Somati system FSTronic IRC-FI User manual

Control unit FSTronic IRC-FI

Designed for drives of sliding (or vertically moving

with counter weight) fire gates with system of battery

backup

Content:

1. Power supply .......................................................... 2

2. Configuration .......................................................... 2

3. Installation and setting............................................. 4

4. Connection of other external devices....................... 11

5. Description of control and terminal blocks................ 13

6. Counter of cycles on control panel .......................... 24

7. Value report on the functional display...................... 25

8. Errors on frequency invertor................................... 27

9. Connectors............................................................ 28

10. Control panel ........................................................ 30

11. Regular service...................................................... 32

12. Circuit diagrams .................................................... 34

manual for version: IRC-FI v 1_0

version

STANDARD

Vrersion

COMPACT

www.somati-system.cz

2

1. Basic data and power supply

Casing size: 400 x 400 x 210 mm (W x H x D)

Weight: 23 kg (without batteries 18kg)

Installation: vertically on the wall

Connection: the inlets and outlets of the power and control

circuits are via PG bushings on the underside of the

switchboard

Voltage system: 1-N-PE, 50 Hz, 1 x 230 V, TN-S

Input fusing: see table with versions and sizes according to

frequency invertor

! if RDC (Residual current device) is udes

sensitivity not lees than 100mA !!

Unit supply current: 0,3A without external devices and accumulators

0,6A without external devices and with charging

Of accumulators. Current under load acc. to size

Operating voltage: 24 VDC

Output voltage for ext. devices: max.24 VDC/1,2A –max for each output see details

of outputs –sum cannot exceed max. 1,2A

Output voltage for motor brake: 103 VDC/0,3A

Output voltage for motor: 0÷125 Hz, 3 x 0÷230 VAC

Control inputs: 24V/10mA pro bezpotenciální kontakty

Accumulators: part of control unit –2pcs 12V/7-10Ah

additionals –up to 3 sets of 2pcs 12V/7-10Ah

Fusing of accumulators: ceramic fuse 10x38 gG in disconnector

tube fuse F6,3A in transformator SCP-35-24

Operating temperature: +10°C up to +35°C, at temperatures above + 25 ° C

and below + 15 ° C the battery life decreases.

Exceptionally, it can be operated at lower

temperatures up to -5 ° C, provided that it is

permanently connected to a power supply that

provides heating of the circuits.

Air humidity: max 93% without condensation

Degree of protection: IP 54

Protection against electric shock is made according to ČSN 33 2000-4-41 by automatic

disconnection of defective part from power supply and supplementary connection of safety

circuits.

2. Configuration

FSTronic IRC-FI is designed to control drive of sliding (or vertically moving with counter weight)

fire gates - using asynchronous motors (eg. EPO) with system of battery back up.

Power supply of control box is backed up by batteries to close gate (or to open gate)

in case of power failure, using special battery backup system and frequency inverter. In case

of power failure gate stays in position, in which the power failure occurred, for the set time

www.somati-system.cz

3

(0 - 30 min.) in parameter “8” or until the battery is discharged to a critical level –gate

closes if the power supply is not restored and battery voltage drops below the limit 22,0 V.

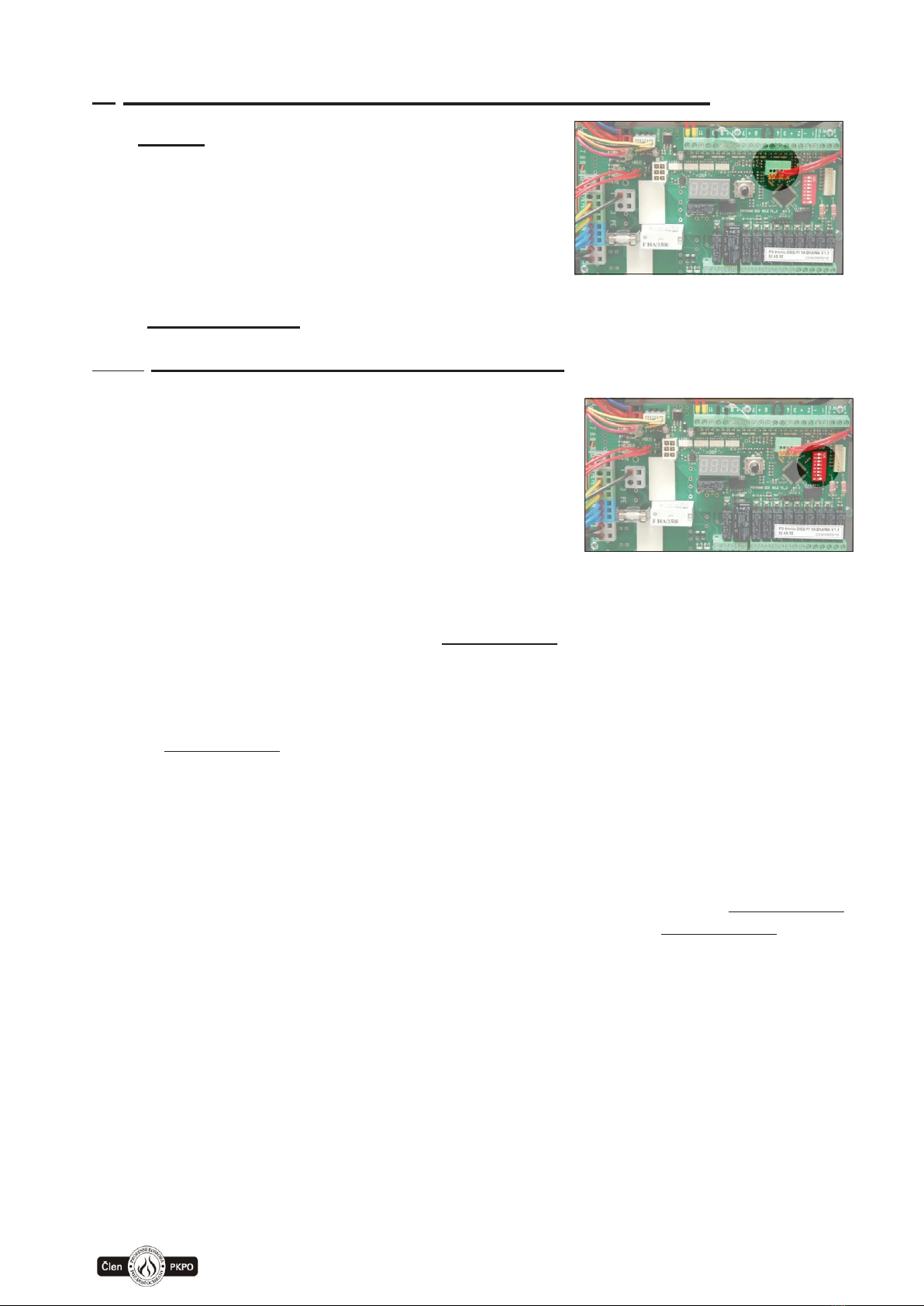

Control box FSTronic IRC-FI is supplied in two basic types according to motor performance

and size of frequency inverter:

FSTronic IRC-FI STANDARD:

Description of versions FSTronic IRC-FI with batteries in control unit

series

2A

4A

Type of

FSTronic

FSTronic IRC-FI 2A STANDARD

FSTronic IRC-FI 4A STANDARD

Main inner

fusing

LTNB10 –10A

LTNB10 –10A

Type of

inverter

Yaskava

CIPR-GA50CB002EBAA-BAAASA

With integrated filter

CIPR-GA50CB004EBAA-BAAASA

With integrated filter

motors

EPO 120W

EPO 250W

EPO 180W

EPO 350W

FSTronic IRC-FI COMPACT:

Description of versions FSTronic IRC-FI with batteries in control unit

series

2A

4A

Type of

FSTronic

FSTronic IRC-FI 2A COMPACT

FSTronic IRC-FI 4A COMPACT

Main inner

fusing

LTNB10 –10A

LTNB10 –10A

Type of

inverter

Yaskava

CIPR-GA50CB002EBAA-BAAASA

With integrated filter

CIPR-GA50CB004EBAA-BAAASA

With integrated filter

motors

EPO 120W

EPO 250W

EPO 180W

EPO 350W

FSTronic IRC-FI is available in the COMPACT version, this version differs from the basic version only in

the range of standard equipment - the COMPACT version does not include a keyswitch lock on the control

panel.

1. Installation and setting

Drive control unit is pre-set by parameter “r” for motor with which is deliveried or for the

weakest motor, control unit permanently verifies correct setting of frequency inverter

parameters. It is necessary to set parameter for motor selection Parameter “r”. To ensure

proper operation we have to install appropriate type of control box designed for particular

motor group or control box designed for a higher group of motors.

www.somati-system.cz

4

After connection of external control devices (controls and end switches) the drive requires

only a control of function. It is important to ensure that the end switches function well.

Their incorrect setting or electric connection can cause damage of mechanical part of gate.

Before putting into operation the installation of mechanical part of gate has to be

completely finished to avoid mechanical damage of gate when starting the motor.

Before starting connect only:

1. Motor cable FSTronic IRC-FI (can be part of motor)

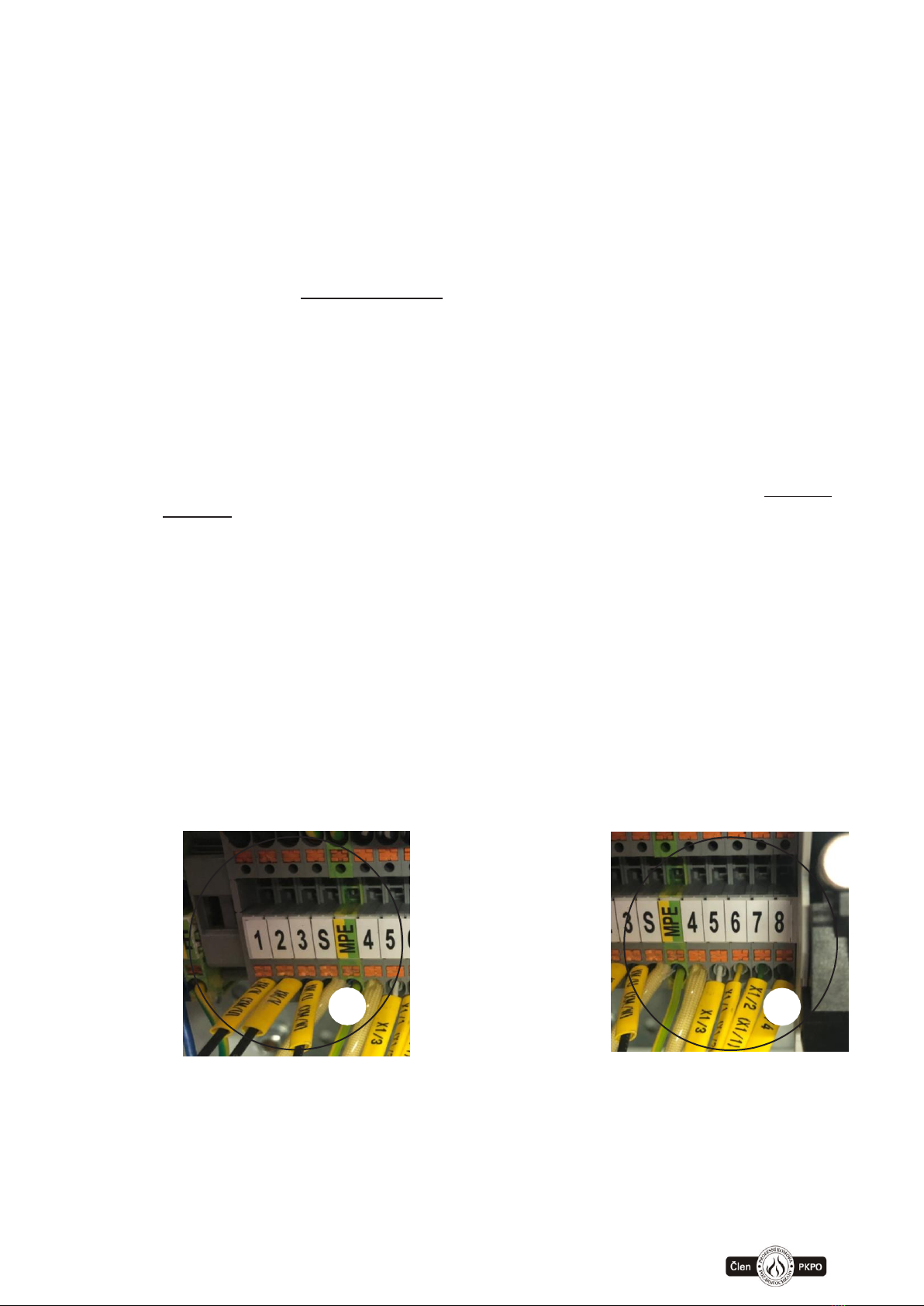

-Motor power - terminal block X4 terminals 1, 2, 3, S, PE (picture 1.1)

oterminal 1 (motor phase) –wire marking XM/U (eventually 1)

oterminal 2 (fáze motoru) – wire marking XM/V (eventually 2)

oterminal 3 (fáze motoru) – wire marking XM/W (eventually 3)

note. - by switching the motor phases, it changes the direction of rotation

- see point 3.1.1 setting the direction of movement

oterminal S (shielding of motor cable) –grey wire without marking

oterminal MPE (ground) –wire green-yellow

-Communication cable of possition sensor IRC –end switches –terminal

block X4 nterminals 4, 5, 6, 7, 8 (picture 1.2)

oterminal 4 (shielding of sensor cable) –grey wire without marking

oterminals 5 a 8 (power supply for sensor 24V)

terminal 5 (0V) –sensor wire marking X1/3 (eventually 5)

terminal 8 (+24V) –sensor wire marking X1/4 (eventually 8)

note - the polarity of the sensor power supply must be correct!!

oterminals 6 a 7 (output signal from sensor)

terminal 6 –sensor wire marking X1/1 (eventually 6)

terminal 7 –sensor wire marking X1/2 (eventually 7)

note - the output signals of the sensor can be reversed, this changes the

direction and the direction of movement must be set / confirmed again,

see.point 3.1

1.2

1.1

www.somati-system.cz

5

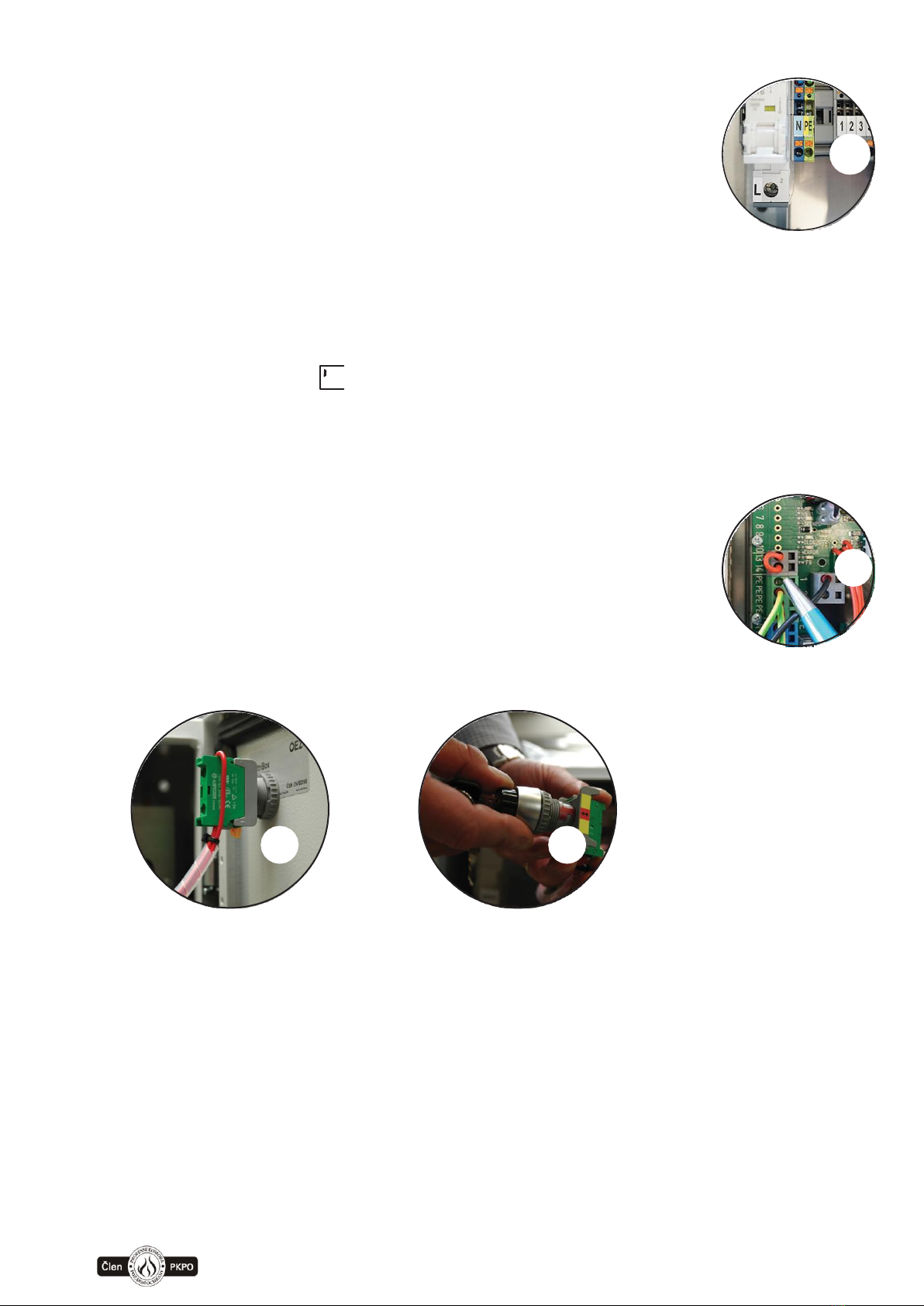

2. Power cable –terminal block X4 terminals L,N,PE

Necessary to connect all wires including

grounding. Without grounding (PE) can be unit

damaged.

After connecting the switchboard to the mains,

the batteries can be connected by inserting a

fuse into the disconnector, see point 3.7

3. Connect terminals EPS - fire contact

(X2:+ and X:10) by default set as input NC contact - can be

changed by parameter (default setting when the door is

open, the door is still in alarm). Originally supplied with the

wire jumper marked “fire contact”.

4. Terminals of safety brake - (X1:13 and X1:14)

or the IRC_FI version, this input is used to block the motor in

the closed position. The input is NO, if it closes in the closed

position then the motor is blocked - it is used for input of the

inductive sensor of the door hook lock. Do not connect the

terminals

5. Install key switch - due to transport is delivered disassembled

Note:

For version compact key switch is not part of standard

delivery. Can be additionally added.

2.

!

4.

5.

5.

www.somati-system.cz

6

6. External battery (voluntarily accessory), recommended only

original accumulators - 24V (2x12V) with fusing

7. Installation of the battery fuse. Fuse is delivered together with control unit,

but is not inserted in connector. Is fixed on the door of control unit. Fuse

type tubular fuse 10x38 gG32a.

Do not connect any external controls or any other devices before setting

the end switches –it can cause automatic start, which is not restricted

due to the unset end switches.

Steps for connection to power:

Connect power supply and only then connect batteries (see point 7.)

Steps for disconnecting power:

First disconnect batteries and then disconnect power supply.

6.

6.

6.

7.

7.

!

www.somati-system.cz

7

3.1. Setting of end switches IRC (incremental)

First check the value of parameter “r”, if is equal to used motor.

If the control panel has already been used in the past, we recommend performing a

complete reset of the control panel by calling the function , see the description

in point 3.2

After switching on the control panel power supply, which has already been set in the

past, an attempt will always be made to find the reference position. The display shows

. that no reference has been made (reference = end point search where the

IRC sensor is reset, by default the reference point is set to the closed position)

Subsequently, a message appears on the display or which indicates

that the door is looking for a reference point (r_CL = referencing to position closed,

r_OP referencing to position open, see parameter settings

The reference position is searched at reduced speed, see parameter settings

When searching for a reference at the moment of reaching the stop (end position),

the drive is overloaded and after the time set by the parameter has elapsed, it

evaluates as reaching the reference point and resets the position sensor.

Unintentional evaluation of the end position can occur if the motor is overloaded when

searching for a reference when there is no free movement of the door - check the

door mechanism.

If the control panel was set up correctly in the past and the door mechanism has not

changed, the drive is ready for use after searching for a reference point (reference).

During referencing, this process can be interrupted and new settings can be made,

proceed according to point 3.1.1

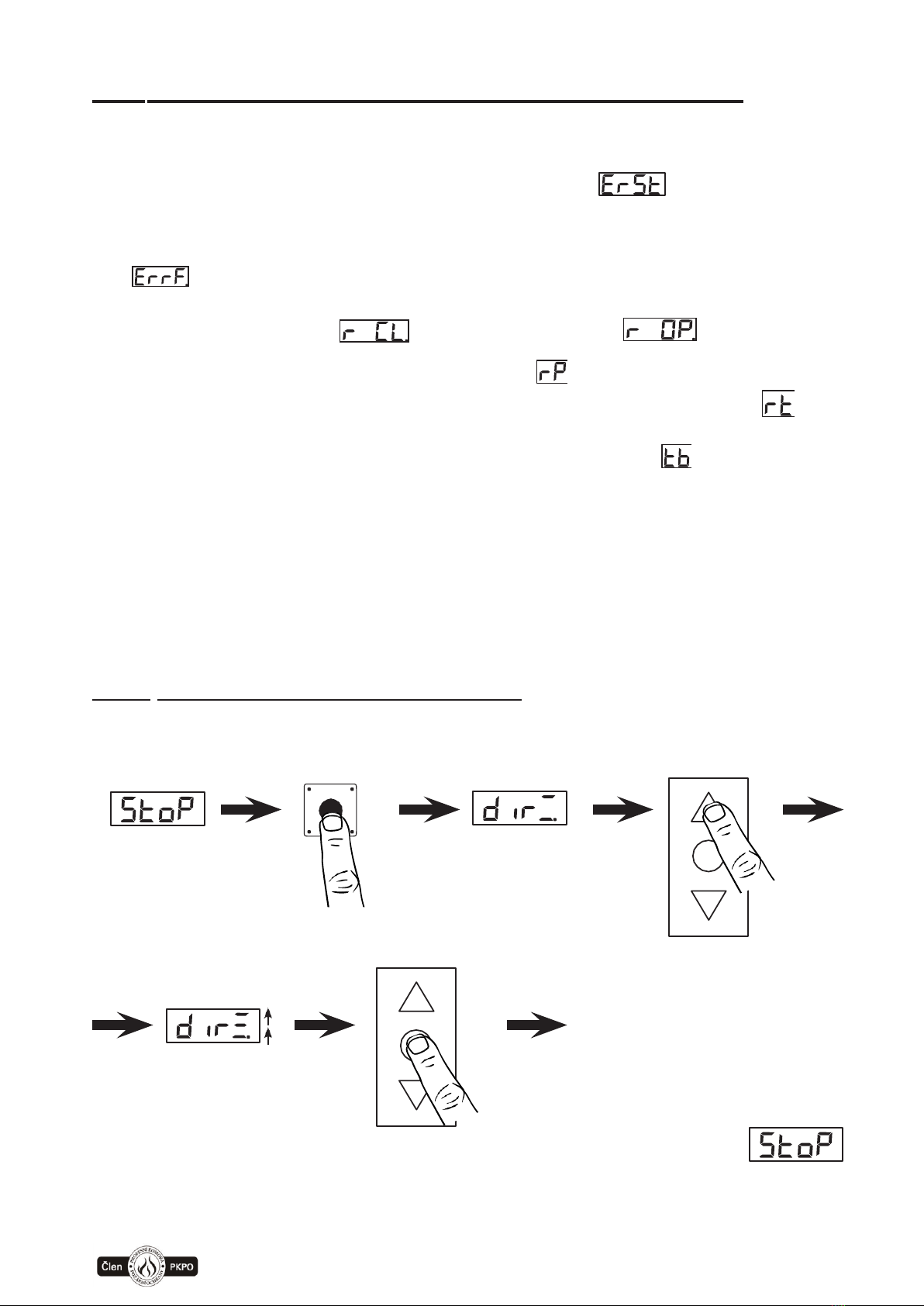

3.1.1. Setting of movement direction:

1. 2.

press 9s press 3s

press

5s

direction saved

Setting is possible only from STOP state, “stop” must be shown on display.

1)

press and hold knob button –during approx. 9 s. it passes to setting of movement,

and display shows „ dir

ˍ

“

(by holding the knob button, after 4 seconds there is at first displayed „Par“ „Par“ it is

!

www.somati-system.cz

8

necessary to hold the knob button until display shows:

a)

„ dir

ˍ

“ –if two horizontal lines light, the direction has been already set

b)

„ dir

ˍ

“ –if two horizontal lines flash, the direction has not been set yet

2)

Afterwards press keyboard buttons “open” or “close” (keyboard has to be unlocked

by key switch), if the movement takes longer than 3 seconds, then three horizontal

segments, shown on the display, start rolling in direction specified with keyboard.

After releasing the button of movement direction, all three segments flashes:

•

if the actual direction of movement is different, it is necessary to switch 2 cable

phase conductors to motor and repeat point 2) setting of movement direction

•

if the direction of movement corresponds, it is possible to save the setting –which

can be done by pressing STOP button on keyboard and holding the button for 5

seconds.

After saving the direction of the movement (by holding STOP on keyboard for 5 seconds)

we automatically proceed to setting of end switches.

It is possible to skip setting of direction („dir“) by pressing knob button – to get directly

to setting of end positions. It is possible to use function „dir“ for manual movement of gate

in emergency situations –only used for service (for example in case of getting out of range

of end positions or during the activation of safety end switches).

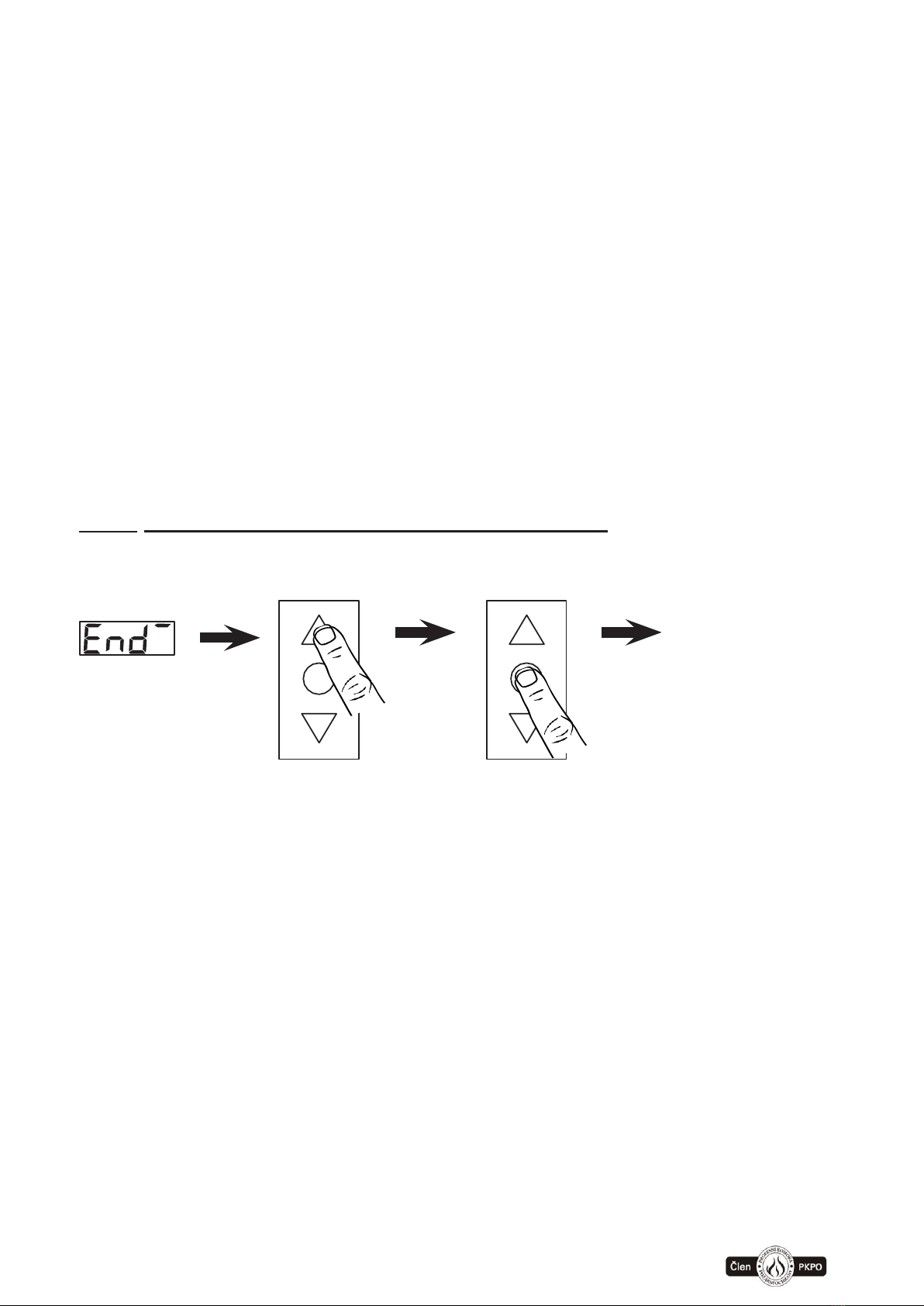

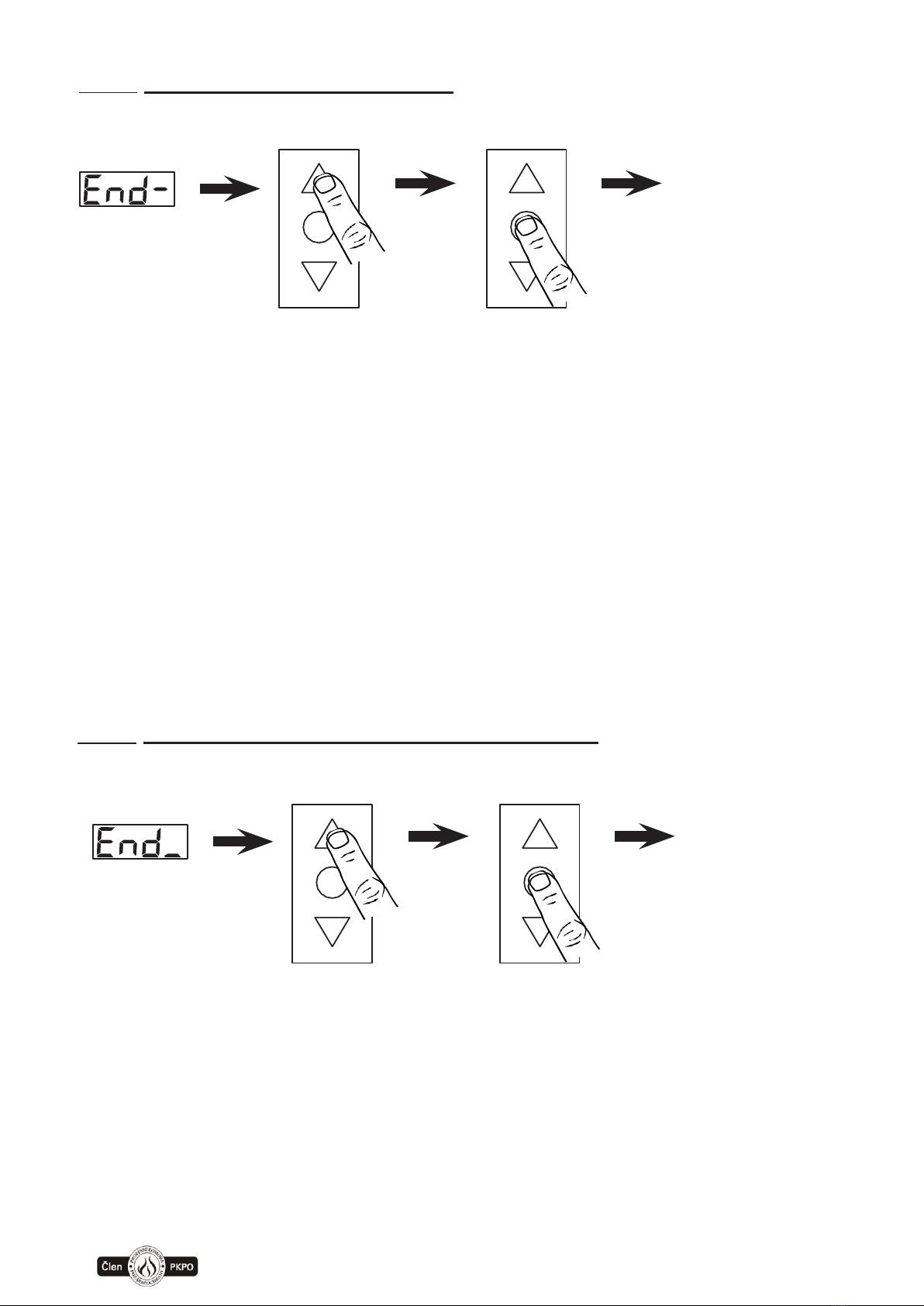

3.1.2. Setting of upper end position „opened“:

press press 5s

upper position

saved

1)

This setting is available automatically after saving the setting of direction or by

pressing knob button, the display shows:

a)

„End “ –if the upper line lights, the position has been already set

b)

„End “ –if the upper line flashes, position has not been set yet

2)

Afterwards press keyboard buttons OPEN or CLOSE (keyboard has to be unlocked

by key switch) and move gate into position, in which we want to set the end position

“opened”:

•

If the actual position of gate corresponds with the required position, it is possible

to save the setting –by pressing STOP button on keyboard and holding the

button

for 5 seconds.

•

After saving the upper end position (by holding STOP on keyboard for 5

seconds) we automatically proceed to setting of middle position.

•

It is possible to skip setting of upper end position (in case it has been already set)

by pressing button knob –then we proceed directly to setting of middle position.

www.somati-system.cz

9

3.1.3. Setting of middle position:

press press 5s

middle position

saved

1)

We can start setting of middle position after saving the position “opened” or by

pressing button knob, there is displayed:

a)

„End - “ –if the middle line lights up, the position has been already set

b)

„End - “ –if the middle line flashes, position has not been set yet

2)

Afterwards press keyboard buttons OPEN or CLOSE (keyboard has to be unlocked

by key switch) and move gate into position, in which we want to set the middle position.

•

If the actual position of gate corresponds with the required position it is possible to

save the setting –by pressing STOP button on keyboard and holding the button

for 5 seconds.

•

After saving the middle position (by holding STOP on keyboard for 5 seconds),

we automatically proceed to setting of lower end position.

•

It is possible to skip setting of the middle position by pressing the knob button –

and proceed to setting of the lower end position –IT IS NECESSARY TO SET the

middle end position to put the gate into standard operation, the middle position is

used for additional functions (e.g. emergency open…)

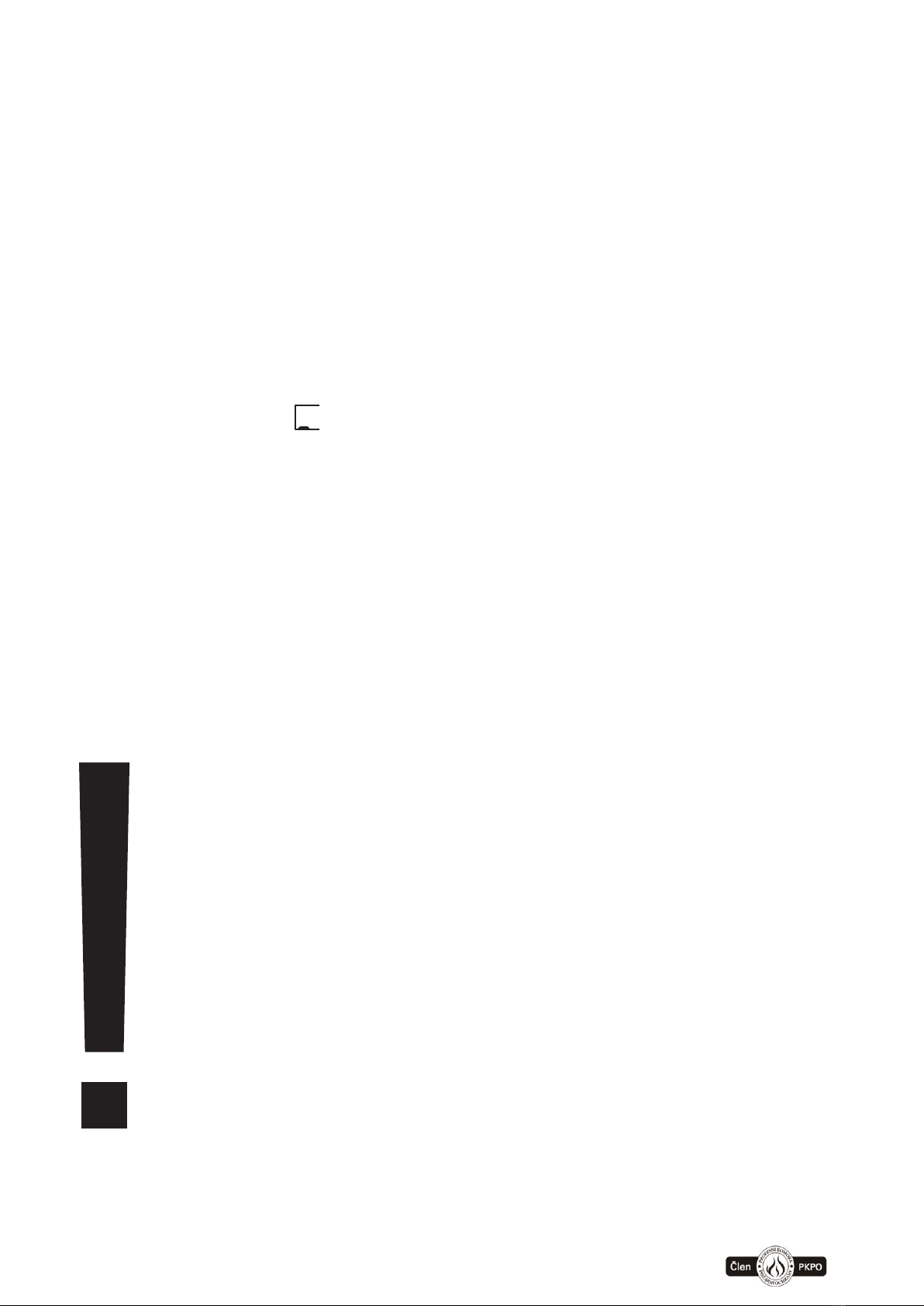

3.1.4. Setting of lower end position „closed “:

press press 5s

lower position

saved

1)

We can start setting of the lower end position after saving the middle position

or by pressing the knob button, on display is shown:

a)

„End ˍ “ – if the lower line lights, the position has been already set

b)

„End ˍ “ – if the lower line flashes, the position has not been set yet

2)

Afterwards press keyboard buttons OPEN or CLOSE (keyboard has to be unlocked

by key switch) and move gate into position, in which we want to set the lower end

position.

www.somati-system.cz

10

•

If the actual position of gate corresponds with the required position it is possible

to save the setting –by pressing STOP button on keyboard and holding the button

for 5 seconds.

•

After saving the lower end position (by holding STOP on keyboard for 5 seconds),

we automatically proceed to calibration of opening time.

•

It is possible to skip setting of the lower end position by pressing knob button –

and proceed to setting of the calibration of opening time.

It is possible to use function „End -“ setting of end positions, for manual movement of gate

in emergency situations –only used for service (for example, when passing the range of

end positions or during the activation of safety end switches).

To put the gate into operation, it is necessary to do final calibration of operation time.

This is a safety function, which is important when preparing gate for standard operation.

3.1.5. Calibration of time and torque (max. motor force)

Calibration of time and torque is a necessary task for the complete commissioning of the

door. If this function is not performed correctly, an error will be displayed, ie a

movement time error or a maximum torque error . This function is safety and is used

to check the movement time and the maximum torque during operation.

During calibration, the maximum running time between the end positions is measured also

the maximum torque when moving the door - this maximum torque can be exceeded during

standard door movement by the value set by the parameter , thus increasing insensitivity

in the event of an obstacle. The time for which the maximum torque can be exceeded is set

in parameters and

press press

Setting of calibration:

It is important to set lower (“closed”) and upper (“opened”) end position.

1)

Display shows „CL“ – by pressing keyboard button CLOSE –to get to position “closed”

(position “closed” has to be set). After setting the position “closed” the motor stops

and display shows „t OP“

2)

By pressing keyboard button OPEN and its holding (without interrupting) we get into

position “opened” (position “opened” has to be set). In “opened” position the motor

stops and unit goes to normal operation –setting of direction and positions

is successfully completed)

If the pressing/holding of keyboard button is interrupted before reaching the opened

position, the setting automatically returns to point 1) and it is necessary to repeat the

calibration process. You have to return to position “closed” and repeat the calibration

process.

www.somati-system.cz

11

It is possible to terminate the calibration by pressing knob button –however, thecalibration

of time is not set and the unit cannot work automatically.

3.2.Complete reset of unit

If necessary it is possible to make complete reset (e.g. in case of using on other motor).

Deletes end positions calibration of the time all parameters will be set to default and

parametr “r” will be set for weakest motor r=1.

Deleting is possible only from STOP state, on display must be shown

Press and hold knob button –after approx. 20s the delete operation

starts, on display is shown “ErSt”. Reset must be confirmed.

a)

If we press knob button –we return to STOP state without deleting)

b)

If we turn the knob, select “YES” and press knob button –the deletion is accomplished

and we return to “STOP”.

c)

If we turn the knob, select ESC and press knob button –we return to STOP

without deletion.

4. Connection of other external devices

After testing the setting of end positions (IRC) it is possible to continue with connection of

other external devices.

Control box FSTronic DES-FI is standardly equipped with keyboard buttons „Open“ and

„Close“, which can be used to open the gate in “Dead man” mode. For automatic operation

(one- press start) upwards, it is necessary to connect terminals X2:+ and X2:3 by connection

or safety device. If it is possible to hang on the surface of gate leaf or to pass an object

through the gate, it is necessary to add a safety device “upper safety sensor” to maintain

automatic operation

Automatic operation close is activated by connecting safety sensor „lower safety sensor“

with terminals X2:+ and X2:2 („lower safety sensor“) or by connecting optical safety edge

OSE with terminals X2:G and X2:W and X2:B (ATTENTION - OSE safety bar must be

activated, see 5.2.1 - DIP8. If the safety sensor is disconnected (or OSE or contact strip is

activated) during closing, gate moves back and stops (see setting of DIP6 and selection of

parameter „4“).

In case the „lower safety sensor“ is disconnected (or OSE or contact strip is activated)

permanently, it is possible to close the gate in “Dead man” mode. “Lower safety sensor” has no

influence on opening of gate.

It is also possible to connect safety contact strip of the system with closed loop by resistance

(8,2kΩ) –this function is identical with the function of OSE or “lower safety sensor”. If the contact

strip is not connected, terminals X2:39 and X2:40 has to be connected to resistance 8,2kΩ -

without the resistance the automatic operation does notwork.

When pull switch (X2:8) is activated, gate opens into the open end position and remains

in this position for a time set in parameter „6“, then the gate automatically closes.

Control Step-by-step (X2:7) enables to open and close gate with a single button. When we press

www.somati-system.cz

12

the button, the gate starts to open to the end position or stops after we press the button again.

When we do another press of the button, the gate starts to close to the end position or after another

press of the button the gate stops. The gate can be stopped anytime with button STOP.

When EPS (fire alarm system) is activated –contact between X2:+ and X2:10 is disconnected

and gate is in alarm mode = the gate immediately closes (if there is not set a closing time

for delayed closing –pre-flash) or opens in case of set functionality for “ventilation”.

In the event of a power failure, the door will remain in the open position according to the setting

of parameter "8". If the parameter "8" is set to "-", the battery capacity is controlled and they

remain in position for a maximum of until the voltage on the backup battery falls below the 22

V threshold (the time depends on the condition and charge of the battery). Then they close to

the lower end position by closing as in the alarm state.

During the alarm closing it is possible to stop the gate with STOP button–it is stopped as long

as the button is held, „lower safety sensor“ or optical safety edge OSE stops the closing without

moving back. If the „lower safety sensor“ or optical safety edge OSE is disconnected longer

than time set in parameter (default 10 sec), the gate starts to close again.

In case the gate is closed by fire alarm (EPS, detectors..), it is possible to do an emergency

open into the middle position using button Emergency open (X2:9). In the middle position (set

according to parameter ”9”) gate remains for the set time in parameter „A“, then it is closed like

in alarm mode. A pre-flash is not set before this emergency open. The function only applies in

case of present power supply 1x230V or if the backup power is correctly dimensioned. In

parameter „O“ –it is possible to select maximum of 10 attempts to open, however it is

dependent on status of battery charge and its size.

Function of audio and visual signalization (Pre-flash) causes that during the set time

in parameter „2“, before the standard operation of gate, signalization starts functioning (flash

and sound = warning light). When using function „Pre-flash“ and „Dead man“ it is necessary to

permanently hold pressed button in required direction of gate movement and wait until the end

of set time of pre-flashing before the gate starts moving into the required position

IF SAFETY DEVICES (FUSES) IN CONTROL BOX ARE BLOWN,

IT IS POSSIBLE TO TURN THEM ON ONLY ONCE –IF THEY ARE

BLOWN ONCE MORE, IT IS NOT PERMITTED TO TURN THEM ON

AGAIN

IF THE PROCEDURE STATED IN THE TECHNICAL DOCUMENTATION

IS NOT RESPECTED, IT MAY LEAD TO THE LOSS OF WARRANTY

IN THE EVENT OF MALFUNCTION, FIRST IT IS NECESSARY TO DETECT

POSSIBLE CAUSE OF THE MALFUNCTION AND REPAIR IT. AFTER

THE MALFUNCTION IS REPAIRED, IT IS POSSIBLE TO TURN

ON THE BLOWN FUSE

AGAIN.

IT IS FORBIDDEN TO MANIPULATE WITH CIRCUITS OF THE

CONTROL BOX AND CHANGE THEIR CONNECTIONS. IN THE EVENT OF

FAILURE TO COMPLY WITH THIS CONDITION, IT IS NOT POSSIBE TO

APPLY WARRANTY ON THE CONTROL BOX

CONTROL BOX CANNOT BE OPENED BY A PERSON WITHOUT APPROPRIATE

TRAINING AND QUALIFICATION ACCORDING TO THE DECREE No. 50/1978, §6

www.somati-system.cz

13

5. Description of control and terminal blocks

5.1.

Func

Terminal block of function FUNC is used to internal functional

connection of the control box, nothing has to be connected

on this terminal block.

5.2. DIP switch

5.2.1 Description of DIP switch functions

DIP1 –activates signalization of lower safety

sensor on LED indicator

DIP2 –activates upper safety sensor on LED indicator

DIP3 –activates automatic closing after opening by pressing “open” button on the

keyboard of control panel, “open” button has same function in case of activation as

pull switch (i.e. after setting time in parameter „6“, gate is automatically closed)

DIP4 –activates shortening of automatic closing time when passing safety sensor.

If the function is activated and safety sensors are installed, the gate immediately

closes when passing the safety sensor and does not wait to the end of the set time

in parameter „6“

DIP5 –selects if lock on the control panel only locks the panel buttons (open /close)

or it also locks all external inputs on the terminal block (e.g. remote control...)

DIP6 –selects response mode to collision with an obstacle during closing. It is possible

to select either 1) that the gate only moves back and then stops or 2)

that after collision the gate fully opens and after the end of set time in parameter „5“

it tries to close again (number of attempts for closing is set by parameter „4“)

DIP7 –no function

DIP8 –activates signalization of safety edge OSE –in case safety edge OSE

is not connected, it is necessary to cancel its signalization on the panel. If OSE

is connected, then we have to activate its function.

www.somati-system.cz

14

5.2.2. Description of setting functions on DIP SWITCH

POSITION OFF ON

1 lower safety sensor

ON

OFF

2 upper safety sensor

ON

OFF

3 “open”button

Placed on control panel

OFF

ON

4 shortening of closing

when passing safe. sensor

OFF

ON

5 locking of external

inputs impulse+pull

OFF

ON

6 detection of obstacle

during automatic closing

fully opened

partly closed

7 no function

8 activation of OSE

OFF

ON

www.somati-system.cz

15

5.3. Description of functions on display device

5.3.1. Control of menu on display

press 1x

1x press showes actual version of program.

press 4s press 1x

Description of setting of optional parameters on display device. To enter the setup we have

to hold knob button and after 4 seconds display shows „Par“.

parameter 1 on value 0

press 1x

changing parameter 1

on value 1

by turning change

the parameter

After displaying „Par“ press knob button to display the individual parameters and their set

value.

By turning the knob button you can display individual parameters and after pressing

the knob button you can start to change the set values of the particular parameter –the

value flashes. The parameter value can be changed by turning the knob button and after

reaching the required value, it can be saved by pressing the knob button. If we do not want

to change the parameter value, then we have to turn by the knob until the display shows

„ESC“ and then by pressing the knob button we move forward.

www.somati-system.cz

16

5.3.2. Parameters and their values

Parameter - Audio & visual signalization

- warning light (output X2:26, X2:27)

during movement during alarm

•0 = active with delay active with delay, during alarm duration

•1 = not active active with delay, during alarm duration

•2 = active without delay active without delay, only during movement

•3 = not active active without delay, only during movement

•4 = not active active with delay, only during movement

Parameter –Time of pre-flash - alarm

Range of values: 0–999 seconds,

Note: In case of setting time delay follow rules in standard EN 14637.

Default = 0

Parameter –Time of pre-flash under normal operation

Range of values: 0–999 seconds,

Note: (when setting parameter „1“ “warning light” on value 1, there is running only

the time of pre-flash, warning light is not active)

Default = 0

Parameter –number of attempts to close

Range of values:

•0-10 attempts

•„-„ = endless number of attempts

Note: (according to the setting DIP6 gate moves back or fully

opens) Default = 0

Parameter –delay of closing attempts

Range of values: 1–50

seconds Default = 10

Parameter –time of automatic closing

Time after which the gate, opened by pull switch, starts to

close. Range of values: 3–999 seconds

Default = 10

Parameter –duration of movement back

Motion back after collision with obstacle.

Range of values: 1–10 seconds

Default = 3

www.somati-system.cz

17

Parameter –time of battery discharging

Time after which the gate, held on batteries, closes during power

failure. Range of values:

•0-30 minutes

•„-„ = depends on battery condition and

load Default = 10

Parameter –Emergency Open width

Setting of width for automatic open in alarm and activation of button

Emergency Open (input X2:+, X2:9) Range of values:

•30–100 % gate width

•„-„ = according to the setting of middle position

Note: When we have end switches NES it is possible to set only „-“ and the position

follows the setting of middle position.

Default = 50%

Parameter –Emergency Open time

Setting of time during which the gate waits in the set position

after activation of button Emergency Open.

Range of values: 5–999

seconds Default = 10

Parameter –Permanent Open

Selection of input function of pull switch (input X2:+, X2:8)

•0 –without permanent open –standard pull switch

•1 –function “permanent open” is activated – if the input of pull switch

is connected then it opens always when it is possible –closes only in alarm

•2 –function permanent

close Default = 0

Parameter –Return after alarm

What happens after cancelling the alarm:

•0 = after cancelling the alarm, do nothing

•1 = return to the state before alarm

•2 = after alarm Open

•3 = after alarm Close

•4 = after alarm Reset will finish closing as the alarm will be

active Default = 0

Parameter –Passing of closed position

Is used to pass the end position “closed” during alarm – can close the

door beyond the end position when closing the alarm - special

application.

Range of values: 0–100 % from 6 % gate height. Default = 0

www.somati-system.cz

18

Parameter –time of Smoke alarm

Time in which the gate remains in alarm „Smoke“ i.e. in

position partly opened before closing again:

•5–999 seconds

•„-„ = time unlimited

Default = 10

Parameter –length of opening time in case of Smoke alarm

activation

•0–100% gate width

•„-„ = according to the setting of middle position

Note: When we have end switches NES it is possible to set only „-“

and position follows the setting of middle position.

Default = 50 %

Parameter –do not monitor OSE / Ledge 8K2

The width from which the safety edge of OSE

is not monitored to prevent the unwanted opening before the contact with stop profile.

Range of values: 1–100 % from 10 promiles of gate width

Default = 30 %

Parameter –correction of the end position “opened”

Range of values: -99 –+99 % from 1 % gate height

Default = 0

Parameter –correction of the end position“closed”

Range of values: -99 –+99 % from 1 % gate height

Default = 0

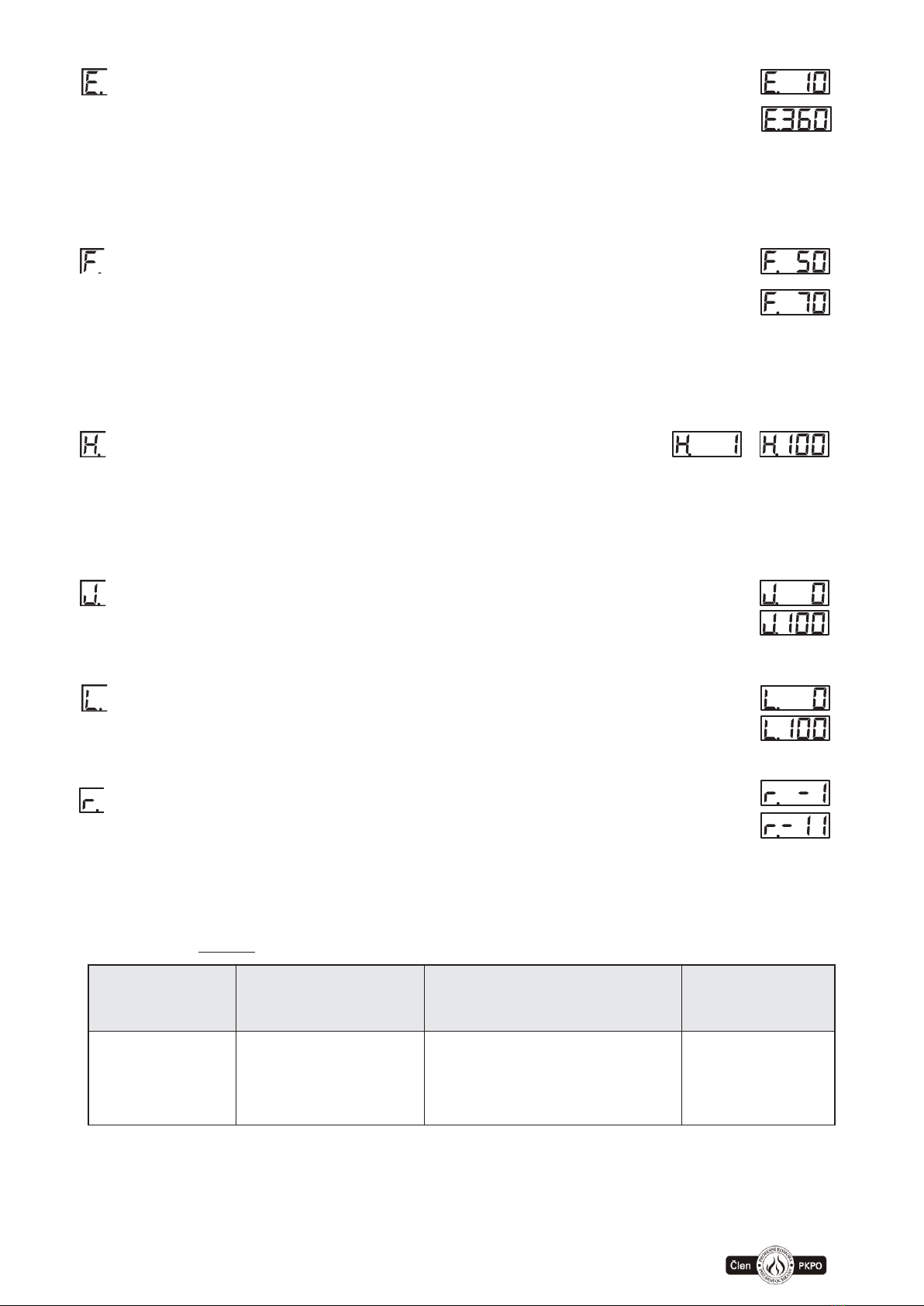

Parameter –selects type of motor for correct setting of

frequency inverter

We select the type of motor and the control box enters,

into the frequency inverter, the appropriate parameters

of the particular motor for its proper and smooth operation.

Note: Control boxes FSTronic IRC-FI are supplied in two sizes of frequency inverter see

the table, point 2.

Value „r“

Motor type

Type od sensor

Power of

inverter

1

EPO 120W

IRC

2 A

2

EPO 180W

IRC

2 A

3

EPO 250W

IRC

4 A

www.somati-system.cz

19

Value „r“

Motor type

Type od sensor

Power of

inverter

4

EPO 350W

IRC

4 A

„-„

Individual motor

settings

„-„ = motor parameters according setting on

frequancy inverter

note: Warning, this value can be used only

based on agreement with the producer. Only

for special applications for non-standard

motors.

Parameter –attempt to open gate using backup power

-0–10 attempts

Default = 0

This parameter is significantly dependent on sizing of backup power hardware according

to the motor size and gate dimensions. Backup power is primarily designed only for

closing of gates.

Note: No influence on setting function ventilation

Parameter –opening speed

Range of values: 40–250 %

Value shows how many percents from maximum frequency 50 Hz

(primary set on frequency inverter) will be the speed of opening (100

% = 50 Hz)

Default = 80 %

Parameter –closing speed

Range of values: 40–150 %

Value shows how many percents from maximum frequency 50 Hz

(primary set on frequency inverter) will be the speed of closing (100 %

= 50 Hz)

Default = 80 %

Parameter –acceleration time

Range of values: 10–50 (1–5 seconds) steps 0,15

Value shows length of acceleration ramp in seconds (35 = 3,5 seconds), higher value

means slower and smoother motor acceleration.

Default = 1,5 seconds

Parameter –field of deceleration open possition

Range of values: 1–10 %

Value of the lenght distance before reaching open end possition.

Value is shown in percent of traveling distance.

Default = 3 %

www.somati-system.cz

20

Parameter –field of deceleration closed possition

Range of values: 1–10 %

Value of the length distance before reaching bottom end possition.

Value is shown in percent of traveling distance.

Note: In case of roller gate influenced by non linearity of roll up diameter.

Default = 3 %

Parameter –cross optocell

Possible to set functionality of safety sensor (input X2:+,X2:2) for cross connection.

Opportunity to use two optocells with cross safety beams under door leave. During closing

gate will be functionality of safety sensor deactivated when reached position set by LS1

so moving door leaf will not activate the sensor. Necessary to set right possition LS1.

When this parameter set on value 1 then safety sensor between LS1 and bottom

possition is not active. (Typical application for conveyors –vertically moving door)

Range of values:

•0 = normal

•1 = cross optocell

Default = 0

Parameter –speed in alarm mode

Range of values: 20–150 %

Value showes how many percents from maximum frequency 50 Hz

(primary set on frequency inverter) will be the speed in case of alarm

(100 % = 50 Hz).

By reducing of this speed possible to reach longer operation from battery backup.

Default = 40 %

Parameter - service period (cycles)

service period 1 - 50 cycles, steps in 1000 cycles

Note: 0 = 10 cycles

Default = 3 (3000 cycles)

Parameter - conveyor confirmation

type of reaction when activated input “SMOKE” (X2:43 and X2:44)

0 = standard function “SMOKE”

1 = conveyor confirmation - in case of alarm and running time delay can be gate closed

immediately when activated this input. When conveyor is clear gate can close quicker.

Default = 0

Parameter - initial alarm braking time

Allows you to select the length of the stop time in case of the FIRST

activation of the safety device during closing in alarm.

Range of values: 1–999

second/s Default = 10

This manual suits for next models

4

Table of contents

Popular Control Unit manuals by other brands

Continental Refrigerator

Continental Refrigerator FE4CNX210 Manual and user guide

IBM

IBM 3274 user guide

National Instruments

National Instruments 9225 CALIBRATION PROCEDURE

Automationdirect.com

Automationdirect.com Productivity 1000 P1-08TA manual

A.R.I.

A.R.I. Eliptix R-30 S 2W Installation, Operating, Maintenance

Nakanishi

Nakanishi E3200 Series Operation manual