:12

3 second beep.

Continuous beep until door is opened.

5 beep bursts until door is opened.

2

OP:20

Eliminates beep.

Key Beep Volume

OP:21

Sets volume to low.

OP:22

Sets volume to medium.

OP:23

Sets volume to high.

3

Key Beep

OP:30

OP:31

Prevents beep when pad is pressed.

Allows beep when pad is pressed.

4

Active Display

OP:40

OP:41

OP:42

15 seconds after oven door is opened, keyboard disabled.

30 seconds after oven door is opened, keyboard disabled.

1 minute after oven door is opened, keyboard disabled.

OP:43

2 minutes after oven door is opened, keyboard disabled.

5

On-the Fly Cooking

OP:50

OP:51

Prevents

Allows

.

.

6

Reset to Ready Mode

OP:60

OP:61

Opening oven door does not reset oven back to ready mode.

Opening oven door resets oven back to ready mode.

7

(some models)

MaximumHeatingTime

OP:70

OP:71

Allows 60 minutes of heating time (some models).

Allows 10 minutes of heating time.

8

Manual Operation

OP:80

OP:81

Allows use of preprogrammed pads only.

Allows use of manual time entry and preprogrammed pads.

9

(some models)

Double Digit Operation

OP:90

OP:91

Allows 10 (0-9) preprogrammed pads.

Allows 100 (00-99) preprogrammed pads.

0

OP:00

Do not display message.

Clean Filter Message

OP:01

Display message for 24 hours every 7 days.

OP:02

Display message for 24 hours every 30 days.

OP:03

Display message for 24 hours every 90 days.

11

4

Components Location

12

Components Location

13

Disassembly

Door Removal

·

Disassembly

Control Removal

·

Wire terminals

5

14

Disassembly

Door Removal

1.

Disconnect power tooven.

2.

Open oven door, remove top hinge cap, and slowly lift door to disengage the hinge pins at top and bottom.

3.

To reinstall door, place top pin into slot first, then align bottom pin.

4.

Reinstall top hinge cap.

Choke

cover

Outer

Door

panel

Latch

assembly

* Door

Handle

Doorframe/

Spring

choke assembly

*Apply thread lock compound to threads, tighten side screw first.

Top

cap

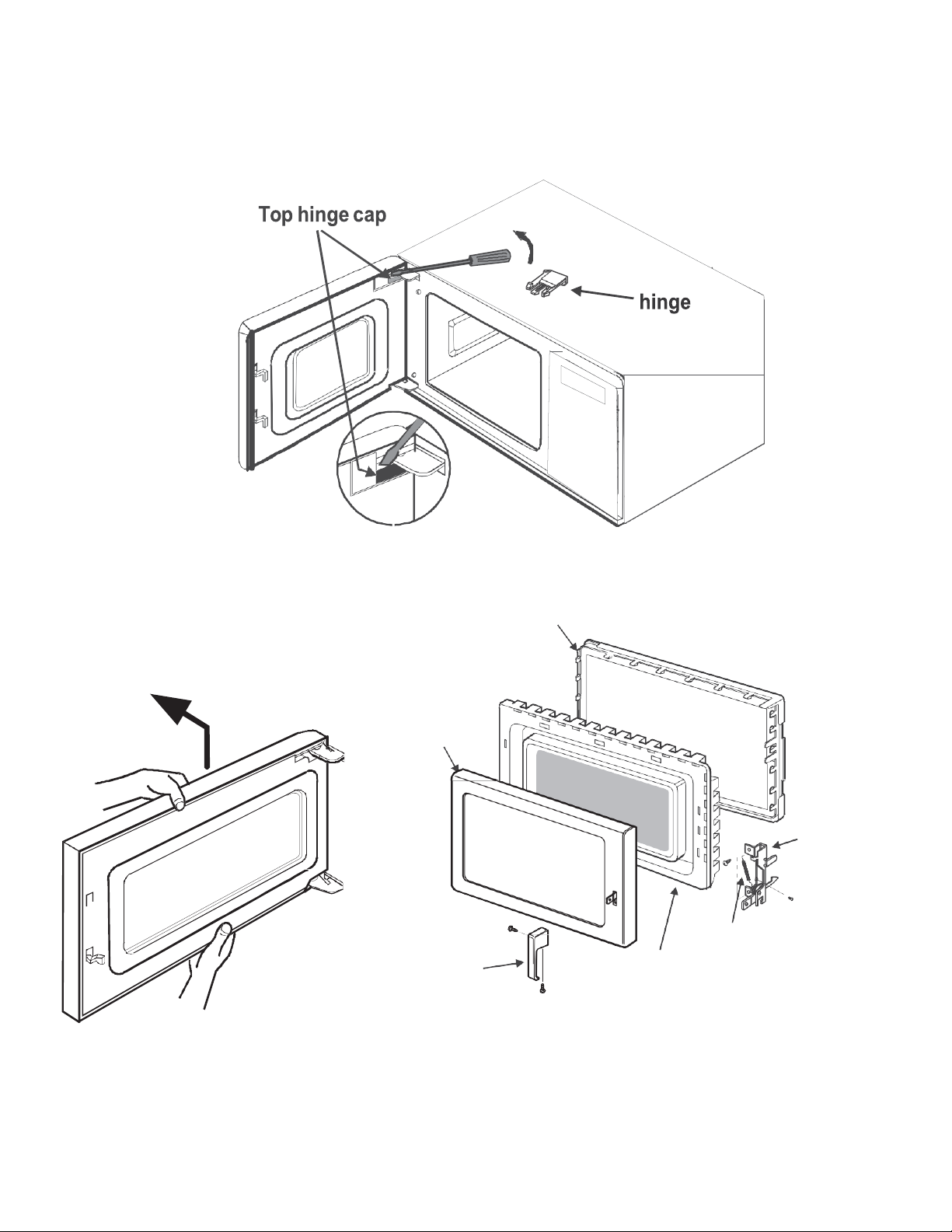

15

Control Panel Removal

1.

Disconnect power to oven and remove outer case.

2.

Disconnect and label wires from controller/timer.

3.

Open oven door.

4.

Remove screw securing top of control panel to cavity. Lift control panel up and out to release tabs.

Disconnecting Wire Terminals

All wire terminals are locking-type terminals.

Proceed as follows to disconnect wire terminals:

Insulated terminals:

Grasp insulator and pull back. DO NOT PULL ON WIRE.

Non-insulated terminals:

Use a small blade screwdriver to depress locking-tab and pull on terminal. DO NOT PULL ON WIRE.

2 Pull

Pod

1 Grasp

1

Release

locking-tab

2 Pull

16

Performance Testing

6

17

Performance Testing

All SOLWAVE microwave oven power outputs are rated using the IEC705 standards. Using the IEC705 test

method requires precision measurements and equipment that is not practical to be performed in the field. Using

the test shown below will indicate if the oven performance is satisfactory.

Test equipment required:

•

1000 ml test container and thermometer.

•

Digital watch / watch with a second hand for use on ovens with electromechanical timers.

Important Notes:

•

Low line voltage will cause low temperature rise / power output.

•

Ovens must be on a dedicated circuit, properly grounded, and polarized. Other equipment on the same

circuit may cause a low temperature rise / power output.

•

This test and results are not a true IEC705 test procedures and are only intended to provide servicers with

an easy means of determining if the microwave oven cooking output is correct.

Procedure

1.

Determine correct Power Output Wattage by referring to Model/Serial tag.

2.

Fill the test container to the 1000 ml line with cool tap water.

NOTE: Water temperature should be approximately 65°F / 16°C

3.

Using the thermometer, stir water for five to ten seconds; measure, and record the temperature (T1).

4.

Place test container of water in the center of oven cavity and close door.

5.

Heat the water for a 33-second full power cycle.

NOTE: Use a digital watch or a watch with a second hand for ovens with electromechanicaltimers.

6.

At end of the cycle, remove test container. Using the thermometer, stir water for five to ten seconds and record

temperature (T2).

7.

Subtract the starting water temperature (T1), from the ending water temperature (T2) to obtain the temperature

rise (∆T).

8.

If the temperature rise (∆T) meets or exceeds the minimum, the test is complete. If the temperature rise (∆T)

fails to meet the minimum temperature rise, test the line voltage to verify it is correct. Then repeat steps 1 - 6

making sure to change the water. If the temperature rise (∆T) fails to meet the minimum temperature rise again

the oven will require service.

Minimum Temperature Rise at Thirty -Three (33) Seconds Run Time

∆T Cooking

(°F) Power Output

∆T Cooking

(°F) Power Output

∆T Cooking

(°C) Power Output

∆T Cooking

(°C) Power Output

10 ................. 1000

20 ................. 2000

5 .............. 1000

11............ 2000

11 ................. 1100

21 ................. 2100

5.5 ............ 1100

11.5......... 2100

12 ................. 1200

22 ................. 2200

6.5 ............ 1200

12............ 2200

14 ................. 1400

24 ................. 2400

7.5 ............ 1400

13............ 2400

17 ................. 1700

25 ................. 2500

9.5 ............ 1700

13.5......... 2500

18 ................. 1800

27 ................. 2700

10 ............. 1800

15............ 2700

19 ................. 1900

30 ................. 3000

10.5 .......... 1900

16.5......... 3000

To avoid risk of electrical shock, personal injury or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires it.

18

Component Specifications

7

This manual suits for next models

2

Table of contents

Other Solwave Microwave Oven manuals

Solwave

Solwave 180MW1000SS User manual

Solwave

Solwave 180MW1000D User manual

Solwave

Solwave 180MWHD12 User manual

Solwave

Solwave 180MW112T User manual

Solwave

Solwave 180MWASHD12 User manual

Solwave

Solwave SWAFP Series User manual

Solwave

Solwave 180MW1000D User manual

Solwave

Solwave 180MW1200T User manual

Solwave

Solwave 180MW1000T User manual

Solwave

Solwave SWA-T Series User manual