www.sonicairsystems.com

©Copyright 2010-Sonic Air Systems Inc. Page 5of 26

draw increases). As air volume decreases (valves close, filters clog), the amp draw decreases. Always check

a fully installed system to ensure the motor is not overloaded.

2.6. Blower Cavitation (Surging)

The Sonic 350 blower operates properly in the range of flows between 650 and 3500 SCFM without

overheating or surging. At flows lower than 650 SCFM the surging is mild however if the blower is run

repeatedly at these low settings, the life of the bearings will decrease.

2.7. Blower Interfaces

Blower Inlet – The blower inlet must be coupled to an air inlet filter-silencer or an inlet air safety screen. A

Sonic Air inlet filter-silencer should be used in every application in order to protect the blower internal

components, to provide the level of air filtration imposed by the application and to reduce the inherent noise

which accompanies the flow at the inlet of a turbomachine. Sonic standard filters are rated at 10 microns

and are available with paper or polyester elements. Inlet air temperatures must not exceed 125˚F (52˚C). If

the blower is in an enclosed space and the inlet air is piped from another area, make sure that the ambient

temperature around the blower/motor does not exceed 110˚F (43˚C). When air is re -circulated from an

Airknife zone, In-Line filters and Water Separators must be used.

Blower Outlet – The blower outlet must always be coupled to a discharge silencer or system piping and

directed away from personnel. Discharged air should be silenced to levels required by occupational

safety and health standards. In order to minimize the pressure drop and noise transmission, Sonic

recommends the use of smooth bore tubing (hard plastic or metal)

Flex Hose and Sleeves – Flex hose can have high-pressure drop and should only be used when

absolutely necessary. Flex hose should be able to handle pressures of 10 PSIG at 200ºF (93ºC). Flex

hose can be used for connecting misaligned piping and bend radii that do not match standard elbows. Be

aware that flex hose can collapse inside and should be inspected if flow problems occur. Short rubber

sleeves with T-bolt clamps are standard for blower and piping connections.

Butterfly Valves – Sonic Butterfly Valves are designed to regulate system air flow during normal

operation and to allow air leakage in the closed position to prevent blower surging.

3. EQUIPMENT INSPECTION AND INSTALLATION

3.1. Equipment Inspection

Upon receipt of the Sonic Air Centrifugal Blower, make sure that all components listed on the packing slip

are present. Check to see that the serial number stamped on the blower housing nameplate matches the

packing slip. Inspect the blower to ensure that it is mounted with the correct outlet position and that the

motor has the correct horsepower rating, voltage and enclosure. If the inspection reveals any shortages,

discrepancies or shipping damage, please call the nearest Sonic Distributor or Sonic Air Systems

immediately to have the problems corrected.

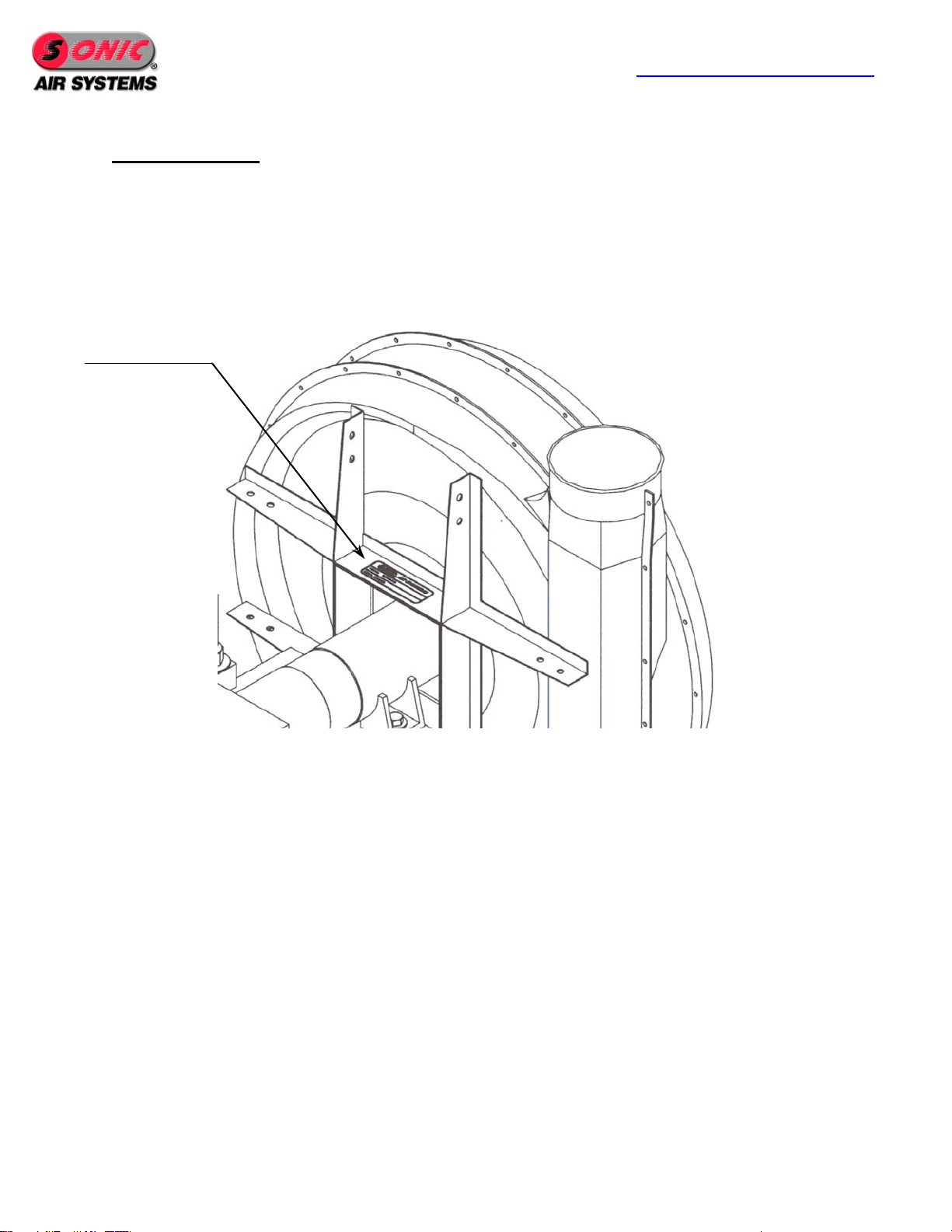

3.2. Identification of Blower and Motor

There are two points of identification:

1) Serial number stamped on the nameplate located on the top horizontal rib on the rear of the blower (see

Fig. 1).