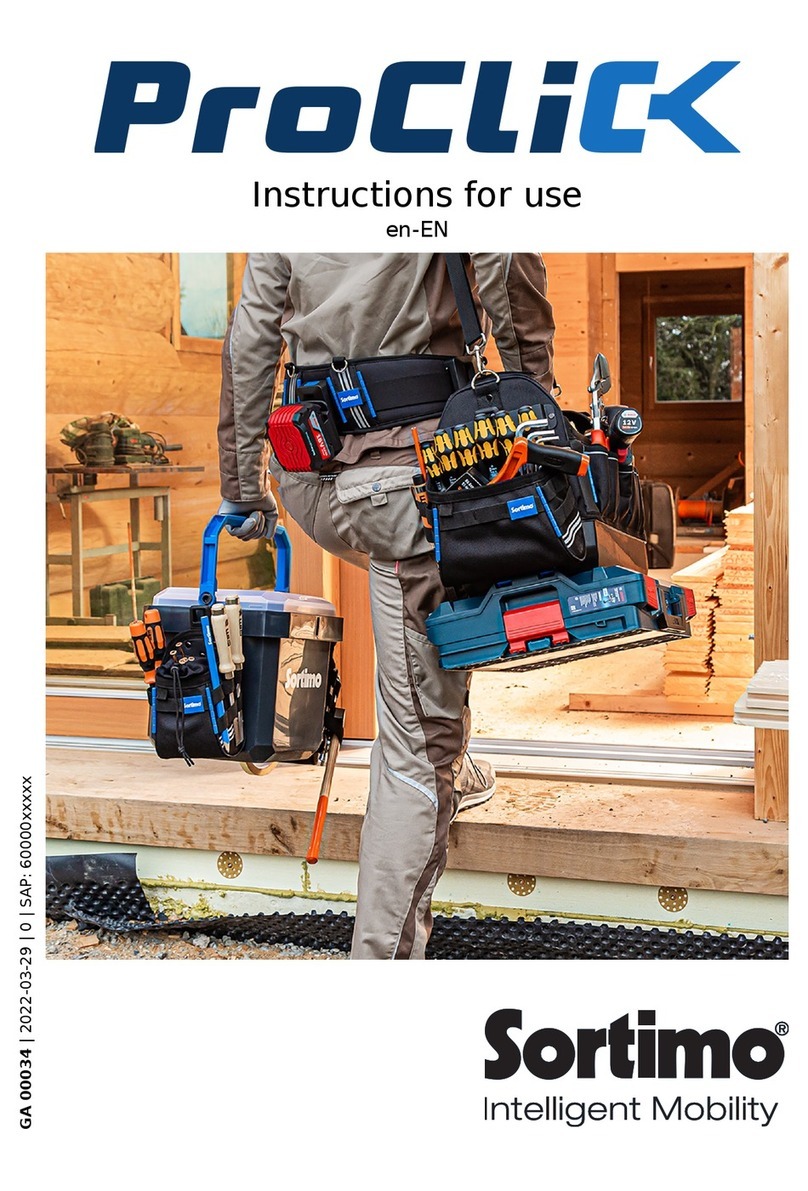

Sortimo GL4 User manual

2

© Sortimo International GmbH

Table of contents

Warnings and symbols.........................................................................................................................4

A distinction is made between the following:....................................................................................4

Symbols ..........................................................................................................................................4

Information on the document...........................................................................................................5

Intended use ...................................................................................................................................5

Foreseeable misuse ........................................................................................................................6

Operator’s obligations .....................................................................................................................6

Requirements for the user...............................................................................................................6

Safety markings ..............................................................................................................................7

Adhesive labels ...............................................................................................................................7

Securing of load ..............................................................................................................................7

Checking van racking system ..........................................................................................................8

Limitations of use ............................................................................................................................8

Gas transport ..................................................................................................................................9

Transport regulation ........................................................................................................................9

Disposal ..........................................................................................................................................9

Load-carrying capacities ....................................................................................................................10

Lashing capability ..............................................................................................................................11

Globelyst unit .....................................................................................................................................12

Anti-slip mats, noise-absorbing ..........................................................................................................13

Drawer ...............................................................................................................................................13

Tool tray inlays...................................................................................................................................15

Universal cabinet ...............................................................................................................................15

Case fixation ......................................................................................................................................16

Dual directional block .........................................................................................................................17

Lifting flap ..........................................................................................................................................18

Hinged workbench .............................................................................................................................19

Heavy, folding workbench ..................................................................................................................20

Workbench slide ................................................................................................................................21

Folding parallel vice ...........................................................................................................................22

Shelf ..................................................................................................................................................23

Shelf tray............................................................................................................................................25

3

© Sortimo International GmbH

Shelf flap, wide/narrow.......................................................................................................................27

Long components tray........................................................................................................................28

Jumbo-Unit ........................................................................................................................................29

Multi-functional pull-out element.........................................................................................................30

SR-BOXX...........................................................................................................................................31

L-/LS-BOXX .......................................................................................................................................31

i-BOXX...............................................................................................................................................33

T-BOXX .............................................................................................................................................33

Metal small components case ............................................................................................................34

Case rail.............................................................................................................................................35

Case tray ...........................................................................................................................................36

WorkMo .............................................................................................................................................38

ProSafe gas cylinder holder ...............................................................................................................39

Ventilation / air extraction ...................................................................................................................40

Roof vent ...........................................................................................................................................41

Narrow roof vent ................................................................................................................................43

ProSafe floor lashing rail ....................................................................................................................44

ProSafe front upright ..........................................................................................................................44

Telescopic restraint pole ....................................................................................................................45

Ramp rail ...........................................................................................................................................46

Multifunctional bar..............................................................................................................................47

Hose holder .......................................................................................................................................47

Handiwash unit ..................................................................................................................................48

C-BOXX .............................................................................................................................................48

4

© Sortimo International GmbH

Warnings and symbols

- These instructions contain information about possible dangers that could arise with incorrect

use and/or improper behaviour.

A distinction is made between the following:

Danger!

Failure to observe the warning can cause severe personal injury and/or serious material damage!

Caution!

Failure to observe the instructions can cause personal injury and/or material damage!

Important!

Failure to do so can result in material damage!

Information!

Recommendations and useful hints!

Symbols

This symbol indicates that the screw fixing is only to be tightened hand-tight!

5

© Sortimo International GmbH

Information on the document

Caution!

Injury from lifting too heavy a load

The van racking system may be too heavy for one person, depending on the configuration. This

could result in minor injuries.

•Installation should be carried out by two persons.

•Ensure a safe working environment; park the vehicle on a flat and solid surface.

•If the vehicle is to be driven off normal roads, all screw connections need to be fitted

using an appropriate screw locking tool.

•When installing the van racking system, make sure that all existing service access points

(e.g. first-aid box, spare wheel) remain accessible after installation.

Information!

Depending on the configuration, several van racking systems are included in the delivery. We

recommend that you install them separately from each other.

Important!

Ensure that the specified screw fixing torques are adhered to.

M5 = 4 Nm ±10%

M6 = 7.5 Nm ±10%

M8 = 20 Nm ±10%

If other torques are required, they are specified in the instructions!

Intended use

The Sortimo “Globelyst” van racking system is designed for use in vans / panel vans due to its

durability.

The rack system is used to transport and store a wide variety of tools and materials.

6

© Sortimo International GmbH

Foreseeable misuse

Caution!

Damage to property and a risk of injury from damaged products.

Severe injuries can result from the use of damaged products.

•Do not use damaged products.

•Replace damaged products with new products.

•Do not repair damaged products at your own discretion.

Operator’s obligations

Ensure that ...

• the applicable laws and standards are observed (e.g. StVO road traffic regulations and

professional association guidelines).

• the safety labels are visible and legible on the product.

• the safety equipment is present and undamaged. The safety devices include:

odivider,

oventilation/air extraction.

• the van racking is regularly inspected for wear or damage.

• there are sufficient lashing points available.

• suitable lashing and load securing devices are provided.

• the vehicle has suitable ventilation and air extraction when gas cylinders are being

transported.

• the user has read and understood this document.

• the user has the required knowledge and can apply it.

Requirements for the user

Life phases Knowledge

Fitting and

dismantling the

product

- Technical expertise

Working on the

electrics

- Specialist electrical engineering knowledge

- Applicable legislation and standards, e.g. VDE 0100-717

Securing of load - The applicable legislation and standards governing the securing of loads,

e.g. the German Road Traffic Act StVO and the German Regulation on

the Approval of Road Vehicles StVZO.

Transporting gas

cylinders

- Applicable laws and standards governing the transport of dangerous

materials, such as GGVSE, ADR and SDB.

- Operation of the ventilation and air extraction systems.

7

© Sortimo International GmbH

Safety markings

Caution!

Dangerous situations cannot be avoided if safety markings are illegible or missing from the product.

•Make sure every day that all safety labels are visible on the product.

•Replace a safety marking if it is missing or illegible.

Adhesive labels

There are adhesive labels affixed at various points in the vehicle. These adhesive labels act as guides.

The adhesive labels must be legible; if they are not legible, they must be replaced.

Securing of load

This safety label can be found in the vehicle’s cargo

area. It contains instructions for securing cargo with ProSafe

lashing straps.

•If cargo is lashed to the side of the van racking, the cargo

must be in contact with the floor. In addition, the weight of the

load must not exceed 150 kg.

•The lashing points are resilient to a maximum of 200 daN.

•If cargo is lashed on the SoboPro, the distance between the

load and the lashing point must not exceed 15 cm.

•Only use designated lashing points.

•The lashing hooks of a lashing strap must be fastened to

lashing points of the same element.

oExample: If the first lashing hook is attached to the

floor, then the second lashing hook must be

attached to another lashing point of the floor.

Caution!

Braking, accelerating, taking bends or swerving causes forces on the cargo. An unsecured load

can topple over or slip.

•Secure all objects in the cargo area against tipping and slipping.

•Secure cargo inside the van racking with a tight fit.

•Use dividers and anti-slip mats inside drawers and shelves.

•Check that the load is secure before setting off every time.

Observe the applicable laws in accordance with StVO §22, 23 and StVZO §30, 31 relating to load

securing.

8

© Sortimo International GmbH

Checking van racking system

Check the following elements regularly for wear or damage.

- Car body,

- Floor,

- Van racking system,

- Screw connections.

Interval:

- At least every 5000 km.

- After any unusual loads, e.g. emergency braking.

Care:

- Use a damp cloth to clean the van racking system at regular intervals. Avoid using highly

corrosive cleaning agents to prevent damage to the van racking system.

Repairs:

- Repair work may only be carried out by Sortimo partners.

Limitations of use

Danger!

The maximum permitted load weight must not be exceeded!

•Pay attention to the weight of your van racking system.

•Note the maximum permitted load capacity/payload of the elements.

•When using, make sure that the tools and consumables are held securely in place.

•Danger from falling objects

•Observe the specifications in the handbook and in the vehicle documentation.

oMaximum permissible axle load,

oMaximum permissible total weight.

9

© Sortimo International GmbH

Gas transport

Risk of suffocation/explosion

Danger!

If gas cylinders are transported without the specified ventilation and air extraction equipment,

leaking gas can cause suffocation, poisoning or an explosion in the cargo area!

•According to legal regulations, vehicles that transport gas cylinders must be equipped

with ventilation and air extraction equipment.

•It is not permitted to transport gas cylinders if there is no ventilation and air extraction

equipment that meets the legal requirements installed in the mobile workshop.

The law requires there to be vehicle ventilation when transporting gas cylinders.

The ventilation and air extraction must not be blocked (not even temporarily) or closed through

other measures! There is risk of explosion and suffocation!

Transport regulation

The products are delivered in proper packaging and must be immediately checked for externally

recognisable transport damage upon receipt.

Any complaints must be sent to the carrier immediately.

•Dispose of packaging material in accordance with local/national regulations.

Disposal

The Sortimo “Globelyst” van racking system is made of recyclable materials such as aluminium, steel

or high-quality plastics. The van racking system can be reused at the end of the user cycle, thus

helping to protect the environment.

•Dispose of the van racking system in accordance with local/national regulations or by

returning it directly to the manufacturer.

10

© Sortimo International GmbH

Load-carrying capacities

Designation Remark Maximum

permissible load

weight

Storage pocket Load-carrying capacity 3 kg

Storage pocket for paperwork Load-carrying capacity 2 kg

Shelf Surface load 80 kg

Drop-down front Surface load 80 kg

Shelf tray Surface load 80 kg

Hook strip Load-carrying capacity 12 kg

Case rail Surface load 25 kg

Case tray Surface load 25 kg

Long components tray Surface load 25 kg

i-BOXX Load-carrying capacity 3 kg

i-BOXX wall holder Load-carrying capacity 3 kg

L-BOXX / LS-BOXX Load-carrying capacity 12 kg

L-BOXX trolley Load 100 kg

Metal cases Load-carrying capacity 20 kg

Hose holder Load-carrying capacity 5 kg

Drawer Surface load, indication on

telescopic extension

30 / 60 / 90 kg

Multi-functional pull-out element Surface load 150 kg

Jumbo-Unit Surface load 100

T-BOXX Load-carrying capacity 12 kg

SR-BOXX Load-carrying capacity 12 kg

Workbench slide Carrying capacity 50 kg

Hinged workbench Carrying capacity 100 kg

Heavy, hinged workbench Carrying capacity 150 kg

11

© Sortimo International GmbH

Lashing capability

The following table lists all components which have ProSafe lashing points.

Designation Maximum load

Frame 200 daN

Frame traverse 200 daN

Floor panel/SoboPro 200 daN

Lashing rail 200 daN

Floor lashing rail 200 daN

Restraint pole <1.8 m → 300 daN

≥1.8 m – 2.2 m →200 daN

12

© Sortimo International GmbH

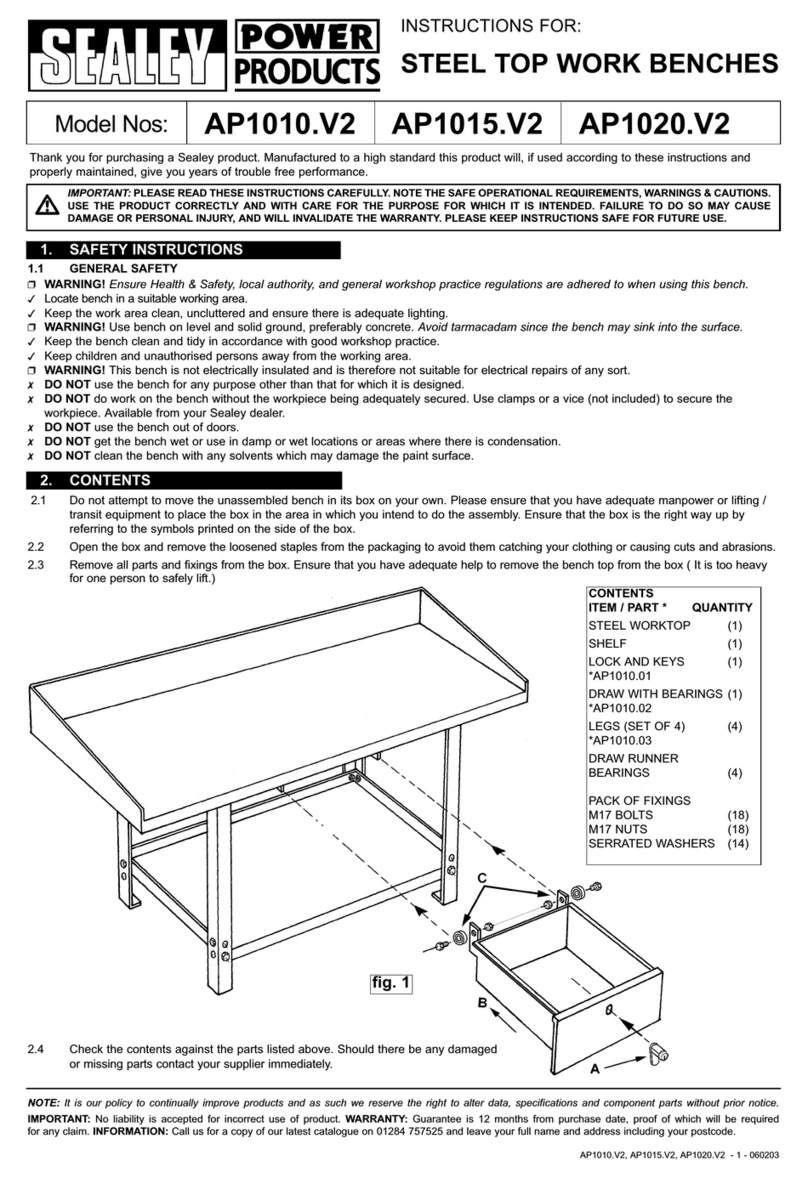

Globelyst unit

Field load:

Van racking can be divided into fields. A field is an area between two profiles that are directly

connected to the installation and load securing floor.

Each field can take a maximum of 200 kg.

Important!

•Observe the maximum payload and maximum axle load of the vehicle!

Grid height

Number of the field

Field

Maximum load

Uprights

13

© Sortimo International GmbH

Anti-slip mats, noise-absorbing

Protects the contents as well as the drawer.

Used for drawers, shelf, shelf tray with edge and long components tray.

Drawer

There is a catch on both the left and right securing the drawer when it is closed. This ensures that the

drawer stays securely closed and free of torsion even when fully loaded. The drawers’ telescopic

slides have a lock that prevents open drawers from closing by themselves when the vehicle is

standing inclined.

Opening:

•Pull drawer (A) out by the recessed grip (B); drawer is unlocked.

•Pull out drawer (A) completely past the tangible resistance; drawer is stopped.

Closing:

•Completely close drawer (A) by pressing it lightly.

Telescopic slides load-carrying capacity per drawer 30 kg / 60 kg / 90 kg

The maximum load-carrying capacity is indicated on the left and right sides, on the telescopic slide

(C).

B

A

C

14

© Sortimo International GmbH

Removing drawer:

Telescopic slide 30 kg

Press on the plastic catches (A) on both sides and pull out (B).

Telescopic slides 60 kg / 90 kg

Press both the left and right levers (A) upwards while pulling out the drawer (B).

Installing drawer:

Re-insert both telescopic slides into the guide rails and close the drawer while pressing on both sides

(C).

Divider for drawer:

You can position the dividers in drawers according to your requirements.

If required, you can obtain additional dividers from any Sortimo sales partner.

A

B

C

B

A

C

15

© Sortimo International GmbH

Tool tray inlays

Customisable foam inserts for drawers, BOXXes and cases protect the tools they contain and ensure

they can be easily accessed.

Universal cabinet

The universal cabinet offers storage space for objects of all kinds. Optional insert shelves create

additional intermediate levels within the cabinet which can be adapted to the contents.

•Optionally with lock.

Opening:

•On the closing flap of the door, press the button (A) until the lever (B) pops out, then use it

to open the door.

Closing:

•Close the door until the lever (B) engages.

A

B

16

© Sortimo International GmbH

Case fixation

Clamping/releasing:

Wrap your hand around the handle of the case fixation and simultaneously press on the clamping

lever (A).

To fix the case in place, press towards the impact plate (B).

•Can also be combined with shelf

•Variable height for all case types

•One-hand operation

A

B

17

© Sortimo International GmbH

Dual directional block

The drawers, rotated by 90°, allow quick removal of tools and materials from the drawers facing the

side door, so you don’t have to enter the vehicle.

Opening:

•Pull drawer (A) out by the recessed grip (B); drawer is unlocked.

•Pull out drawer (A) completely past the tangible resistance; drawer is stopped.

Closing:

•Completely close drawer (A) by pressing it lightly.

The maximum load-carrying capacity is indicated on the left and right sides, on the telescopic slide

(C).

A

B

B

18

© Sortimo International GmbH

Lifting flap

Caution!

When closing the lifting flap, there is a risk of crushing between the lifting flap and the frame of the

base.

Gas pressure springs hold the lifting flap open.

•The system can be completely closed, preventing dirt from getting in.

•Adjustable to any height.

•Above floor rail,

•Above base plinth,

•Above shelf,

•Above shelf tray.

•Optionally with lock.

Opening:

The lifting flap is designed for single-handed operation.

•Grab the handle bar (A) and pull the lifting flap (B) upwards.

Closing:

•Grab the handle bar (A) and push the lifting flap (B) downwards against the resistance.

•Towards the end of the closing procedure, brake the lifting flap (B) a bit with your hand.

A

B

19

© Sortimo International GmbH

Hinged workbench

Caution!

There is a risk of crushing when folding open/closed!

Important!

The folding workbench must be folded away and engaged after use!

The folding workbench is folded away for driving.

To work with it, it must be folded open with the rear door open.

In combination with the parallel vice, the hinged workbench enables simple assembly work to be

carried out directly at the vehicle.

The working height of the workbench varies according to the loading edge of the vehicle.

•Parallel vice in different sizes.

•Swivel vice plate for parallel vice can be rotated 360°.

Carrying capacity max. 100 kg

Folding down:

•Push the lever (A) backwards by hand, thereby unlocking the workbench.

•Do not pull the support (B) forwards, but only push the workbench (C) downwards.

Securing:

•Push the lever (A) upwards with your hand; the workbench is secured and can be used.

•

Folding up:

•Push the lever (A) downwards by hand, thereby unlocking the workbench.

Raise the workbench only until the locking lever audibly engages.

A

B

C

20

© Sortimo International GmbH

Heavy, folding workbench

Caution!

There is a risk of crushing when folding open/closed!

Important!

The folding, heavy workbench must be folded away and engaged after use!

The folding workbench is folded away for driving.

To work with it, it must be folded open with the rear door open.

In combination with the parallel vice, the hinged workbench enables simple assembly work to be

carried out directly at the vehicle.

In two designs, suitable for vehicles with a high or low loading edge.

•With height-adjustable support legs.

•Parallel vice in different sizes.

•Swivel vice plate for parallel vice can be rotated 360°.

Carrying capacity max. 150 kg

Folding down:

•Take the support leg (A) out of the catch and press the workbench (B) downwards with your

hand.

Folding up:

•Lift the workbench (B) by hand and move it upwards; it stabilises itself automatically; push

the foot (B) back into the catch.

A

B

Table of contents

Other Sortimo Tools Storage manuals

Popular Tools Storage manuals by other brands

Armorgard

Armorgard sitestation SS2-T Operational And Maintenance Manual

Ranger design

Ranger design T4-RS36-3 installation guide

Beta

Beta C24S/5-0 Instructions for use

Gladiator

Gladiator VERSATOP Series installation instructions

Würth

Würth ORSY Flex 350 operating instructions

General International

General International 10-700 user manual