3

1. SERVICING NOTE......................................................... 4

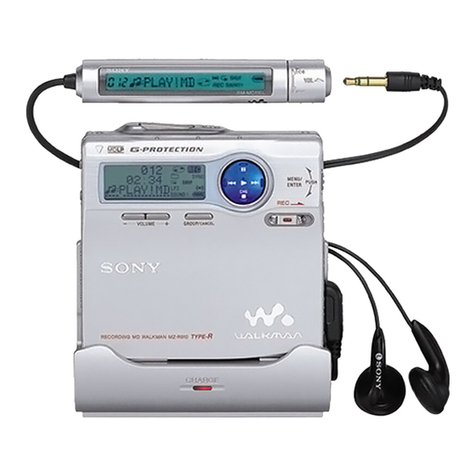

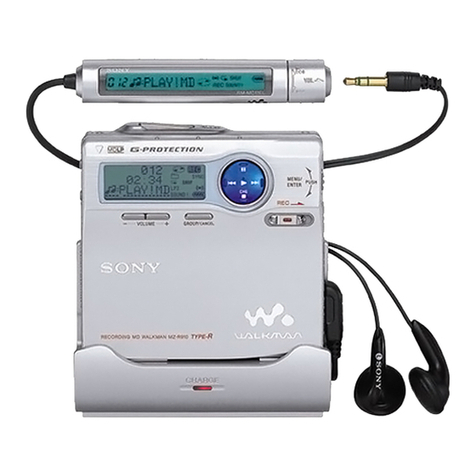

2. GENERAL

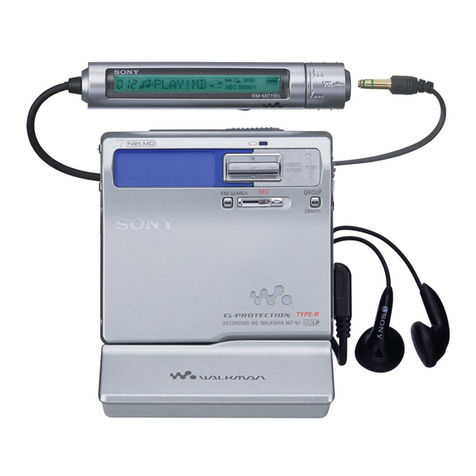

Looking at the controls ....................................................... 5

3. DISASSEMBLY

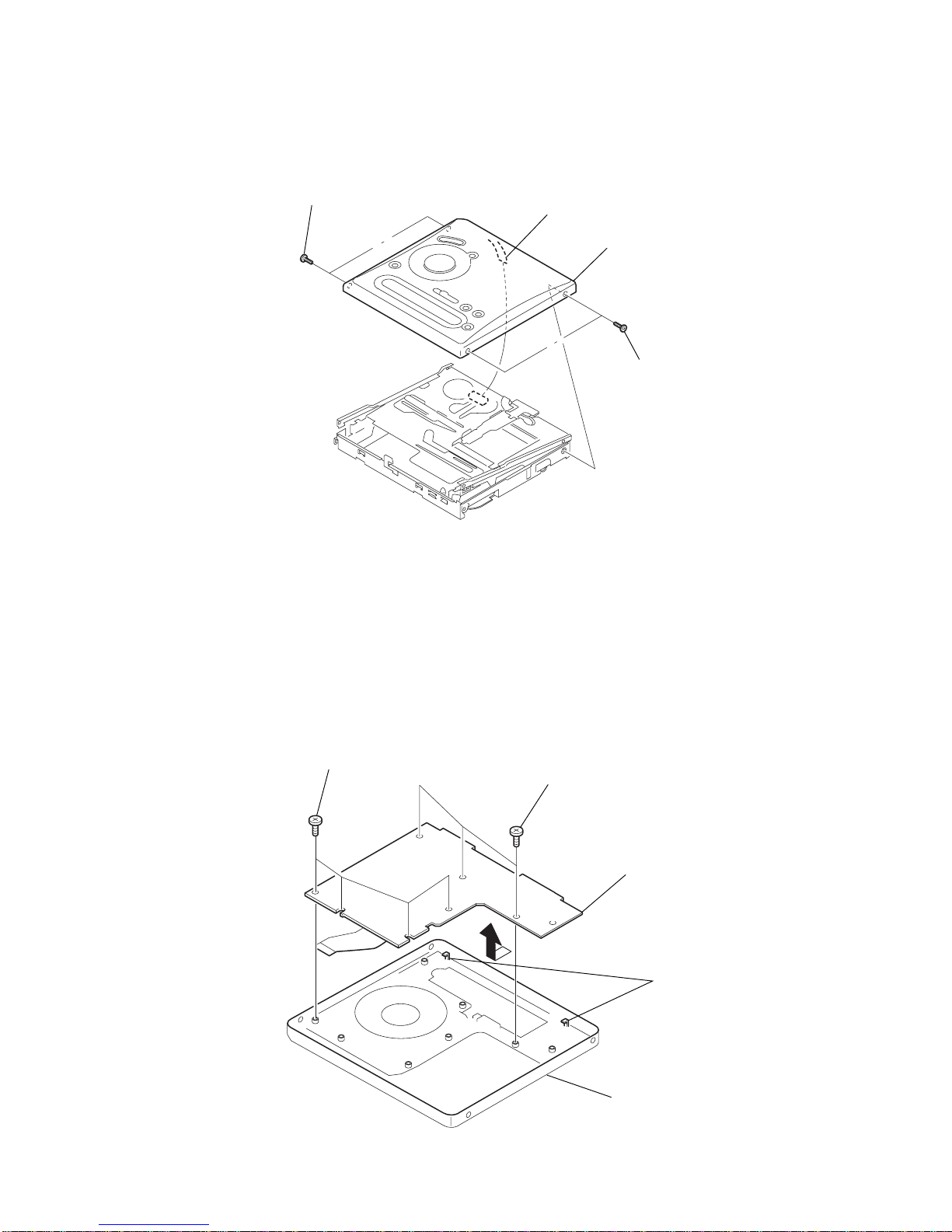

3-1. Bottom Panel Assy .............................................................. 6

3-2. Upper Panel Assy ................................................................ 7

3-3. LCD Module ....................................................................... 7

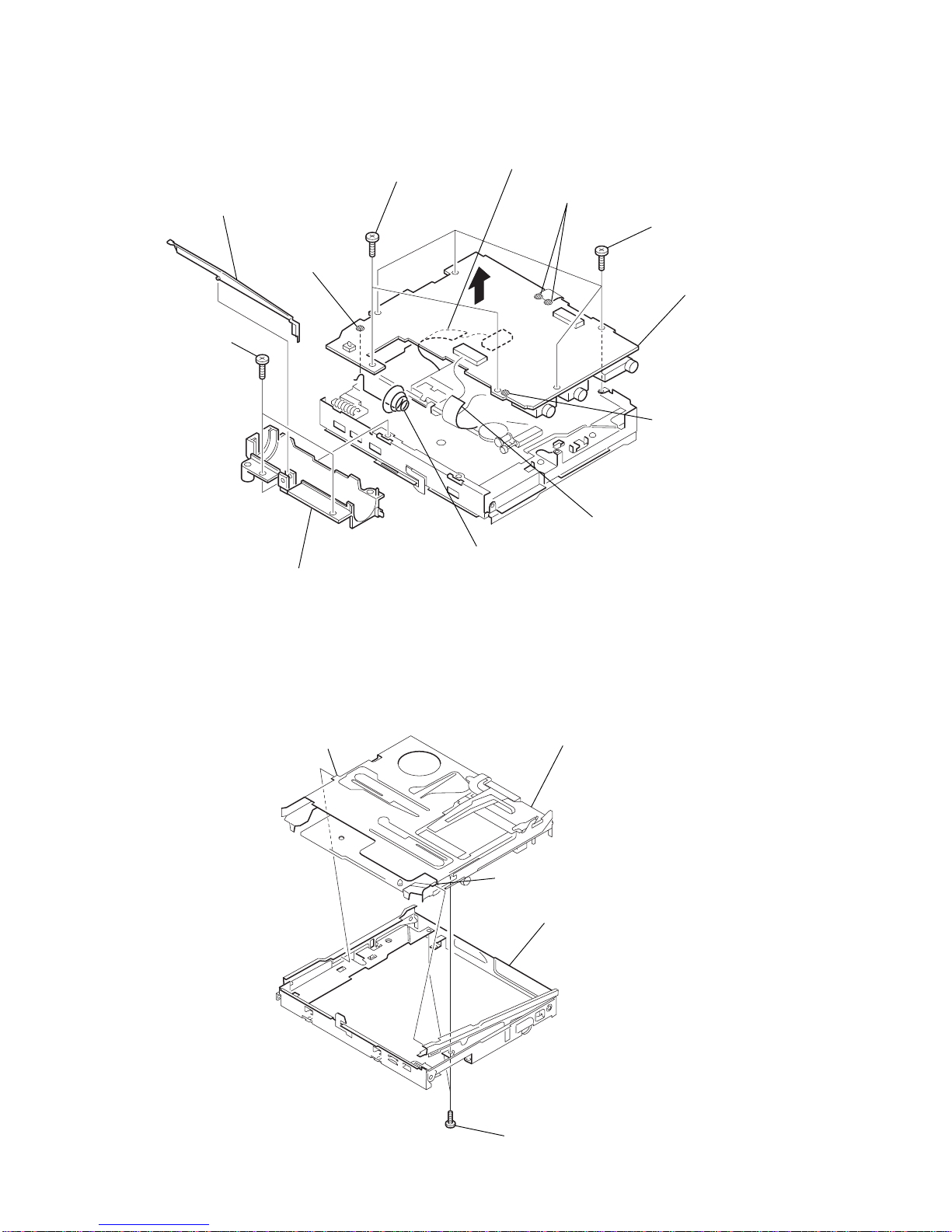

3-4. Main Board ......................................................................... 8

3-5. MD Mechanism Deck .........................................................8

3-6. OP Service Assy.................................................................. 9

3-7. Holder Assy......................................................................... 9

3-8. Motor Flexible Board ........................................................ 10

3-9. DC Motor (M602) .............................................................10

3-10. DC Motor (M601), DC Motor (M603) ............................. 11

4. TEST MODE

4-1. Outline ............................................................................... 12

4-2. Setting Method of Test Mode ............................................ 12

4-3. Operation in Setting the Test Mode................................... 12

4-4. Releasing the Test Mode ................................................... 12

4-5. Configuration of Test Mode .............................................. 13

4-6. Manual Mode .................................................................... 13

4-7. Overall Adjustment Mode ................................................. 14

4-8. Self-diagnosis Result Display Mode ................................. 14

4-9. Result the Error Display Code .......................................... 15

4-10. Sound Skip Check Result Display Mode .......................... 16

4-11. Key Check Mode............................................................... 16

TABLE OF CONTENTS

5. ELECTRICAL ADJUSTMENTS

5-1. Outline ............................................................................... 18

5-2. Precautions for Adjustment ............................................... 18

5-3. Adjustment Sequence ........................................................ 18

5-4. NV Reset ........................................................................... 18

5-5. Power Supply ManualAdjustment.................................... 19

5-6. Temperature Correction..................................................... 20

5-7. Laser Power Check ........................................................... 20

5-8. Overall Adjustment Mode ................................................. 21

6. DIAGRAMS

6-1. IC Pin Descriptions .......................................................... 24

6-2. Block Diagram – Servo Section – ..................................... 31

6-3. Block Diagram – Audio Section – .................................... 32

6-4. Block Diagram – System Control/Power Section – .......... 33

6-5. Printed Wiring Board – Main Section – ............................34

6-6. Schematic Diagram – Main Section (1/3) – ...................... 37

6-7. Schematic Diagram – Main Section (2/3) – ...................... 38

6-8. Schematic Diagram – Main Section (3/3) – ...................... 39

6-9. IC Block Diagrams............................................................ 40

7. EXPLODED VIEWS

7-1. Panel Section ..................................................................... 43

7-2. Chassis Section ................................................................. 44

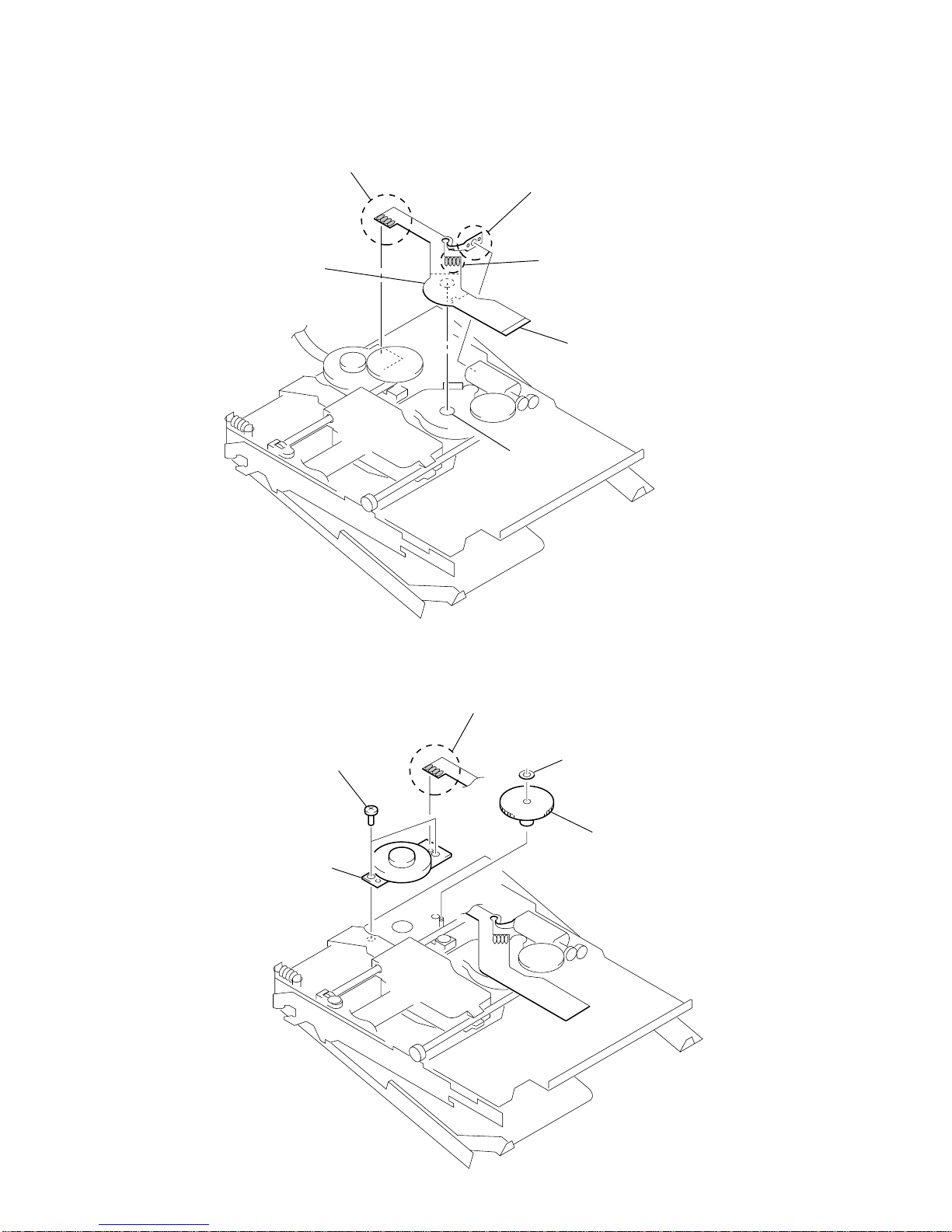

7-3. MD Mechanism Deck Section ..........................................45

8. ELECTRICAL PARTS LIST...................................... 46

MZ-G755