– 2 –

TABLE OF CONTENTS

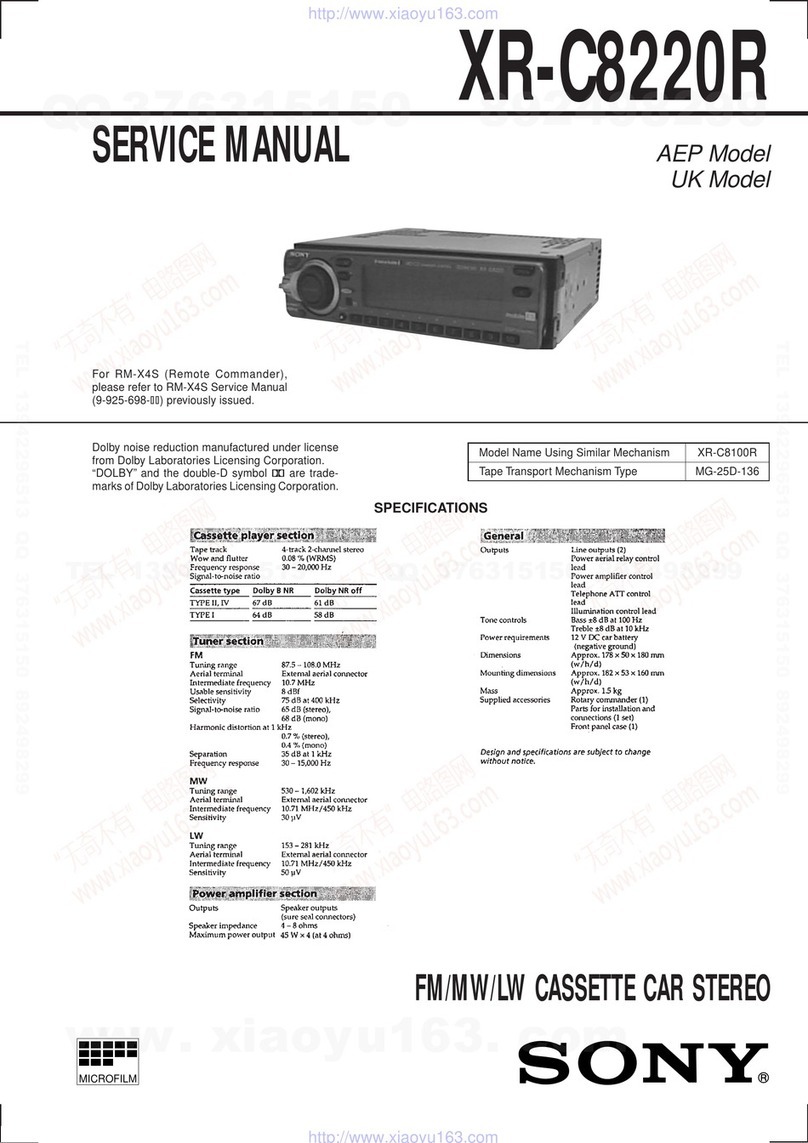

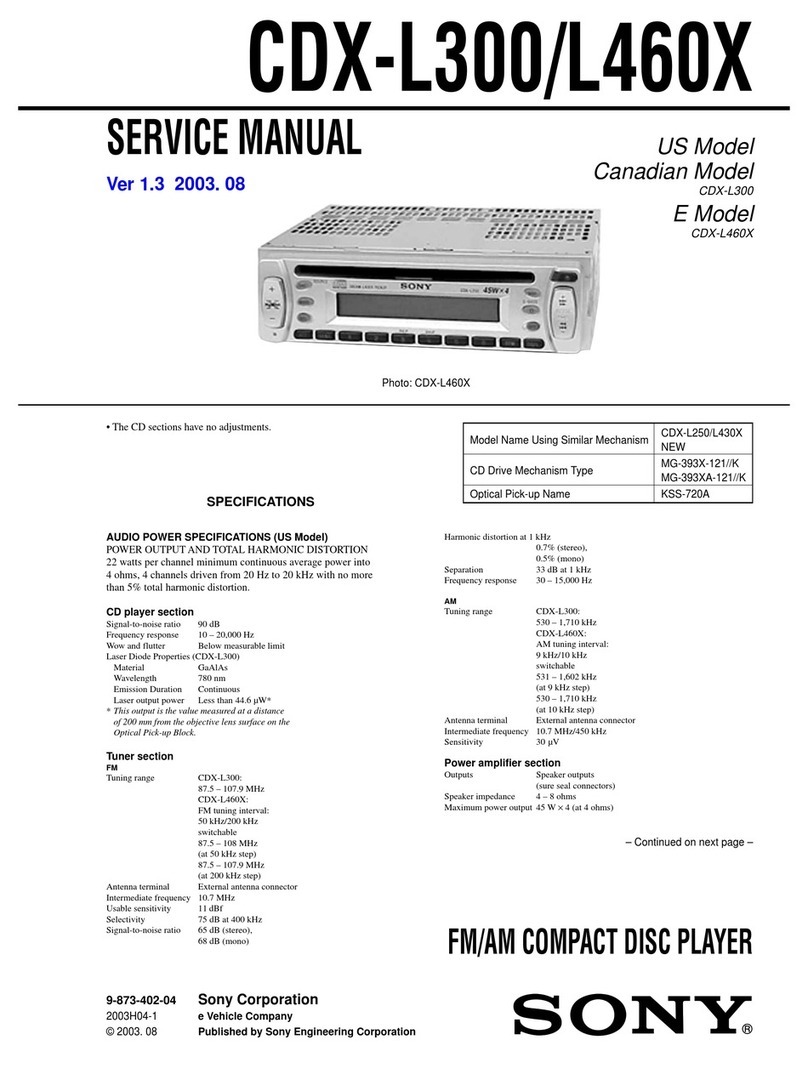

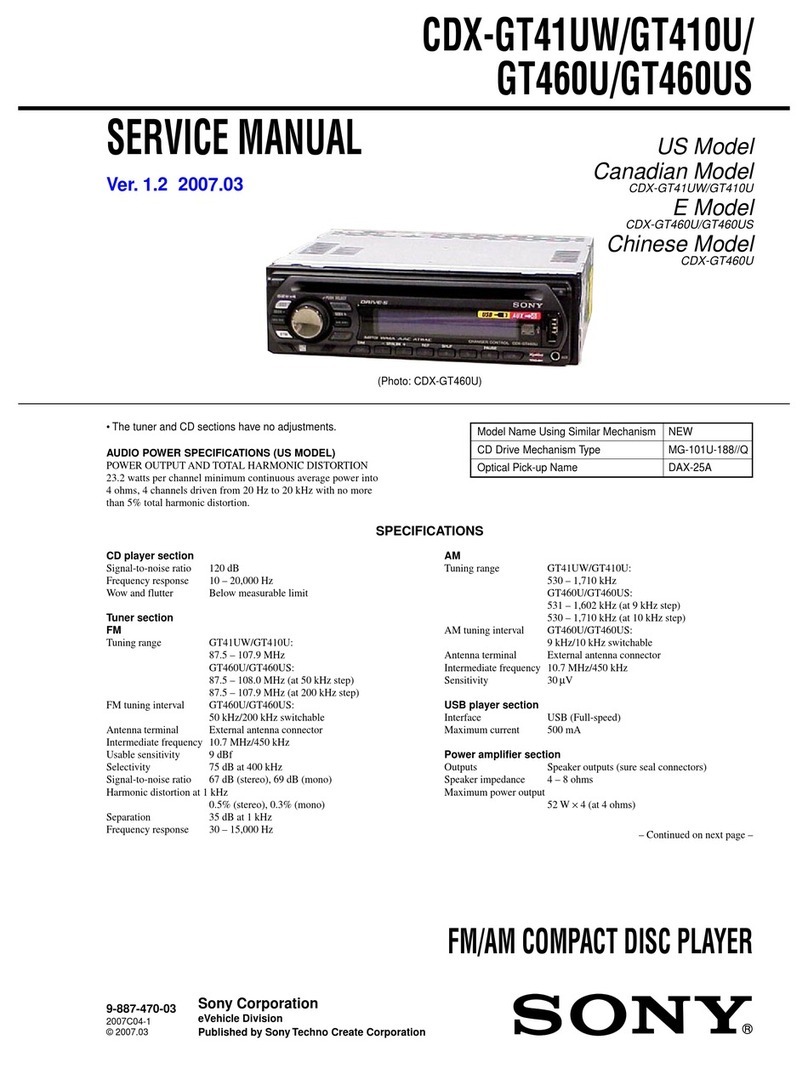

1. GENERAL

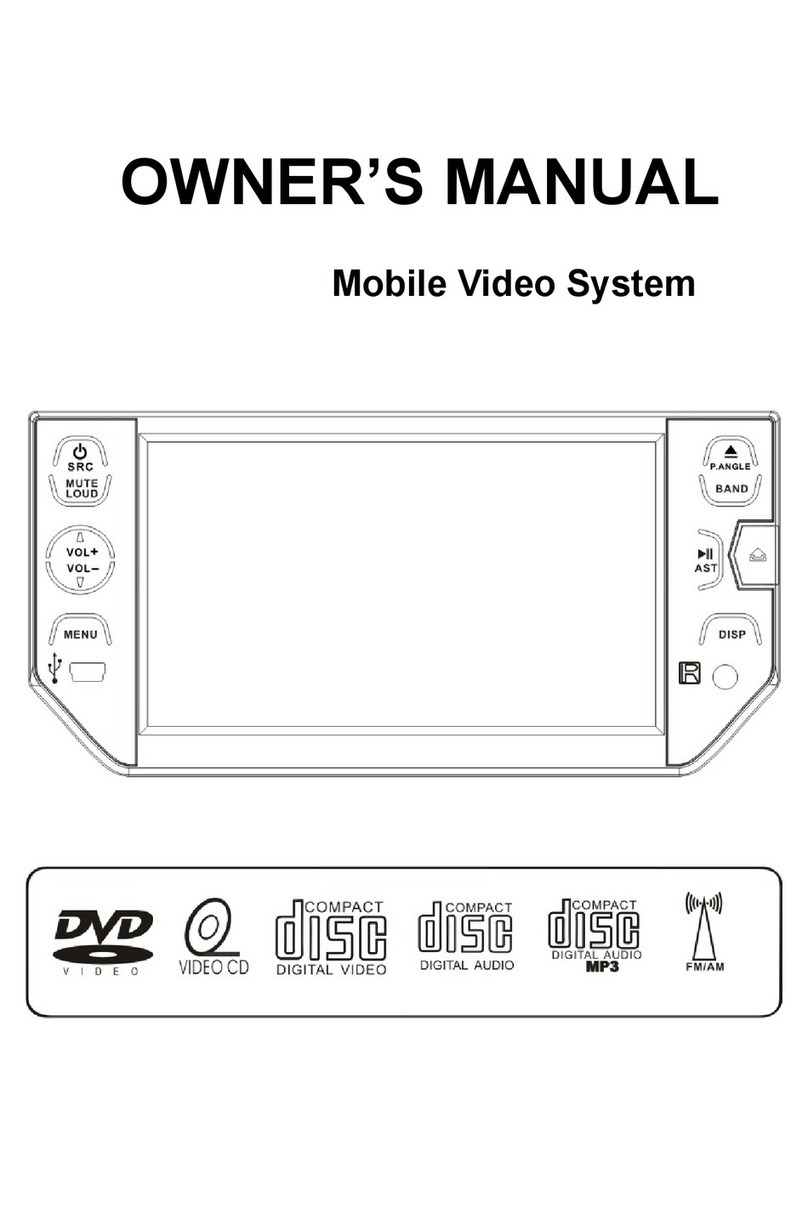

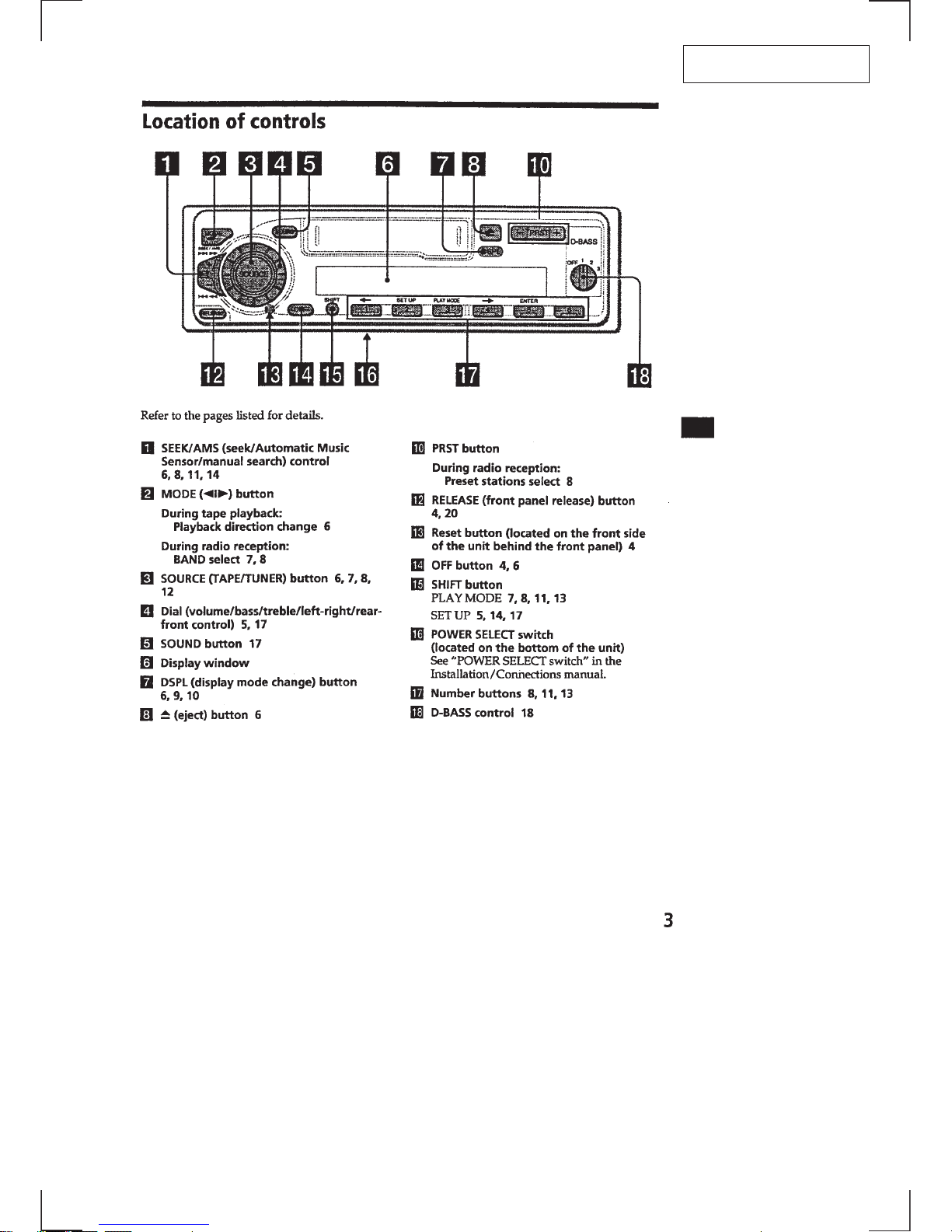

Location of Controls ....................................................... 3

Resetting the Unit ........................................................... 4

Detaching the Front Panel............................................... 4

Setting the Clock............................................................. 4

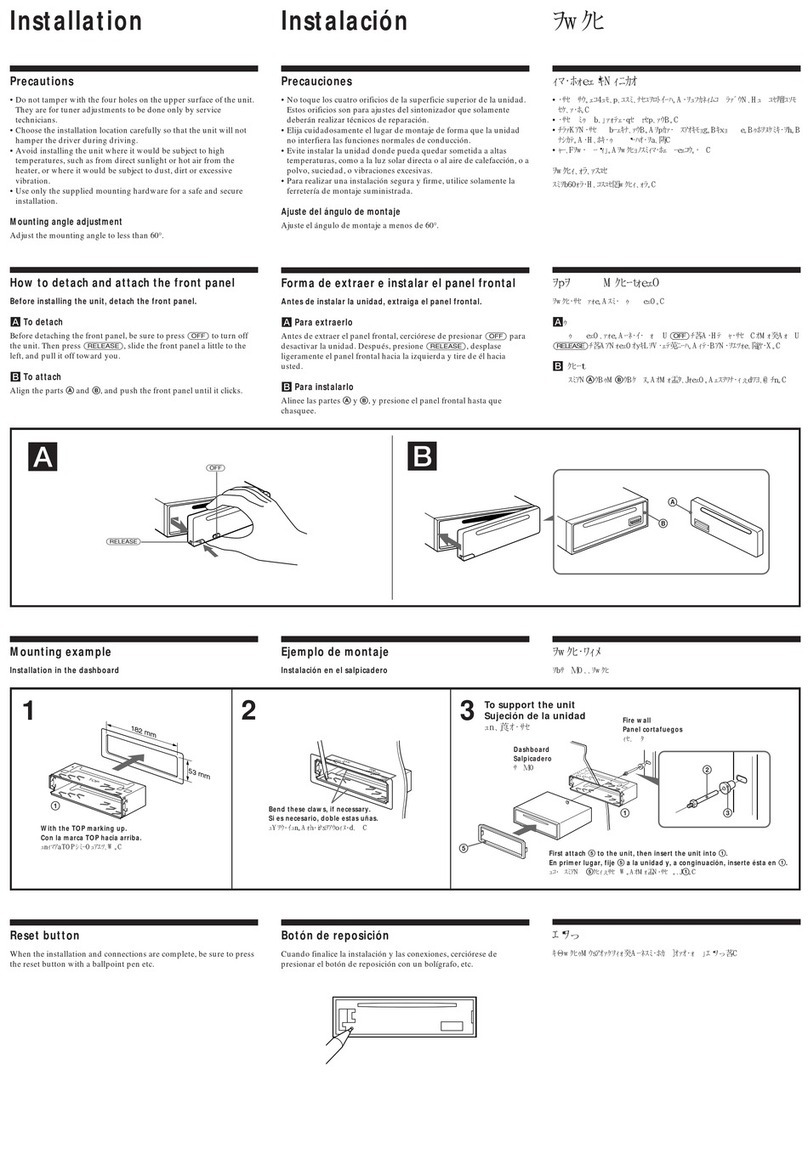

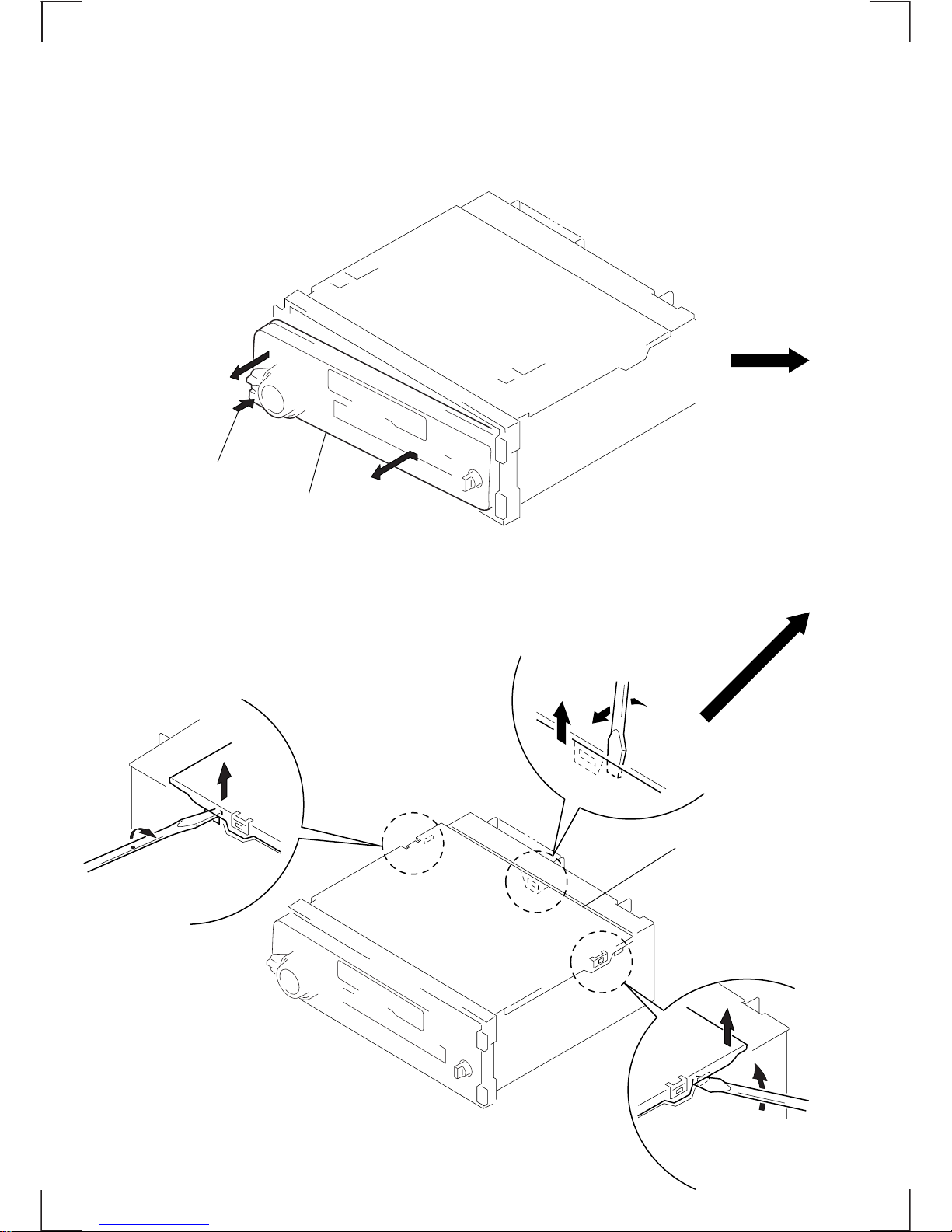

Installation....................................................................... 5

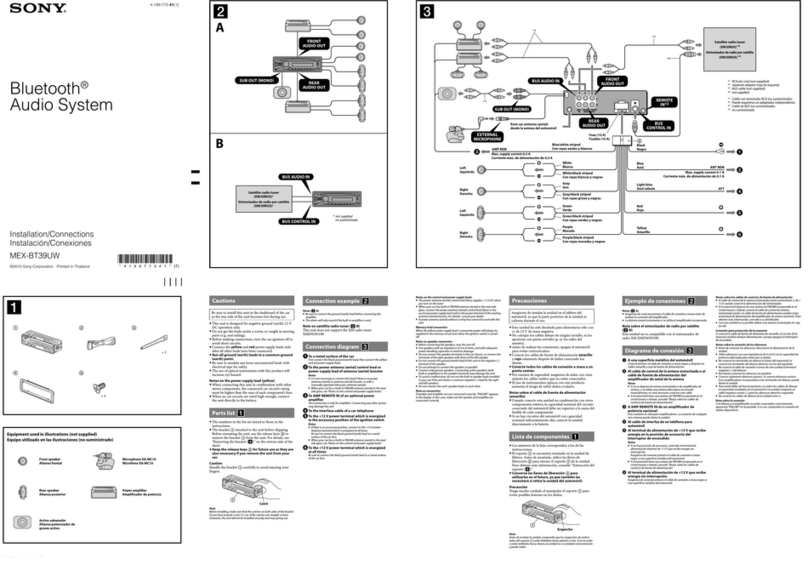

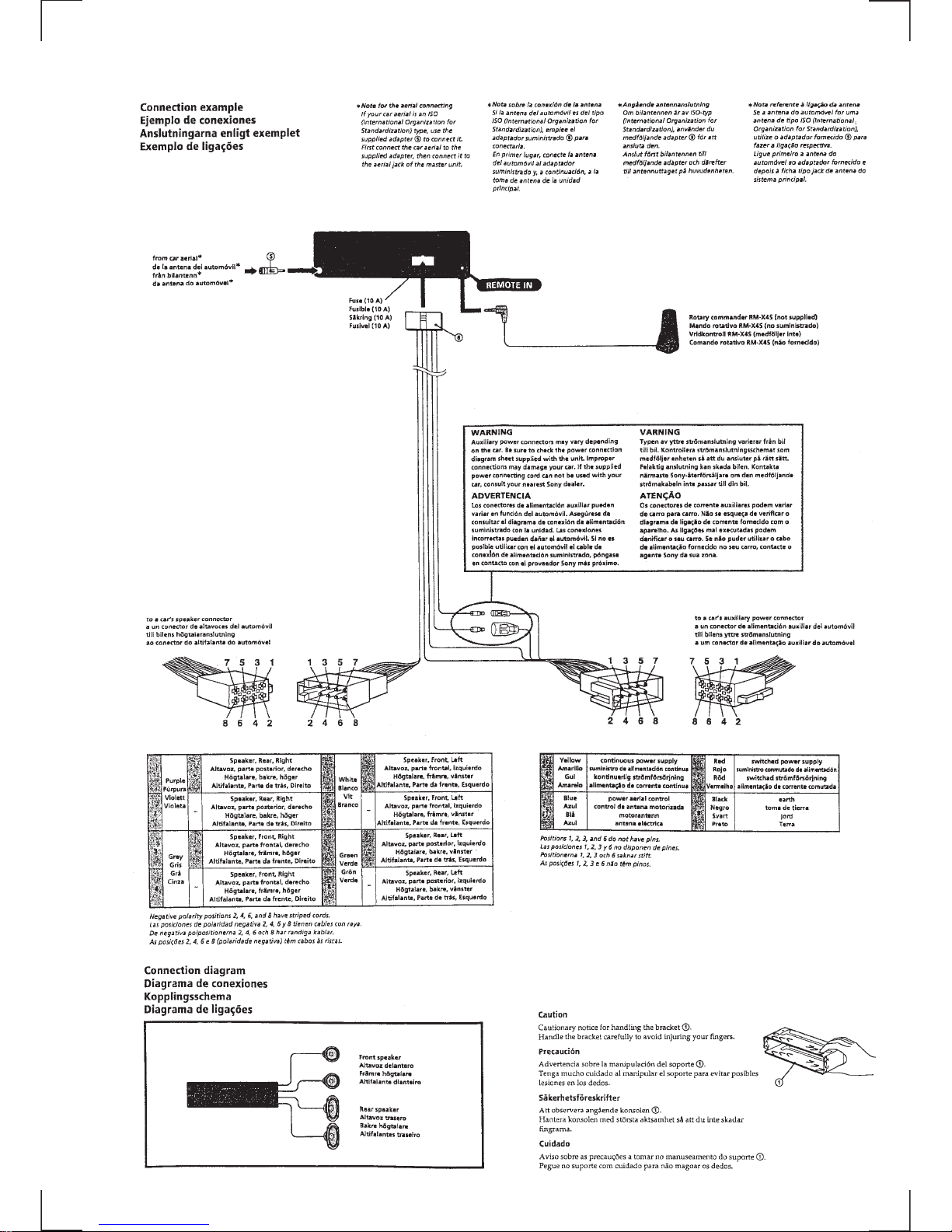

Connections..................................................................... 6

2. DISASSEMBLY ......................................................... 8

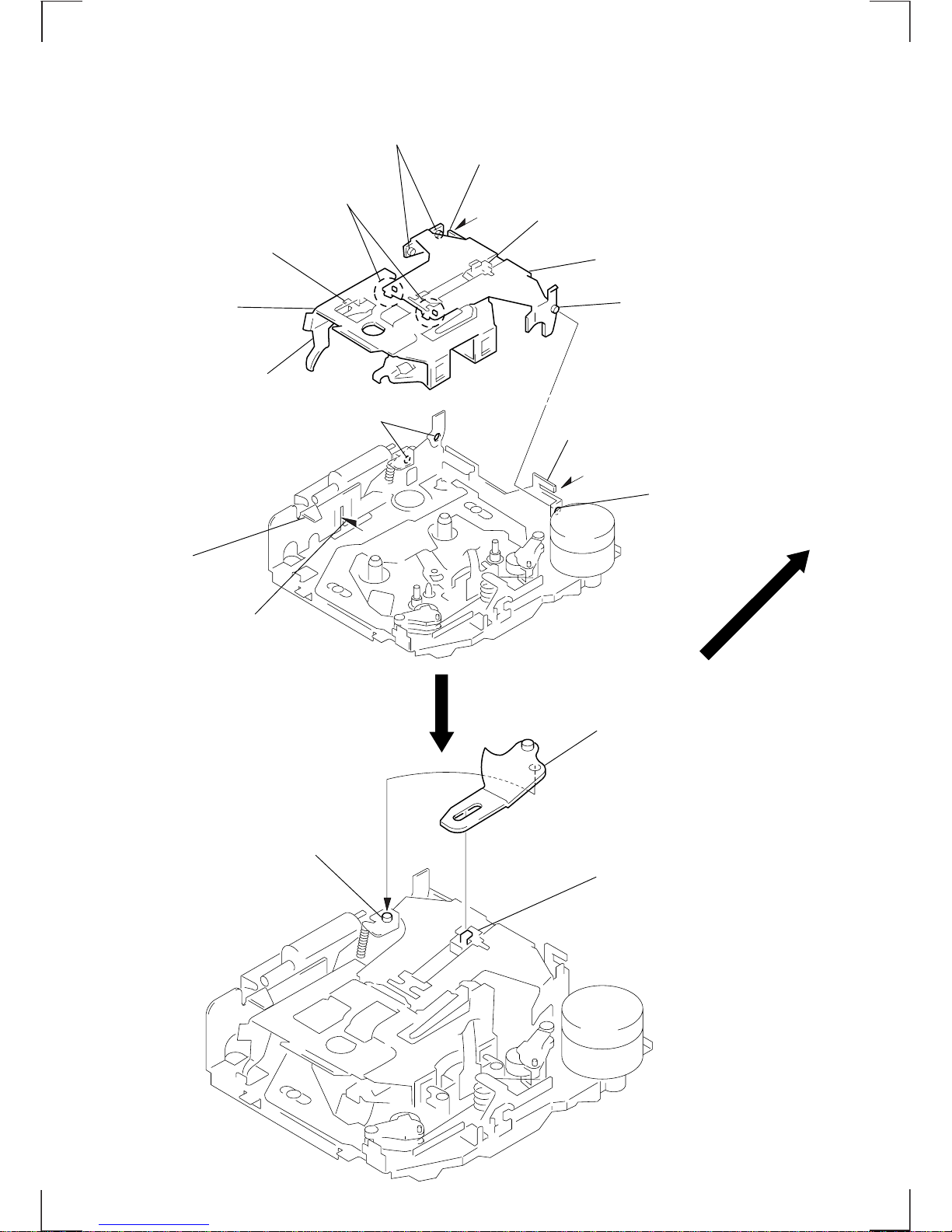

3. ASSEMBLY OF MECHANISM DECK ............ 10

4. MECHANICAL ADJUSTMENTS....................... 13

5. ELECTRICAL ADJUSTMENTS

Test Mode ........................................................................ 13

Tape Deck Section .......................................................... 13

Tuner Section .................................................................. 14

6. DIAGRAMS ................................................................. 17

6-1. Printed Wiring Board –MAIN Section– ........................ 19

6-2. Schematic Diagram –MAIN (1/2) Section–.................. 21

6-3. Schematic Diagram –MAIN (2/2) Section–.................. 23

6-4. Printed Wiring Board –PANEL Section– ...................... 25

6-5. Schematic Diagram –PANEL Section– ......................... 27

6-6. IC Pin Function Description ........................................... 29

7. EXPLODED VIEWS................................................ 31

8. ELECTRICAL PARTS LIST ............................... 34

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.