5

Owner’s Information

(C)

(i) (ii) ( iii) (iv) (v) (vi)

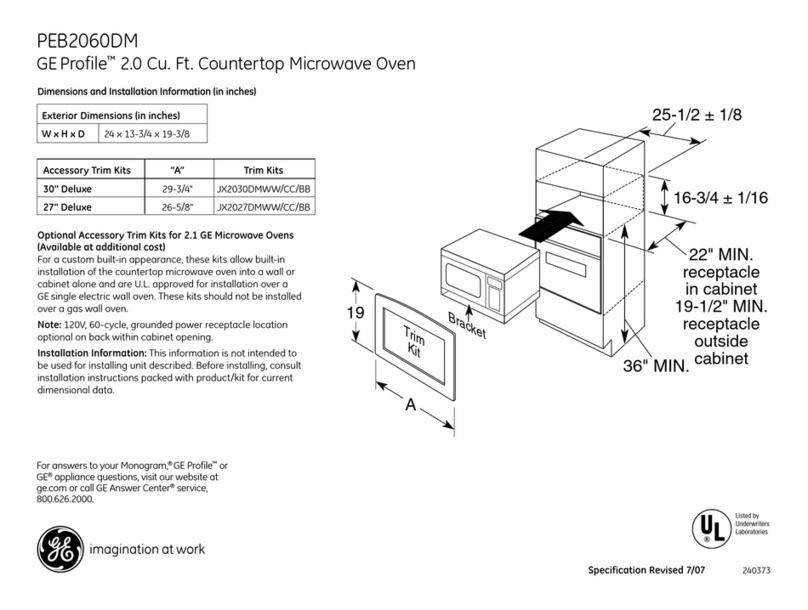

OVEN CLEARANCES

A.

Allow at least 2” (5.1 cm) of clearance

around top of oven. Proper air

flow around oven cools electrical

components. With restricted air flow,

oven may not operate properly and life

of electrical parts is reduced.

B.

SWAHD12 & SWAHD18 models:

There is not an installation clearance

requirement for the back of the oven.

SWAHD21: Allow at least 1” (2.54

cm) of clearance around back of

oven.

C.

Allow at least 1” (2.54 cm) of clearance

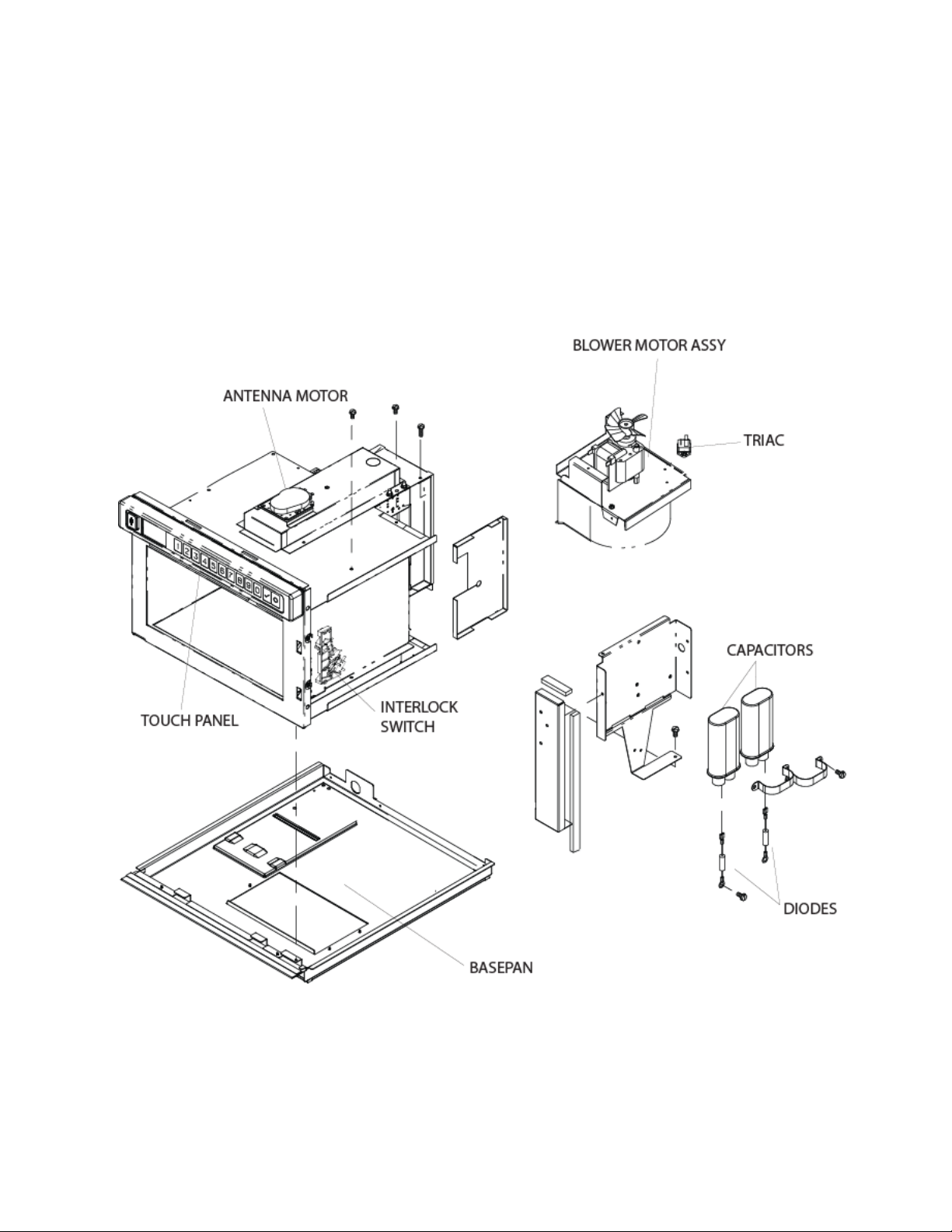

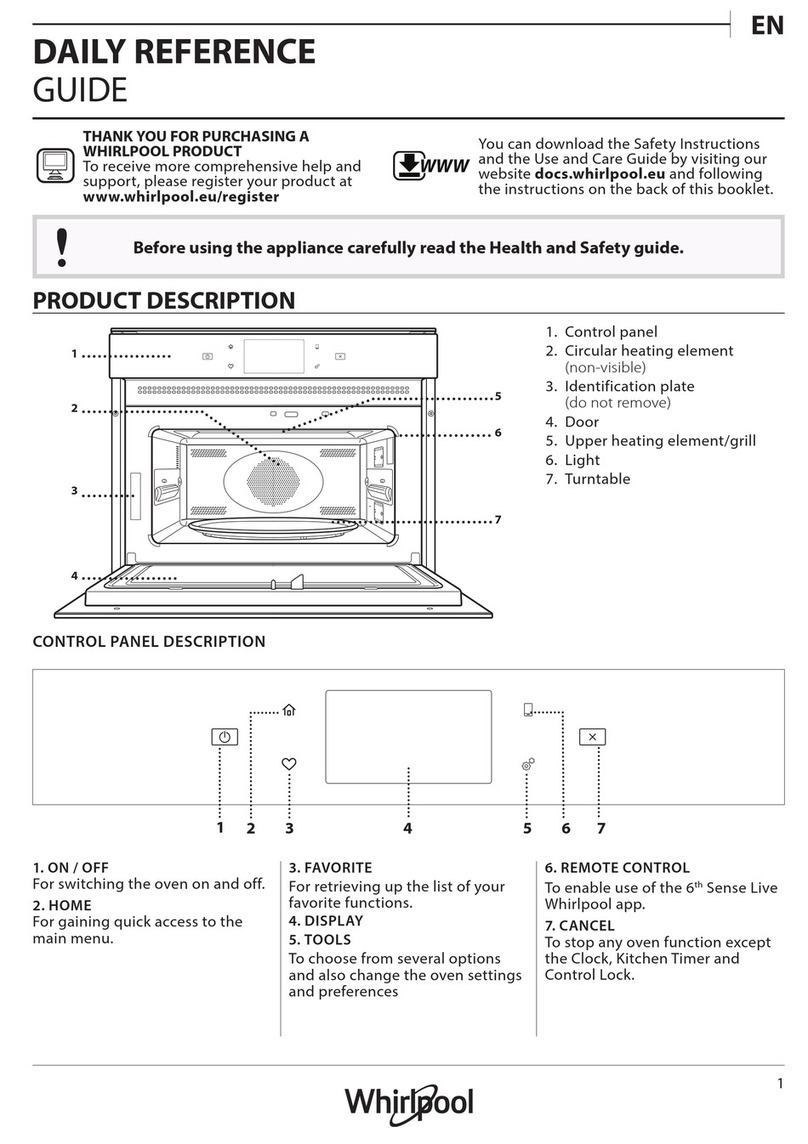

CONTROL PANEL FEATURES

(A)

USB Port

(B)

Display

(C)

Number Keypads

(D)

Start/ OK Keypad

(E)

Stop/ Reset Keypad

(F)

Secondary Function Keypads

To activate, press and hold corresponding

number keypad.

(i)

Manual Time Entry Mode (keypad “1”)

(ii)

Power Level (keypad “2”)

(iii)

Programming Mode (keypad “3”)

(iv)

User Options (number keypad “4”)

(v)

X2 - Double Quantity Cooking (keypad “5”)

(vi)

Menu A/B (keypad “6”)

around sides of oven.

D.

Install oven so oven bottom is at least

3 feet (91.5 cm) above floor.

Preset Program Keypads

To cook food using preprogrammed cooking

sequences:

1.

Open oven door, place food in oven,

and close oven door.

2.

Press desired number keypad(s).

3.

Oven operates and time counts down.

4.

At the end of the cooking cycle, the

oven beeps. Carefully remove food

from oven.

X2 - DOUBLE QUANTITY COOKING

1.

Press and hold number keypad “5”/ X2

to toggle double quantity feature ON.

“X2” appears at top center of screen

when enabled.

2.

Press desired number keypad(s).

Display counts down cooking time for

two quantities.

MENU A/B (select models)

Press and hold number keypad “6” to toggle

between A and B menus.

Manual Time Entry Mode

Time entry mode allows the user to manually enter cook time and power level, without

changing the preset program keypads.

1.

Open oven door, place food in oven, and close door.

2.

Press and hold number keypad “1”/ TIME ENTRY.

3.

Press number keypads to enter desired cook time.

4.

Press and hold number keypad “2”/ POWER LEVEL to change power level.

•

Press number keypads to enter % microwave power (“1”=10%, “2”=20%,etc.)

For 100% power level, press and hold number keypad “2”/ POWER LEVEL.

5.

Press START/OK keypad to begin cooking.

6.

At the end of the cooking cycle, the oven beeps. Carefully remove food from oven.

Programming Mode

1.

Press and hold number keypad “3”/ PROGRAM.

2.

Press number keypad(s) to open the desired program location.

3.

To edit name: Press number keypad “0”. Press number keypads to enter recipe name.

Press START/OK keypad.

4.

To edit cook time for Stage One: Press number keypad “1”. Press number keypads to

enter cook time. Press START/OK keypad.

5.

To edit power level for Stage One: Press number keypad “5”. Press number keypads to

enter % microwave power (“1”=10%, “2”=20%,etc.). For 100% power level, press and hold

number keypad “2”/ POWER LEVEL.

6.

If stage cooking is desired, repeat steps 4-5 for each additional stage, substituting

corresponding number keypads for each stage.

7.

To save and exit programming mode: Press START/OK keypad.