D-555/Z555

|

TABLE

OF

CONTENTS

Section

Title

Page

Specifications:

++++++r

etree

eects

cece

cence

teen

eens

1

1.

GENERAL

Location

and

Fanction

of

Controls:-+:--::++++::

2

2.

SERVICING

NOTES

Notes

on

Handing

the

Optical

Pick-up

Block::

3

Flexible

Circuit

Board

Reparing:::::++:++++++++:

3

Notes

on

Chip

Component

Replacement::++:::++

3

Before

Replacing

the

Optical

Block

-+--:++++++::

3

Notes

on

Laser

Diode

Emission

Check-::-++-++*

4

Laser

Diode

Check

Procedure

--++---++-++++++#+++.

4

Service

Mode

(service

program)

-:++++rsssterrees

5

Section

Title

Page

3.

ELECTRICAL

ADJUSTMENTS:---:-----+++--+++++5:

6

’

4,

DIAGRAMS

4-

i.

Waveforms

errr

e

rere

eee

ee

ee

ee

ee

ay

12;

4-2,

Block

Diagram

-:+s+tstesese

eet

ee

tects

eeees

13

4-3.

Printed

Wiring

Boards—Main

Section—---:

16

4-4,

Schematic

Diagram—Main

Section—-::::::-

21

4-5.

Schematic

Diagram—Servo

Section—::-::::

24

4-6.

Printed

Wiring

Boards—Servo

Section—-:-:

27

4-7.

IC

Block

Diagram

--+++recsceeeeeeeeeeeeeeee

31

5.

EXPLODED

VIEWS.

-

0050+

esiisinsie

ec

cdse

sesamiae

33

G.

ELECTRICAL

PARTS!

LIST

«+

+=isiis's

cscs

sessions

37

SECTION

1

GENERAL

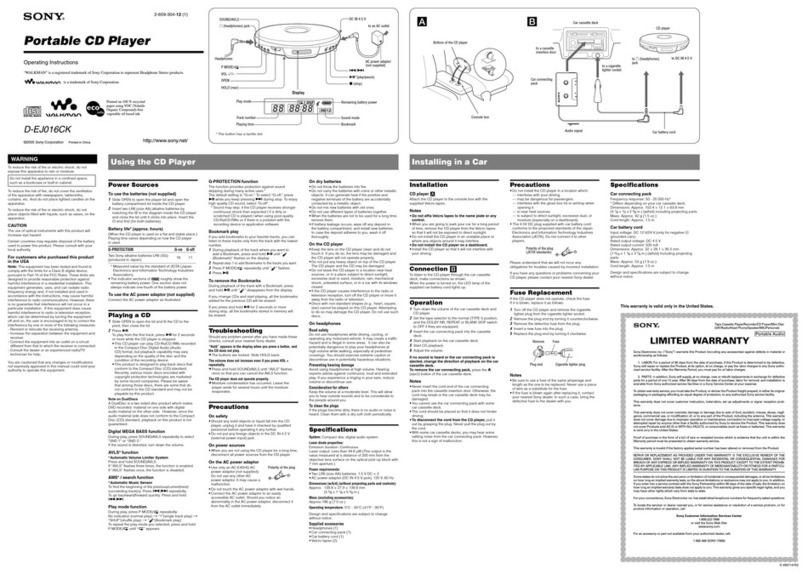

Kd

/

BR

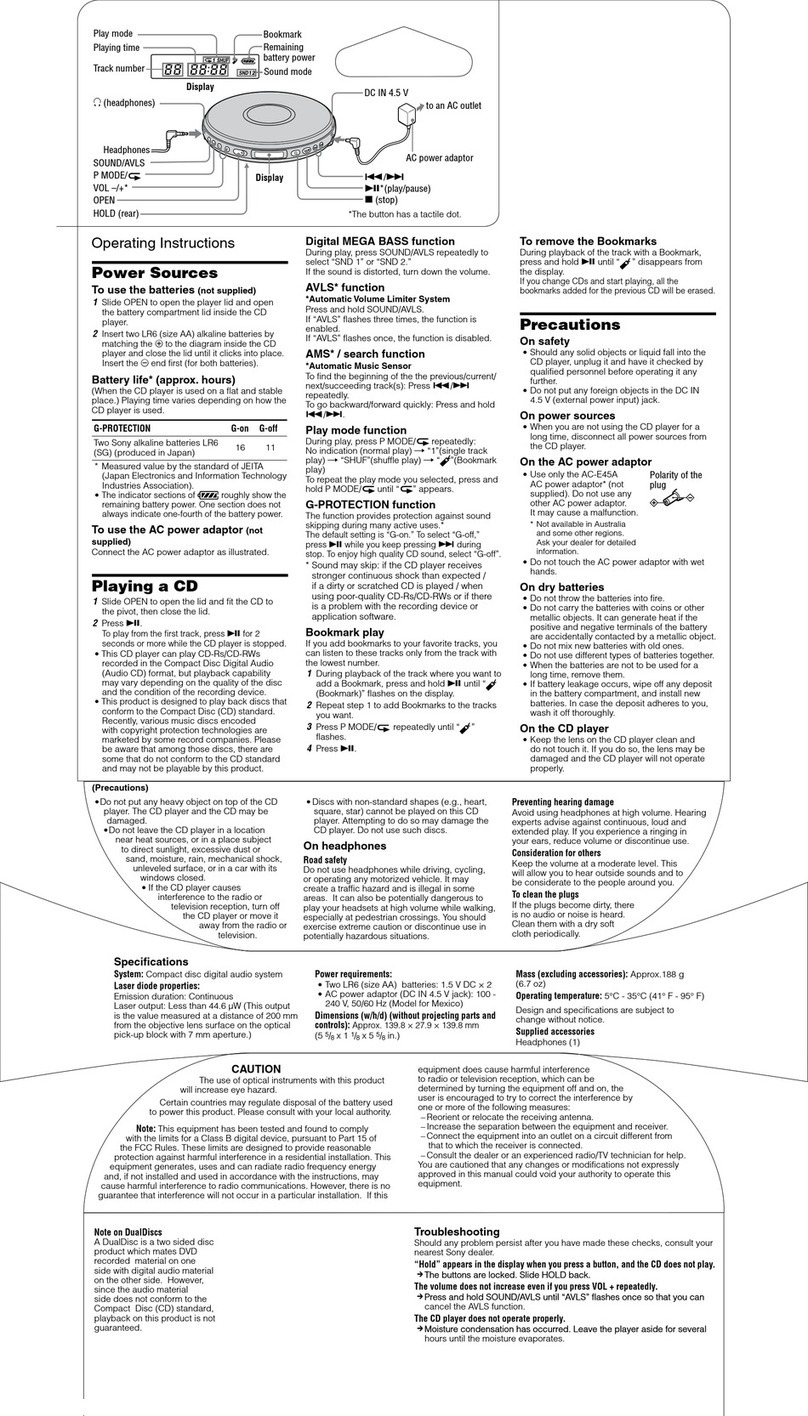

(AMS*/

SEARCH/INDEX)

buttons

@

(stop)

button

OPEN

button

®&

Il

(play/

pause)

button

p,_/_f\_\

PHONES

(headphones)

jack

HOLD

switch

Hee

(stereo

minijack)

KEY

MODE

(locating

mode

select)

button

Front

display

window

Normally

displays

the

track

number

and

the

elapsed

playing

time.

When

the

power

is

supplied

through

the

DC

IN

9V

jack

the

window

will

light

up.

°°

PLAY

MODE

(playing

mode

select)

button

ENTER/REMAIN

button

*AMS

is

the

abbreviation

of

Automatic

Music

Sensor.

“If

lit

for

a

long

time,

the

unit

may

become

warm,

but

that

is

not

a

problem.

EFFECT

(sound

effect

control)

button.

EQ

(graphic

equalizer

band

select

button)

VOLUME

control

buttons

Adjusts

the

sound

from

the

PHONES

jack.

EFFECT

MODE

(sound

effect

mode

select)

button

REMOTE

jack

LINE

OUT

jack

(stereo

minijack)

DC

IN

SV

(external

power

:

OPTICAL

DIGITAL

OUT

input)

jack

connector

Upper

display

window

Normally

displays

the

level

of

the

volume

and

the

left

(L)-and

right

(R)

-

channel.

When

the

power

is

supplied

through

the

DC

IN

9V

jack

the

window

will

light

up.

a