– 3 –

SECTION 1

SERVICING NOTES

SAFETY CHECK-OUT

After correcting the original service problem, perform the follow-

ing safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

TheAC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’instructions to use these

instruments.

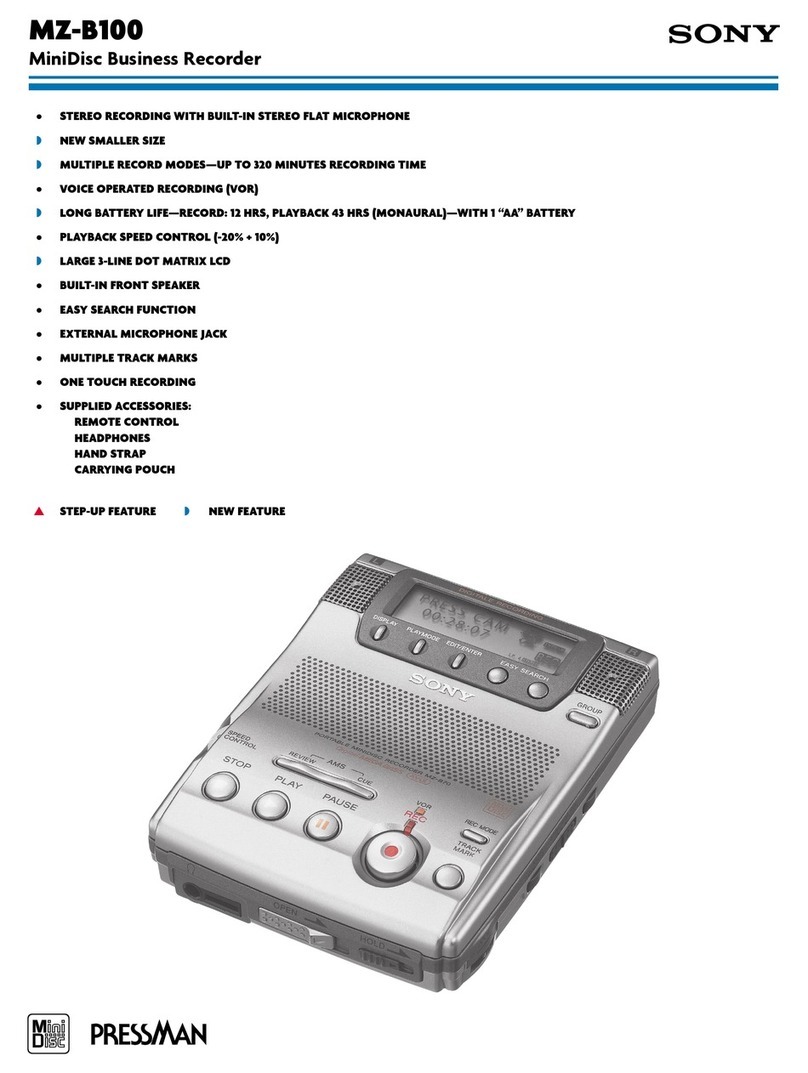

2. A battery-operatedAC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indica-

tion is 0.75 V, so analog meters must have an accurate low-

voltage scale. The Simpson 250 and Sanwa SH-63Trd are ex-

amples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 VAC range are suit-

able. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 k

Ω

0.15

µ

FAC

voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

MODEL IDENTIFICATION

— LOWER SIDE CABINET (BOTTOM VIEW) —

Part No.

Front Side

4-210-100-1

π

: AEP and UK models

4-210-100-2

π

: US and

Canadian models

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instruc-

tions.

The laser diode in the optical pick-up block may suffer electro-

static break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emis-

sion, observe from more than 30 cm away from the objective lens.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT