Sound Skulptor SK99 User manual

www.soundskulptor.com

Document revision 1.1 – Last modification : 10/08/17

SK Assembly guide

Safety warning

The kits are main powered and use potentially lethal voltages. Under no circumstance should someone undertake the

realisation of a kit unless he has full knowledge about safely handling main powered devices.

Please read the “DIY guide” before beginning.

Print or open the following documents :

• SK Schematics

• SK Components layout

• SK Parts list

Follow this guide from item number 1 till the end, in this order. The assembly order is based on components height, from

low to high profile, in order to ease the soldering process : The component you are soldering is always taller than the

previously assembled ones and it is pressing nicely against the work area foam.

SK Assembly guide

1. Soldering

All the PCB holes are metallized. It means the connection between the top and bottom pads is already

done. The parts must be soldered only from the bottom side (unless differently stated).

Use only small diameter solder, 0.5 or 0.7 mm, 1mm maximum. Use the minimum possible amount of

solder. Bad joints are almost always caused by too much solder.

Here are two excellent introduction to soldering videos:

http://www.eevblog.com/2011/06/1 /eevblog-180-soldering-tutorial-part-1-tools/

http://www.eevblog.com/2011/07/02/eevblog-183-soldering-tutorial-part-2/

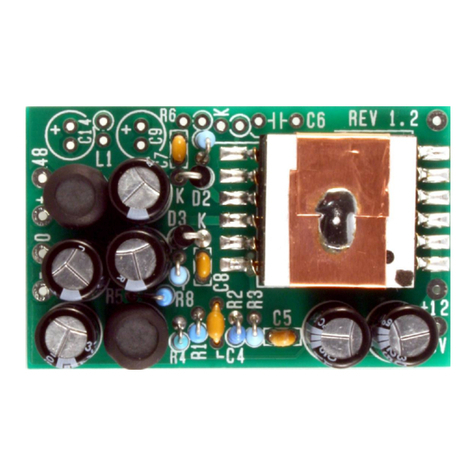

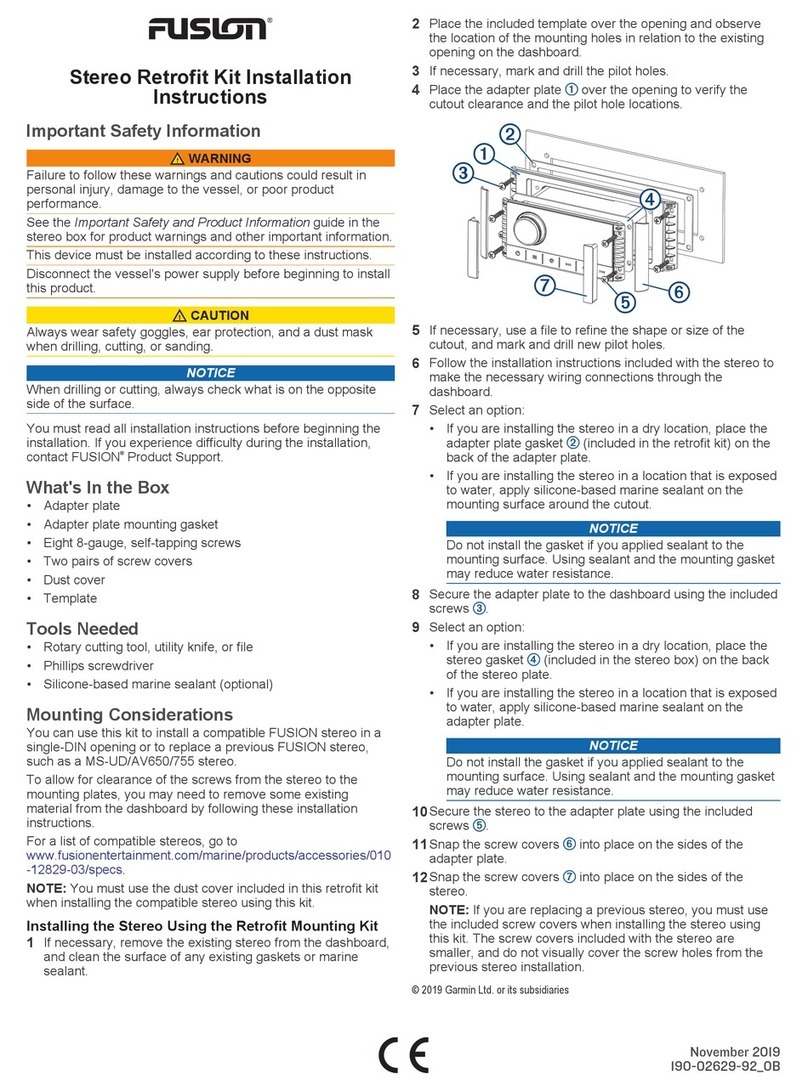

2. PCB split

Split the PCB into 3 parts along the lines shown by the red arrows.

3. Pins

Insert and solder the 6 golden pins. The pins are inserted from below the

PCB.

The best solution to keep the pins perfectly perpendicular is to use the final

host PCB (like the MP512, MP5 ) as a guide: Insert the 6 pins into the

1mm sockets of the receiving PCB, position the DOA PCB over the pins and

solder.

It is a good idea to protect the golden pins with some wire insulating sleeve

before doing other component soldering.

Copyright ©2014 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 10/08/17

SK Assembly guide

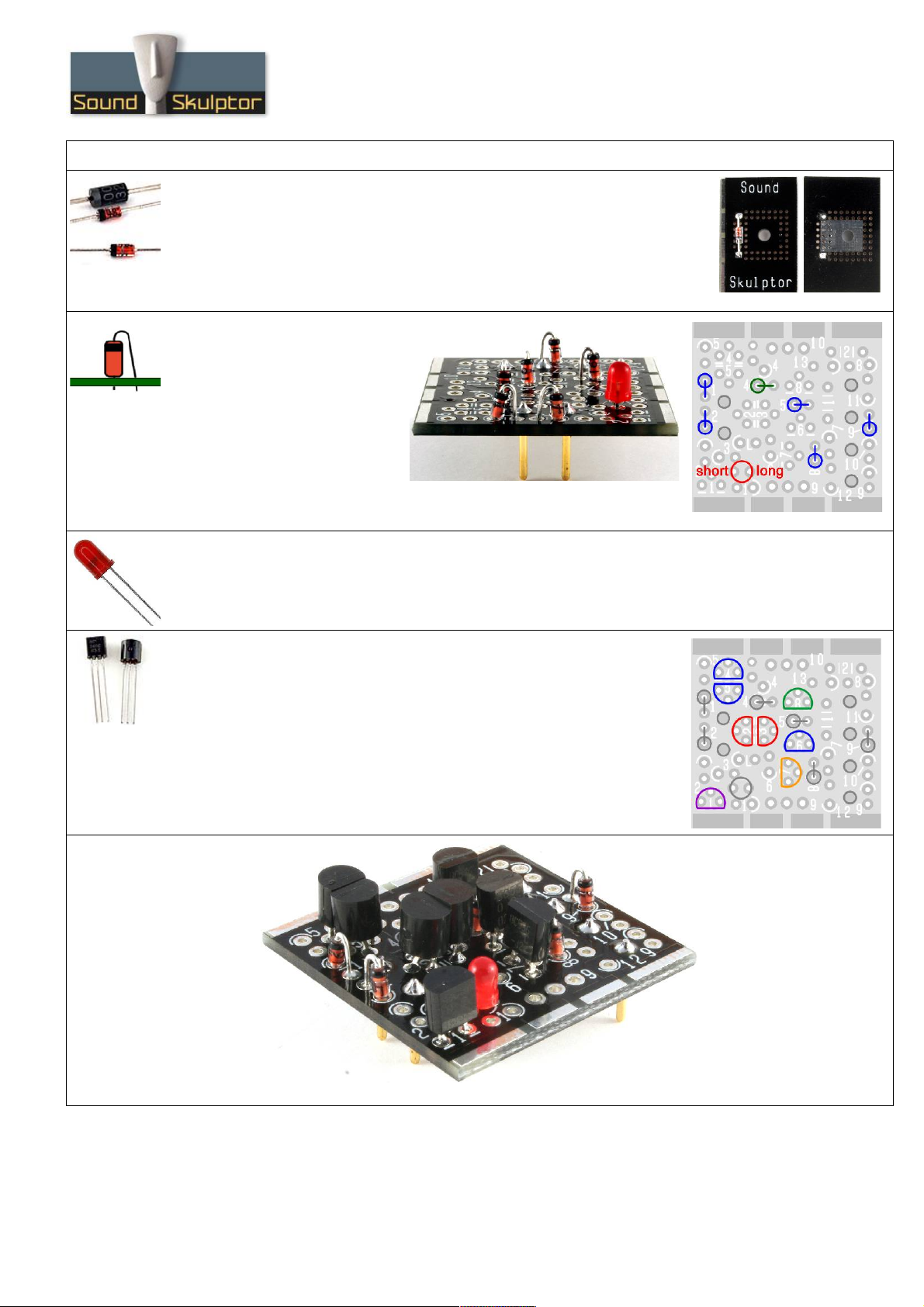

4. Diodes D5 & D6

Add D5 and D6 on the 2 heatsink PCB's.

When soldering, be careful not putting any solder on the power transistor

plane.

Warning: Make sure to respect the direction of the diodes which is marked by

a ring on the component and a double line on the PCB marking.

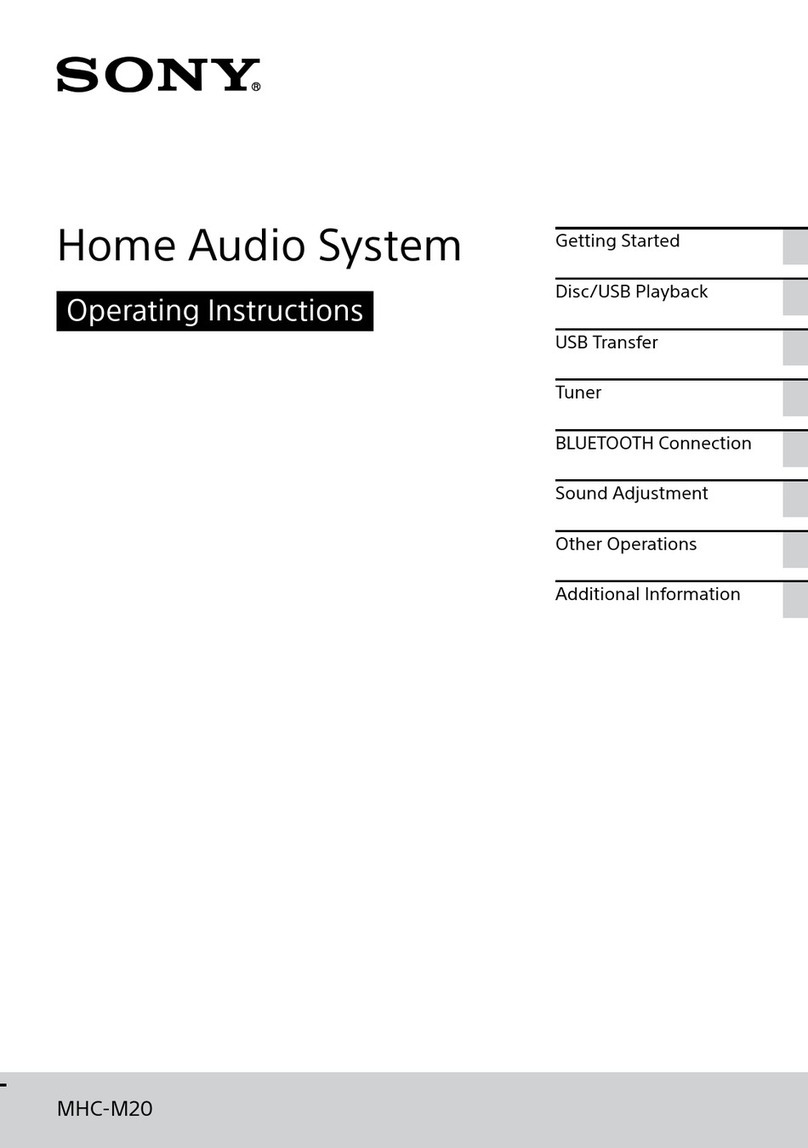

5. Other diodes

These diodes are mounted

vertically, cathode (black ring) up.

Add D1, D2, D7, D8, D :

1N4148, blue on the picture.

Add D4: zener 5.1V, green on

the picture.

Warning : Make sure to respect the direction of the diodes. D7, D8, D

are mis-labeled on the PCB, follow the layout document.

6. LED

Add the red LED D3, red on the picture.

Warning : Make sure to respect the long lead/short lead direction of the diode.

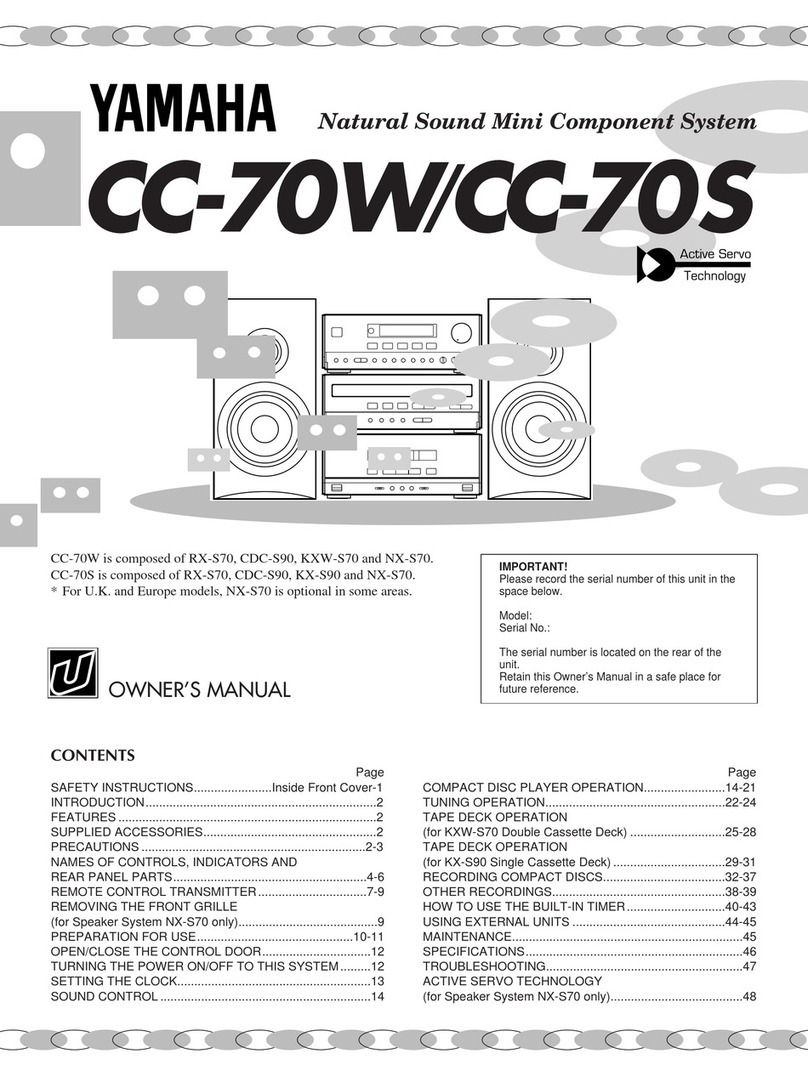

7. Transistors

Add Q1: BC560C (purple)

Add Q2, Q3: KSA 2 (red)

Add Q4, Q5, Q6: BC550C (blue)

Add Q7: BC556C (orange)

Add Q8: BC546C (green)

Press firmly the transistors against the PCB in order to keep the profile

low.

Copyright ©2014 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 10/08/17

SK Assembly guide

8. Inductor

Add L1 (red).

Bend sharply one of the leads against the body of L1 for a vertical

insertion.

. Resistors

Bend sharply one of the leads against the body the resistor for a vertical

insertion.

Add R1 to R13.

Warning : It is very important to check the resistors value with a DMM

because the colour code can be ambiguous. For example 1K (brown-black-

black-brown-brown) can be confused with 110R (brown-brown-black-black-

brown).

10. Capacitors

Add C1 and C2.

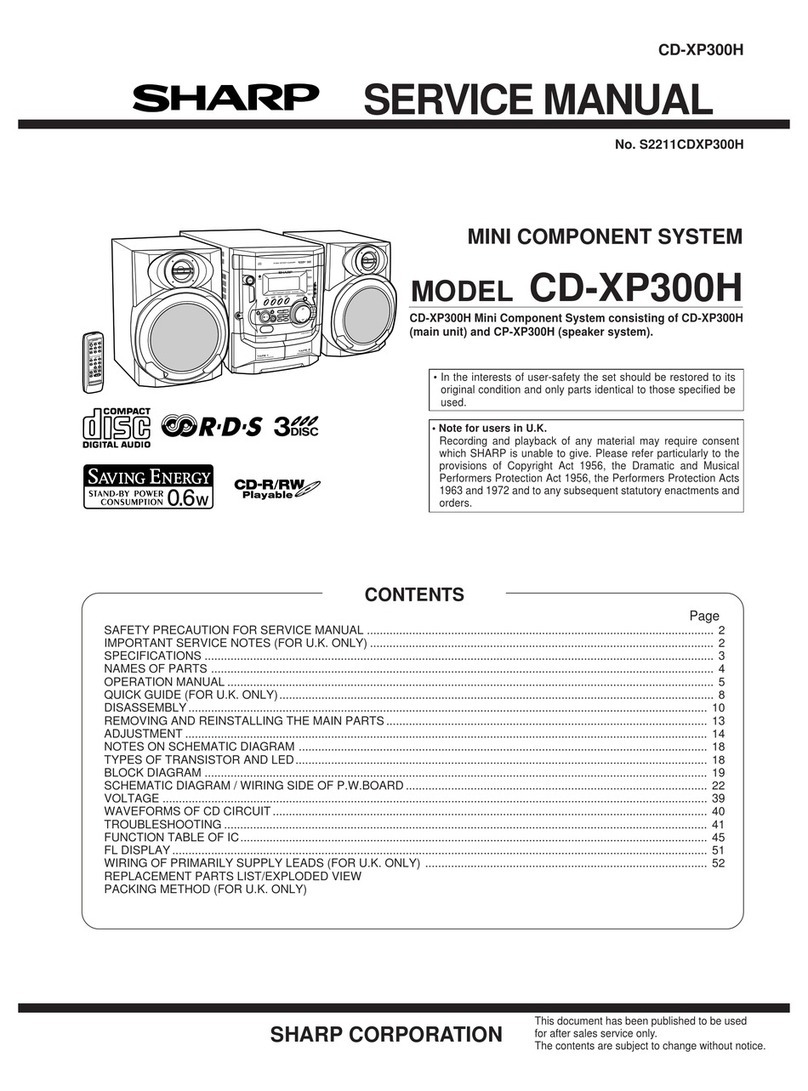

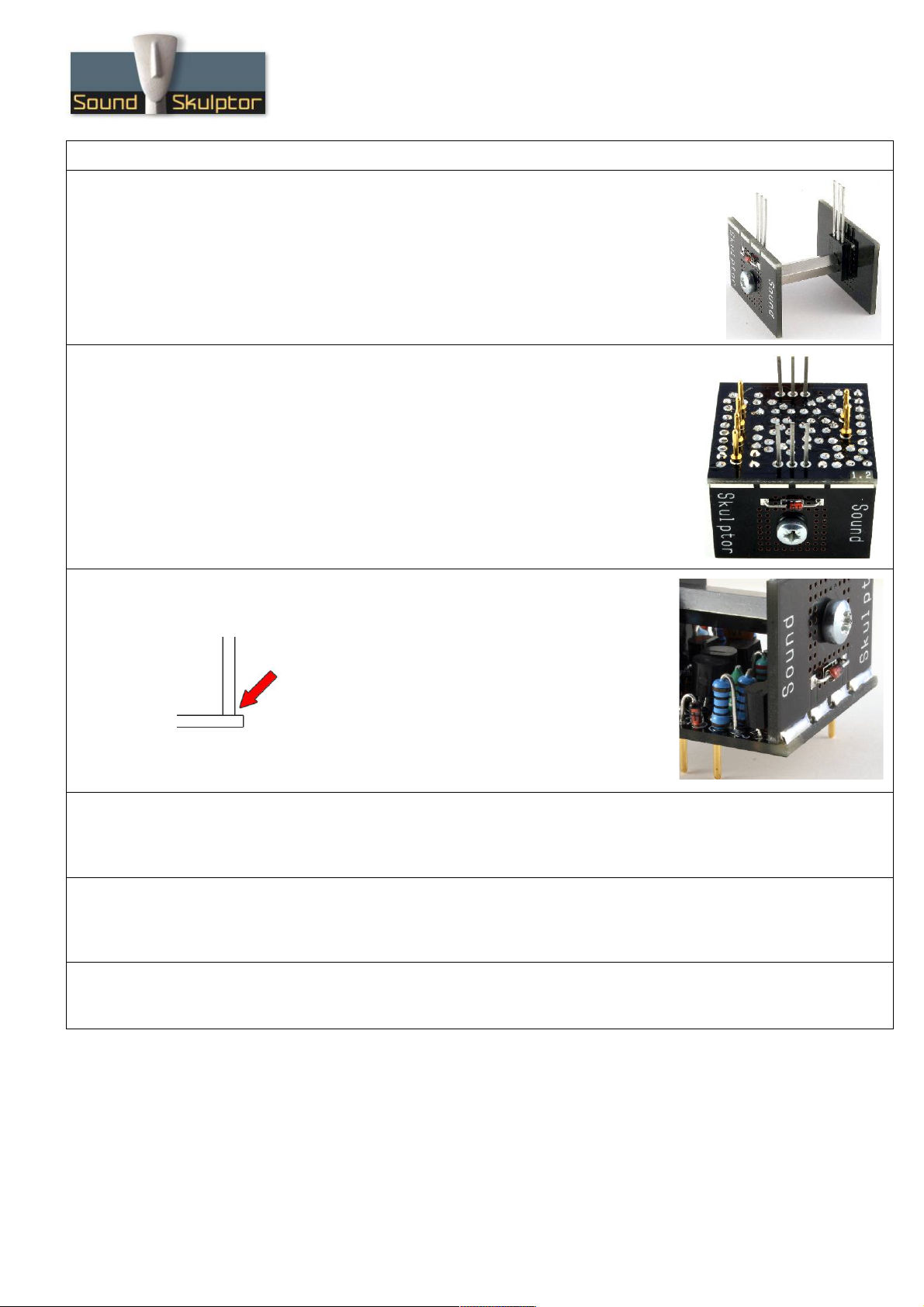

11. Q & Q10 assembly

Attach Q (BD13 ) to the heatsink PCB marked “Sound Skulptor” with

a M3x12 mm screw and a M3x20 mm spacer. The transistor is placed

on the side with no writing.

Tighten softly, by hand for now.

Copyright ©2014 to Today SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 10/08/17

SK Assembly guide

12. Q & Q10 assembly

Similarly, attach Q10 (BD140) to the heatsink PCB marked “SK ” with a

M3x12 mm screw and screw it into the other side of the spacer. The transistor

is placed on the side with no writing.

Tighten softly, by hand for now.

13. Q & Q10 assembly

Insert the 2 power transistor leads into the main PCB. The word “Sound” is

on the input side (2 golden pins). The word “Skulptor” is on the output side

(4 golden pins).

Turn upside down, press on a flat table, adjust the position, making sure that

the heatsinks are parallel to the main PCB edge then solder the transistor

pins. Cut the leads sharp.

Keeping the DOA pressed against the table, tighten the 2 screws with a

screwdriver.

14. Q & Q10 assembly

Solder the 4 pads at the bottom of both heatsinks

that connect to the main PCB. These solders improve

the mechanical stiffness of the DOA and make the

electrical connection of diodes D5 & D6.

15. R1

Pull R1 back a little in order to avoid its top touching the solder joint of D5. In several cases we

have seen failures caused by such a contact in spite of the paint covering the resistor body.

16. D5 & D6 thermal contact

Press the body of D5 and D6 against the heatsink and put a drop of instant glue between the two. This

will create a permanent thermal contact.

17. Congratulations!

Your SK is ready for test.

Copyright ©2014 to Today SoundSkulptor

Table of contents

Other Sound Skulptor Stereo System manuals