6Issue 02 DEC.20

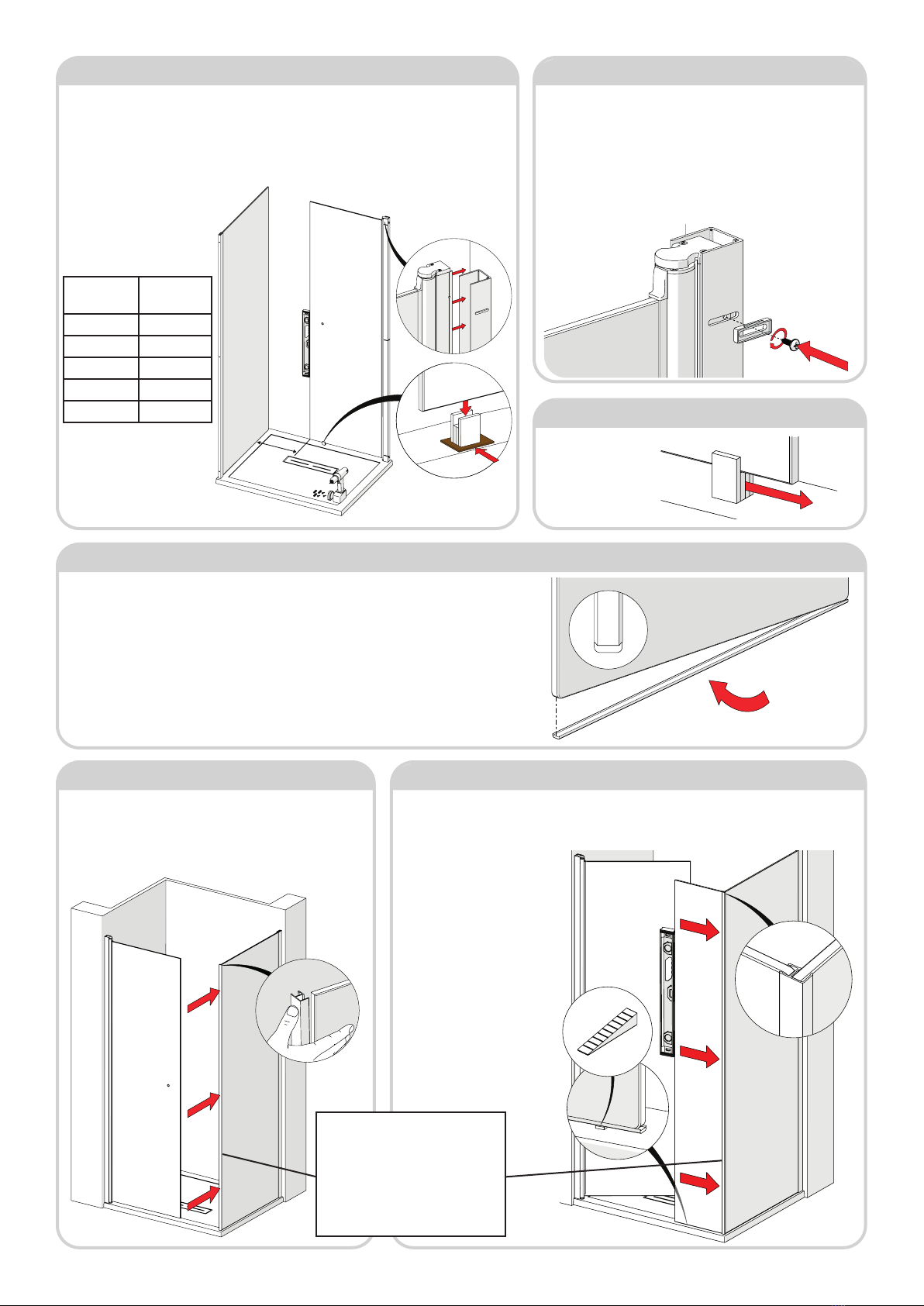

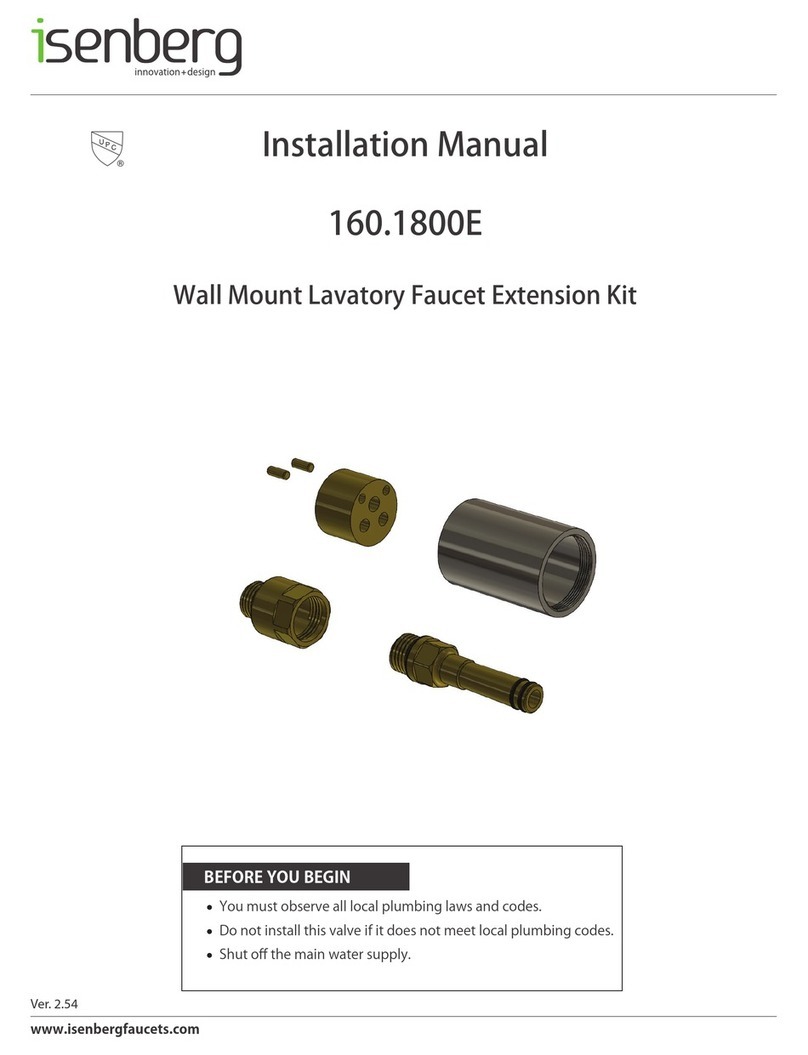

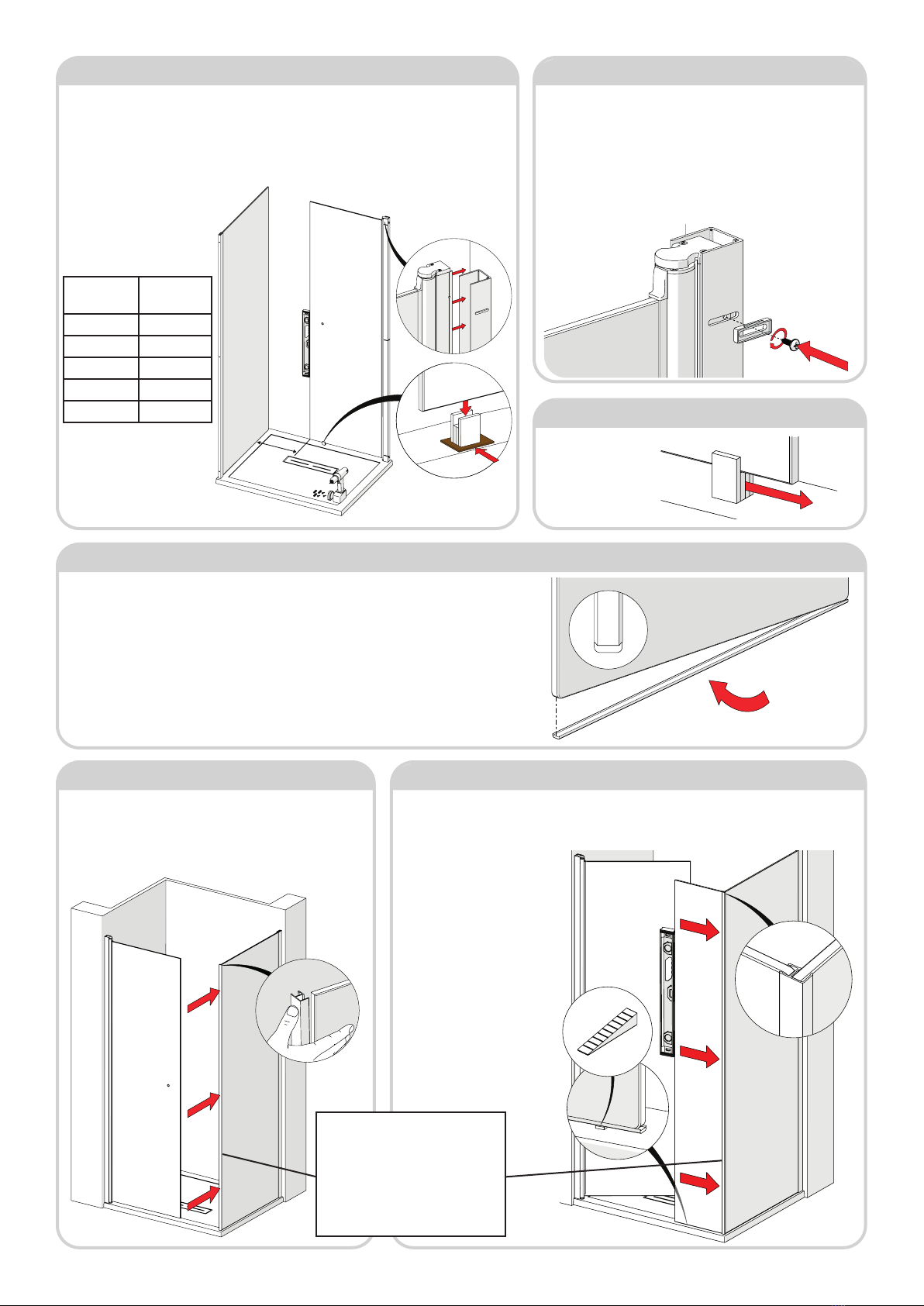

Step 13 - Fit Glass to Glass Corner Seal

X

1. Carefully t Door Glass Assembly into wallpost. Slot the glass into the ‘BLOCK’ already

positioned, as shown. This will take the weight of the door. Use your level to make sure

the door edge is ‘plumb’ vertical. If not ‘plumb’ vertical use additional packing

(e.g cardboard) to raise the ‘Packer’, as shown.

2. Position vertical edge of the Door Glass ‘X’ mm to the In-Line Panel wallpost, as shown -

refer to table to the below.

Door Size

(nominal)

‘X’

Dimension

800 134

900 234

1000 334

1200 534

1400 734

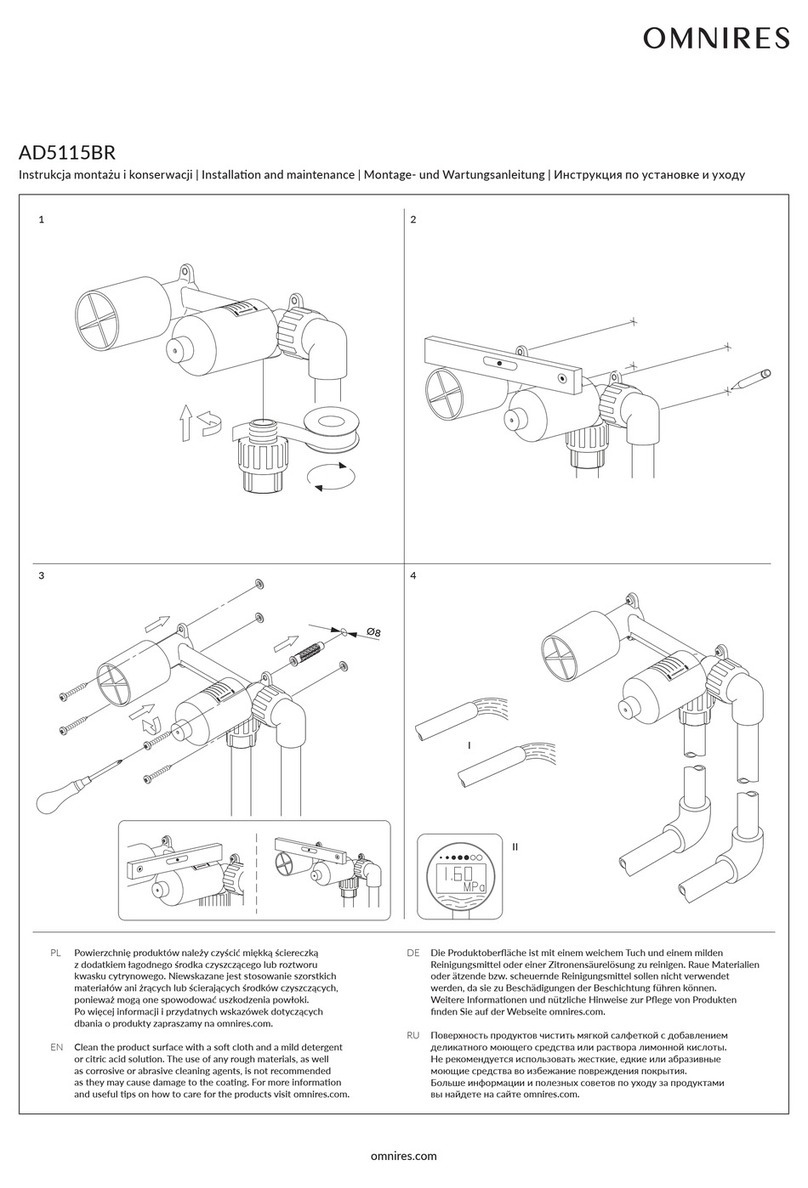

Step 9 - Position Door Assembly

1. Remove ‘Packer’

from under the Door

Glass by sliding out, as

shown below. Do not

discard.

Step 11 - Remove Door ‘Packer’

Inside view

1. Take the three ‘Wallpost Screw Mouldings’ from the Door

Installation Pack and place them into the slots on the Door Wallpost

from the inside of the enclosure, as shown.

2. Fix the door Assembly in position using the 3 x No.6x13 PH S/S

Shallow, as shown.

Note: if you find the brush seal isn’t in contact with the pivot barrel

simply loosen the middle screw and level outwards the inner profile until

the brush seal makes contact with the barrel. Retighten screw.

Step 10 - Fix Door Assembly

1. Fit glass to glass corner seal to edge of side glass panel.

Note orientation of seal. Make sure the seal is fully inserted

from top to bottom, use your thunb to apply pressure, as

shown.

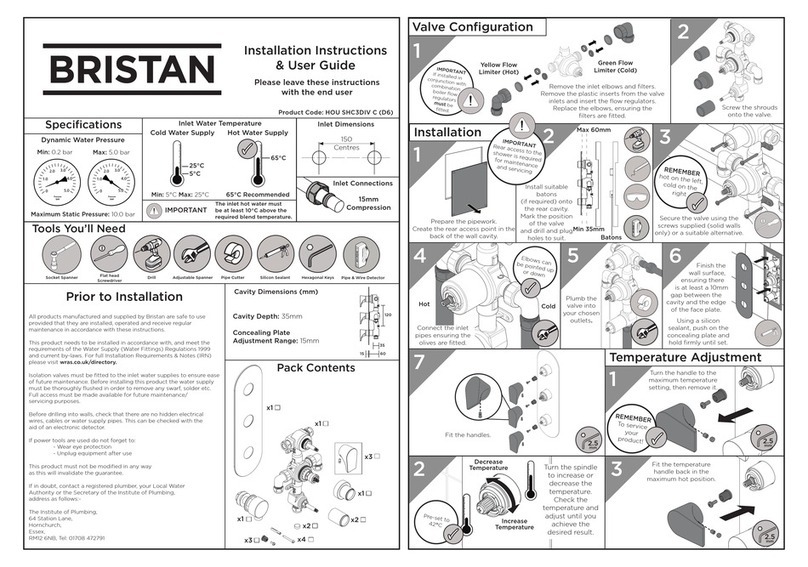

1. Take note of label ‘This surface to outside’ this will determine which is the bottom edge of

your installation.

2. Clean glass edge, then make sure it’s completely dry.

3. Acquire the WTR-0001 Trim from the In-line Panel Corner Pack. Peel off a small length of the

bottom trim adhesive tape and apply to bottom up to the vertical edge. Continue along length of

trim, peeling away the tape as you go, until the full trim length is adhered to the panel.

Use small upturned edges on bottom trim against chamfered glass edges to ensure trim is tted

centrally.

Step 12 - Fit Bottom Trim To In-Line Panel

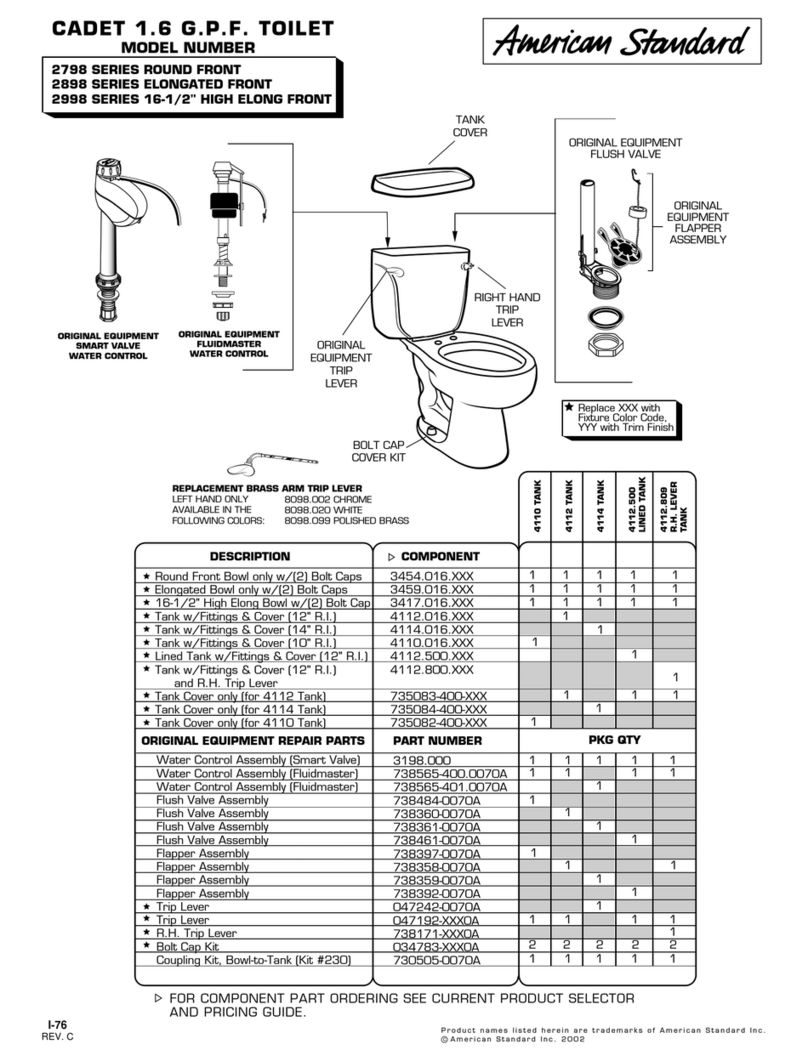

Step 14 - Fit In-line Panel

1. Carefully insert the In-line Panel into corner seal, ensuring panel is parallel to tray edge.

2. Ensure In-line Panel is square to rst panel. Corner seal must be fully inserted onto both

panels.

3. Ensure outer edge of side

panel is vertical, as shown, using

spirit level. Often shower trays

have different angled top faces,

in order to help keep the glass

supported use the ‘Shim (M193-

01)’ supplied. On the inside

of the enclosure measure the

gap between the bottom of the

glass and top of the tray, select

the height required from the

shim strip supplied, break off and

insert under rail. The shim will

be concealed by silicone sealant

later.

If tight, lubricate corner seal and glass

edges with a damp CLEAN cloth to

ease tment - the water will evaporate

over a short period. DO NOT USE

silicone spray or any other substance

other than water, these will not fully

dry out and will compromise the grip

and rigidity of the joint.

Inside view