SonoSite SiteStand User manual

SonoSite™

SiteStand™Mobile Docking Station

Service Manual

:

ii

P01117-01 Rev B 10/00

Copyright © 2000 by SonoSite, Inc.

All rights reserved. Printed in the USA.

iii

Manufactured for

SonoSite, Inc.

21919 30th Drive SE

Bothell, WA, USA 98021-3904

Telephone: 1-888-482-9449 or +1-425-951-1200

Fax: +1-425-951-1201

European Headquarters

SonoSite

P.O. Box 4

St. Neots

PE19 6LR

England

Telephone: +44-1480-217-522

Fax: +44-1480-217-489

Asia Headquarters

SonoSite

Suite 2201, 50 Gloucester Road

Wanchai, Hong Kong

Telephone: +852-2529-2881

Fax: +852-2529-5881

CAUTION: United States federal law restricts this device to sale by or on the order of a

physician.

“PowerMap,” “SiteCharge,” “SitePack,” “SiteStand,” “SonoHeart,” and “SonoSite” are trademarks of SonoSite, Inc.

Non-SonoSite product names may be trademarks or registered trademarks of their respective owners.

SonoSite products may be covered by one or more of the following U.S. patents: 4214269, 4387365, 4387597, 4432371,

4435614, 4454884, 4534357, 4542653, 4552607, 4581636, 4603702, 4607642, 4644795, 4670339, 4773140, 4817618,

4883059, 4887306, 5016641, 5095910, 5099847, 5123415, 5158088, 5197477, 5215094, 5226420, 5233994, 5255682,

5275167, 5287753, 5305756, 5353354, 5365929, 5386830, 5390674, (5,423,220), 5438994, 5450851, 5456257, 5471989,

5471990, 5474073, 5476097, 5482045, 5485842, 5492134, 5517994, 5529070, 5546946, 5555887, 5603323, 5606972,

5617863, 5634465, 5636631, 5645066, 5648942, 5669385, 5706819, 5715823, 5718229, 5720291, 5722412, 5752517,

5782769, 5800356, 5817024, 5833613, 5846200, 5860924, 5893363. Other patents pending.

:

iv

SiteStand Service Manual v

Table of Contents

CHAPTER 1Introduction 1

1.1 Description................................................................................1

1.2 Setup and Operation..................................................................1

1.3 Specifications............................................................................3

1.3.1 SiteStand.............................................................................3

1.3.1.1 Electrical ........................................................................3

1.3.2 SiteStand Display ...............................................................3

1.3.2.1 Display Type..................................................................3

1.3.2.2 Electrical ........................................................................3

CHAPTER 2Safety 5

2.1 Electrical Safety........................................................................5

2.1.1 Equipment Protection.........................................................6

2.1.2 Electrical Safety Testing ....................................................6

CHAPTER 3Servicing the SiteStand 7

3.1 Introduction...............................................................................7

3.1.1 Contacting SonoSite Technical Support.............................7

3.2 Troubleshooting the SiteStand..................................................7

3.3 Disassembling the SiteStand.....................................................8

3.3.1 Required Tools...................................................................9

3.3.2 Replacing the Sleeve Assembly and the Docking PCBA ..9

3.3.3 Replacing the Power Supply ..............................................9

3.3.4 Replacing the Foot Pedal....................................................9

3.3.5 Repairing/Replacing the Front Panel Connectors............10

3.3.6 Replacing the SiteStand Fuse...........................................10

3.4 SiteStand Performance Tests ..................................................11

3.4.1 Setup.................................................................................11

3.4.2 AC Power Verification.....................................................11

3.4.3 Docking Video .................................................................11

3.4.4 RS-232..............................................................................11

3.4.5 Printer Interface................................................................11

APPENDIX ASchematic and Parts List 13

A.1 Schematic and Wiring Diagram..............................................13

:

vi SiteStand Service Manual

A.2 Replacement Parts List ...........................................................13

A.3 Ordering Replacement Parts...................................................13

A.4 SiteStand Wiring Diagram......................................................14

A.5 Schematic Diagram, Docking Stand PCB ..............................15

A.6 SiteStand Assembly................................................................16

A.7 SiteStand Sleeve Assembly ....................................................17

APPENDIX BService Event Report 21

SiteStand Service Manual 1

CHAPTER Introduction

Before servicing the SiteStand mobile docking station (SiteStand), read and be

familiar with the information in this manual.

1.1 Description

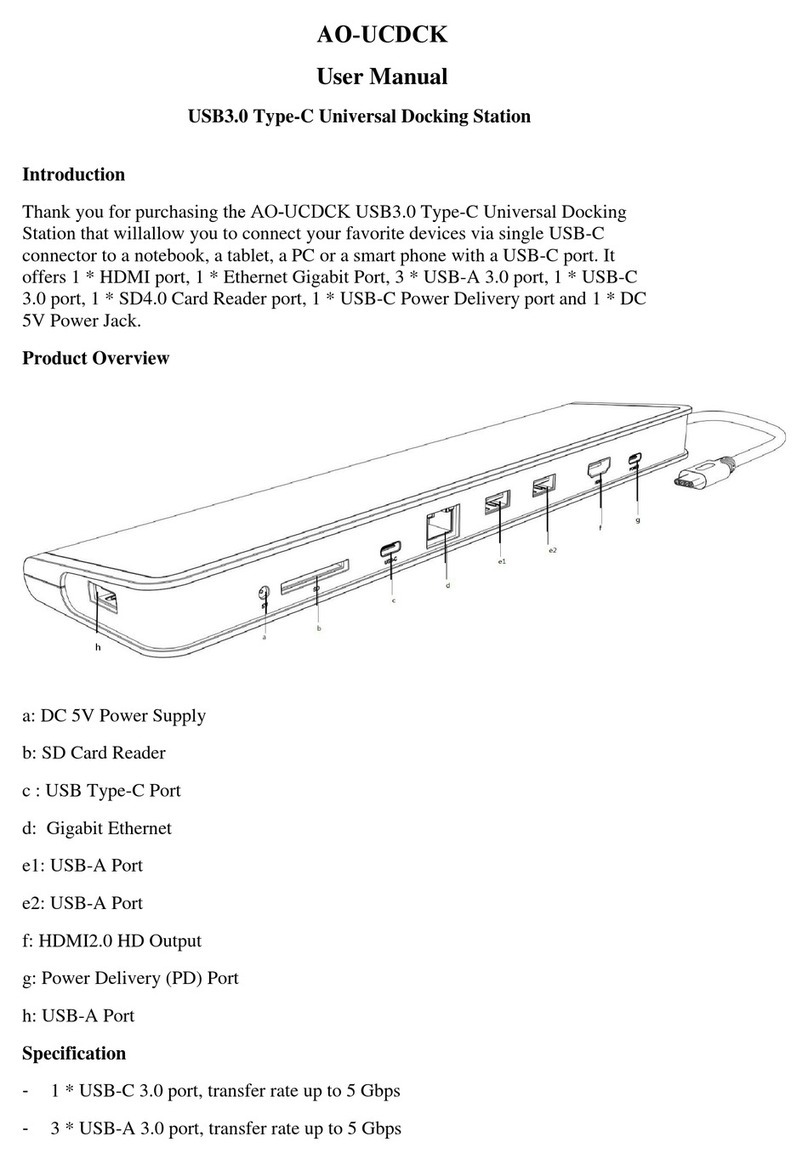

The SiteStand (Figure 1.1) provides power, video, print, and image transfer

capabilities for the system. The SiteStand has storage for two transducers and a tray

for a recommended black-and-white printer. It provides the following connections:

three video ports, an RS-232C port, a printer control port, and two AC mains IEC

power receptacles. You can also tilt the system and adjust the height of the system

when it is in the docking station.

1.2 Setup and Operation

For setup and operation of the SiteStand, refer to the SiteStand User Guide (P01542-

01).

Chapter 1: Introduction

2SiteStand Service Manual

Figure 1.1 SiteStand with Display

SiteStand display

SonoSite system

SiteStand

Printer tray

Height adjustment

pedal

Locking levers

Sleeve

Specifications

SiteStand Service Manual 3

1.3 Specifications

1.3.1 SiteStand

1.3.1.1 Electrical

SiteStand input: 100-120/220-240 VAC, 50/60 Hz, 1.0-0.50 A.

SiteStand outputs: + 16Vdc, 2.8 A. and 100-120/220-240 VAC, 50/60 Hz, 2.0 A.

(2x)

AC power adapter input: 100-120/220-240 VAC, 50/60 Hz, 1.0-0.50 A.

AC power adapter output: + 16Vdc, 2.8 A.

1.3.2 SiteStand Display

1.3.2.1 Display Type

TFT LCD 640 x 480 pixels

1.3.2.2 Electrical

SiteStand flat panel display input: + 12VDC, 2.75 A.

AC power adapter input: 100-120/220-240 VAC, 50/60 Hz, 0.85 A maximum.

AC power adapter output: + 12VDC, 2.75 A.

Chapter 1: Introduction

4SiteStand Service Manual

SiteStand Service Manual 5

CHAPTER Safety

Please read this information before servicing the SiteStand.

A WARNING describes precautions necessary to prevent injury or loss of life.

A CAUTION describes precautions necessary to protect the products.

2.1 Electrical Safety

For maximum safety observe the following warnings and cautions:

WARNINGS:

Shock hazards exist if the AC power adapter is not properly grounded. Grounding

reliability can only be achieved when equipment is connected to a receptacle marked

“Hospital Only,”“Hospital Grade,”or the equivalent. The grounding wire must not

be removed or defeated.

To avoid the risk of electrical shock and fire hazard, inspect the AC power adapter

cord and plug on a regular basis. Ensure they are not damaged.

Connection of peripherals not recommended by SonoSite could result in electrical

shock. Avoid electrical shock hazards by using peripherals and accessory cables

recommended by SonoSite.

To avoid the risk of electrical shock, use commercial grade peripherals

recommended by SonoSite on battery power only. Do not connect these product to

AC mains power when using the system to scan or diagnose a patient/subject. Call

SonoSite technical support or your local representative for a list of the commercial

grade peripherals available from or recommended by SonoSite.

CAUTIONS:

Electrostatic discharge (ESD), or static shock, is a naturally occurring phenomenon.

ESD is common in conditions of low humidity, which can be caused by heating or

2: Safety

6SiteStand Service Manual

air conditioning. Static shock is a discharge of the electrical energy from a charged

body to a lesser or non-charged body. The degree of discharge can be significant

enough to cause damage to a transducer or an ultrasound system. The following

precautions can help reduce ESD: anti-static spray on carpets, anti-static spray on

linoleum, and anti-static mats.

For labeling symbols used with the SiteStand, please refer to the SonoSite 180 or

SonoHeart User Guide. For information about the flat panel display, please refer to

the Operating Instructions for the Series DV-3000 Colour LCD Rugged Monitor.

2.1.1 Equipment Protection

To protect your ultrasound system, transducer, and accessories, follow these

precautions.

CAUTIONS:

Excessive bending or twisting of cables can cause a failure or intermittent operation.

Improper cleaning or disinfecting of any part of the system can cause permanent

damage.

Do not handle PCBs without proper static protection. Damage to components may

result from improper handling.

2.1.2 Electrical Safety Testing

*Note: 300uA is the limit for 120V stands only!

Table 2.1 Acceptable Earth Leakage Current Values

AC VOLTAGE LEAKAGE CURRENT (UA)

NC SFC

100 - 240 0 < I < 300 / 500 (*) 0 < I < 1000

SiteStand Service Manual 7

CHAPTER Servicing the SiteStand

3.1 Introduction

Before servicing the SiteStand, read and be familiar with the information in this

manual. The SiteStand assembly drawings and part lists are located in Appendix A,

Schematic and Parts List on page 13.

3.1.1 Contacting SonoSite Technical Support

For technical support or to order spare parts, do one of the following:

•For U.S. customers, call 1-877-657-8118.

•For international customers, call +425-951-1330.

•Connect to SonoSite on the World Wide Web at www.sonosite.com. Select

Products, then choose Technical Support.

•E-mail service @sonosite.com

3.2 Troubleshooting the SiteStand

The intent of this section is to help isolate potential problems associated with the

SiteStand. Table 3.1 provides an observation of the problem, the possible cause, and

the corrective action for the SiteStand.

Chapter 3: Servicing the SiteStand

8SiteStand Service Manual

3.3 Disassembling the SiteStand

Disassembly of the SiteStand is dependent on the repairs required. The following

order of disassembly is recommended in order to prevent damage to the SiteStand

and facilitate efficient repairs. The service provider should use good judgement in

altering this order to provide repairs to various parts of the SiteStand.

Table 3.1 SiteStand Troubleshooting

OBSERVATION POSSIBLE CAUSE CORRECTIVE ACTION

The system battery doesn’t

charge in the SiteStand. If the charge function of the

system is acceptable, the

possible causes are:

•the power supply has

failed or become

disconnected

•the dock PCBA located

in the sleeve assembly

has failed

•the docking connectors

on the sleeve assembly

are broken or bent.

Verify the SiteStand is at

fault by attempting to charge

the battery with the power

supply connected directly to

the system. If it does not

charge, refer to the SonoSite

180 Service Manual for

troubleshooting.

There is no video from the

SiteStand video out

connection.

The SiteStand docking

PCBA has failed.

The docking connections or

the sleeve assembly have

been broken.

See Replacing the Sleeve

Assembly and the Docking

PCBA on page 9.

There is no AC power from

the SiteStand power

connection.

The SiteStand fuse has

failed. See Replacing the SiteStand

Fuse on page 10.

There is no remote printer

control to the printer on the

SiteStand.

The printer remote control

cable has failed or is not

attached correctly.

Replace the printer remote

cable (P00762).

There is no output from the

RS-232 communication port. The SiteStand docking

PCBA has failed.

The docking connections on

the sleeve assembly are

broken or bent.

See Replacing the Sleeve

Assembly and the Docking

PCBA on page 9.

The sleeve assembly does

not raise or lower. The foot pedal is damaged.

The gas spring is loose or

damaged.

The foot pedal has fallen off.

See Replacing the Foot

Pedal on page 9.

The SiteStand does not roll

easily or in a straight line. A castor(s) is broken or bent.

The SiteStand base is

damaged.

Replace the failed part.

Disassembling the SiteStand

SiteStand Service Manual 9

3.3.1 Required Tools

•#1 Phillips screwdriver

•Allen wrench set (5/32-inch, 1/8-inch, and 5/64-inch)

•Slotted screwdriver

•Open end wrench (11/16-inch)

•Round punch (1/4-inch)

3.3.2 Replacing the Sleeve Assembly and the Docking

PCBA

1. Tilt the sleeve assembly to its most upright position.

2. Use a #1 Philips screwdriver to remove the six screws from the metal base of the

sleeve assembly.

3. Turn the sleeve assembly over and remove the two screws holding the cable

connector to the sleeve assembly.

4. Unplug the connectors and set the sleeve assembly aside.

5. Remove the five Phillips screws attaching the PCBA to the sleeve assembly.

3.3.3 Replacing the Power Supply

1. Lay the SiteStand on a bench with the base facing you.

2. Use an Allen wrench to remove the four 5/32-inch Allen screws holding the

base.

3. Remove the base and set it aside.

4. Use an Allen wrench to remove to remove the six 5/32-inch Allen screws and

the 11/16-inch nut on the gas spring securing the subplate.

5. Remove the subplate.

6. The power supply is visible in the forward section of the SiteStand and is

secured by Velcro. Pull the power supply loose and disconnect the connectors.

7. To reassemble the SiteStand follow steps 1 through 6 in reverse order.

3.3.4 Replacing the Foot Pedal

Earlier versions of the SiteStand use a pin to hold the foot pedal in place. If the pin

has become loose, you should replace the foot pedal with foot pedal repair kit

(P01321).

1. Remove the pin using any round punch.

2. Install the foot pedal using the shoulder bolt in place of the pin.

3. Attach the locking nut and tighten so the nut is secure and that the foot pedal

moves freely.

Chapter 3: Servicing the SiteStand

10 SiteStand Service Manual

3.3.5 Repairing/Replacing the Front Panel Connectors

1. To access these connectors, use an Allen wrench to remove the six connector

cover 5/64-inch Allen screws.

2. Extend the gas spring to its maximum height by pressing the foot pedal.

3. Remove the blade cap by gently prying it up from the sides with a flat blade

prying tool. There are no screws holding it in place.

4. Use an Allen wrench to remove the eight 5/32-inch Allen screws from the top

subplate.

5. Left the blade cap and subplate to the top of the shaft and secure it in place.

6. Gently pull the connector assembly out the top of the blade assembly.

7. The connector can now be repaired or replaced.

8. Reassemble the SiteStand by performing steps 1 through 8 (in this section) in

reverse order.

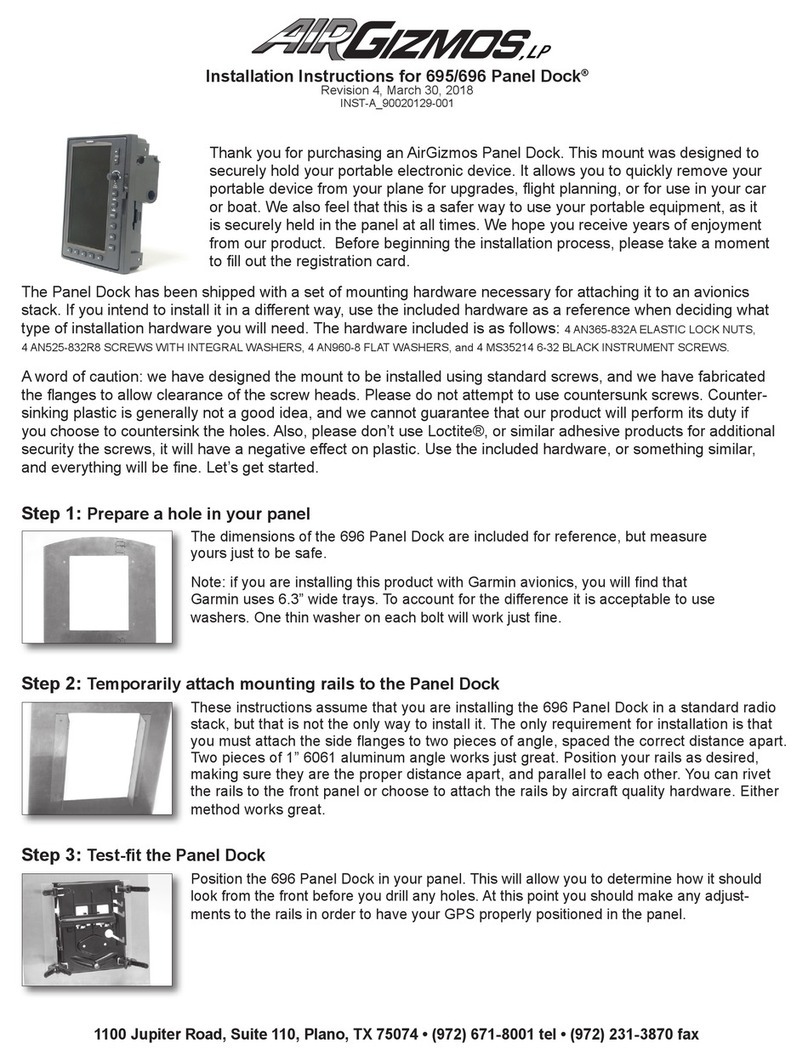

3.3.6 Replacing the SiteStand Fuse

AC power

receptacle

Video output

receptacles

RS-232C

communication

port

Power output

connectors

Black-and-white thermal

printer

Printer remote

control connector

Video output

receptacle

Fuse drawer

SiteStand Performance Tests

SiteStand Service Manual 11

To replace the electrical fuse:

1. Disconnect the AC line cord from the hospital-grade electrical outlet.

2. Disconnect the AC line cord from the bottom of the SiteStand mobile docking

station.

3. Use a small, slotted screwdriver to remove the fuse drawer (located directly

below the input AC receptacle on the SiteStand mobile docking station).

CAUTION: You should identify the cause of the blown fuse prior to plugging

the docking station back into AC power.

4. Carefully replace the blown fuse with a 250 volt, 6.3 amp, 5.0 x 20 mm Slo-

Blo®-type fuse.

5. Install the fuse drawer.

6. Connect the AC power to the SiteStand mobile docking station.

3.4 SiteStand Performance Tests

3.4.1 Setup

•Install a SonoSite 180 or SonoHeart, without a battery into the docking station

•Apply AC power, 120V 60Hz to SiteStand “AC in”receptacle

3.4.2 AC Power Verification

Use an AC Tester to verify both IEC output receptacles are wired correctly.

3.4.3 Docking Video

•Turn on the system.

•Connect a Test Monitor to each of the video outputs on the docking stand.

•Verify the same video pattern exists on the Test Monitor as is present on the

System LCD Display.

3.4.4 RS-232

The RS-232 interface can only be field tested using the SiteLink Image Management

software. If that software is installed, verify the information on the PC according to

the SiteLink Image Management User Guide on the SiteLink CD-ROM.

3.4.5 Printer Interface

1. Connect the black and white video printer to the SiteStand. Ensure that the

control and AC power cables are attached, but not the video cable.

2. Verify that the printer produces an audible beep and that the user interface

replies with its own tone.

Chapter 3: Servicing the SiteStand

12 SiteStand Service Manual

3. Repeat steps 1 and 2 (above) at least one more time to verify that the status line

is connected.

SiteStand Service Manual 13

APPENDIX Schematic and Parts List

This section contains a list of field-replaceable parts.

A.1 Schematic and Wiring Diagram

A schematic and a wiring diagram are provided for the SiteStand and the docking

stand PCB.

A.2 Replacement Parts List

The following tables contain all the replaceable parts for the SiteStand. All

quantities are one unless otherwise noted.

A.3 Ordering Replacement Parts

To order parts, contact SonoSite technical support at 1-877-657-8118 (U.S.) or

+425-951-1330 (international).

Appendix A: Schematic and Parts List

14 SiteStand Service Manual

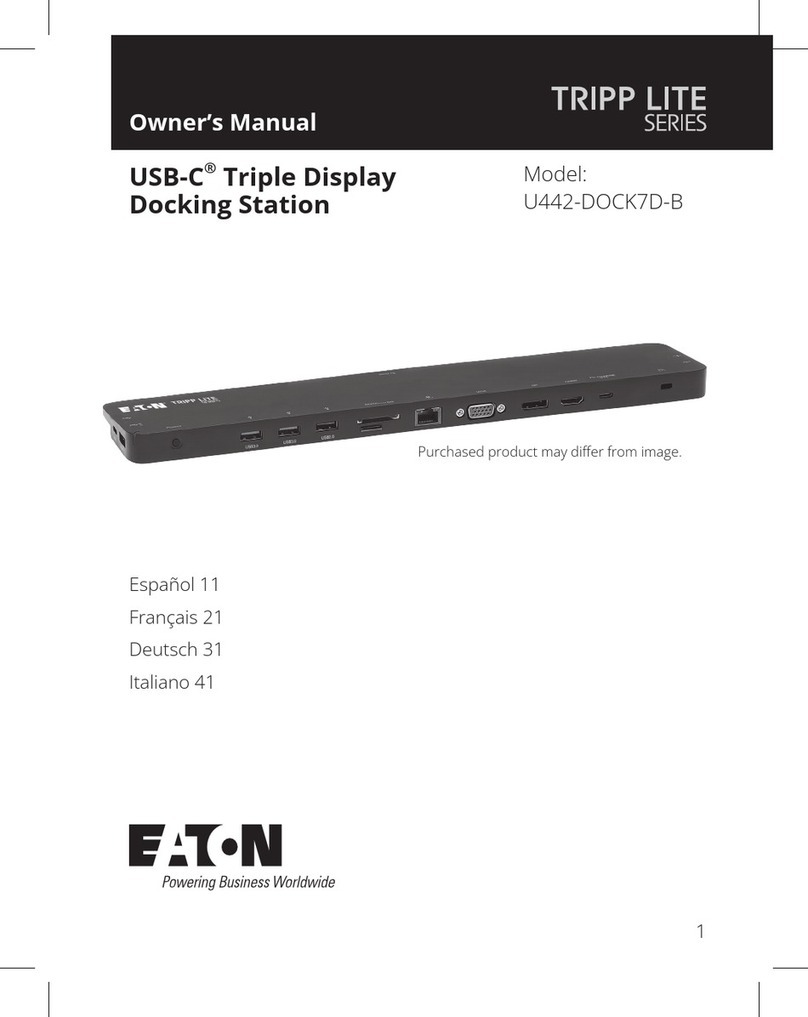

A.4 SiteStand Wiring Diagram

IEC Input AC Receptacle (male)

Input Fuses:

Hot & Neutral

6.3A

B/W Printer Power

Output - IEC

Receptacle (female)

Auxiliary Power

Output - IEC

Receptacle (female)

100-240VAC

INPUT

Universal AC Input (100-240V 50-60Hz) Power

Adapter.

Output = 16VDC

CSA/UL approved to IEC601 Based Standards

Docking Stand PCB

16VDC

16VDC RTN

1: V+

2: V-

3: Video

4: GND

5: Print Control

6: Print Status

7: GND

8: Rx

9: Tx

10: GND

11: Rts

12: Cts

13: Sense

14: Spare

NOTE:

Docking Stand is disabled with

no voltages at 14 output

contacts until SonoSite 180 is

placed in Stand connecting V- to

Ground.

SonoSite 180

Printer Control / Status

Video Out to B/W Printer

Auxiliary Video Output

RS-232 Communications Port

Table of contents

Other SonoSite Docking Station manuals

Popular Docking Station manuals by other brands

Sony

Sony RDP-XF100iP Marketing Specifications

AIR GIZMOS

AIR GIZMOS Panel Dock 695 installation instructions

Monster

Monster tron manual

Yamaha

Yamaha PDX 30 - Portable Speakers With Digital Player... owner's manual

Eaton

Eaton TRIPP LITE Series owner's manual

Onkyo

Onkyo UP-A1 - Dock For The iPod instruction manual