8

MDS-SE9

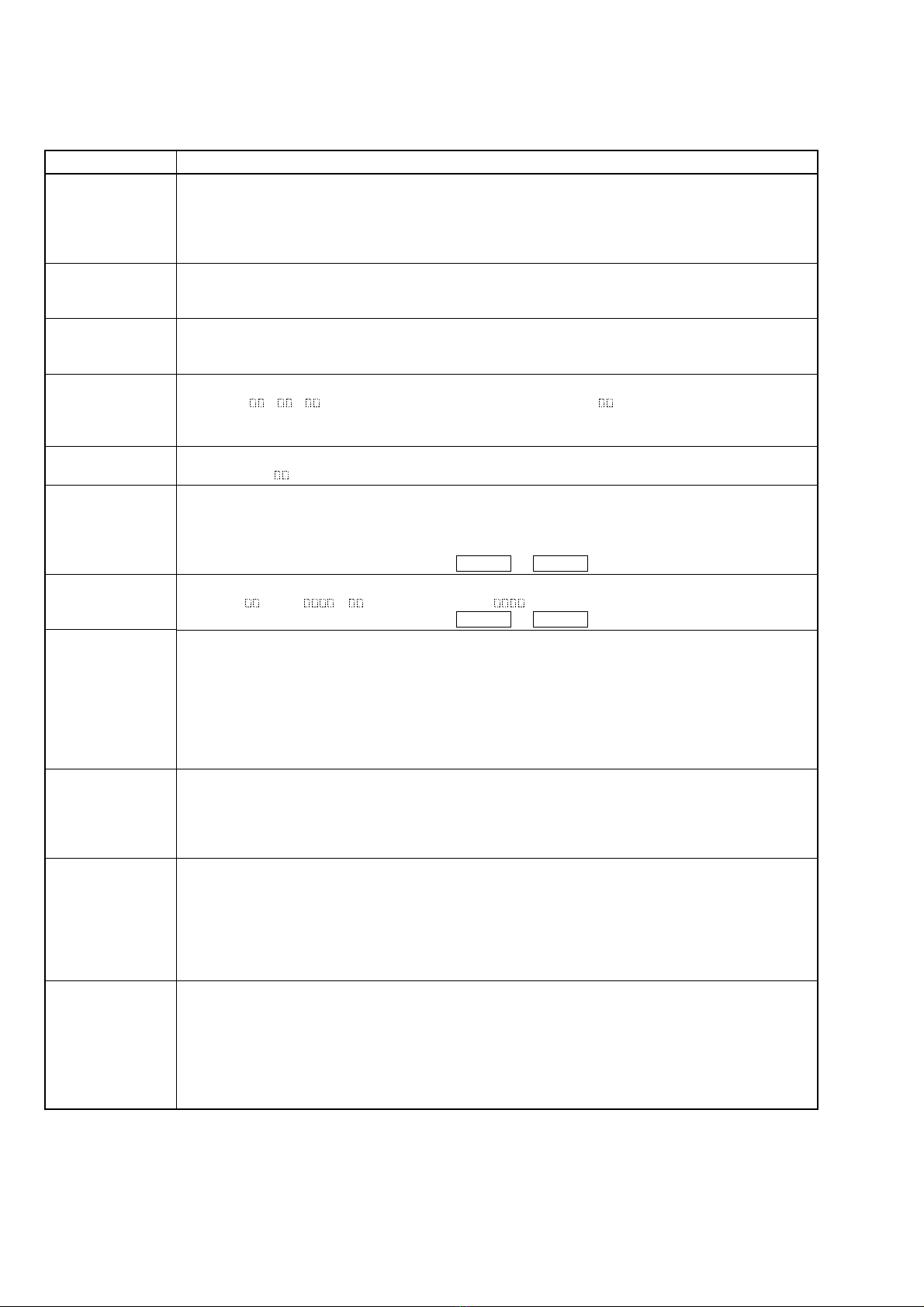

Items of Error History Mode Items and Contents

Display

op rec tm

op play tm

spdl rp tm

retry err

total err

err history

retry adrs

er refresh

tm refresh

op change

spdl change

History

Displays the accumulated recording time.

When the accumulated recording time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

The display time indicates the time when the laser is set to high power more, which is about 1/4 of the actual

recording time.

Displays the accumulated playback time.

When the accumulated playback time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the accumulated rotating time of the spindle motor.

When the accumulated rotating time is more than 1 minute, displays the hour and minute

When less than 1 minute, displays “Under 1 min”

Displays the accumulated number of retry errors during recording and playback.

Displays “r p ”. after “r” is the number of errors during recording. after “p” is the number of errors

during playback.

This is displayed in hexadecimal from 00 to FF.

Displays the total number of errors.

Displays “total ”. This is displayed in hexadecimal from 00 to FF.

Displays the past ten errors.

Displays “0X ErrCd@@”.

X is the history number. The younger the number, the more recent is the history (00 is the latest). @@ is the

error code.

Select the error history number by pressing the MD .or MD > Stick.

Displays the past five retry addresses.

Displays “ ADRS ”, is the history number, is the cluster with the retry error.

Select the error history number by pressing the MD .or MD > Stick.

Mode for erasing the error and retry address histories.

Procedure

1. Press the [TAPE REC] button when displayed as “er refresh”.

2. When the display changes to “er refresh?”, press the [ENTER/START] button

When “Complete!!” is displayed, it means erasure has completed.

Be sure to check the following after executing this mode.

*Data has been erased.

*Perform recording and playback, and check that the mechanism is normal.

Mode for erasing the accumulated recording time and accumulated playing time.

Procedure

1. Press the [TAPE REC] button when displayed as “tm refresh”.

2. When the display changes to “tm refresh?”, press the [ENTER/START] button.

When “Complete!” is displayed, it means erasure has completed.

Mode for erasing the accumulated time of op rec tm, op play tm.

Use these histories as a guide line for the time of replacement of the optical pick-up. If the optical pick-up

has been replaced, perform this procedure and erase the past history.

Procedure

1. Press the [TAPE REC] button when displayed as “op change”.

2. When the display changes to “op change?”, press the [ENTER/START] button.

When “Complete!” is displayed, it means erasure has completed.

Mode for erasing the accumulated spdl rp tm time.

Use these histories as the guide line for the time of replacement of the spindle motor. If the spindle motor has

been replaced, perform this procedure and erase the past history.

Procedure

1. Press the [TAPE REC] button when displayed as “spdl change”

2. When the display changes to “spdl change?”, press the [ENTER/START] button.

When “Complete!” is displayed, it means erasure has completed.