SAFETY CHECK-OUT

After correcting the original service problem, perform the follow-

ing safety checks before releasing the set to the customer:

Checktheantennatermmals, metal trim, "metallized"knobs, screws,

and all otherexposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, mustnotexceed0.5 rnA (500 microampers). Leak-

age current can be measured by any one

of

three methods.

I. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers' mstructions to use these

mstruments.

2.

A battery-operated AC milliammeter.

The

Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistorby means

of

a YOM

orbattery-operatedAC voltmeter. The

"hmit"

indicatiOn is 0.75

Y,

so analog meters must have an accurate low-voltage scale.

The

Simpson 250 and Sanwa SH-63Trd are examples

of

a pas-

sive YOM that is suitable. Nearly all battery operated digital

multimeters that have a

2Y

AC range are smtable. (See Fig. A)

0

1511F

To

ExposedMetal

Parts on

Set

1.5/<Q

..,.

Earth Ground

AC

voltmeter

(0

75V)

Fig.

A.

Using

an AC voltmeter

to

check AC

leakage.

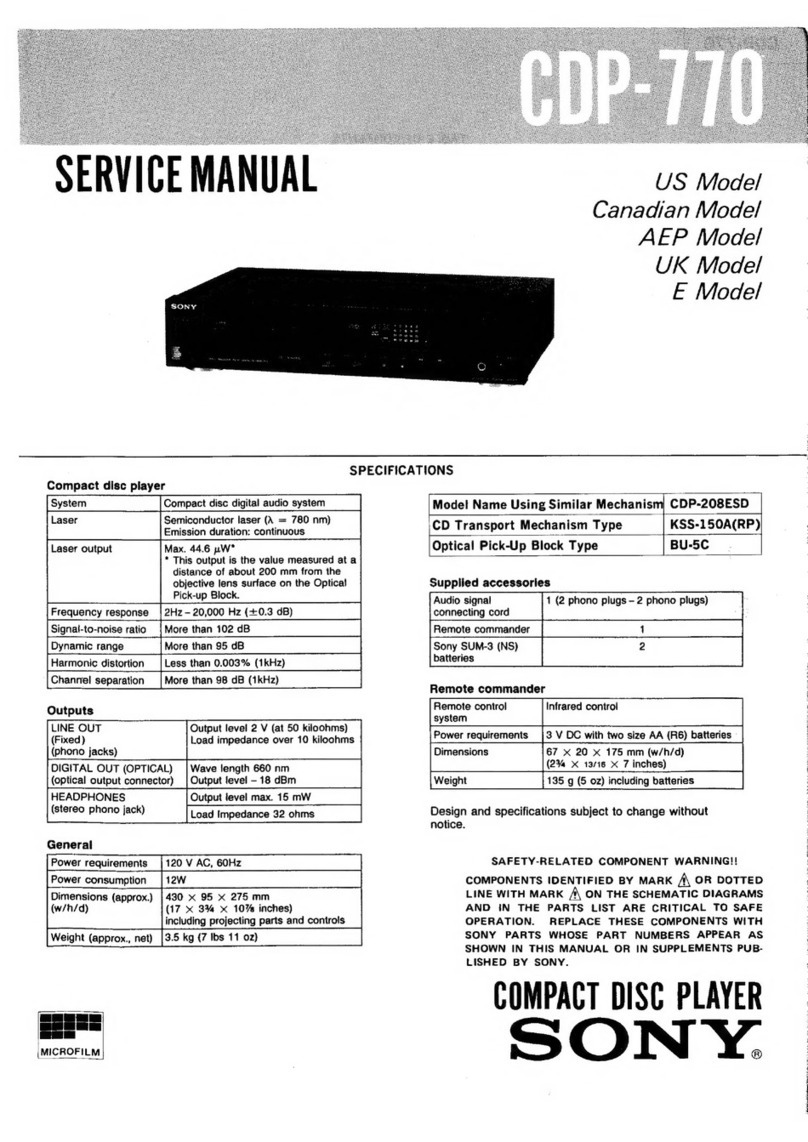

SAFETY-RELATED COMPONENT WARNING

!!

COMPONENTS IDENTIFIEDBYMARK,±;OR DOTTED LINE

WITH MARK

,±;

ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL

TO

SAFE OPERATION.

REPLACE

THESE

COMPONENTS

WITH

SONY

PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SECTION 1

SERVICING NOTE

NOTES ON HANDLINGTHE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laserdiode in the optical pick-up block may sufferelectrostatic

breakdown because

of

the potential difference generated by the

charged electrostatic load, etc. on clothmg and the human body.

During repair, pay attention to electrostaticbreakdown and also use

the procedure in the printed matter which is mcluded in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to befocused on

the

d1sc

reflective surface by the objective lens m the optical pick-

up block. Therefore, when checking the laser diode emiss10n, ob-

serve from more than

30

em

away from the objective lens.

LASER

DIODE

AND

FOCUS

SEARCH

OPERATION

CHECK

Carry out the "Scurve check" m

"CD

section adjustment" andcheck

that the S curve waveform is output repeatedly.

ATTENTION

AU

COMPOSANT AVANT RAPPORT

ALA SECURITE!!

LES COMPOSANTS IDENTIFIES

PAR

UNE MARQUE LtSUR

LES DIAGRAMMES SCHEMATIQUES ET LA LISTE DES

PIECES

SONT

CRITIQUES

POUR

LA

SECURITE

DE

FONCTIONNEMENT.NE REMPLACER CES COMPOSANTS

QUE PAR

DES

PIECES

SONY

DONT

LES NUMEROS

SONT

DONNES

DANS

CE

MANUEL

OU

DANS

LES

SUPPLEMENTS PUBLIES

PAR

SONY.

-3-