Sonotron NDT ISONIC utPod User manual

O

Op

pe

er

ra

at

ti

in

ng

g

M

Ma

an

nu

ua

al

l

R

Re

ev

vi

is

si

io

on

n

1

1.

.1

18

8

S

So

on

no

ot

tr

ro

on

n

N

ND

DT

T

I

IS

SO

ON

NI

IC

C

u

ut

tP

Po

od

d

U

Ul

lt

tr

ra

a-

-P

Po

or

rt

ta

ab

bl

le

e

M

Mu

ul

lt

ti

i-

-P

Pu

ur

rp

po

os

se

e

U

Ul

lt

tr

ra

as

so

on

ni

ic

c

T

Te

es

st

ti

in

ng

g

I

In

ns

st

tr

ru

um

me

en

nt

t

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 2 of 94

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 3 of 94

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without

the express written permission of:

Sonotron NDT, 4, Pekeris st., Rabin Science Park, Rehovot, Israel, 76702

Covered by the United States patent 6545681; other US & foreign patents pending

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 4 of 94

Sonotron NDT

4, Pekeris str., Rabin Science Park, Rehovot, 76702, Israel

Phone:++972-(0)8-9477701 Fax:++972-(0)8-9477712

http://www.sonotronndt.com

EC Declaration of Conformity

Council Directive 89/336/EEC on Electromagnetic Compatibility, as amended by

Council Directive 92/31/EEC & Council Directive 93/68/EEC

Council Directive 73/23/EEC ( Low Voltage Directive ), as amended by Council

Directive 93/68/EEC

We, Sonotron NDT Ltd., 4 Pekeris Street, Rehovot, 76702 Israel, certify that the product

described is in conformity with the Directives 73/23/EEC and 89/336/EEC as amended

ISONIC utPod

Ultra-Portable Multi-Purpose Ultrasonic Testing Instrument

The product identified above complies with the requirements of above EU directives by

meeting the following standards:

Safety

EN 61010-1:1993

EMC

EN 61326:1997

EN 61000-3-2:1995 /A1:1998 /A2:1998 /A14:2000

EN 61000-3-3:1995

ABCDEF

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 5 of 94

Sonotron NDT

4, Pekeris str., Rabin Science Park, Rehovot, 76702, Israel

Phone:++972-(0)8-9477701 Fax:++972-(0)8-9477712

http://www.sonotronndt.com

EC Declaration of Conformity

Council Directive 89/336/EEC on Electromagnetic Compatibility, as amended by

Council Directive 92/31/EEC & Council Directive 93/68/EEC

Council Directive 73/23/EEC ( Low Voltage Directive ), as amended by Council

Directive 93/68/EEC

We, Sonotron NDT Ltd., 4 Pekeris Street, Rehovot, 76702 Israel, certify that the product

described is in conformity with the Directives 73/23/EEC and 89/336/EEC as amended

ISONIC utPod LF

Ultra-Portable Multi-Purpose Ultrasonic Testing Instrument Adapted for Low Frequency

Ultrasound Applications

The product identified above complies with the requirements of above EU directives by

meeting the following standards:

Safety

EN 61010-1:1993

EMC

EN 61326:1997

EN 61000-3-2:1995 /A1:1998 /A2:1998 /A14:2000

EN 61000-3-3:1995

ABCDEF

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 6 of 94

FCC Rules

This ISONIC utPod / ISONIC utPod LF multi-functional ultrasonic testing instrument (hereinafter called ISONIC utPod / ISONIC utPod LF) has been

tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna

Increase the separation between the equipment and receiver

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

Consult the dealer or an experienced radio/TV technician for help

Safety Regulations

Please read this section carefully and observe the regulations in order to ensure your safety and operate the system as intended

Please observe the warnings and notes printed in this manual

The ISONIC utPod / ISONIC utPod LF has been built and tested according to the regulations specified in EN60950/VDE0805. It was in perfect working

condition on leaving the manufacturer's premises

In order to retain this standard and to avoid any risk in operating the equipment, the user must make sure to comply with any hints and warnings included

in this manual

Exemption from statutory liability for accidents

The manufacturer shall be exempt from statutory liability for accidents in the case of non-observance of the safety regulations by any operating person

Limitation of Liability

The manufacturer shall assume no warranty during the warranty period if the equipment is operated without observing the safety regulations. In any such

case, manufacturer shall be exempt from statutory liability for accidents resulting from any operation

Warranty

When used in accordance with the manufacturer’s written instructions and under normal operating conditions, ISONIC utPod / ISONIC utPod LF is

conditionally guaranteed to be free from defects in material and workmanship for a period of 12 months from date of shipment. Second year warranty

requires the instrument to be re-certified by Sonotron NDT or by an authorized representative or distributor, within 13 months of the date of purchase. A

normal recalibration and re-certification fee will apply. All repair work will be made ex-works at the factory premises or at the premises of authorized

representative or distributor provided the defective unit

is returned properly packed with all transportation charges prepaid. Any and all equipment replacement will be at the sole discretion of Sonotron NDT. This

warranty shall not apply to equipment subjected to misuse or abuse, improper installation, alteration, neglect, or accident

This warranty is limited to the original purchaser and is not transferable. No other warranty, expressed or implied, is made.

Exemption from warranty

The manufacturer shall be exempt from any warranty obligations in case of the non-observance of the safety regulations

The manufacturer will only warrant safety, reliability, and performance of the ISONIC utPod / ISONIC utPod LF if the following safety regulations are

closely observed:

Setting up, expansions, re-adjustments, alterations, and repairs must only be carried out by persons who have been authorized by manufacturer

The electric installations of the room where the equipment is to be set up must be in accordance with IEC requirements

The instrument must be operated in accordance with the instructions

Any expansions to the instrument must comply with the legal requirements, as well as with the specifications for the unit concerned

Confirm the rated voltage of you’re the instrument’s external AC/DC converter / charger matches the voltage of your power outlet

The mains socket must be located close to the instrument and must be easily accessible

Use only the power cord furnished with the instrument

Any required cable connectors must be hooked into the casing

The instrument must be disconnected from external AC/DC converter / charger before opening

To interrupt power supply, simply disconnect AC/DC converter / charger from the mains

Any balancing, maintenance, or repair may only be carried out by manufacturer authorized specialists who are familiar with the inherent dangers

If the instrument has suffered visible damage or if it has stopped working, it must be assumed that it could no longer be operated without any danger.

In these cases, the instrument must be switched off and be safeguarded against accidental use

Do not drop small objects, such as paper clips, into the instrument

Disconnect the power cord whenever a thunderstorm is nearby. Leaving the power cord connected may damage the instrument or your property

Do not allow any cables, particularly power cords, to trail across the floor, where they can be snagged by people walking past

Charge of the battery for the instrument is allowed only with use of the AC/DC converter / charger supplied along with it

Remember this before:

balancing

carrying out maintenance work

repairing

exchanging any parts

Software

ISONIC utPod / ISONIC utPod LF is a software controlled inspection device. Based on present state of the art, software can never be completely free of

faults. ISONIC utPod / ISONIC utPod LF should therefore be checked before and after use in order to ensure that the necessary functions operate

perfectly in the envisaged combination. If you have any questions about solving problems related to use the ISONIC utPod / ISONIC utPod LF, please e-

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 7 of 94

1. INTRODUCTION .............................................................................................................................................................9

2. TECHNICAL DATA........................................................................................................................................................10

3. ISONIC UTPOD – SCOPE OF SUPPLY .......................................................................................................................11

4. OPERATING ISONIC UTPOD ......................................................................................................................................16

4.1. PRECONDITIONS FOR ULTRASONIC TESTING WITH ISONIC UTPOD..................................................................................16

4.1.1. General............................................................................................................................................................16

4.1.2. Training............................................................................................................................................................16

4.2. ISONIC UTPOD CONTROLS AND TERMINALS................................................................................................................17

4.3. TURNING ON /OFF ....................................................................................................................................................18

5. FLAW DETECTOR MODE ............................................................................................................................................20

5.1. TOP LEVEL SCREEN...................................................................................................................................................20

5.2. SUBMENU BASICS ...................................................................................................................................................20

5.2.1. Gain .................................................................................................................................................................21

5.2.2. Display Delay, Range, US Velocity ..................................................................................................................22

5.2.3. Reject ..............................................................................................................................................................22

5.2.4. AUTO CAL.......................................................................................................................................................23

5.3. SUBMENU PULSER ..................................................................................................................................................25

5.3.1. SINGLE / DUAL ...............................................................................................................................................25

5.3.2. Pulse Repetition Frequency (PRF ) .................................................................................................................25

5.3.3. Initial Pulse: Shape, Duration (Pulse Width), Firing Level................................................................................26

5.4. SUB MENU RECEIVER.............................................................................................................................................27

5.4.1. SINGLE / DUAL ...............................................................................................................................................27

5.4.2. Filter.................................................................................................................................................................27

5.4.3. Rectification .....................................................................................................................................................28

5.5. SUB MENUS GATE A/GATE B.................................................................................................................................29

5.5.1. Switch Gate ON / OFF.....................................................................................................................................29

5.5.2. Gate Start, Width, Threshold ...........................................................................................................................30

5.5.3. Draw Gate........................................................................................................................................................30

5.6. SUB MENU ALARM...................................................................................................................................................31

5.6.1. Switch Alarm ON / OFF ...................................................................................................................................31

5.6.2. Alarm Logic......................................................................................................................................................31

5.6.3. Alarm Example ................................................................................................................................................32

5.7. SUB MENU DAC .......................................................................................................................................................33

5.7.1. Theoretical DAC – dB/mm (dB/in)....................................................................................................................33

5.7.2. Experimental DAC: recording signals from variously located reflectors ...........................................................34

5.7.3. DGS.................................................................................................................................................................37

5.7.4. Multi-Curve DAC / DGS ...................................................................................................................................39

5.7.5. DAC Mode .......................................................................................................................................................40

5.8. SUB MENU MEASURE .............................................................................................................................................41

5.8.1. Probe Delay, Incidence Angle..........................................................................................................................41

5.8.2. X-Value............................................................................................................................................................41

5.8.3. Link Display Delay and Probe Delay Settings ..................................................................................................43

5.8.4. Value Being Measured ....................................................................................................................................44

5.8.5. Multiple Gate Measurements ...........................................................................................................................46

5.8.6. Flank and Top..................................................................................................................................................47

5.8.7. Geometry Corrections......................................................................................................................................48

5.8.8. Freeze, Freeze Peak, Locking Peak Envelop ..................................................................................................52

5.8.9. API Evaluation .................................................................................................................................................53

5.8.9.1. API-Evaluation: Standardization ...............................................................................................................53

5.8.9.2. API-Evaluation: Sizing Reflector ...............................................................................................................55

5.9. ZOOM A-SCAN ..........................................................................................................................................................56

5.10. 100 /110 %RANGE SWITCH....................................................................................................................................57

6. THICKNESS GAUGE MODE ........................................................................................................................................58

6.1. THICKNESS GAUGE START SCREEN ............................................................................................................................58

6.2. CALIBRATION –TOP LEVEL SCREEN ............................................................................................................................58

6.2.1. Probes With / Without Delay Line: Measurement Techniques .........................................................................59

6.2.2. Submenu BASICS ...........................................................................................................................................60

6.2.2.1. Gain, USVelocity, Reject, Range, Display Delay ......................................................................................60

6.2.2.2. Automatic Calibration................................................................................................................................61

6.2.3. Submenu PULSER ..........................................................................................................................................62

6.2.4. Submenu RECTIFY .........................................................................................................................................62

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 8 of 94

6.2.5. Submenu GATE A ...........................................................................................................................................63

6.2.6. Min / Max .........................................................................................................................................................63

6.2.7. Data Logger.....................................................................................................................................................64

6.2.7.1. Defining Format of the Data Logger..........................................................................................................64

6.2.7.2. Filling Data Logger with Measurements Results .......................................................................................65

6.2.7.3. Exporting Data Logger File from ISONIC utPod to Computer...................................................................65

6.2.7.4. Emptying Data Logger Memory ................................................................................................................66

6.3. MEASUREMENT .........................................................................................................................................................67

6.3.1. Pure Digital / Combined Thickness Display .....................................................................................................67

6.3.2. Min/Max ...........................................................................................................................................................67

6.3.3. Data Logger.....................................................................................................................................................67

6.4. ZOOM A-SCAN ..........................................................................................................................................................67

7. CORROSION GAUGE MODE.......................................................................................................................................68

7.1. CORROSION GAUGE START SCREEN ...........................................................................................................................68

7.2. CALIBRATION –TOP LEVEL SCREEN ............................................................................................................................68

7.2.1. Measurement Techniques ...............................................................................................................................69

7.2.2. Submenu BASICS ...........................................................................................................................................70

7.2.2.1. Gain, USVelocity, Reject, Range, Display Delay ......................................................................................70

7.2.2.2. Automatic Calibration................................................................................................................................71

7.2.3. Submenu PULSER ..........................................................................................................................................72

7.2.4. Submenu RECTIFY .........................................................................................................................................73

7.2.5. Submenu GATE A ...........................................................................................................................................73

7.2.6. Min / Max .........................................................................................................................................................73

7.2.7. Data Logger.....................................................................................................................................................73

7.3. MEASUREMENT .........................................................................................................................................................74

7.3.1. Pure Digital / Combined Thickness Display .....................................................................................................74

7.3.2. Min/Max ...........................................................................................................................................................74

7.3.3. Data Logger.....................................................................................................................................................74

7.4. ZOOM A-SCAN ..........................................................................................................................................................74

8. ISONIC UTPOD FOR PC SW PACKAGE .....................................................................................................................75

8.1. ISONIC UTPOD –CONNECTION TO COMPUTER............................................................................................................75

8.2. ISONIC UTPOD INSTRUMENT CONTROL ......................................................................................................................75

9. MISCELLANEOUS ........................................................................................................................................................76

9.1. SETTINGS .................................................................................................................................................................76

9.2. ISONIC UTPOD VIEWER ............................................................................................................................................76

9.3. ISONIC UTPOD FIRMWARE UPDATE ...........................................................................................................................77

9.3.1. Prior to Updating..............................................................................................................................................77

9.3.2. Updating ISONIC utPod Firmware...................................................................................................................78

9.4. TOUCH SCREEN CALIBRATION ....................................................................................................................................79

9.5. BUILT-IN BUZZER ON/OFF ........................................................................................................................................81

9.6. BLANK SCREEN –SLEEP MODE ..................................................................................................................................82

10. ISONIC UTPOD REAL TIME LOGGER ......................................................................................................................83

10.1. GENERAL................................................................................................................................................................83

10.2. DOCKING TERMINAL.................................................................................................................................................83

10.3. OPERATING REAL TIME LOGGER ...............................................................................................................................86

10.3.1. Calibration......................................................................................................................................................86

10.3.2. New Real Time Log Record...........................................................................................................................89

10.3.2.1. Start Logging ..........................................................................................................................................90

10.3.2.2. Interrupt Logging Until it Started .............................................................................................................90

10.3.2.3. Finish Logging ........................................................................................................................................90

10.3.3. Overwriting Existing Log Record....................................................................................................................91

10.3.4. Delete Existing Log Record ...........................................................................................................................91

10.3.5. Download Log Record into Computer ............................................................................................................91

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 9 of 94

1. Introduction

Ultra-portable Multi-Purpose Ultrasonic Testing Instrument ISONIC utPod uniquely comprises:

Top Performance Flaw Detector

All-Functional A-Scan Thickness Gauge

Simple Corrosion Gauge

Comprehensive Data Logger

ISONIC utPod is fully controllable from an external PC via USB

ISONIC utPod LF is a modified version of ISONIC utPod adopted for the low frequency ultrasound

applications. Comparing to ISONIC utPod it is characterized by the different frequency band and limits for

settling the duration of the initial pulse – refer to the Chapter 2 of present Operating Manual

ISONIC utPod ADL and ISONUC utPod LF ADL are the models additonally featured with the continous

automatic data logging function and docking terminal for integrating the instrument into autonomously

operating inspection systems – refer to the Chapter 10 of present Operating Manual

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 10 of 94

2. Technical Data

Operating Modes: Flaw Detector

All-Functional A-Scan Thickness Gauge

Simple Corrosion Gauge

Initial Pulse Type:

Bipolar Square Wave Pulse

Initial Transition:

5 ns (10-90%)

Pulse Amplitude:

Smoothly tunable (12 levels) 60 V … 300 V pp into 50

Pulse Duration:

ISONIC utPod

ISONIC utPod LF

50…600 ns for each half wave synchronously controllable in 10 ns step

50…10000 ns (10 s) for each half wave synchronously controllable in 10 ns step

Modes:

Single / Dual

PRF:

15...2000 Hz controllable in 1 Hz resolution

Gain: 0...100 dB controllable in 0.5 dB resolution

Advanced Low Noise

Design:

81 V peak to peak input referred to 80 dB gain / 25 MHz bandwidth

Frequency Band:

ISONIC utPod

ISONIC utPod LF

0.2 … 25 MHz Wide Band

0.03 … 15 MHz Wide Band

Digital Filter: 32-Taps FIR band pass with controllable lower and upper frequency limits

Ultrasound Velocity: 300…20000 m/s (11.81…787.4 "/ms) controllable in 1 m/s (0.1 "/ms) resolution

Range: 0.5...7000 s controllable in 0.01 s resolution

Display Delay: 0...3200 s controllable in 0.01 s resolution

Probe Angle: 0…90ocontrollable in 1oresolution

Probe Delay: 0 to 70 s controllable in 0.01 s resolution

Display Modes: RF, Rectified (Full Wave / Negative or Positive Half Wave)

Reject: 0...99 % of screen height controllable in 1% resolution

DAC / TCG: Multi-curve (up to 4)

Theoretical – through keying in dB/mm (dB/") factor as used for AWS evaluation,

inspection of highly attenuative materials, and the like

Experimental – through recording echo amplitudes from variously distanced equal

reflectors, up to 40 points

46 dB Dynamic Range, Slope 120 dB/s

Available for Rectified and RF Display

DGS: Standard Library for 18 probes / expandable

Gates: 2 Independent Gates

Gate Start and Width: Controllable over the whole range of A-Scan time base settings

in 0.1 mm / 0.001" resolution

Gate Threshold: 5…95 % of A-Scan height controllable in 1 % resolution

Signal Evaluation – Digital

Readout:

19 automatic functions / expandable; curved surface / thickness / skip correction for

angle beam probes; material velocity and probe delay auto-calibration for all types of

probes; AWS / API evaluation

Freeze: Freeze All / Freeze Peak

Data Storage Capacity: At least 100000 sets including calibration dumps accompanied with A-Scans

Data Logger: 1D (linear), 2D (X, Y), 3D (X, Y, Z), or 4D (X, Y, Z, retake) array

Internal Flash Memory:

2 Gigabytes

Output: USB – calibration and data files transfer to / from PC, generation of inspection reports

in editable format and hard copy / full control by PC

Screen:

3.2" High Color Resolution QVGA Sun-Readable Active Matrix LCD with an embedded

PICASO-GFX2 graphics controller

Controls: Touch Screen

Power: On-board Li-Ion Rechargeable Battery, 6-10 hours continuous operation depending on

mode of use

Mains - External AC/DC converter / charger 100-240 VAC, 40-70 Hz

Housing: IP 67 rugged plastic case

Dimensions: 1308442 mm (5.12"3.31"1.65")

Weight: 400 g (0.88 lbs) - with battery

Hardware Warranty: 12 months

Firmware Warranty:

Lifetime free update with the latest version available for free access at

www.sonotronndt.com/support.htm

ISONIC utPod for PC

Software Warranty:

Lifetime free update with the latest version available for free access at

www.sonotronndt.com/support.htm

Available in three colors: Blue, Red, Black

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 11 of 94

3. ISONIC utPod – Scope of Supply

# Item Order Code

(Part #)

Note

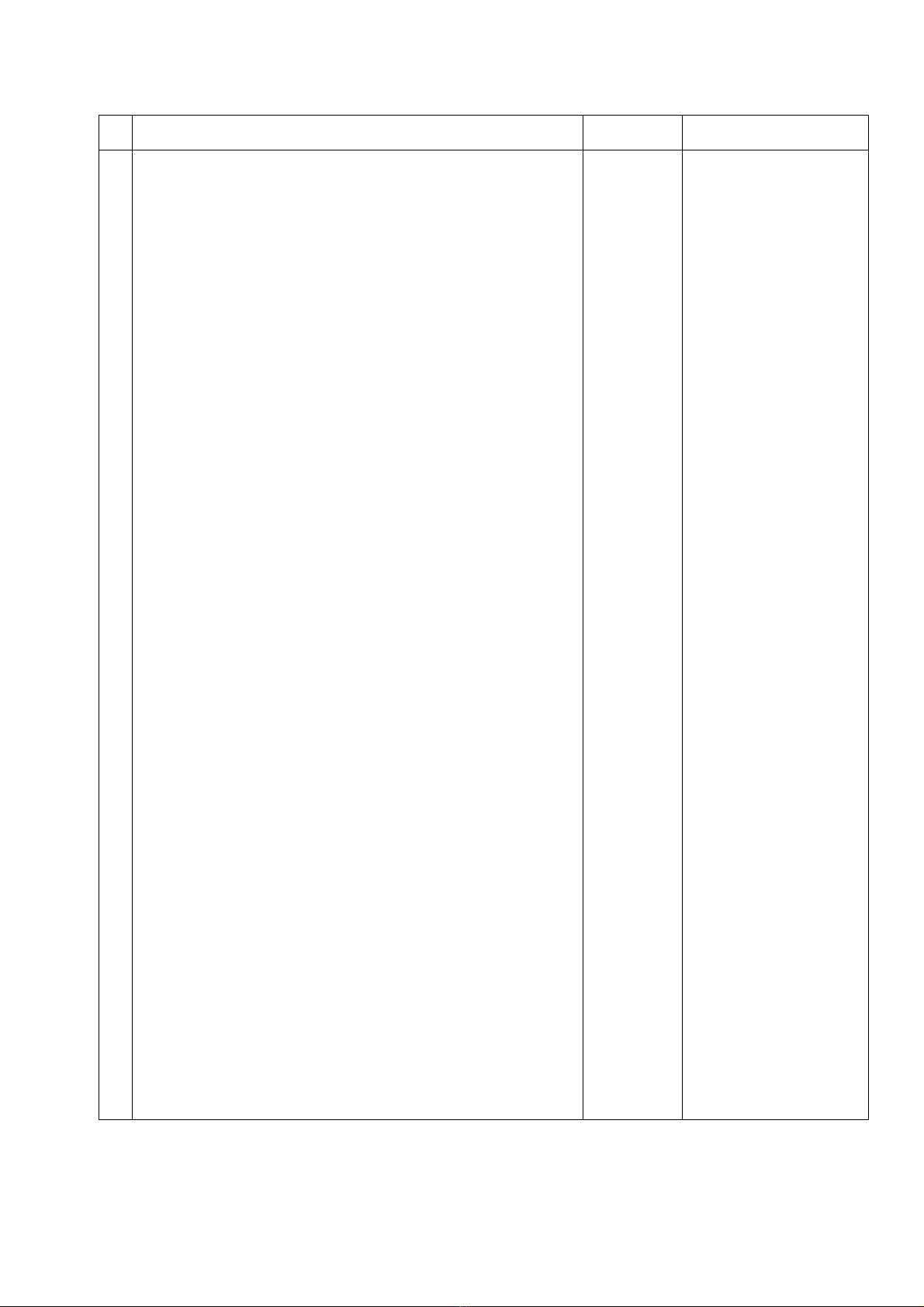

1 ISONIC utPod – Ultra-Portable Multi-Functional Ultrasonic

Testing Instrument

SA 80810

Including:

Top Performance Flaw Detector with DAC, DGS, TCG, Bipolar /

Unipolar Square Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue

Gain, AWS / API Evaluation

All-Functional A-Scan Thickness Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of single element probes with / without delay line

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switchable into the simplest thickness gauge mode (digial readout

only)

All-Functional A-Scan Corrosion Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of dual element probes

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switchable into the simplest corrosion gauge mode (digial readout

only)

Comprehensive Data Logger

Supervisor lock / unlock function

Full USB Controllability

ISONIC utPod for PC SW package (SW 808012) on the backup USB

key:

USB Connection to PC with live large high quality A-Scan /

instrument control over USB

Storing Calibrations / A-Scans / Data Logger files directly onto PCs

disk drive

Exporting Calibrations / A-Scans / Data Logger files from instrument

onto PCs disk drive

Importing Calibrations / A-Scans / Data Logger files from PCs disk

drive into instrument

Generating Inspection / Calibration Report - hard copy. PDF file,

editable MS Word file

Exporting Data Logger data Into Excel file

Operating Manual on the backup USB key

USB Cable for connection to the PC (S 808014)

Backup USB Key (S 808016)

Integrated Li-Ion Battery Pack (S 808018)

Stylus Stick (S 808020)

External charger with power cable (S 808022) - on-board battery

charging

2 G Internal Memory (SD Card)

400 g (0.88 lbs) including battery

12-month warranty for electronics and batteries

Lifetime free firmware upgrade for the instrument through

www.sonotronndt.com

Lifetime free software upgrade for the ISONIC utPod for PC SW

package through www.sonotronndt.com

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 12 of 94

# Item Order Code

(Part #)

Note

2 ISONIC utPod LF – Ultra-Portable Multi-Functional Ultrasonic

Testing Instrument Adapted for Low Frequency Ultrasound

Applications

SA 80812

Including:

Top Performance Flaw Detector with DAC, DGS, TCG, Bipolar /

Unipolar Square Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue

Gain, AWS / API Evaluation

Extended Low Frequency Band - down to 30 kHz: 30 kHz ... 15

MHz

Expanded Range for Initial Pulse Width Tuning: 50 ns ... 10000 ns

(10 s)

All-Functional A-Scan Thickness Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of single element probes with / without delay line

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switchable into the simplest thickness gauge mode (digial readout

only)

All-Functional A-Scan Corrosion Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of dual element probes

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switchable into the simplest corrosion gauge mode (digial readout

only)

Comprehensive Data Logger

Supervisor lock / unlock function

Full USB Controllability

ISONIC utPod for PC SW package (SW 808012) on the backup USB

key:

USB Connection to PC with live large high quality A-Scan /

instrument control over USB

Storing Calibrations / A-Scans / Data Logger files directly onto PCs

disk drive

Exporting Calibrations / A-Scans / Data Logger files from instrument

onto PCs disk drive

Importing Calibrations / A-Scans / Data Logger files from PCs disk

drive into instrument

Generating Inspection / Calibration Report - hard copy. PDF file,

editable MS Word file

Exporting Data Logger data Into Excel file

Operating Manual on the backup USB key

USB Cable for connection to the PC (S 808014)

Backup USB Key (S 808016)

Integrated Li-Ion Battery Pack (S 808018)

Stylus Stick (S 808020)

External charger with power cable (S 808022) - on-board battery

charging

2 G Internal Memory (SD Card)

400 g (0.88 lbs) including battery

12-month warranty for electronics and batteries

Lifetime free firmware upgrade for the instrument through

www.sonotronndt.com

Lifetime free software upgrade for the ISONIC utPod for PC SW

package through www.sonotronndt.com

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 13 of 94

# Item Order Code

(Part #)

Note

3 ISONIC utPod ADL – Ultra-Portable Multi-Functional Ultrasonic

Testing Instrument with Real Time Logger

SA 80814

Including:

Top Performance Flaw Detector with DAC, DGS, TCG, Bipolar /

Unipolar Square Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue

Gain, AWS / API Evaluation

All-Functional A-Scan Thickness Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of single element probes with / without delay line

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switchable into the simplest thickness gauge mode (digial readout

only)

All-Functional A-Scan Corrosion Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of dual element probes

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switchable into the simplest corrosion gauge mode (digial readout

only)

Comprehensive Data Logger

Automatic Real Time Logger

Docking Terminal for Integration into Autonomous Automatic Inspection

System

Supervisor lock / unlock function

Full USB Controllability

ISONIC utPod for PC SW package (SW 808012) on the backup USB

key:

USB Connection to PC with live large high quality A-Scan /

instrument control over USB

Storing Calibrations / A-Scans / Data Logger files directly onto PCs

disk drive

Exporting Calibrations / A-Scans / Data Logger files from instrument

onto PCs disk drive

Importing Calibrations / A-Scans / Data Logger files from PCs disk

drive into instrument

Generating Inspection / Calibration Report - hard copy. PDF file,

editable MS Word file

Exporting Data Logger data Into Excel file

Operating Manual on the backup USB key

USB Cable for connection to the PC (S 808014)

Backup USB Key (S 808016)

Integrated Li-Ion Battery Pack (S 808018)

Stylus Stick (S 808020)

External charger with power cable (S 808022) - on-board battery

charging

2 G Internal Memory (SD Card)

400 g (0.88 lbs) including battery

12-month warranty for electronics and batteries

Lifetime free firmware upgrade for the instrument through

www.sonotronndt.com

Lifetime free software upgrade for the ISONIC utPod for PC SW

package through www.sonotronndt.com

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 14 of 94

# Item Order Code

(Part #)

Note

4 ISONIC utPod LF ADL – Ultra-Portable Multi-Functional

Ultrasonic Testing Instrument with Real Time Logger Adapted for

Low Frequency Ultrasound Applications

SA 80816

Including:

Top Performance Flaw Detector with DAC, DGS, TCG, Bipolar /

Unipolar Square Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue

Gain, AWS / API Evaluation

Extended Low Frequency Band - down to 30 kHz: 30 kHz ... 15

MHz

Expanded Range for Initial Pulse Width Tuning: 50 ns ... 10000 ns

(10 ms)

All-Functional A-Scan Thickness Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of single element probes with / without delay line

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switcheable into the simplest thickness gauge mode (digial readout

only)

All-Functional A-Scan Corrosion Gauge - Bipolar / Unipolar Square

Wave Pulser, 100 MHz Sampling Rate, 100 dB Analogue Gain, High

Precision

Use of dual element probes

Through-Paint / Through Coating Thickness Measurement with use

of regular single element probes - no limit on the thickness of paint / coating

layer

Far Side Wall Thickness Measurement in tubes with use of regular

single element probes

Switcheable into the simplest corrosion gauge mode (digial readout

only)

Comprehensive Data Logger

Automatic Real Time Logger

Docking Terminal for Integration into Autonomous Automatic Inspection

System

Supervisor lock / unlock function

Full USB Controllability

ISONIC utPod for PC SW package (SW 808012) on the backup USB

key:

USB Connection to PC with live large high quality A-Scan /

instrument control over USB

Storing Calibrations / A-Scans / Data Logger files directly onto PCs

disk drive

Exporting Calibrations / A-Scans / Data Logger files from instrument

onto PCs disk drive

Importing Calibrations / A-Scans / Data Logger files from PCs disk

drive into instrument

Generating Inspection / Calibration Report - hard copy. PDF file,

editable MS Word file

Exporting Data Logger data Into Excel file

Operating Manual on the backup USB key

USB Cable for connection to the PC (S 808014)

Backup USB Key (S 808016)

Integrated Li-Ion Battery Pack (S 808018)

Stylus Stick (S 808020)

External charger with power cable (S 808022) - on-board battery

charging

2 G Internal Memory (SD Card)

400 g (0.88 lbs) including battery

12-month warranty for electronics and batteries

Lifetime free firmware upgrade for the instrument through

www.sonotronndt.com

Lifetime free software upgrade for the ISONIC utPod for PC SW

package through www.sonotronndt.com

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 15 of 94

# Item Order Code

(Part #)

Note

5 Table Stand for desktop usage of the ISONIC utPod S 808040 Optional Item

6 "Goose Neck" Adaptor S 808042 Optional Item

5 Arm Fixture for instrument usage in the field

S 808044 Optional Item

6 Soft case for ISONIC utPod S 808046 Optional Item

7 Ultrasonic probes, fixtures, scanners, cables and other

accessories depending on the inspection tasks to be resolved

Optional Items

Ultrasonic probes, fixtures,

scanners, cables and other

accessories from any manufacturer

may be used

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 16 of 94

4. Operating ISONIC utPod

Please read the following information before you use ISONIC utPod. It is essential to read and understand

the following information so that no errors occur during operation, which could lead damaging of the unit or

misinterpretation of inspection results

4.1. Preconditions for ultrasonic testing with ISONIC utPod

4.1.1. General

The correct and effective use of ultrasonic test equipment requires the interaction of three factors:

The test equipment itself

The specific test applications

The operator

The purpose of this operating manual will be to give instructions in the basic set-up and functional operation

of ISONIC utPod. Such information is covered in detail within the manual. Other variable factors, some of

which are noted below, and the actions necessary to control them, are the responsibility of the user. Details

regarding these factors are beyond the scope of the operating manual

4.1.2. Training

The adequate training of the operators should be provided to assure competence in the operation of the

ISONIC utPod and in the associated factors. Operator of ISONIC utPod must be certified as at least Level 2

Ultrasonic Examiner. The operator must understand and provide for interpretation and compliance with the

specifications covering its work, generated by such groups as in-house Quality Assurance, Technical

Societies, Industry Groups, or Government Agencies

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 17 of 94

4.2. ISONIC utPod Controls and Terminals

DC Charger Input

for Internal Battery

Battery

Charge

Status LED

RED – charging

GREEN - full

Sun Readable qVGA

Touch Screen

Power

Switch

Button

USB PortProbe Terminal 2Probe Terminal 1

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 18 of 94

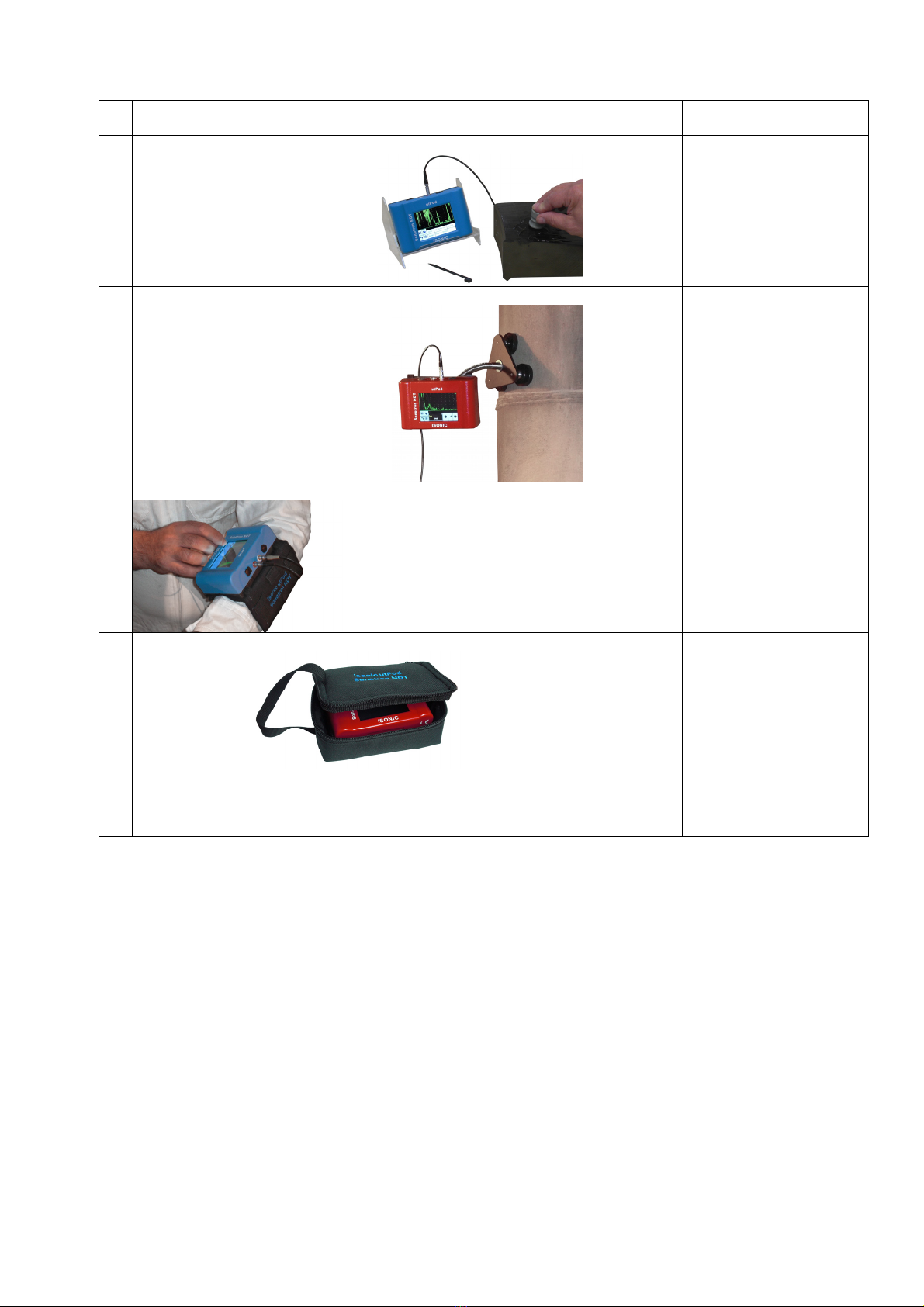

4.3. Turning On / Off

ISONIC utPod is powered by built-in rechargeable battery

To turn ISONIC utPod on press on power switch button. An automatic system test and boot-up routine will

be executed then indicating the screen as below

Wait until ISONIC utPod start screen appears upon boot-up completed:

Click on to operate ISONIC utPod as flaw detector (refer to chapter 5 of the operating manual)

Click on to operate ISONIC utPod as thickness gauge using single element probes (refer to

chapter 6 of the operating manual)

Click on to operate ISONIC utPod as corrosion gauge using dual element probes (refer to chapter

7 of the operating manual)

Click on to format data logger of ISONIC utPod (refer to chapter 8 of the operating manual)

Battery Status

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 19 of 94

Click on in order to:

select measurement units (metric or imperial)

select the dialogue language

calibrate touch screen

switching built-in buzzer ON or OFF

setting power saving (sleep mode) parameters

identifying version (release number) of the currently installed firmware

Refer to Chapter 9 of present Operating Manual

To turn ISONIC utPod off click on or press power switch button during few seconds

ISONIC utPod from Sonotron NDT - Operating Manual – Revision 1.18 - Page 20 of 94

5. Flaw Detector Mode

5.1. Top Level Screen

Click on to store A-Scan

accompanied with signal evaluation

results and calibration set into a file

Click on to upload A-Scan

accompanied with signal evaluation

results and calibration set from a

file

Click on to freeze / return to

live A-Scan

Click on to return to upper

level menu. Current settings of flaw

detector will be kept as default then

5.2. Submenu BASICS

Click on in the Top Level Screen to enter, the screen as below appears

Table of contents

Popular Test Equipment manuals by other brands

ViewZ

ViewZ VZ-7IPTM user manual

Promax

Promax OL-612 user manual

Avtech

Avtech AVX-FILT Series instructions

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. KEW 4506 instruction manual

Applied Instruments

Applied Instruments XR-3 Operation manual

Unit

Unit UT673A quick start guide

Metrix

Metrix GX-1030 user manual

Pro's Kit

Pro's Kit 8PK-4103IN manual

FRONIUS

FRONIUS Calibration system 2.0 operating instructions

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 4200 instruction manual

phase II+

phase II+ PHT-5000 Operation manual

Dilog

Dilog DL9120 operating instructions