• Top View...................................................4-1

• Bottom View ............................................4-1

1. Drum Assembly .........................................4-2

2. Plate Top ...................................................4-4

3. Holder Assembly CST...............................4-4

4. Opener Door .............................................4-4

5. Bracket Assembly L/D Motor.....................4-4

6. Gear Assembly Rack F/L ..........................4-4

7. Arm Assembly F/L.....................................4-4

8. Lever Assembly S/W.................................4-4

9. Arm Assembly Cleaner..............................4-5

10.Head F/E ...................................................4-5

11. Base Assembly A/C Head .........................4-5

12.Brake Assembly T .....................................4-6

13.Brake Assembly RS ..................................4-6

14.Arm Assembly Tension..............................4-6

15.Reel S / Reel T..........................................4-6

16.Base Assembly P4 ....................................4-7

17.Opener Lid ................................................4-7

18.Arm Assembly Pinch .................................4-7

19.Lever T/up / Arm T/up ...............................4-7

20.Belt Capstan/Motor Capstan.....................4-8

21.Lever F/R ..................................................4-8

22.Clutch assembly D35 ................................4-8

23. Brake assembly Capstan .........................4-8

24.Gear Drive/Gear Cam ...............................4-9

25.Gear Sector...............................................4-9

26.Plate Slider................................................4-9

27.Lever Tension............................................4-9

28.Lever Spring..............................................4-9

29.Gear Assembly P2/

Gear Assembly P3 ..................................4-10

30.Base Assembly P2/

Base Assembly P3 ..................................4-10

31.Base Loading ..........................................4-11

32.Base Tension ...........................................4-11

33.Arm Assembly Idler Jog ..........................4-11

• Tools and Fixtures for Service.............4-12

1. Mechanism Alignment Position Check....4-13

2. Preparation for Adjustment......................4-14

3. Checking Torque .....................................4-14

4. Guide Roller Height Adjustment..............4-15

4-1. Preliminary Adjustment ....................4-15

4-2. Precise Adjustment ..........................4-15

5. Audio/Control (A/C) Head Adjustment ....4-16

5-1. Preliminary Adjustment ....................4-16

5-2. Confirmation of Tape Path between

Pinch Roller and Take-up Guide .....4-17

5-3. Precise Adjustment(Azimuth Adjustment)

.........................................................4-17

6. X-Value Adjustment .................................4-17

7. Adjustment after Replacing Drum Assembly

(Video Heads) .........................................4-18

8. Check the Tape Travel after Reassembling

Deck Mechanism.....................................4-18

8-1. Checking Audio and RF Locking Time

during Playback after CUE or REV

.........................................................4-18

8-2. Checking Tape Curling or Jamming

.........................................................4-18

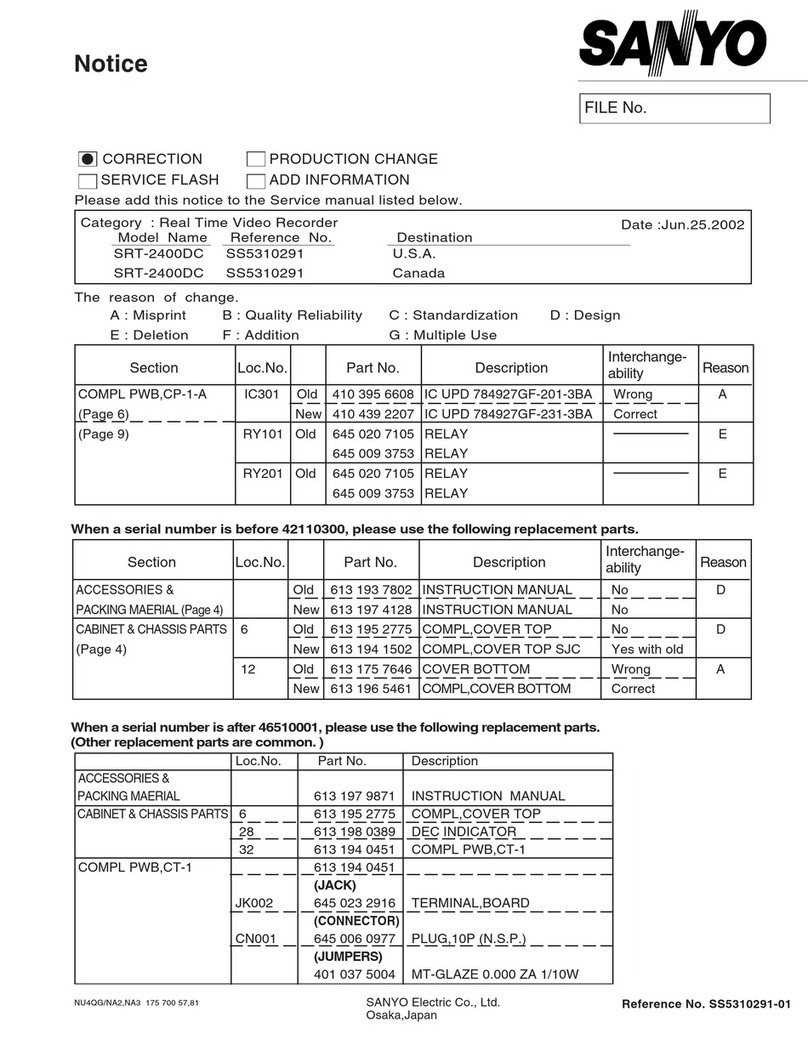

1. Check before starting Repairs ................4-19

2. Required Maintenance ............................4-20

3. Scheduled Maintenance..........................4-20

4. Supplies Required for Inspection and

Maintenance............................................4-20

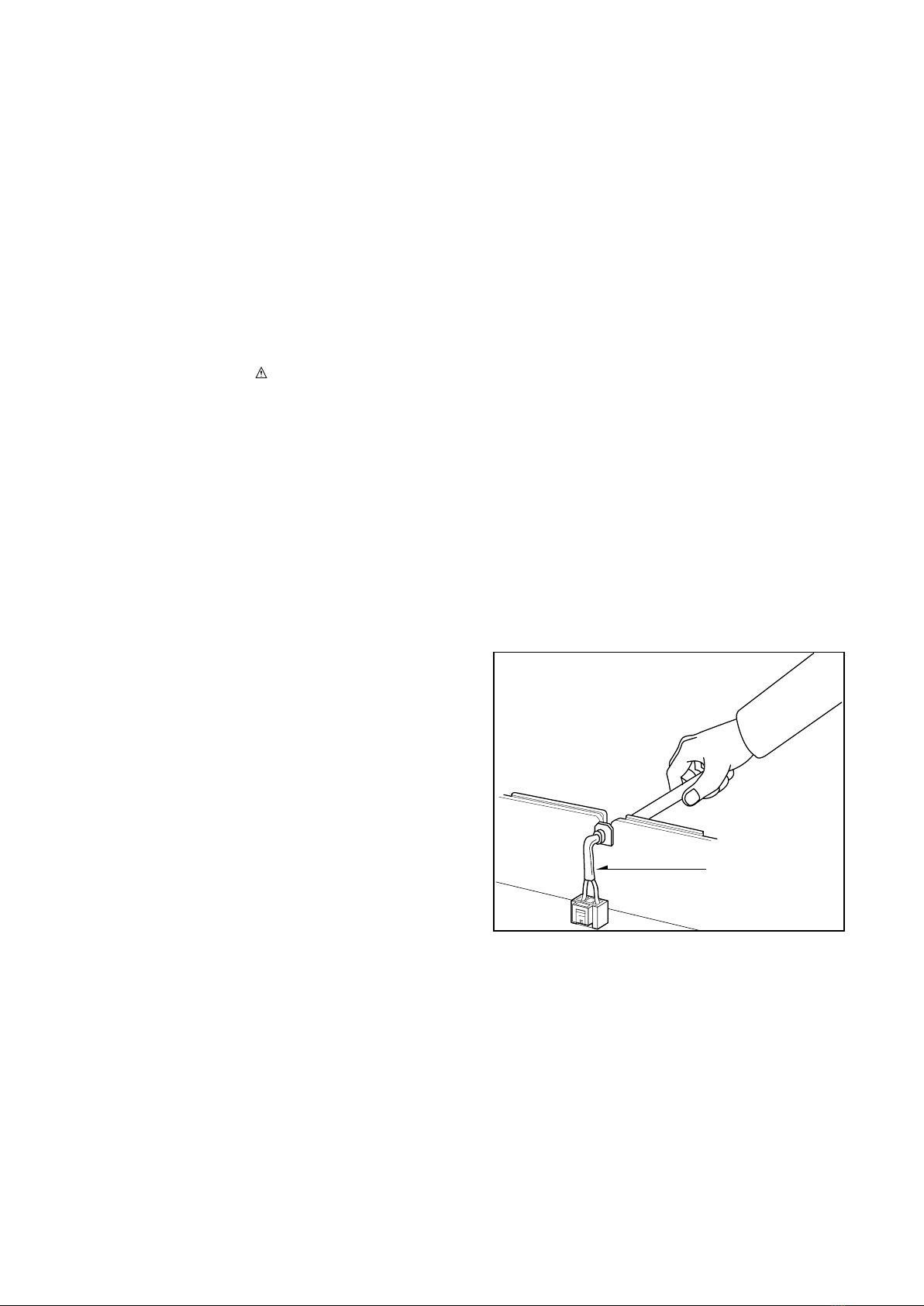

5. Maintenance Procedure ..........................4-20

5-1. Cleaning...........................................4-20

5-2. Greasing ..........................................4-21

1. Deck Mechanism.....................................4-23

2. Front Loading Mechanism.......................4-26

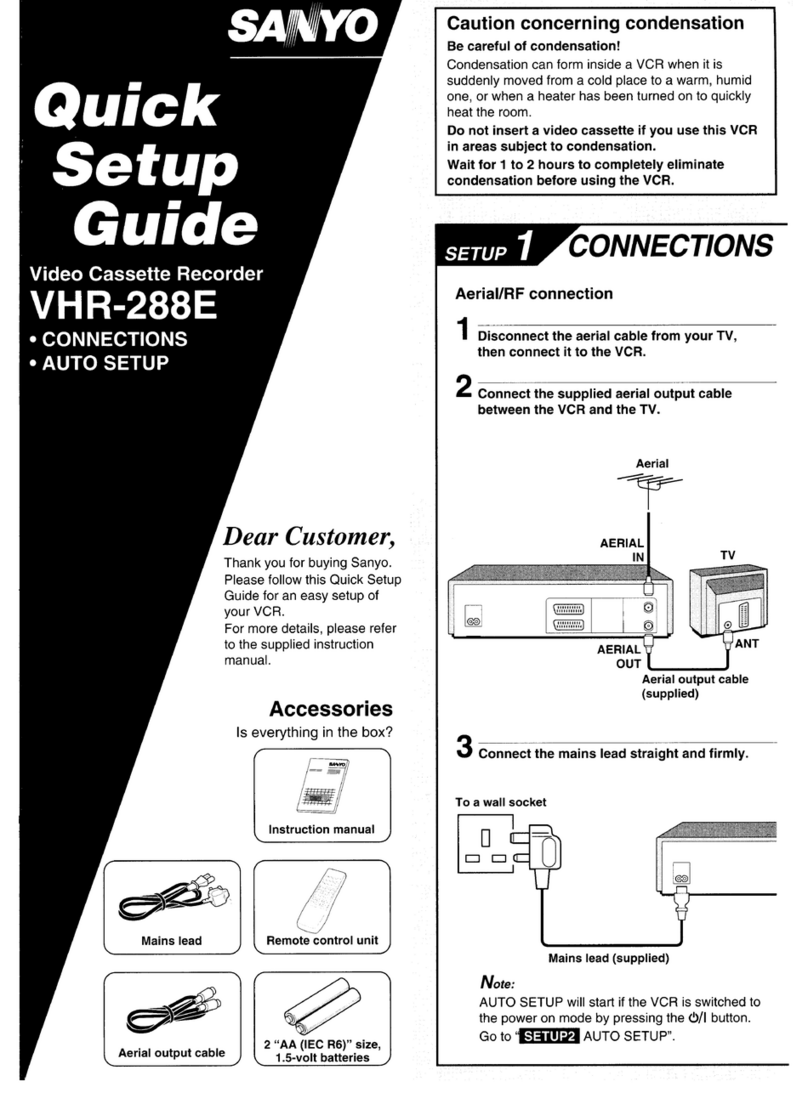

1. Front Loading Mechanism Section .........4-28

2. Moving Mechanism Section (1)...............4-29

3. Moving Mechanism Section (2)...............4-30

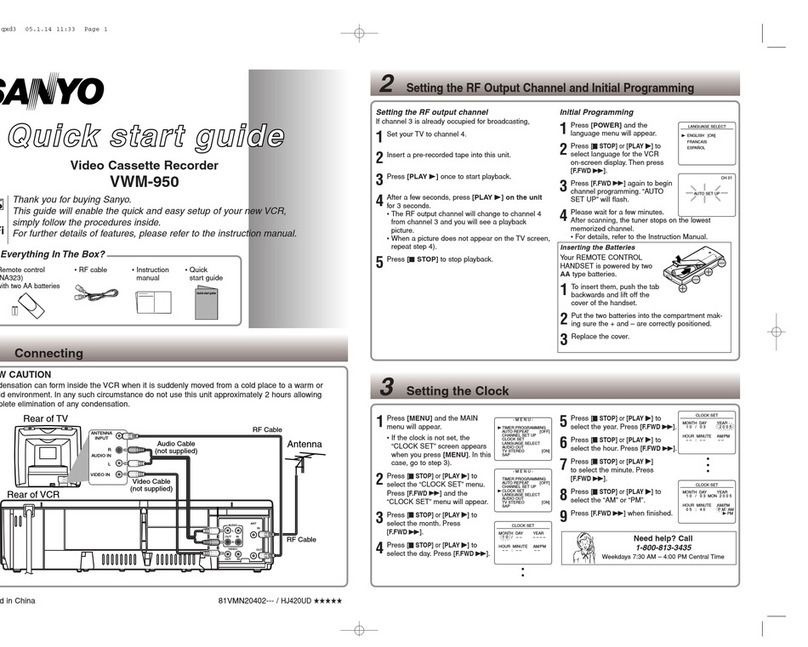

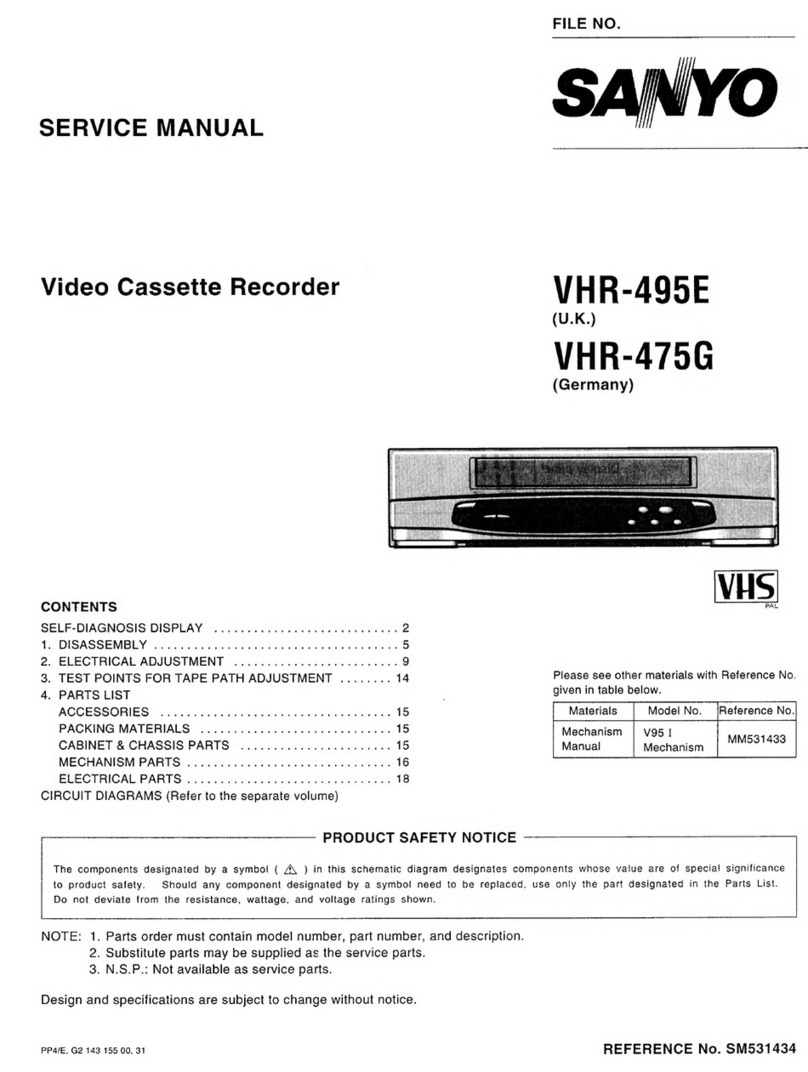

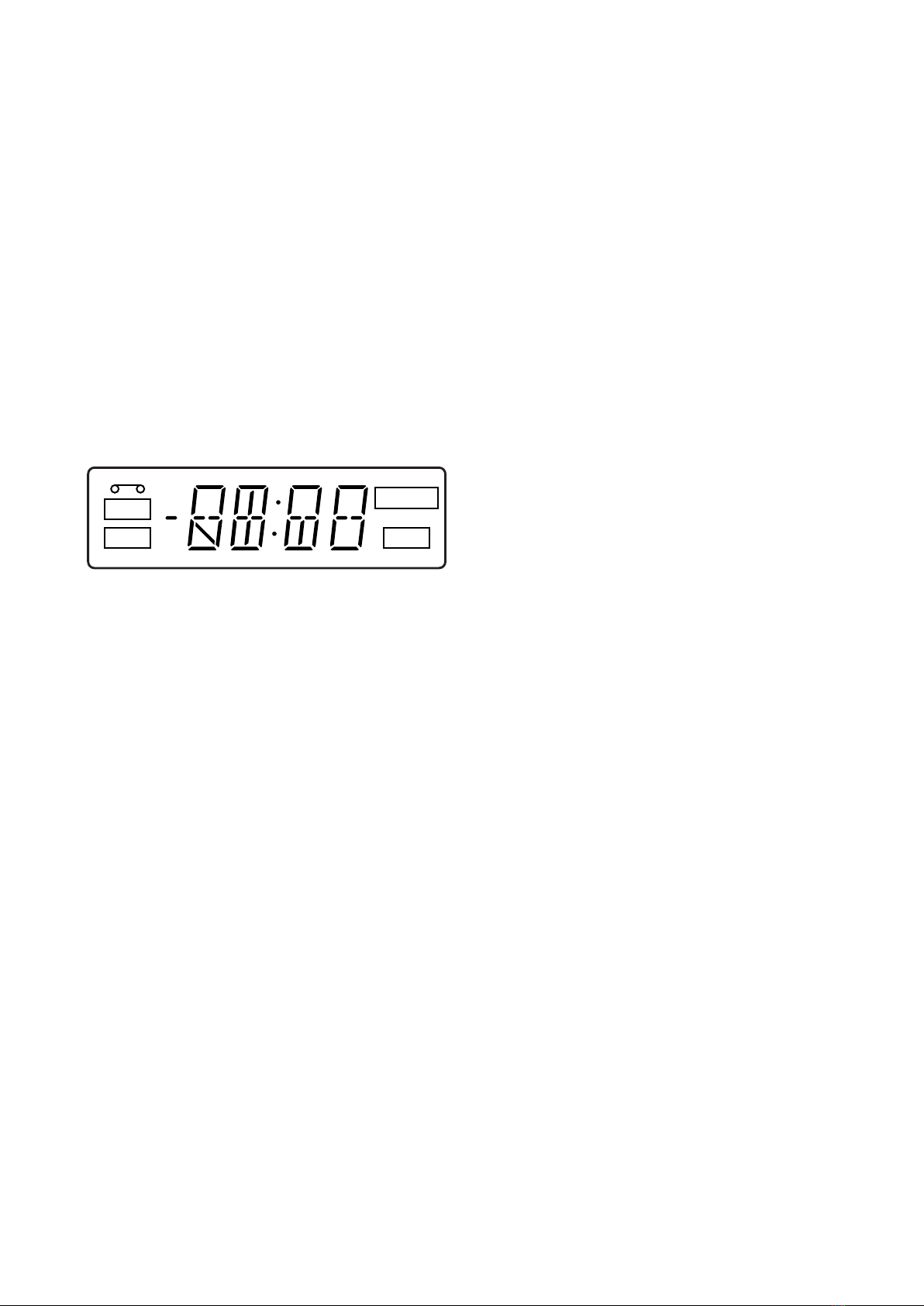

SECTION 4 MECHANISM

DECK MECHANISM PARTS

LOCATIONS

DECK MECHANISM ADJUSTMENT

MAINTENANCE/INSPECTION

PROCEDURE

EXPLODED VIEWS

CONTENTS

DECK MECHANISM

DISASSEMBLY

MECHANISM TROUBLESHOOTING

GUIDE