Sony Disman D-25 User manual

Other Sony CD Player manuals

Sony

Sony D-VJ65 User manual

Sony

Sony CDP-CX235 - Mega Changer Installation guide

Sony

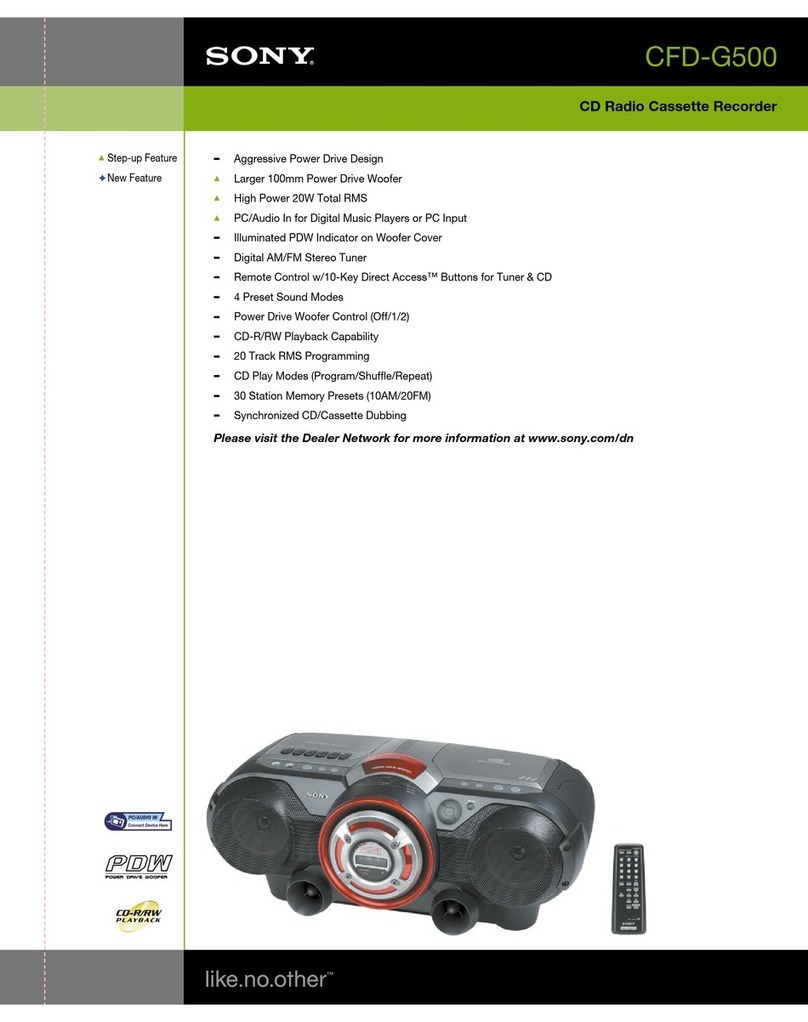

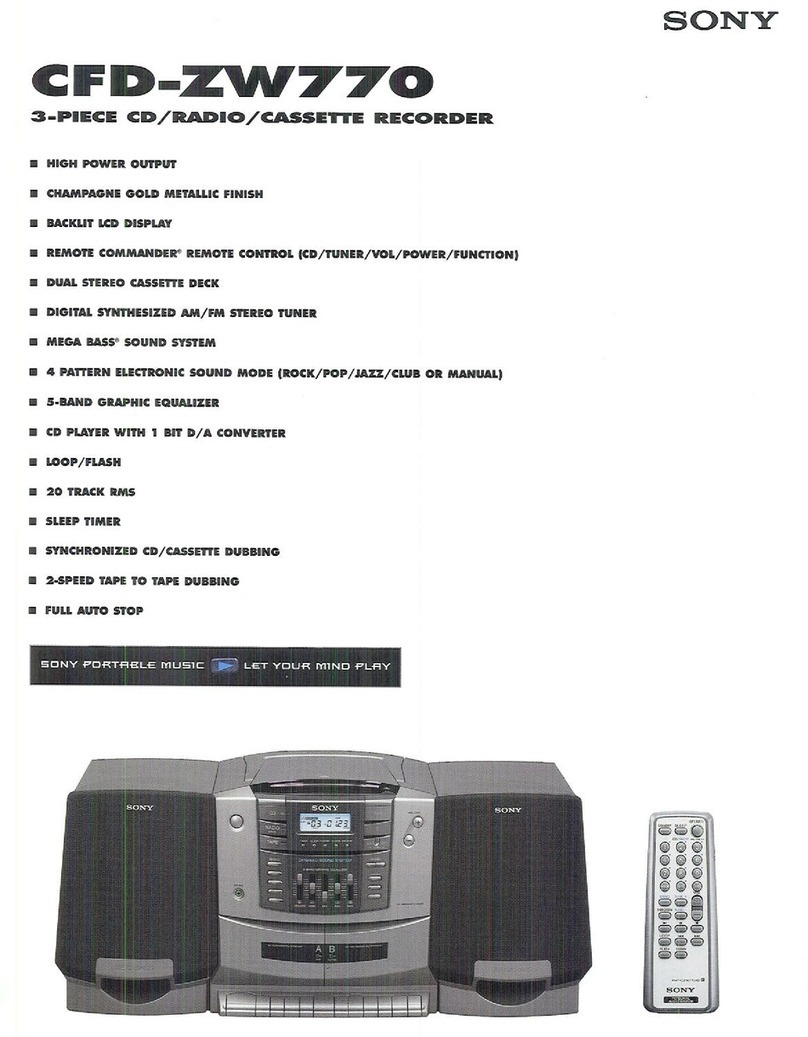

Sony CFD-ZW770 - Cd Radio Cassette-corder User manual

Sony

Sony CDX-GT07 - Fm/am Compact Disc Player User manual

Sony

Sony CDP-CX151 User manual

Sony

Sony CFD-S250 - Cd Radio Cassette-corder User manual

Sony

Sony Walkman MZ-RH710 User manual

Sony

Sony CDP-XB720 User manual

Sony

Sony CDX-U300 User manual

Sony

Sony D-NE715 - Portable Cd Player User manual

Sony

Sony D-NF611 - Portable Cd Player User manual

Sony

Sony CFM-A50 User manual

Sony

Sony CDJ-500 User manual

Sony

Sony Walkman D-NE511 User manual

Sony

Sony CFD-S28 - Cd Radio Cassette-corder User manual

Sony

Sony CDX-454XRF User manual

Sony

Sony CDX-RA700 - Motorized Synchro-flip Detachable... Product guide

Sony

Sony Walkman NW-A605 User manual

Sony

Sony D-NE718CK ATRAC Guide User manual

Sony

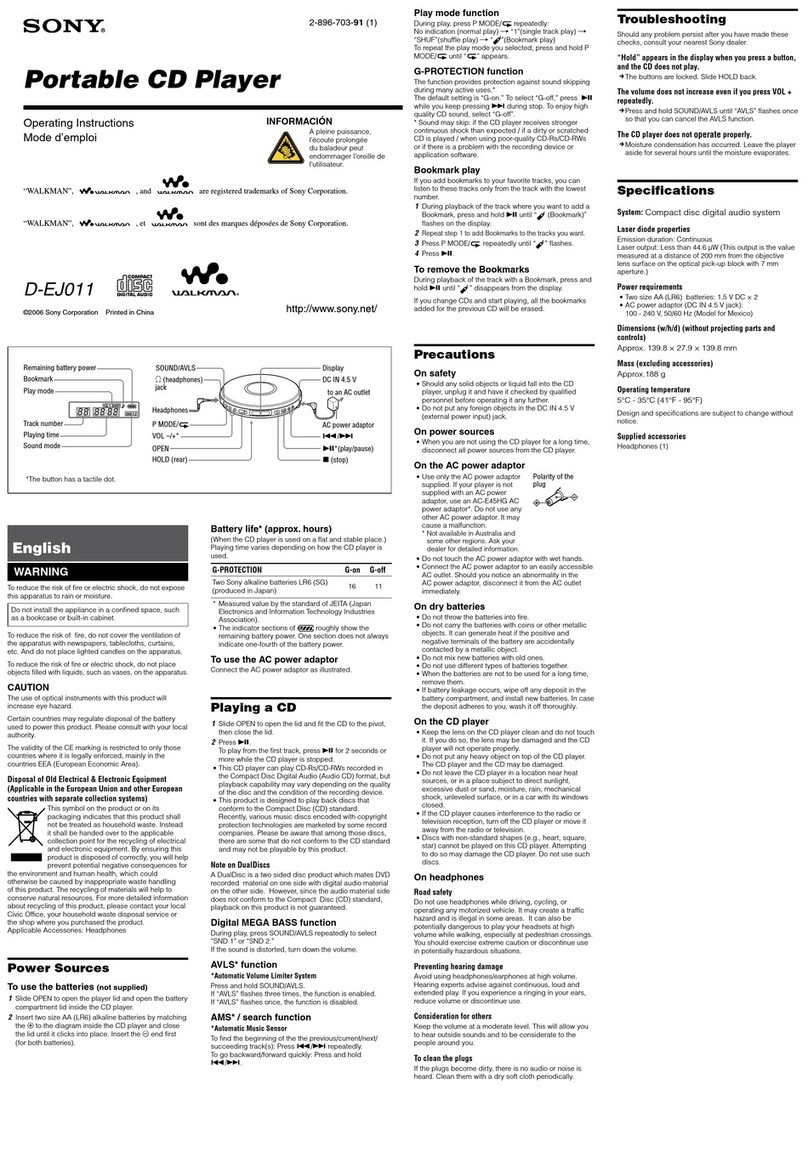

Sony CD Walkman D-EJ011 User manual