Sottoriva VELA 90-130/1 User manual

INSTRUCTION BOOK

Spiral mixer

mod.

VELA 90-130/1-160/1

Version: ENGLISH - Arc. 43

Code: 3529.0084.01

Revision: n° 0 dated 19/07/2004

Costruzioni Meccaniche SOTTORIVA S.p.A.

Via Vittorio Veneto, 63 - 36035 MARANO VICENTINO (VI) ITALIA

Tel. (+39) 0445.595.111 - Fax (+39) 0445.595.155

Internet: http//www.sottoriva.com - E-mail: sottoriva@sottoriva.com

VELA 90-130/1-160/1 - Code: 3529.0084.01

Rev. 0

dated 19/07/2004

Arc. 43-ig

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

1

Table of contents

1. Introduction

.........................................................................................................

5

1.1 Foreword

........................................................................................................

5

1.2 Warranty: terms and conditions

......................................................................

5

1.3

User instructions and precautions

..................................................................

7

2. Descriptive manual

.............................................................................................

9

2.1 Foreword

........................................................................................................

9

2.2 Description

......................................................................................................

9

2.3 Machine plate

.................................................................................................

10

2.4 Overall dimensions and other data

.................................................................

11

3. Operation and installation manual

....................................................................

13

3.1 Foreword

........................................................................................................

13

3.2 Getting the workplace ready

...........................................................................

13

3.3 Hoisting and transportation

.............................................................................

14

3.4 Assembly and installation

...............................................................................

15

3.4.1 Installation precautions

...........................................................................

15

3.4.2 Instructions for the electrician

.................................................................

15

3.5 Start-up

...........................................................................................................

15

3.6 Operation

........................................................................................................

18

4. Maintenance manual

..........................................................................................

21

4.1 Foreword

........................................................................................................

21

4.2 Daily maintenance

..........................................................................................

21

4.3 Monthly maintenance

.....................................................................................

21

4.4 Troubleshooting

..............................................................................................

24

4.5

Changing wearing parts

..................................................................................

24

4.5.1 Replacing the transmission belts ref. 1

Fig. 5

on page 25

from the motor to the tool

.....................................................................

27

4.5.2 Replacing the transmission belts ref. 1 and ref. 6

Fig. 6

on page 26

for bowl motion

...................................................................................

27

4.5.3 Replacing the kneading tool motor

..........................................................

28

4.5.4 Replacing the motor ref. 8

Fig. 6

on page 26 of the bowl

.......................

29

4.5.5 Replacing the kneading tool

....................................................................

29

Rev. 0

dated 19/07/2004

VELA 90-130/1-160/1 - Code: 3529.0084.01

2

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-ig

4.6 Spare parts

.....................................................................................................

31

4.6.1 Spare parts list (ref.

Fig. 7

on page 30)

..................................................

31

4.6.2 Spare parts list (ref.

Fig. 8

on page 32)

..................................................

33

4.6.3 Spare parts list (ref.

Fig. 9

on page 34)

..................................................

35

4.6.3.1 Vela 90D - Vela 90D 2 Bowl Speeds

...............................................

35

4.6.3.2 Vela 130/1D - Vela 130/1D 2 Bowl Speeds

.....................................

36

4.6.3.3 Vela 130/1R - Vela 130/1R 2 Bowl Speeds

.....................................

36

4.6.3.4 Vela 160/1D - Vela 160/1D 2 Bowl Speeds

.....................................

37

4.6.3.5 Vela 160/1R - Vela 160/1R 2 Bowl Speeds

.....................................

37

4.6.4 Spare parts list (ref

Fig. 10

on page 38)

.................................................

39

4.7 Electrical diagram section

...............................................................................

40

4.7.1 Power circuit diagrams

............................................................................

40

4.7.1.1 Version with 230 V 50 Hz

.................................................................

40

4.7.1.2 Version with 400 V 50 Hz

.................................................................

40

4.7.2 Control circuit diagrams

..........................................................................

40

4.7.3 Electrical maintenance

............................................................................

41

4.8 Cleaning the machine

.....................................................................................

42

5. Safety and food hygiene manual

.......................................................................

43

5.1 General remarks

.............................................................................................

43

5.2 Dangers form mechanical parts and residual risks

.........................................

43

5.2.1 Hazard zone 1

.........................................................................................

43

5.2.2 Hazard zone 2

......................................................................................

44

5.2.3 General remarks

.....................................................................................

44

5.3 Electrical dangers

...........................................................................................

44

5.4 Safety warning signs

......................................................................................

46

5.5 Noise

..............................................................................................................

47

5.6 Food hygiene requirements

............................................................................

47

5.7 Risk of air-borne flour

.....................................................................................

47

5.8 Putting out of service

......................................................................................

48

5.9 Machine demolition - disposal

........................................................................

48

5.10 Final notes

....................................................................................................

48

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-I

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

3

1. Introduction

1.1 Foreword

1.2 Warranty: terms and conditions

The machine is covered by warranty for a period of twelve months from the

date of delivery, the warranty being limited to parts with manufacturing

defects and excluding the motors and electrical system.

Furthermore, any parts damaged during transport, as a result of poor or

incorrect installation or maintenance or because of negligence or improper

use are not covered by the warranty.

The warranty is valid for the original purchaser only and does not, under any

circumstances, include the replacement of the machine. The warranty is

invalidated if the machine is tampered with or subject to alterations or

repairs by personnel not authorised by C.M. SOTTORIVA S.p.A..

The manufacturer is not liable for any injury to persons or animals or

damage to objects caused, either directly or indirectly, by machine

breakdowns or as a result of not being able to use the machine. Defective

parts are normally repaired or replaced on the customer's premises, with the

travel, board and lodging expenses for the personnel sent to effect the

repairs or replacements being charged to the customer. The travelling time

and hours worked by the personnel are also charged to the customer; the

hourly rate will be calculated in accordance with the Anima tables.

If, according to the unquestionable judgement of the engineers, the work

cannot be performed on the customer's premises, then the customer must

have the machine delivered free of carriage to C.M. SOTTORIVA S.p.A.

After the repairs have been effected free of charge, the customer must then

have the machine delivered back to his/her premises, carriage paid. If any

repair work is performed after the expiry of the aforementioned warranty

period, the customer will be charged for labour (in accordance with the

Anima table), travel and board and lodging expenses, the cost of the

replaced parts and any transportation costs for the replaced parts. The rates

will be calculated in accordance with the Anima table in the possession of

the engineering staff.

Caution!

Read the information in this publication thoroughly before setting

the machine to work and follow all the instructions carefully.

CONSERVE this manual and all its enclosures in an accessible place

known to all operators and routine maintenance staff the manual

must be kept in a dry place and, if possible, in an bag to protect it

from external agents such as dust, moisture, light, etc.

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

4

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-I

As a necessary condition for entitlement to warranty cover, the warranty

certificate (see facsimile below) must be sent off, duly completed, within

15

days

of the delivery date.

Moreover, if the applicant is unable to show the copy of the certificate kept

by the customer, the warranty may be considered as annulled.

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-I

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

5

1.3 User instructions and precautions

The manufacturer declines all responsibility for any injury to persons or

animals or damage to objects resulting from the failure to observe any of the

previous or following information and instructions on the use or maintenance

of the machine:

z

DO NOT USE

the equipment for any purposes and/or loads different to

those stated by the manufacturer;

z

EVERY DAY, CHECK

the safety devices, oil level and general state of the

equipment;

z

EVERY DAY

clean the equipment thoroughly;

z

TAKE ALL THE NECESSARY PRECAUTIONS

andsafety measureswhen

loading, adjusting, changing parts or carrying out repair or maintenance

workon themachine,to make sure thatthemachine orany partsof it arenot

accidentally started up by other persons;

z

DO NOT TAMPER WITH

the guards and safety devices on the machine;

z

DO NOT REMOVE

the guards and safety devices on the machine unless

actually necessary for work purposes and without adopting the measures

designedtoreducetherisktothe minimum possible,asdescribedfullyand

frequently in this manual;

z

PUT BACK

all the guards and safety devices as soon as the reason for

their temporarily removal no longer exists;

z

OBSERVE THE FOLLOWING REGULATIONS

regarding workplace

safety and procedures:

-

regulations on safety notices and warnings as stated in DD.PP.RR.27/4/55,

n° 547 and n° 524 of date 8/6/82 and in D. Lgs 493/96 for Italy,orequivalent

regulations in the country where the machine is used;

-

European directives concerning workplace safety as stated in 89/391/CEE,

89/654/CEE, 89/655/EEC, 89/656/EEC, 90/269/EEC, 90/270/EEC,

90/394/EEC, 90/679/EEC, 95/63/EEC;

-

European directives concerning individualprotection measures as stated in

89/656/EEC and 89/686/EEC;

-

European directives on the environment, with special regard to

91/156

/EEC

concerning waste disposal,

91/689

/EEC on the disposalof dangerous waste

and 75/439/EEC on the disposal of used oils.

z

INFORM ALL PERSONNEL

of the specific hazards present in the

workplace.

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

6

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-I

Photo 1

Fig. 1

1

2

3

4

5

6

8

7

9

2

0

46810 12 1416

20

18 2

0

46810 12 1416

20

18

1

3

2

5

7

8

6

9

4

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-II

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

7

2. Descriptive manual

2.1 Foreword

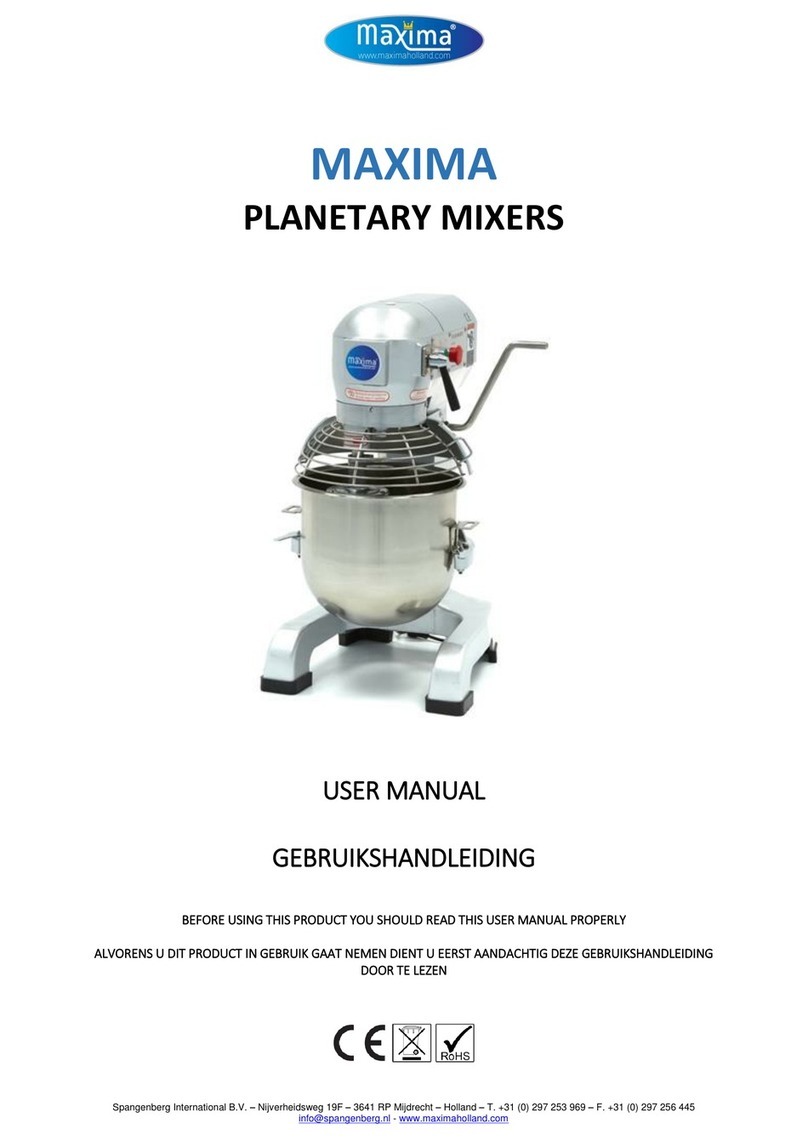

Kneading Machine mod.

VELA 90-130/1-160/1

(see

Photo 1

on page 8) is a

machine for blending ingredients, generally water, flour, yeast and salt with

other secondary ingredients, and their mixture until a homogeneous dough

is produced for subsequent processing and cooking.

Any use for purposes other than those stated above may damage mechanical

components and/or endanger the safety of the machine operator.

2.2 Description

The machine consists in (see

Photo 1

):

1) a rigid structure

ref. 1

Photo 1

containing moving parts for the kneading

tool and tank;

2) a rotating tank

ref. 2

Photo 1

containing ingredients to be kneaded;

3) a kneading tool, to mix and knead the ingredients creating the shape of a

lengthened spiral.

4) An electrical control board

ref. 6

Photo 1

.

The control panel

ref. 4

Photo 1

, fitted to the front of the kneading tool carrier,

includes (see

Fig. 1

on page 8):

-

Start pushbutton

ref. 1

Fig. 1

, for 1st speed (slow);

-

start pushbutton

ref. 2

Fig. 1

, for the 2nd speed (fast);

-

a switch

ref. 4

Fig. 1

with three positions for tank start in either direction for

rotation;

-

an emergency stop button

ref. 3

Fig. 1

;

-

a large pushbutton

ref. 6

Fig. 1

for emergency shut-down;

-

a white warning light

ref. 5

Fig. 1

showing voltage feed;

-

a manually set timer with memory of set timefor slow operation

ref. 7

Fig. 1

;

-

a manually set timer with memory of set timefor fast operation

ref. 8

Fig. 1

;

-

a 3-position switch

ref. 9

Fig. 1

for impulse operation oftank,when the acci-

dent prevention guard is open.

The main switch is located on the electrical panel

ref. 8

Photo 1

.

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

8

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-II

Photo 2

Fig. 2

2.3 Machine plate

In

Fig. 2

showing the machine plate and in

Photo 2

where it is fitted on the

machine with rivets or screws; it is aluminium with puched and silk screen

printed indelible lettering.

C.M. SOTTORIVA S.p.A.

Via Vittorio Veneto, 63

36035 MARANO VICENTINO

(Vicenza) - ITALY

Tel. (+39) 0445.595.111

Fax (+39) 0445.595.155

email:sottoriva@sottoriva.com

P.I. 00768890246

Mod.

n°

V

XXX

Hz

XX

kW

XX

VELA 90 (VELA 130/1-160/1)

XXXXXX

A

XX 3 AC + (N) + T

Mass kg

200_

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-II

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

9

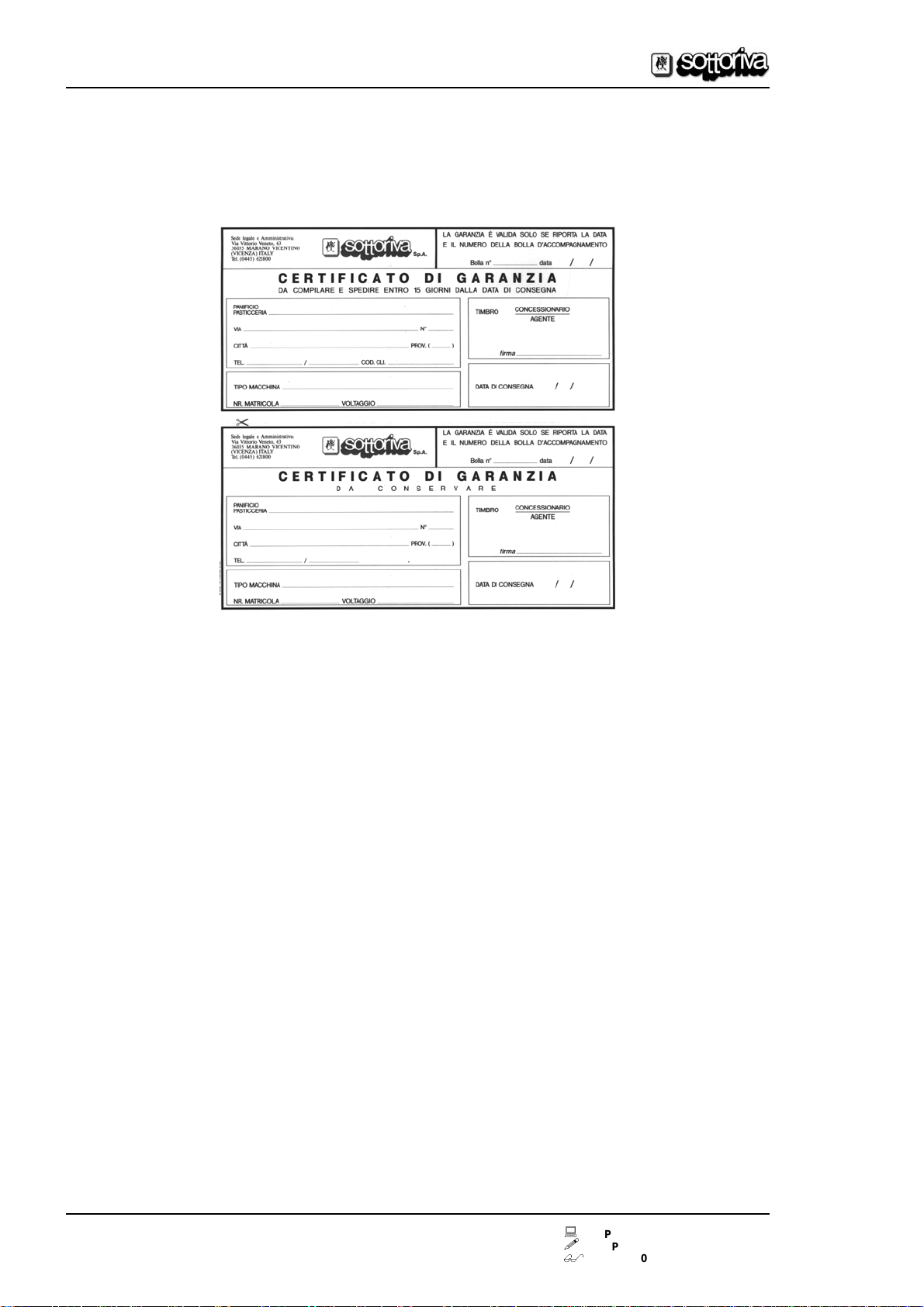

2.4 Overall dimensions and other data

With reference to showing overall dimensions in table 1, motor power

ratings and other data in table 2. (*) for a water/flour ratio of 55/100 for flour

with W=200 and P/L = 0.3.

Fig. 3

Table 1

Table 2

AC

B

D

E

MACHINE

A

B

C

D

E

VELA 90

1174

1296

738

819

530

VELA 130/1

1271

1296

833

963

530

VELA 160/1

1392

1415

929

938

590

MACHINE

mod.

Total

mass

Kg

Bowl power

kW

1st speed 2nd speed

Coil

power

kW

Kneading

capacity

kg (*)

VELA 90

405

0.6

1.1

2 / 3.7

90

VELA 130/1

435

0.6

1.1

2 / 4.7

130

VELA 160/1

660

0.75

1.5

3.7 / 5.9

160

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

10

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-II

Footnote

This page has been left blank intentionally!

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-III

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

11

3. Operation and installation

manual

3.1 Foreword

In compliance with European Community Directive no. 98/37/EEC, and for

the purposes of this manual, the following definitions are used:

1)

"Danger area"

, any area inside or near a machine which might be

dangerous for a bystander.

2)

"Bystander"

, any person entirely or partly situated in a danger area.

3)

"Operator"

, the person or persons installing, running, adjusting,

cleaning, repairing, transporting or performing maintenance work on a

machine.

3.2 Getting the workplace ready

If used for production (including cooking) of bakery products, the workplace

must meet the following requirements:

z

it musthave spaces wide enough to allow the bulkiestparts of the machine

to pass;

z

it must be built in compliance with current regulations;

z

it must be fitted with an electrical system complying with current regula-

tions,inparticulartheearthconnectionsystemand electricalcontrolboard

which must be protected against overload currents and short circuiting.

The rated power of the machine is shown on the machine plate. Electrical

plant must be properly installed throughout, maintained regular and regu-

larlyinspectedby trained electricians issuingcertificates of"good practice"

for all jobs carried out, guaranteeing compliance with current norms.

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

12

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-III

3.3 Hoisting and transportation

To move the machine, it must be lifted as follows:

-

thread a lifting cable under the head, where the head meets the column, as

shown in

Fig. 4

on page 14

and secure as shown in

Fig. 4

to a hoisting

mechanism (crane, bridge crane, hoist, etc.). Place felt cloth between the

hoisting cable and the part of the machine under the head. Place a wood

shim of 70-80 mm thickness betweeen the side of the machine head and

the hoiting cable in order not to damage the paint finish or structure; lift the

machine gradually without any abrupt pulls.

Raising and lowering the machine must be a gradual process to avoid the

build up of kinetic energy which the braking system could not over-ride.

Given the considerable mass of the machine, before pushing it on its wheel

mounts, make sure no-one is standing behind or near the machine, since

impact could cause serious injury.

Fig. 4

Caution!

Before lifting the machine make sure that the cables are strong

enough to bear the load, and thatthe hoisting device has the suitable

capacityon the basis of the arrangementof the cables. In all cases,

equipment used for lifting must comply with current laws and regu-

lations.

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-III

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

13

3.4 Assembly and installation

3.4.1

Installation precautions

The machine should be placed on the ground at the point shown in par. 3.3.

The machine must be lowered onto its supporting platform as gently as

possible in order to avoid damaging either the machine itself or the floor.

The machine should be moved on its wheels by pushing it to the new site

(see precautions above). When the machine is properly located, secure the

legs to the ground

ref. 9

Photo 1

on page 8

by using the knobs

ref. 7

Photo 1

to avoid excessive movements during the kneading process.

3.4.2

Instructions for the electrician

The electrician carrying out the installation must be skilled in this type of

work, properly trained and fully informed of the technical contents and

norms relating to the work, and of the standards of good practice.

The machine must be connected to the bakery's electrical plant in full

compliance with currents norms and regulations on the basis of the machine

specifications given in this manual; the machine is supplied with a CEI20-22

lead and EEC type plug (with the number of poles specified on the machine

plate) for connection to the electricity supply. Use the earth connection

system properly, without running the earth wire along gas or water pipes or

other metal structures not intended for earthing.

The power supply lead must be kept well clear of heated or moving parts.

The cable must not interfere with the movement of people or objects inside

the bakery.

3.5 Start-up

Trained personnel are not required to start up or operate the machine

(whereas properly trained personnel are required for some maintenance

operations; see para

4.1

), although all personnel starting up and operating

the machine must have read this manual from cover to cover and thoroughly

understood its contents.

Caution

Make sure that the mains voltage is the same as the voltage clearly

marked on the machine plate par. 2.3).

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

14

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-III

After placing and securing the machine in its final location, carry out the

following important control operations in the given sequence:

1) check the mains voltage against the voltage shown on the machine plate

(seepar. 2.3)correspondstothelaboratoryvoltage;ifthevoltageisincorrect,

do not make electrical connections under any circumstances. Contact the

supplier or manufacturer immediately.

2) Make sure the machine rotates in the right direction; to do this, after

plugging in, carry out the following procedures:

-

switch the main switch

ref. 8

Photo 1

on page 8 to position 1;

-

set the minimum time on the timer

ref. 7

Fig. 1

on page 8;

-

press the start button for the 1st speed

ref. 1

Fig. 1

;

From the front of the machine, as shown in

Photo 2

on page 10

, the spiral

tool must rotate clockwise.

If this is not the case switch off, using the pushbutton

ref. 3

Fig. 1

; then switch

the main switch

ref. 8

Photo 1

from position 1 to position 0, unplug, unscrew

the plug as shown in the figure and invert the black and brown wires.

If the connection is three-phase + neutral + earth, there are two black wires.

In this case, either black wire may be switched over with the brown wire; if the

cable is three-phase + earth there is only one black wire so there is no

problem in switching over the wires.

Close the plug with the screws, as shown in the above illustration, and plug

back into the mains socket.

Re-check, repeating the sequence given at point 2. of this paragraph.

Rotation should now be clockwise.

Caution!

Never disconnect the yellow-green (earth) and/or blue wires or

change their positions.

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-III

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

15

Caution

Unauthorised alteration or replacement of one or more parts or units

on the machine, or the use of accessories, tools or wearing parts dif-

ferent to the manufacturer's recommendations, may endanger the

safety of the machine operator or other persons close to the

machine. In all such cases, the manufacturer shall not be liable in

criminal or civil law for injury to persons and/or damage to objects

arising from unauthorised actions.

Footnote

After about 50 hours operation following initial installation, carry out

maintenance operations by tightening belts as described below.

par. 4.3.

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

16

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-III

3.6 Operation

z

In

Photo 2

on page 10

shows the normal operator position; the position

should be occupied only for brief moments.

1) Feed into the tank

ref. 2

Photo 1

on page 8

all ingredients to be kneaded,

without exceeding the total mass specified in

Table 2

on page 11.

For this purpose, since the specific weightof flour is much less than water, the

capacity of the tank was designed on the basis of a water/flour ratio of 0.55,

loading the flour first, then the water (causing the flour to gain in density and

lose volume).

2) Switch the main switch

ref. 8

Photo 1

to position 1; the warning light

ref. 5

Fig. 1

on page 8 will come on;

3) Lower the accident-prevention guard

ref. 3

Photo 1

if raised, since in the

raised position the machine will not start).

4) Set timers

ref. 7 and 8

Fig. 1

torequiredkneadingtimesforslow and quick

blending.

5) Press the pushbutton

ref. 1

Fig. 1

for low speed start-up leaving the tool

enough time to "bind" the ingredients.

6) At the same time, switch the switch

ref. 4

Fig. 1

to the right-hand position

to rotate the tank clockwise, or to the left-hand position to rotate the tank

anticlockwise; the movement can be inverted or stopped (switch position 0)

at any time.

After the set time

ref. 7

Fig. 1

, the machine will automartically switch to the

fast cycle, for the set time

ref. 8

Fig. 1

.

Caution!

At the beginning of kneading operations, before the flour has absor-

bed much water and is still in the form of a powder, it is sensible prac-

tice to use the kneading tool at slow speed for 2 minutes to prevent

flour becoming air-borne and getting into the lungs, which, after len-

gthy periods of exposure, is dangerous for the health.

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-III

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

17

7) Press the pushbutton

ref. 2

Fig. 1

to start up the machine directly at the

fast speed (this should not be done if there is still unmixed flour in the tank,

as specified above) or to skip from slow to fast speed at any moment.

8) When the set times for the two cycles have been reached, the tool

automatically shuts down.

9) Activating any of the safety devices or pressing the emergency stop

ref. 6

Fig. 1

, (or by means of the accident-prevention guard

ref. 3

Photo 1

on page

8), moving parts come to a stand still very quickly.

To prevent wear to the electrical emergency devices,

do not use emergency

shut-downs if it is possible to switch off normally

ref. 3

Fig. 1

.

Emergency devices should be used only to prevent dangerous situations

from arising or in dangerous situations (i.e. only in emergencies).

Remove the kneaded materials from the tank manually, in large provisional

portions, using a plastic paddle arm (never use steel paddles or scrapers).

10) Refill the tank with ingredients for the next operation.

Rev. 0

dated 1

9/07/2004

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

18

Technical Assistance Service

Tel. (+39) 0445.595.111

PT

0704

PP

0704

MC

0704

Arc. 43-III

Footnote

This page has been left blank intentionally!

VELA 90-130/1-160/1 -

Code: 3529.0

084.01

Rev. 0

dated 1

9/07/2004

Arc. 43-IV

PT

0704

PP

0704

MC

0704

Technical Assistance Service

Tel. (+39) 0445.595.111

19

4. Maintenance manual

4.1 Foreword

All tasks which can be performed safely without specific training are defined

as "routine maintenance". All operations described par. 4.2 and par. 4.3 are

parts of routine maintenance.

Routine maintenance

as described in paragraphs

4.1

,

4.2

and

4.3

and

where specifically specified in this manual

may be carried out by the

machine operator provided he/she follows instructions to the letter

.

All operations are considered "extraordinary maintenenace" and must be

carried out by trained personnel

or, wherever specified in this manual

,

only

by personnel employed by the manufacturer

.

The manufacturer's telephone number is given at the foot of each page of

this manual; the fax number and internet address are given on the cover.

4.2 Daily maintenance

z

Cleanthemachinecarefullypayingspecialattentiontothepartswhichcome

into contact with food, such as the inside of the tank and the kneading tool

(see also par.

4.8

).

Do not use metal scapers or brushes, only soft plastic cleaning materials.

z

Check the efficiency of the accident-prevention devices.

(See the safety manual, chapter

5

).

4.3 Monthly maintenance

Check the belt tension and wear, and, if necessary replace. Replace for the

slightest wear or damage to the rubber.

Caution

THE MAIN SWITCH ref. 8

Photo 1

on page 8

MUST BE SWITCHED TO THE 0

POSITION OR THE MACHINE UNPLUGGED BEFORE CARRYING OUT ANY

CLEANING OR MAINTENANCE OPERATIONS ON THE MACHINE.

This manual suits for next models

1

Table of contents