—7 —

HVR-M10C/M10E/M10J/M10N/M10P/M10U

•JL-001 (JACK)

PRINTED WIRING BOARD ·······················4-85

•FP-090 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-85

•JU-001 (AV IN JACK)

PRINTED WIRING BOARD ·······················4-87

•FP-095 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-89

•LI-073 (BATTERY)

PRINTED WIRING BOARD ·······················4-89

•MR-048 (REC/PB RF AMP, DRUM/CAPSTAN/

LOADING MOTOR DRIVE)

PRINTED WIRING BOARD ·······················4-91

•PD-222 (LCD DRIVER, TIMING GENERATOR)

PRINTED WIRING BOARD ·······················4-95

•PW-129 (REMOTE COMMANDER RECEIVER)

PRINTED WIRING BOARD ·······················4-99

•SW-436 (FUNCTION PANEL)

PRINTED WIRING BOARD ·····················4-101

•VA-120 (CONNECTOR, VIDEO IN/OUT, VIDEO AMP,

AUDIO IN/OUT)

PRINTED WIRING BOARD ·····················4-105

•FP-088 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·····················4-109

•FP-089 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·····················4-109

•DA-033 (DC/DC CONVERTER)

PRINTED WIRING BOARD ·····················4-113

•DB-018 (DC IN, CHARGE, DC/DC CONVERTER)

PRINTED WIRING BOARD ·····················4-115

•VC-367 (BASE BAND PROCESS, OSD, D3 FILTER,

HDV SIGNAL/RF SIGNAL PROCESS, HDV VIDEO

DECODER, 64MBITY/C-SDRAM, ILINK INTERFACE,

DV/RF SIGNAL PROCESS,VIDEO A/D CONV., HDV

AUDIO SIGNAL PROCESS, AUDIO INPUT SELECT,

AUDIO CONVERTER, DS CONTROL, FRONT

CONTROL, LSI CONTROL, MECHA CONTROL,

CONNECTOR-1, CONNECTOR-2)

PRINTED WIRING BOARD ·····················4-119

•FP-228/FP-467/FP-826 FLEXIBLE

PRINTED WIRING BOARD ·····················4-123

4-4. WAVEFORMS ····························································4-125

4-5. MOUNTED PARTS LOCATION ·······························4-128

5. REPAIR PARTS LIST

5-1-1.OVERALL SECTION·····················································5-3

5-1-2.FRONT PANEL SECTION·············································5-4

5-1-3.CONTROL PANEL SECTION ······································· 5-5

5-1-4.MAIN FRAME SECTION-1 ··········································5-6

5-1-5.MAIN FRAME SECTION-2 ··········································5-7

5-1-6.REAR PANEL SECTION ···············································5-8

5-1-7.MECHANISM DECK OVERALL (Z311) ·····················5-9

5-1-8.LS CHASSIS BLOCK ASSEMBLY·····························5-10

5-1-9.MECHANICAL CHASSIS BLOCK ASSEMBLY·······5-11

Checking supplied accessories ················································5-12

5-2. ELECTRICAL PARTS LIST ········································ 5-14

6. ADJUSTMENTS

1. Before starting adjustment···············································6-1

1-1.

Adjusting items when replacing main parts and boards···

6-2

6-1. MECHANISM SECTION ADJUSTMENT····················6-3

1-1. Preparations for Check, Adjustment and Replacement of

Mechanism Block···························································· 6-3

1-1-1.Cassette Compartment Assy, Damper Assy ····················6-3

1-2. Periodic Inspection and Maintenance

1-2-1.Rotary Drum Cleaning ···················································· 6-4

1-2-2.Tape Path System Cleaning (Refer to Fig. 6-1-2.) ··········6-4

1-2-3.Periodic Inspection List··················································· 6-5

1-2-4.Mode Selector II Operating Procedure····························6-6

2-4-1.Introduction ·····································································6-6

2-4-2.Operation ·········································································6-7

2-4-3.Mechanism Status (Position) Transition Table Using

Mode Selector II ······························································ 6-9

2-4-4.Battery Alarm Indication ················································· 6-9

1-3. Check, Adjustment and Replacement of

Mechanical Parts ···························································6-10

1-3-1.Flowchart of Replacement of Mechanical Parts············6-10

1-3-2.Drum·············································································· 6-11

1-3-3.Cassette Compartment Assy ··········································6-13

1-3-4.TG7 Support ··································································6-14

1-3-5.Motor Holder Block Assy and L Motor Block Assy ·····6-15

1-3-6.MIC Terminal (MIC902) ··············································· 6-16

1-3-7.LED (D901)··································································· 6-17

1-3-8.Retainer Plate ································································6-18

1-3-9.T Reel Table Assy ··························································6-19

1-3-10. Brake (S) and Release Rack (S)··································6-20

1-3-11. Band Adjuster, S Reel Table Assy and

TG2 Arm Block Assy ·················································6-21

1-3-12. ULE Brake Assy ························································· 6-22

1-3-13. Cassette Positioning (S) ··············································6-23

1-3-14. TG7Arm Block Assy and Pinch Arm Assy ················6-24

1-3-15. TG7 ············································································· 6-25

1-3-16. Gooseneck Gear Assy ·················································6-26

1-3-17. LS Guide Retainer and LS Cam Plate ························6-27

1-3-18. LS Chassis Block Assy and

Mechanical Chassis Block Assy ·································6-28

1-3-19. Brake (T) BlockAssy ················································· 6-30

1-3-20. END Sensor (Q901)····················································6-31

1-3-21. TOP Sensor (Q902)·····················································6-32

1-3-22. C-IN Switch (S903), S Reel Sensor (H901) and

T Reel Sensor (H902)···················································· 6-33

1-3-23. Guide Rail ···································································6-34

1-3-24. Conversion Gear ·························································6-35

1-3-25. Coaster (S) Block Assy and

Coaster (T) Block Assy ··············································6-36

1-3-26. TG5 RollerAssy and GL Gear (T) ····························· 6-37

1-3-27. TG2 Cam PlateAssy (N) ············································6-38

1-3-28. LS Arm Assy ·······························································6-39

1-3-29. M Slider Assy (1) ························································6-40

1-3-30. M Slider Assy (2) ························································6-41

1-3-31. EJ Arm ········································································ 6-42

1-3-32. Cam Gear and GL Driving··········································6-43

1-3-33. Rotary Encoder (S902) ··············································· 6-44

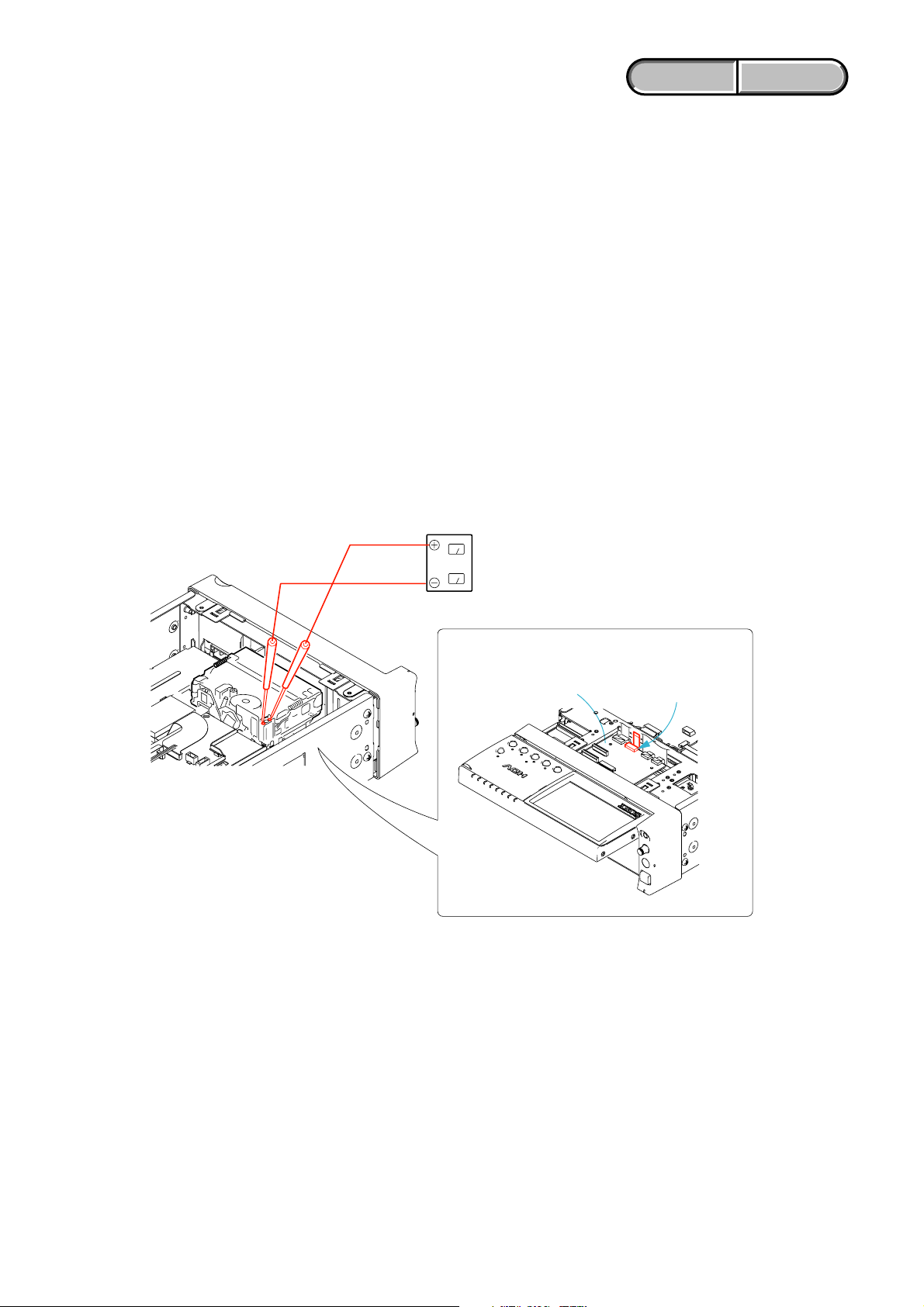

1-3-34. FP-228 Flexible Board (DEW SENSOR) and

FP-467 Flexible Board ···············································6-45

1-4. Adjustment ····································································6-46

1-4-1.FWD Position Adjustment············································· 6-46

1-4-2.Reel Torque Check ························································ 6-46

1-4-3.LS Cam Plate Position Adjustment ·······························6-47

1-4-4.Tape Path Adjustment ····················································6-48

6-2. VIDEO SECTION ADJUSTMENT································6-4

2-1. PREPARATIONS BEFORE ADJUSTMENTS ············ 6-52

2-1-1.Equipment to Required·················································· 6-52

2-1-2.Precautions on Adjusting ···············································6-53

2-1-3.Adjusting Connectors ···················································· 6-54

2-1-4.Connecting the Equipment ············································6-54

2-1-5.Alignment Tapes····························································6-55

2-1-6.Input/Output Level and Impedance ·······························6-55

2-2. INITIALIZATION OF 8, 9, A, B, C, D, 13, 18, 1A,

1B, 1C, 1D PAGE DATA···············································6-56

2-2-1.INITIALIZATION OF A, B, D, 1A, 1B PAGE DATA··6-56

1. Initializing the A, B, D, 1A, 1B Page Data ···················6-56